PC-based control technology in additive manufacturing

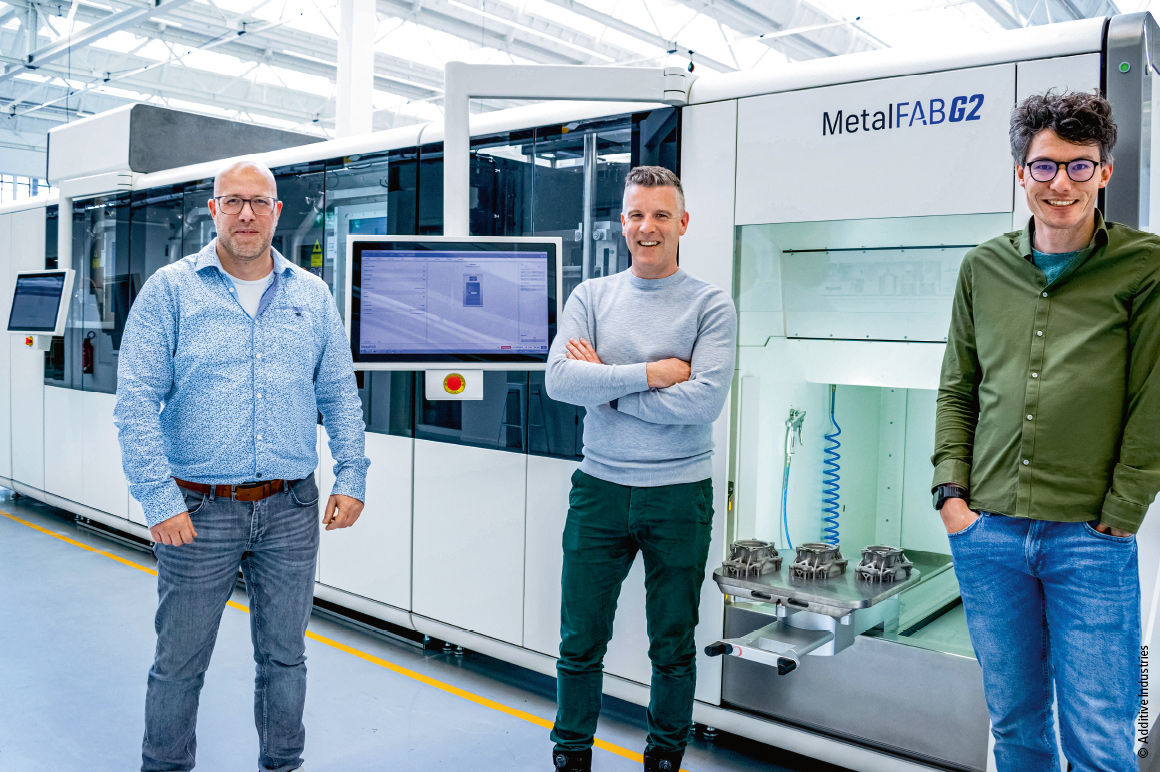

As an open control platform, PC-based control supports different engineering approaches, including low-code programming with frameworks such as Cordis SUITE. The machine builder Additive Industries uses this to create the code for the TwinCAT runtime of its MetalFAB 3D printers. When it comes to automation technology, the company relies entirely on Beckhoff controls, I/Os, and drive technology.

Low-code programming, which refers to software development based on models in a graphical environment, is a long-established approach in IT. Cordis applies this approach in its Cordis SUITE platform for OT systems, where the code for the TwinCAT runtime is automatically generated from state-machines and activity diagrams.

PC-based control – open, right from the start

“Low-code programming started much later in OT than it did in IT because traditional manufacturers shielded their hardware for a long time,” explains Jan Peter Meeuwse, Chief Operating Officer of Cordis. PC-based control from Beckhoff, on the other hand, was open, flexible, and scalable right from the start – and still is. “Although the models developed with Cordis SUITE can also be transferred to other platforms, our customers stay with Beckhoff because of the unique advantages that PC-based control offers,” states Stefan van Amerongen, Product Lifecycle Architect at Additive Industries.

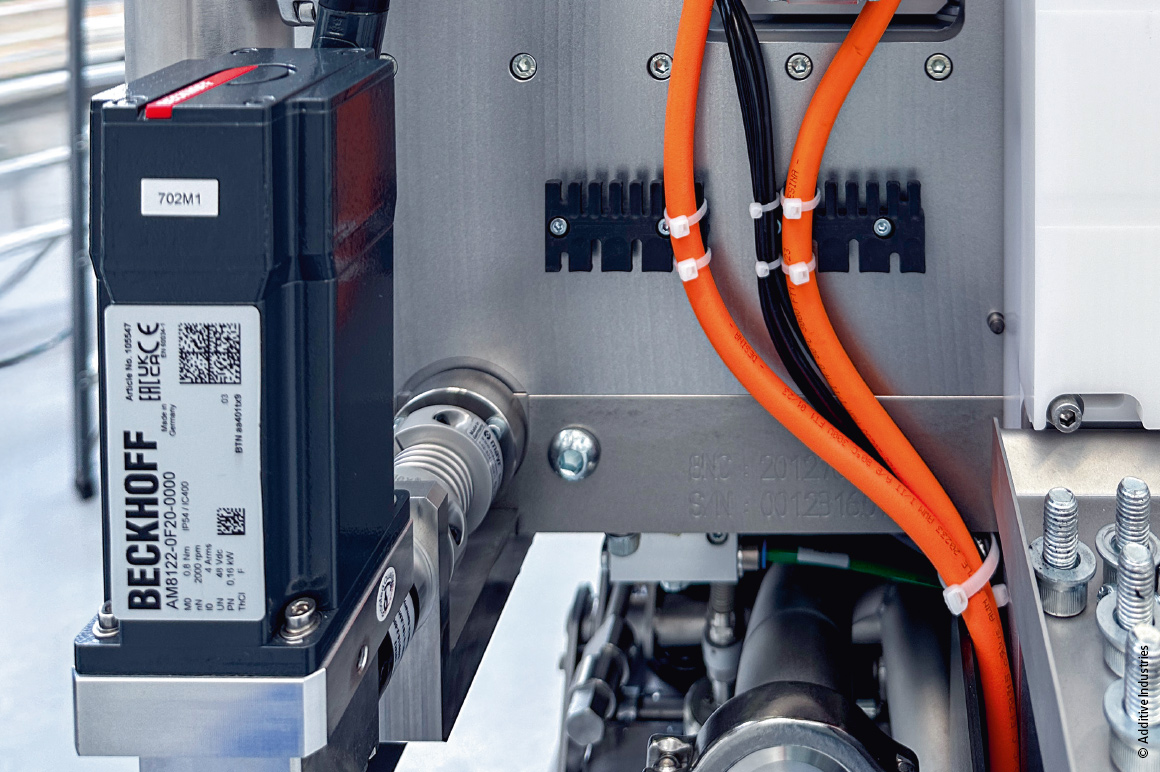

Based in Eindhoven, Additive Industries uses Cordis SUITE to create the software for its MetalFAB industrial 3D metal printers. The company uses Beckhoff’s powerful hardware and software as its automation platform, a CX5230 Embedded PC as the control platform, AX5000 servo drives to control the AM8000 servomotors, and a large number of EtherCAT and TwinSAFE Terminals. “We chose Beckhoff as our system supplier because of the reliability and flexibility of the components. The comprehensive Beckhoff portfolio covers a broad spectrum and fits the modular architecture of our machine concept,” says Stefan van Amerongen.

Compact and precise drive technology

According to Additive Industries, the MetalFAB range offers the most advanced 3D printers for metals and achieves the highest productivity in its category due to its high degree of automation. “The drive technology and motion control from Beckhoff play an indispensable part in this, with reliability and durability that keep the printers’ productivity high,” says Stefan van Amerongen. In order to achieve excellent standards of surface quality in 3D printing, drive technology that is both precise and dynamic is required to move the buildplates during the printing process. AM8000 servomotors are also responsible for dispensing the metal powder, a process that is crucial for forming precise contours. In addition, the servomotors are used in automatic handling of the buildplates by robots. On average, fourteen servomotors are installed in each 3D printer.

The codebase of the 3D printer consists of around one million lines of code, of which Cordis SUITE generates more than half. This PLC code is maintained with just two to three people, whereas the remaining PC code requires a team of ten. „This shows how powerful the modeling is, not only reducing the required workforce, but also improving the quality and adaptability of the code”, emphasizes Stefan van Amerongen. At the same time, the quality and adaptability of the control program increases. This is because the behavior and architecture of the machine are described in the models, so the engineers have very quick access to the program modules they want to adapt. Process specialists can model and configure the machine functions without in-depth programming knowledge. “All they have to do is learn to interpret state models,” explains Stefan van Amerongen. Process experts can use a dashboard to customize all of the software’s functions and variables.

Low-code engineering embedded in TwinCAT

The single-button deployment concept in Cordis SUITE supports simple rollout of the software and seamless integration of the application into TwinCAT. The TwinCAT runtime combines the PLC, HMI, motion control, and image processing. “This does away with the need for additional systems,” explains Stijn de Bruin, Sales Engineer at Beckhoff Netherlands. In addition, Additive Industries benefits from the advantages of open standard PC technology with operating systems such as Windows or Linux® and familiar interfaces with the machine and information systems.

Jan Peter Meeuwse explains: “Our low-code development layer is supplemented by a generic server application that acts as a bridge between IT and OT systems, facilitating the integration of TwinCAT applications with end users’ IT systems and simplifying comprehensive data logging, for example.”

Easy data integration into IT systems is important for Additive Industries, as most customers want to monitor the 3D printers. “The aerospace and automotive industries, for example, need this data for the certification and traceability of their products,” says Stijn de Bruin. Traditional tools can extract sensor data from the process and generate diagrams. Cordis SUITE goes one step further in this case and also displays the historical states of all components or creates comprehensive logs that show the runtime behavior of the software. “This gives a deeper insight into the internal workings of the software and turns the system into an intelligent sensor that provides a wealth of additional machine data,” says Jan Peter Meeuwse.

Close cooperation in the next generation

Additive Industries is currently working on the next generation of its MetalFAB machine. This generation required comprehensive extensions to the control program, as part of which it was possible to reuse many of the existing models and, at the same time, build upon the TwinCAT runtime program code. Stefan van Amerongen comments: “What we have really come to appreciate is the EtherCAT diagnostics and the integrated safety-related communication, as well as the fast, expert support from the staff at Beckhoff Netherlands.”