Monitoring a natural gas supply network with EtherCAT Terminals designed for explosion protection

In western Switzerland, the stations operated by Gaznat for the management of natural gas supplies are gradually being equipped with new monitoring equipment. The energy provider is working with Beckhoff Switzerland to achieve greater efficiency and accuracy, particularly by using ELX terminals for the direct connection of intrinsically safe field devices. In addition, this approach simplifies the processes required for data extraction, minimizes installation effort and considerably reduces costs.

Gaznat S.A., based in Vevey, operates stations where an essential process in the gas industry is carried out: The so-called gas depressurization refers to the pressure reduction necessary for the natural gas to be forwarded to consumers. This reduces the gas pressure from approx. 38 bar to a value below the prescribed threshold of 5 bar. Subsequently, the natural gas is delivered to the local public utility, which assumes responsibility for subsequent delivery to local residents, other end users and industrial consumers.

Acting as an intermediary between the natural gas suppliers and the various municipal utilities and regional entities responsible for the local networks, Gaznat transports an annual energy equivalent of more than 13 TWh. The company's main task is to set up, maintain and operate the high-pressure transmission network in western Switzerland – some 600 km of gas pipelines as well as 50 pressure-reducing and metering stations. Gaznat employs 62 people at its Vevey and Aigle sites.

Digitalization of gas transport infrastructure

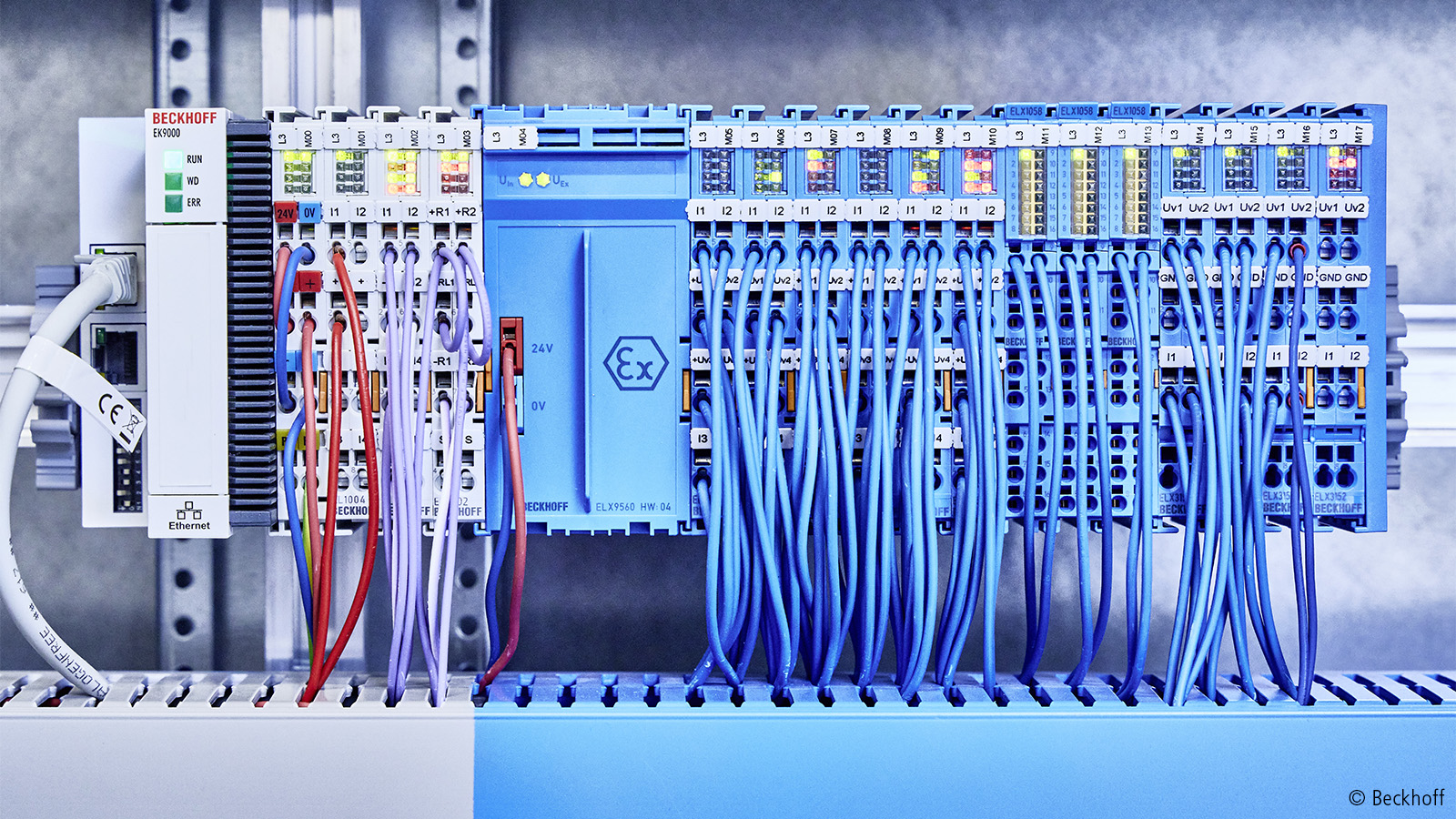

To secure, manage and remotely control its network, Gaznat requires digital and electronic solutions tailored to the technical specifics of its various plants. The infrastructure of the stations includes a large proportion of mechanical equipment, but is also equipped with state-of-the-art electronics, which is a prerequisite for digitalizing the gas supply network. The gas infrastructure – the same as the electrical power grid – is currently trending toward widespread adoption of smart grid systems and devices. According to Gaznat's experience, the digitalization of the gas infrastructure is much facilitated by Beckhoff products: In the control cabinets of the gas pressure control system, the innovative strenght of the automation company is evident in the wide range of EtherCAT I/O components, particularly the ELX terminals for explosion protection applications. The ELX range used comprises digital and analog 12 mm and 24 mm terminals, respectively, which can be used to directly acquire the signals from field devices installed in station sections through which gas flows.

This means that all data points within the plant can be connected directly to EtherCAT Terminals, both in standard and hazardous areas. This greatly simplifies overall installation and wiring, and intermediate devices such as intrinsically safe barriers or other signal converters are dispensed with completely. As a result of the large selection of EL series EtherCAT Terminals available, Gaznat says it has found all the connectivity options it needed, e.g. for monitoring the power consumption with the EL3443 and SCT current transformers, the lighting status in the station and the control data for heating the gas. All this data is then transmitted via the Modbus coupler to the control system for further processing. From Gaznat's point of view, the advantages of the solution are its high flexibility and modularity as well as the comprehensive portfolio of EtherCAT Terminals.

Regarding a particular advantage of the ELX terminals, Bertrand Luisier, Automation Manager at Gaznat, explains: "Beckhoff has developed special firmware for us to use with the ELX1058 8-channel digital input terminal –for connecting intrinsically safe NAMUR field devices – which enables direct interfacing with a gas volume meter. This dispenses with the device normally used for data acquisition from this sensor. Meter information is passed directly to the control system without the need for a serial interface, as was previously the case. It is a great advantage that Beckhoff can respond quickly to such specific customer requirements with its product development team. Ultimately, this implementation, which provides a connection between station data and system monitoring by network operators, now requires fewer electronic devices because the need for traditional safety barriers has been eliminated. In terms of space, everything now fits into one large control cabinet, whereas it used to take two to three."

Significant cost reductions

In terms of economic efficiency, the use of EtherCAT Terminals from Beckhoff, and the ELX1058 in particular, leads to significant cost reductions, according to Gaznat. For example, retrofitted stations show savings of around 50% compared to conventional systems, which is equivalent to many thousands of Swiss francs. In addition, troubleshooting is also simplified.

ELX1058 EtherCAT Terminal

The ELX1058 digital input terminal allows the direct connection of intrinsically safe NAMUR field devices installed in hazardous zone 0/20 and 1/21 areas, and acquires their signals according to IEC 60947-5-6. The sensors are supplied with a voltage of 8.2 V and return a diagnosable current signal. This means that wire breakage and short-circuits can be detected in addition to the current switching state. The LEDs indicate the signal states as well as any error states. On the software side, it is possible to define whether a positive or negative switching sensor is connected for each channel. This means that both NAMUR break contacts and make contacts can be integrated into the control system without any changes. In addition, the error LEDs can be switched off, which enables the connection of potential-free contacts without any errors being displayed.