PC-based control for integrated media and building automation

Integrated concept for control, drive and safety technology

横浜オフィス(本社)

ベッコフオートメーション株式会社

+81 50 1790 1111

info@beckhoff.co.jp

www.beckhoff.com/ja-jp/

Integrated concept for control, drive and safety technology

New thinking brings about new technological demands: whereas multimedia applications, building automation and entertainment concepts were previously implemented separately, all disciplines must now interconnect intelligently. This stems from the complexity of the applications and the comfort standards now demanded in buildings of all kinds. As a platform for centralised control, PC-based control from Beckhoff provides the answer. From audio and video control to control of show effects and device management, as well as newer concepts such as condition monitoring – all disciplines are directly linked with the integrated building automation system. The advantages become immediately clear: all system information is available to the user on one platform due to the inherent continuity and flexibility provided by PC-based control. Operation is simplified, comfort levels are increased and costs can be reduced. References from all around the world validate the reliability of the control components and the expertise of Beckhoff in countless industries and applications.

Performance level scalability, modularity, reliability and long-term availability of components make PC-based automation technology from Beckhoff the ideal toolbox to implement leading-edge media technology applications. Numerous global references are proof of this, ranging from meeting and conference applications, control centres, and building automation to entertainment technology. From audio and video control to control of show effects and device management, as well as newer concepts such as condition monitoring – all disciplines are directly linked with the integrated building automation system. The advantages become clear immediately: all system information is available to the user on one platform due to the inherent continuity and flexibility provided by PC-based control. Operation is simplified, comfort levels are increased and costs can be reduced.

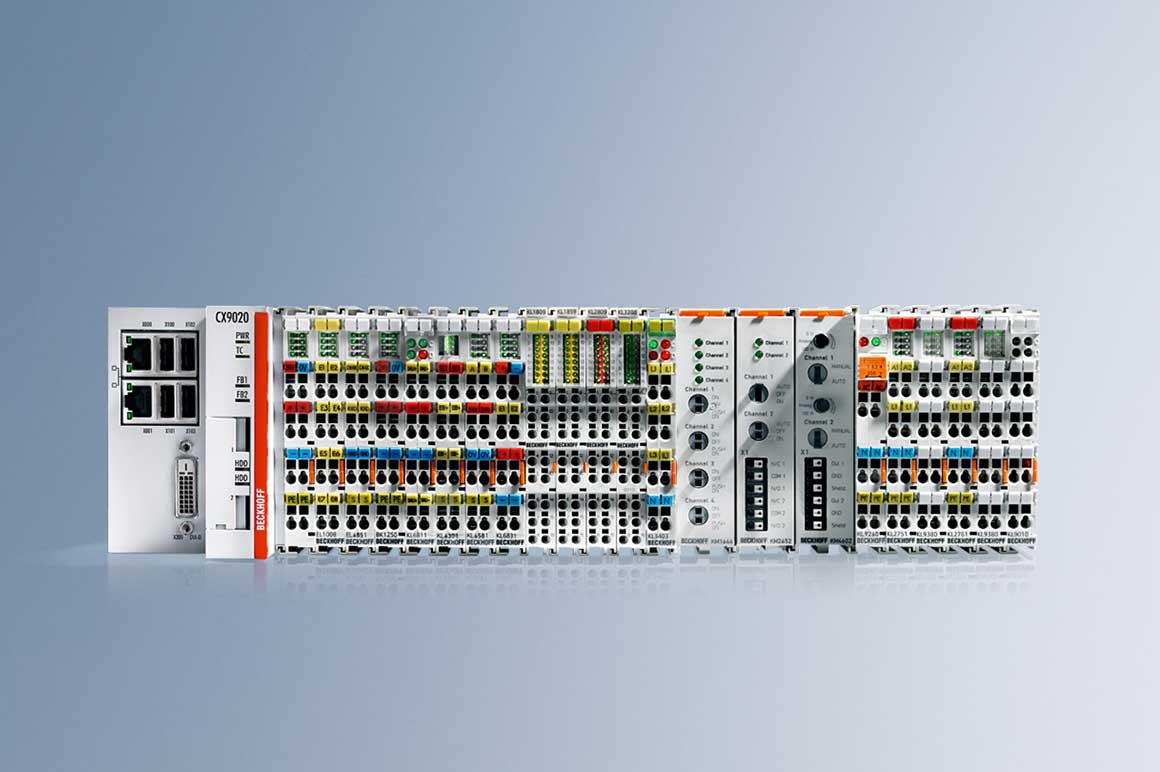

At the heart of the Beckhoff control platform, robust Industrial PCs or embedded controllers using TwinCAT as the universal automation software integrate PLC, visualization, motion control, safety technology and measurement technology tasks. Beckhoff I/O systems can be used to connect the whole range of sensors and actuators. This includes devices used for daylight-dependent lighting and facade control to control of heating, ventilation and air conditioning through to show lighting, sound and projection control. EtherCAT, the real-time-enabled fieldbus system, provides the necessary communication speeds.

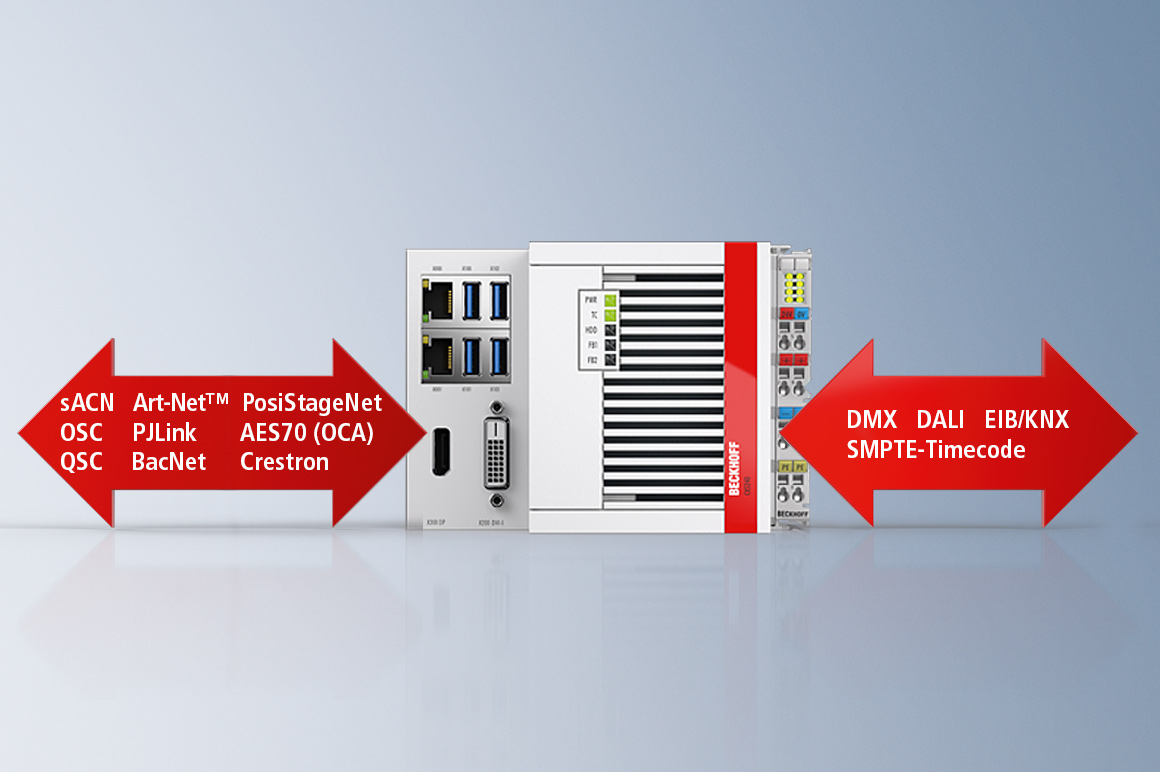

Through the integration of all communication protocols typically found in the areas of A/V, multimedia, building automation and show technology into the PC control platform, all devices from a wide range of manufacturers can be connected and controlled. As the system is modular throughout, its functionality can be easily extended, for example, by adding an I/O terminal that supports the required signal. The various hardware components and their functionalities are programmed and configured in uniform software using TwinCAT.

Your built-in advantages for media technology:

The scalability, modularity and flexibility of all components make PC-based automation technology the ideal toolkit for the implementation of applications in media technology and the configuration of a made-to-measure control solution. All product lines in the areas of Industrial PCs, I/Os, Drive Technology and automation software are individually scalable according to application requirements. The broad portfolio of Industrial PCs, for example, ranges from the ultra-compact C6015 IPC with dimensions of only 82 x 82 x 40 mm through to a many-core computer with up to 36 processor cores.

The Beckhoff I/O portfolio supports about 100 signal types and 36 fieldbus systems, and therefore is suitable for controlling all common actuators and sensors. In combination with the modular TwinCAT automation software suite, users enjoy maximum freedom when configurating their application-specific control systems or subsequent system expansions.

The powerful PC-based automation platform handles control, data processing, connectivity, visualization and remote maintenance. With open software and hardware interfaces, it is ideal either for centralized or decentralized control of all applications in the fields of conferences, control centers, building and entertainment technology, such as audio and video, integrated automation, digital signage as well as operation and monitoring. In addition to integrating building technology standards such as DMX, DALI, LON, KNX/EIB, BACnet, SMI, MP-Bus, M-Bus, EnOcean, RS232/RS485, Modbus and TCP/IP, system integrators also have the most popular interfaces at their disposal for integrating AV and multimedia systems. With sACN, SMPTE Timecode, Art-Net™, AES 70 (OCA), PosiStageNet and PJLink, Beckhoff speaks all the relevant languages in these industries. As a result, the most varied application areas in media, monitoring, building and show technology can be implemented on the basis of standard control components.

Connectivity with common cloud systems can be achieved either from the control system via the IoT communication protocols AMQP, MQTT and OPC UA, or else via the Beckhoff IoT Bus Coupler. Without the need for a specific control program, it enables the simple and standardized integration of I/O data into cloud-based communication and data services.

While TwinCAT IoT supports standard protocols such as AMQP, MQTT and OPC UA for communicating with local or public cloud systems, TwinCAT Analytics facilitates cycle-synchronous recording and analysis of process data as a basis for predictive maintenance.

Beckhoff control components for: Media control, audio installations, video installations and show control

Beckhoff control components for: Lighting, HVAC, energy measurement and facade

Beckhoff control components for: Point of Information (PoI), Point of Sale (PoS) and device monitoring

Beckhoff control components for: Device management, cloud-based services and condition monitoring