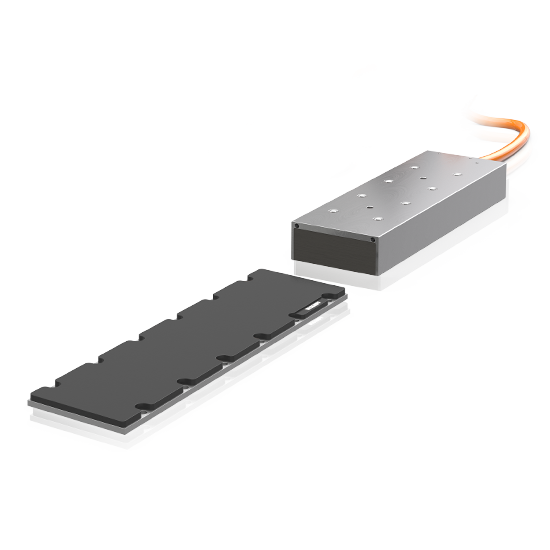

AL8000 | Highly dynamic linear servomotors

The AL8000 motors are characterized by a modular coil concept and the extremely high force density generated from it.

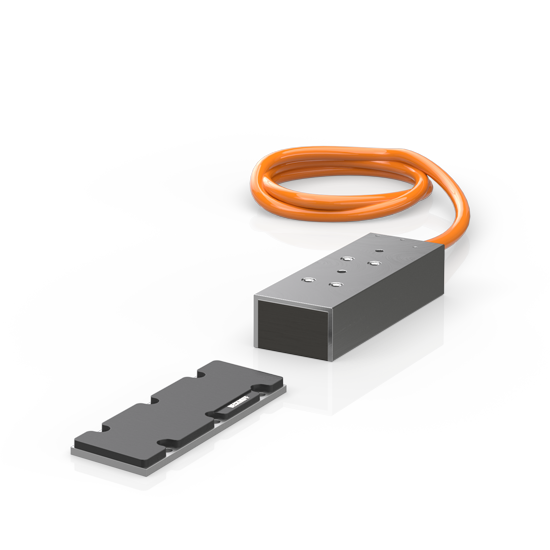

AL8100 | Highly dynamic linear servomotors for compact drive technology

The AL8100s are characterized by a modular coil concept and the extremely high force density that they generate from it for compact drive technology.

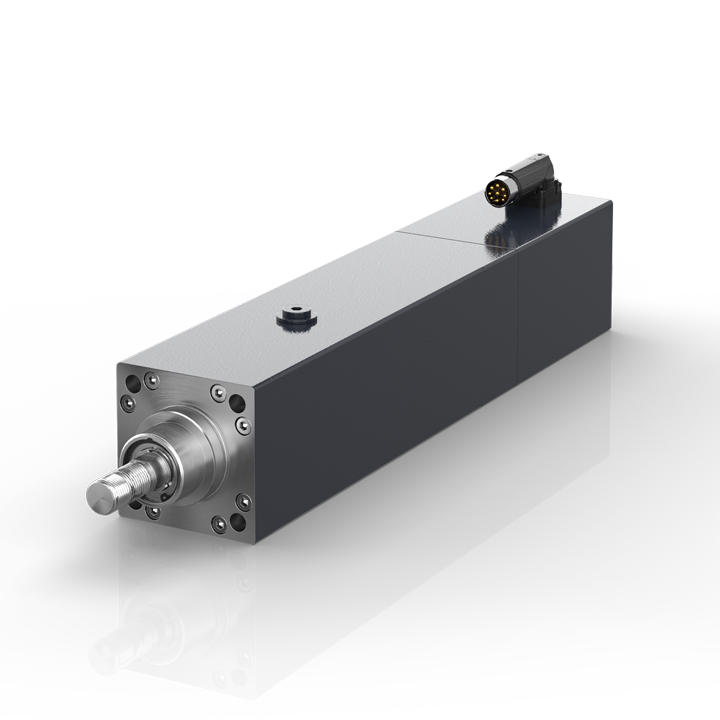

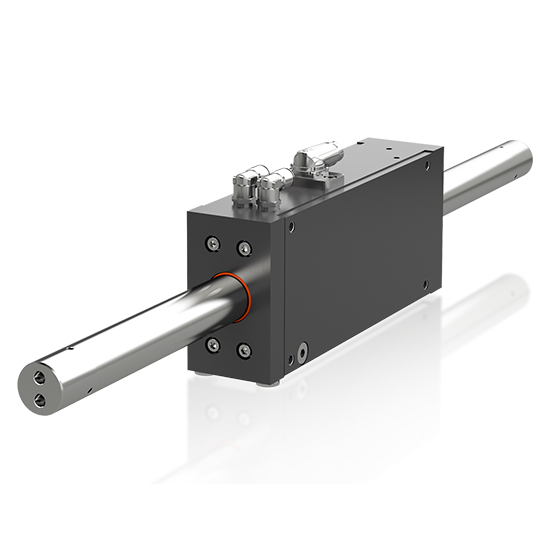

AA3000 | Electric cylinder

The AA3000 are powerful spindle drives for the replacement of pneumatic or hydraulic drives. Optionally available with holding brake and other spindle pitches.

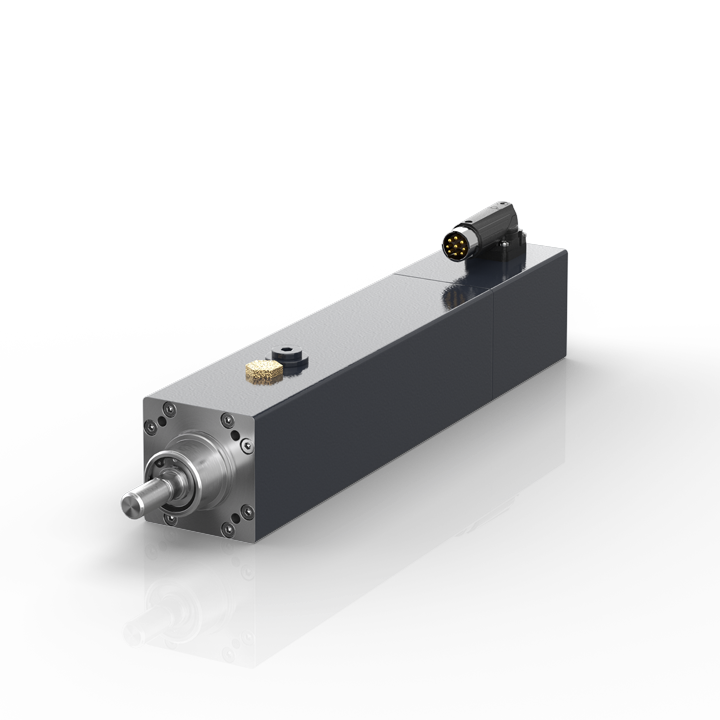

AA3100 | Electric cylinder for compact drive technology

The AA3100 are powerful spindle drives for the replacement of pneumatic or hydraulic drives for compact drive technology. Optionally available with holding brake and other spindle pitches.

AA2500 | Tubular motors

The ironless tubular motors from the AA2500 series are backlash-free and wear-free drives that meet the highest requirements for precision and dynamics.

Software

The motion software products optimally support the selection and commissioning of suitable hardware components for drive solutions.

Direct drives for dynamics and high precision

Translatory servomotor systems come into their own precisely where high dynamics and very high requirements for accuracy are important. There is no need to perform a mechanical implementation that is prone to backlash and reduces the efficiency of the system. The connection of the load to the motor is backlash-free; the position measuring system is mounted directly on the load or on the motor and allows a backlash-free, very dynamic, and precise position control. The direct translatory movement of the linear motor, in combination with high-resolution position feedback, is the basic prerequisite for the realization of high-precision machines.

Modular and highly dynamic

The AL8000 linear motor series, which was developed in a modular design, is available in three widths and with up to 48 coils. Developed and produced in Germany, the series offers a high level of quality, flexible adaptation to customer requirements, and extremely short delivery times. All linear motors from the AL8000 series have an unconnected cable end with a fixed length, which contains both the power supply and the temperature contact. This reduces material costs, possible sources of error, and installation work.

Cogging-free and powerful

The ironless tubular motor from the AA2500 series is completely cogging-free and can perform highly dynamic movements very precisely. Ideally suited for the highest requirements, for example in machine tool construction, the magnetic rod in the motor housing has been arranged absolutely backlash-free and wear-free. This arrangement also simplifies integration into the machine design. In general, the motor can be operated with a moving magnetic rod or moving motor housing and thus offers further application possibilities. The tubular motor is optimally matched to the AX8000 and AX5000 series of servo drives.

The highly integrated electric cylinders from the AA3000 series combine translatory applications with the proven AM8000 construction kit. The linear guided, low-maintenance and highly precise spindle drive is integrated in the motor housing with a rigid and backlash-free bearing and thus makes the most compact dimensions possible. Propulsion is provided by proven AM8000 components, resulting in the typical advantages such as the electronic identification plate, SIL 2 safety encoder or optional holding brakes. The drive is thus fully compatible with the servo drives from the AX5000 or AX8000 series and can be connected as usual with an OCT cable. Flange compatibility with ISO 15552 enables the simple conversion of pneumatics in existing applications.

Supplementary and intuitive

An extensive and optimally matched range of accessories rounds off the translatory product portfolio. The motion software products optimally support you with the selection and commissioning of suitable hardware components for drive solutions.