High accuracy inspection system increases foreign object detection rates up to 500%

The transition from distributor to award-winning OEM likely seems like a long-term process. Kearney, Missouri-based ProSpection Solutions, however, did just that in two years. One of the first solutions its engineering team designed for food inspection won an industry award. Working with Beckhoff has been a large contributor to this success, the company says.

ProSpection specializes in automating product and packaging inspection for meat, dairy and other foods. In 2017, as the company began to shift to machine building, one of the first products its engineering team designed was the IP69K-rated Low-Density Foreign Material Detection and Removal System. At Process Expo 2019, the machine won the Innovation Showcase Award in the Meat, Poultry and Seafood category.

“The inspection system allows our customers to detect and remove foreign objects from their product stream with a significantly higher degree of consistency, accuracy and at a much higher rate than other inspection methods,” says Jeff Youngs, President and CEO of ProSpection. “This system has become Prospection’s flagship product line, drawing attention from the largest CPG (consumer packaged goods) manufacturers in the food industry. The attention drawn to the Foreign Material Inspection System has also helped us grow our other product lines.” The company also offers other types of inspection systems as well as check-weighing solutions.

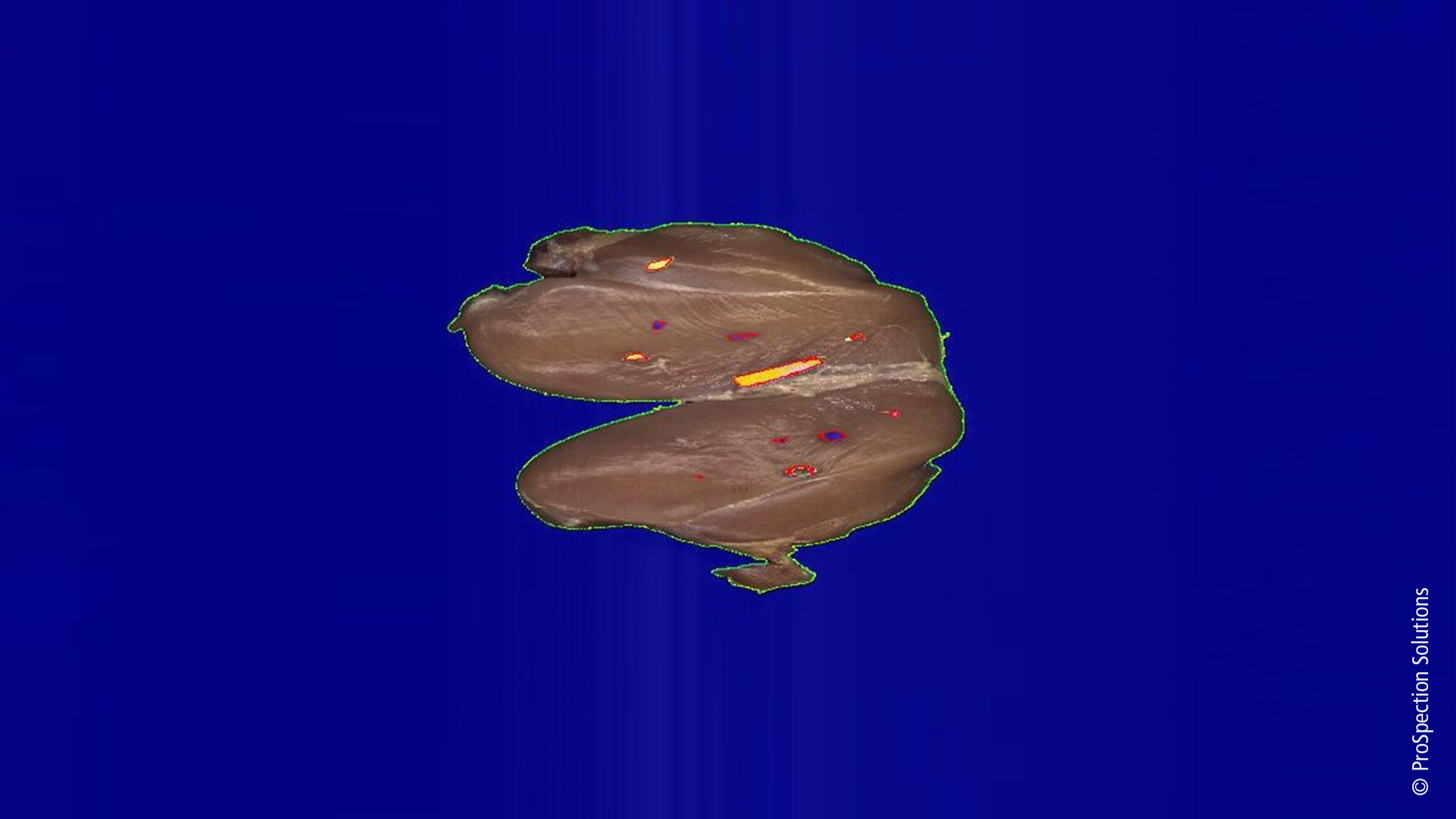

The Foreign Material Inspection System uses multiple camera angles to scan and inspect the entire surface of beef, pork, poultry, pet foods, shredded cheese, pasta and other prepared foods. The machine can detect a wide range of contaminants, including hard and soft plastics, personal protective equipment (PPE) and many other items commonly found in production plants. The machine then automatically ejects any tainted product to remove it from the supply chain to the consumer. Perhaps most importantly, it does not have to flip the product to inspect both sides, since cameras inspect product from the top and bottom simultaneously, and therefore requires a much smaller footprint than competing systems, according to Kyle Knudsen, Vice President of Technology at ProSpection.

Designing and implementing the machine presented several challenges. The system needed to provide a higher throughput, a smaller footprint and a higher degree of reliability than competing machines. The proprietary vision inspection software also needed to communicate in real time with the machine controller to allow for immediate removal of contaminants from the production line. To meet these requirements, ProSpection decided to implement EtherCAT and PC-based control technologies from Beckhoff.

Powerful control technology increases inspection reliability

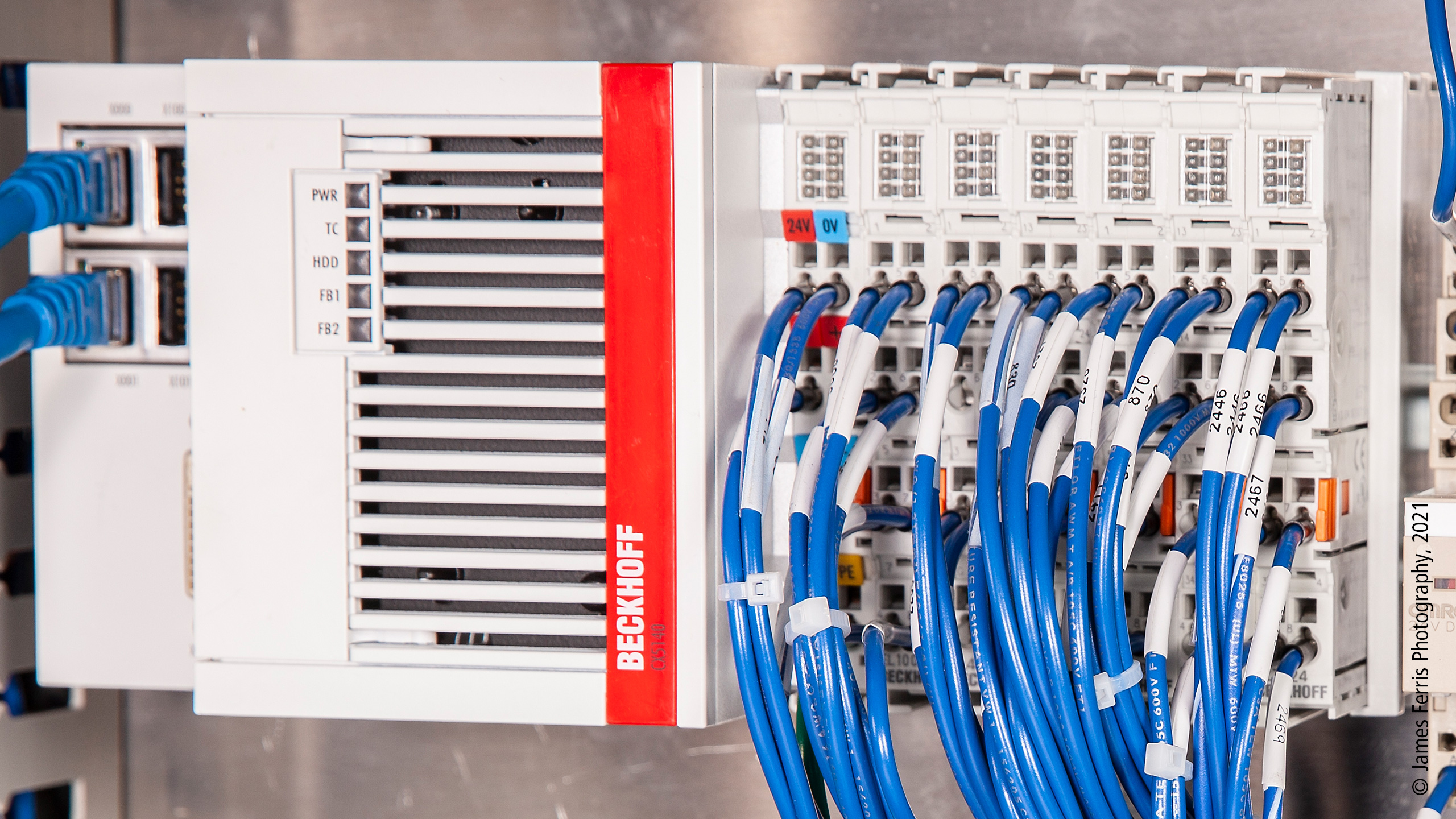

ProSpection began working with the local Beckhoff team – Applications Engineer Marc Wilkinson and Regional Sales Engineers Brian McKee and Brandon Snell – on the design and programming of the Foreign Material Inspection System in summer 2017. The solution features a CX5140 Embedded PC running TwinCAT 3 automation software to control the machine. ProSpection’s proprietary vision software operates on a standalone computer and communicates to the CX5140 in real time via the ADS protocol. Kyle Knudsen believes the controller offers ultimate stability and boosts system reliability. In addition, a stainless steel CP3918 Control Panel with an 18.5-inch multi-touch screen supports advanced HMI concepts for the food industry.

TwinCAT offers the PLC and motion control functionality. However, when the company had just transitioned to building machines, their engineering team had limited programming resources. Kyle Knudsen sees the support they received from the Beckhoff team, and Marc Wilkinson in particular, as critical to the system’s success: “Marc essentially programmed all of the machine control for us when we got started. Marc integrated the communications to our vision software using ADS, and he made the base code very easy to understand and modify for our semi-standard systems.”

Now, ProSpection completes its own PLC programming. Kyle Knudsen, who has a background in computer science, found the TwinCAT 3 platform easy to acclimate to. “Most of my training is in C++, so moving to Structured Text in TwinCAT 3 was an easy transition,” he adds.

EtherCAT and motion control from Beckhoff increase performance

EtherCAT and motion control solutions from Beckhoff provided additional advantages. EtherCAT delivers real time communication with free selection of topology. “ProSpection also appreciated that EtherCAT couplers and gateways to more than 30 prominent communication protocols are available,” Brian McKee from Beckhoff says. “As the company expands in the marketplace, the ability to communicate easily to other fieldbuses, like EtherNet/IP or PROFINET, on equipment upstream and downstream will be essential.” Open PC-based automation also simplifies programming and control for third-party components, such as the retractable nose that diverts rejected products, and linear actuators for camera positioning. The inspection system uses several space-saving EtherCAT I/O Terminals as standard input/output, lighting control for the cameras and ultra-compact drive technology via EL7047 stepper motor terminals. TwinSAFE technology directly incorporates functional safety capabilities, such as STO and SS1, into the TwinCAT engineering environment.

With fast communication from the inspection software to the motion components over EtherCAT, the system can handle 10,000 to 25,000 pounds or 4,535 to 11,340 kg of product per hour with high accuracy. This throughput rate is three to five times higher than typical competitive systems on the market, according to ProSpection. The automation system logs inspection results in a SQL database and stores cropped images showing every contaminant with timestamps, allowing the customer to review detected contaminants, eliminate issues in the plant and reduce waste.