Redesign enhances functionality, simplifies wiring and reduces costs

When Pensar Otra Vez (POV) was asked to develop a machine for final PCB testing at elevated temperatures for an automotive supplier, the company had already gained experience with similar systems. Nevertheless, a redesign of the control technology with Beckhoff yielded major improvements. In addition, the PC-based control technology simplified data acquisition and analysis for the end customer's energy management.

Mechanical engineer Mike Edwards founded Pensar Otra Vez, Inc. in Tucson, Arizona, in 1994. Over the years, the company has built machines for many industries, concentrating on medical, battery and automotive manufacturing. The idea of regularly reevaluating components, processes and strategies is even in the company’s name: It literally means “think again” in Spanish. So, when one long-term customer, a tier-one automotive supplier, needed to build a new elevated-temperature PCB test handler in 2019, it may come as no surprise that Mike Edwards automatically went back to the drawing board rather than copying the existing design. More than 20 of these original test handler machines were already in operation at one of the customer’s plants in Texas, so there was a clear baseline to measure improvements against.

The new handlers receive an incoming PCB at room temperature, elevate the PCB temperature to approximately 110 °C and hold that temperature within ±3 degrees during a final functional test of the PCB to simulate operating conditions in a vehicle. Since the test time is under 120 s, the test handler must quickly add heat to the product. Throughput is important, so the handler needs to maximize testing time versus handling time. Inside the handler, the PCB products progress through four preheat stops on the conveyor to reach the test stop. At each preheat stop, infrared temperature sensors monitor temperature rise. Previously, the integration of the sensors into the control system created a wiring challenge with significant costs in terms of labor and cabling.

Increased performance and transparency through one central platform

The new elevated-temperature PCB test handler needed to increase performance, adhere to testing processes and reduce component costs at the same time. POV wanted to meet these goals while reducing cabling requirements, minimizing footprint and increasing user-friendliness. The end user customer also wanted the machines to improve data acquisition and analytics capabilities as a path toward IIoT and Industrie 4.0 concepts. This automotive vendor has plants around the world with key initiatives aimed at measuring processes and enhancing efficiencies. “Energy management in this customer’s factories is growing more and more important. This includes everything from automatic power down of conveyors when not in use to accurate motor rpm monitoring,” POV Project Manager Mike Edwards explains.

While the customer previously completed the machine programming in-house using Visual Basic (VB), the automotive manufacturer now wanted greater flexibility and access to performance data across the system. Therefore, the engineering team at POV collaborated with Dan Distefano, Owner and Senior Software Engineer at D2 Engineering LLC, on design and programming. “One of the main goals was to provide access to all systems and devices through a single development environment,” Dan Distefano says. “Having more than 20 years of experience with Beckhoff solutions, it was clear that TwinCAT 3 automation software and the EtherCAT industrial Ethernet system were the best fit, as they would also enable simple integration of third-party components.” The team worked closely with Casey Taylor, Regional Sales Engineer at Beckhoff, to specify the best components and systems for the application.

Integrated into Microsoft Visual Studio®, TwinCAT 3 allows programming in computer science standards and all IEC 61131-3 languages with object-oriented extensions. Dan Distefano leveraged several solutions within the software suite: “We implemented TwinCAT HMI for the operator GUI, TwinCAT PLC and Motion for the machine control and TwinSAFE for the integrated functional safety system. Having the same Visual Studio® front end helped us accomplish the main goal of easy access through a single development system.” These capabilities improved the ease of support both in the field and remotely.

The TwinCAT runtime is loaded on a space-saving C6030 ultra-compact Industrial PC (IPC) from Beckhoff that boasts an Intel® Core™ i3 processor. For a more robust and user-friendly operator interface, the handler features a CP3921 multi-touch Control Panel with a 21.5-inch display and custom push-button extensions.

Enhanced communication and motion control

Through its openness, comprehensive built-in diagnostics and high real-time communication performance, EtherCAT improves machine design and operation by connecting all key machine components into one ecosystem. EtherCAT does not use IP addresses for network devices; instead, it automatically identifies and configures each device on the network. “As a result, each device can be accessed, commissioned and debugged without the need for additional software,” Dan Distefano adds.

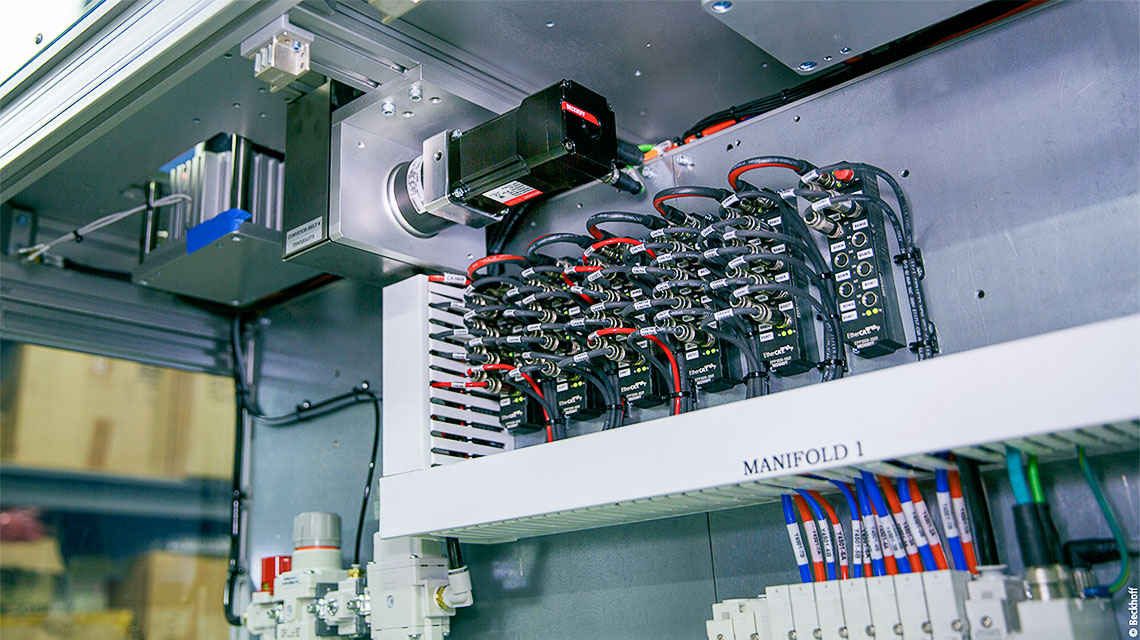

The handler uses a mix of IP20-rated EtherCAT I/O terminals, IP67-rated EtherCAT Box modules and one-cable solutions that provide communication and power for field devices in a single cable. “EtherCAT P and machine-mounted I/O components allowed us to run just a single cable back to the main control cabinet,” Mike Edwards says.

To load the PCBs through the elevated-temperature test stations, the handler machine operates a conveyor powered by Beckhoff AS2022 stepper motors paired with AG2250 gearboxes. The IP54-rated AS2022 stepper motors powered by EL7047 EtherCAT Terminals feature a torsion-proof, integrated encoder. “The previous design used a motor plus gearbox for each side of the edge belt conveyor. The motor speed output value was a numerical analog number that didn’t read as motor rpm or belt fpm,” Casey Taylor says. “The Beckhoff drive technology could easily display true motor rpm, so the two conveyor sides could be accurately monitored and adjusted.”

Redesign yields major improvements

“In the automation world, it is relatively rare to have the opportunity to directly compare newer technology with the previous way of performing the task,” Mike Edwards says. “Redesigning the elevated-temperature PCB test handler for our automotive-industry client offered the perfect chance for an apples-to-apples comparison.” Use of EtherCAT I/O modules led to a savings of 9% in cost, 11% in field wiring labor through improved wiring efficiency and 12.8% in electrical cabinet size. Also important to the POV team was the significant reduction in debugging time. All of this was possible along with easy integration of third-party devices, such as the infrared sensors, on the all-encompassing EtherCAT network.

After the design and build were complete, the Beckhoff benefits included a reduction in controls design time of about 36 hours for the project, according to Mike Edwards. “Programming was consolidated into a single point, and additional features – such as temperature control and measurement, energy usage and speed monitoring – that were not available with prior components offered greater flexibility,” he says. This is part of the strength of the Beckhoff platform, according to Dan Distefano: “Networking all devices over EtherCAT allowed us to gather more information for machine processes and diagnostic support with minimal software development and no additional hardware.” The redesigned handler has been operating in the field without issue, and the Pensar Otra Vez team would like to retrofit the others with the new Beckhoff architecture eventually.