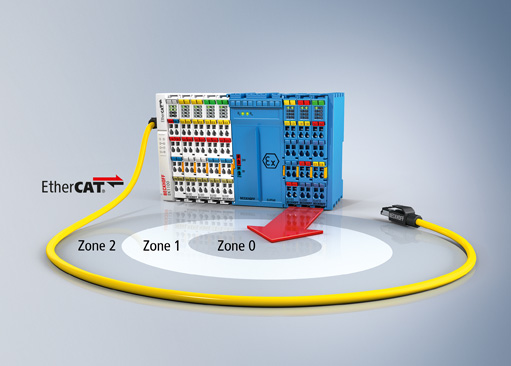

The new ELX series EtherCAT Terminals with intrinsically safe inputs/outputs and highly compact design enable direct connection of field devices located in hazardous areas – classified Zones 0, 1 and 2. PC-based control from Beckhoff now seamlessly combines automation and process technology, including all the benefits of integrated and comprehensive diagnostics from the EtherCAT system.

Beckhoff offers a system-integrated solution for explosion protection requirements – a comprehensive range of explosion-proof components facilitate barrier-free solutions across hazardous areas up to Zone 0/20. In addition to the ELX series EtherCAT Terminals with intrinsically safe interfaces, the portfolio also includes new Control Panels and Panel PCs in the CPX series, suitable for use in Ex Zone 2/22, and TwinCAT control software with a wide range of interfaces specific to process technology.

The ELX series expands the comprehensive Beckhoff EtherCAT Terminal system, which already offers more than 100 different signal types, with I/O terminals that feature explosion protection. The combination of remarkably compact I/O modules and integrated safety barrier functionality results in high-performance EtherCAT Terminals for connecting intrinsically safe field devices. The slim terminals reduce space requirements in the control cabinet by up to 50 percent. This solution offers clear advantages, particularly in hazardous areas with confined spaces that typically require elaborate and expensive enclosure technology. Eliminating the need for external barriers significantly reduces installation effort and costs.

With the upcoming certification in compliance with ATEX and IECEx, the ELX series meets all industry-specific guidelines for explosion protection and can be used in nearly all markets worldwide. The I/O terminals have either 12 mm housings with up to four intrinsically safe inputs or 24 mm housings with up to eight similar inputs.

With the new ELX terminals, users with explosion protection requirements can benefit from ultra-fast and sophisticated EtherCAT technology. Benefits include time stamp functionality, which ensures high measurement accuracy and highly precise synchronisation − even in widely distributed process applications. In addition, integrated EtherCAT diagnostics capabilities with 100 Mbit data rates enable fast and convenient error identification. In this way, downtime can be minimised, maintenance simplified and system availability increased.

Products

Industries

Viktoria Zuberbühler

Beckhoff Automation AG

Rheinweg 7

8200 Schaffhausen

Switzerland