PC-based control for solar fuel synthesis on an industrial scale

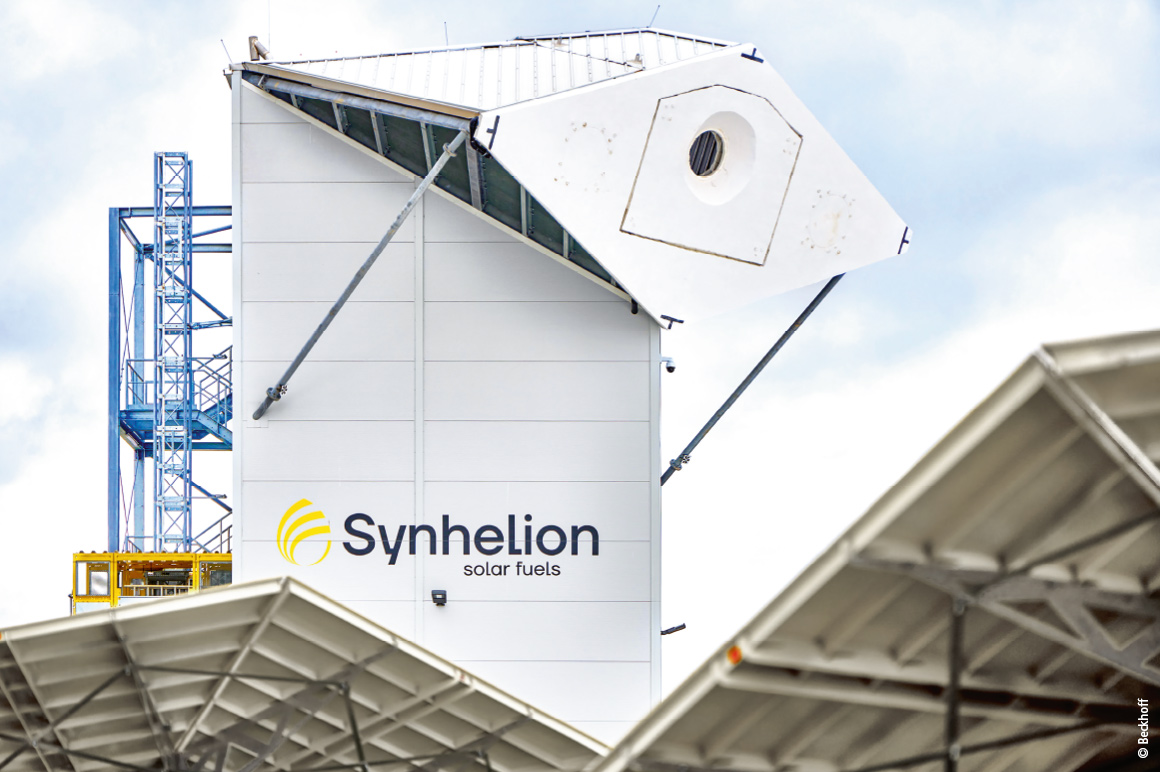

Switzerland’s Synhelion AG produces sustainable, synthetic fuels using solar energy. In summer 2024, the first industrial demonstration plant, DAWN, was put into operation in Jülich. Automated and monitored with PC-based control from Beckhoff as the process control technology, this represents an important milestone on the way to a large-scale industrial plant.

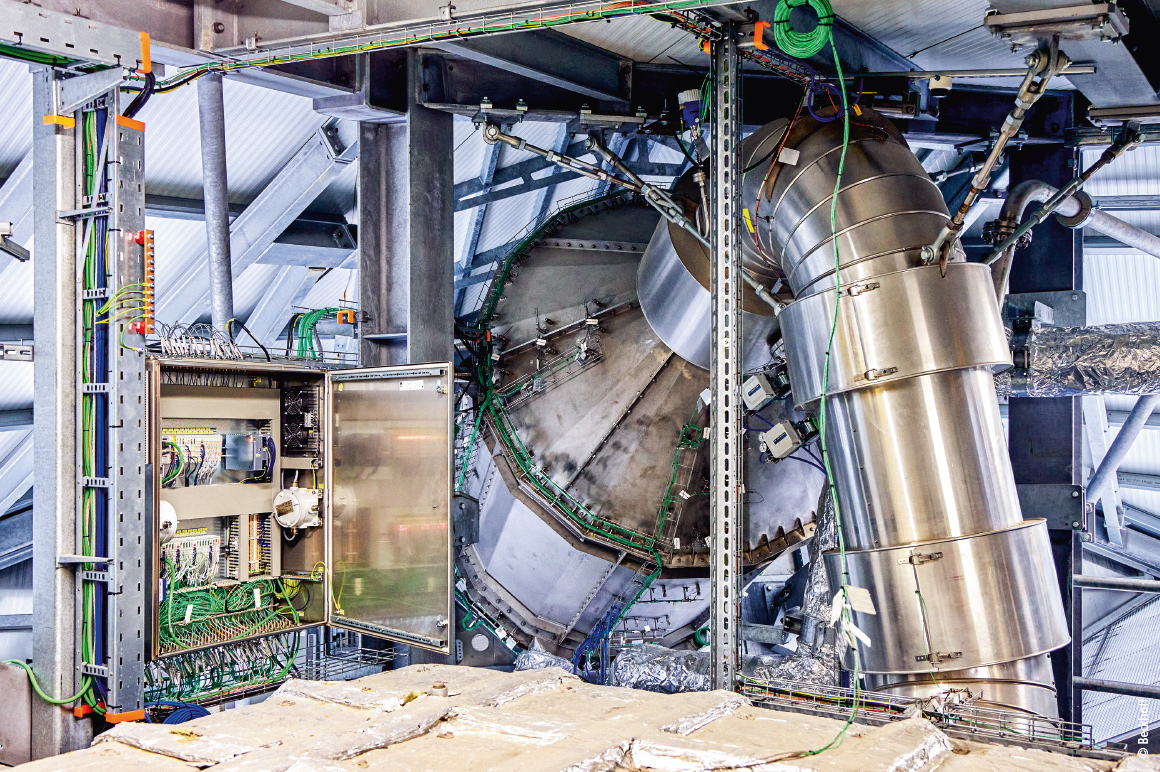

In the DAWN industrial demonstration plant, Synhelion uses the “sun-to-liquid” process with concentrated solar thermal energy (CST) for the production of solar fuels. The plant consists of four central components: the heliostats (mirrors), the receiver with 600 kW thermal output, the thermochemical reactor, and the thermal energy storage unit.

Over 200 heliostats focus the solar radiation onto the receiver, i.e., a combustion chamber at the top of the tower in which a heat transfer medium is heated to over 1,500°C for a sustained period. The process heat generated in this way is fed into a thermochemical reactor, which produces a synthesis gas from a RED-certified carbon source (CO2+CH4) and water. This gas is then turned into fuels using industrial processes. “Our focus is on kerosene, diesel, and gasoline so we can supply the transportation sector with sustainable fuels,” says Adrian González, Head Engineer for Process Automation at Synhelion. The advantage of these fuels is that the existing infrastructure (tank farms, transporters, dispensers) can continue to be used. Instead of the usual kerosene, one of the tanks will contain the ecofuel in this case to be added in accordance with the regulations. “This is much easier and more efficient than converting a fleet of aircraft to hydrogen,” says Adrian González.

The excess energy from the receiver is fed into a thermal energy storage unit developed by Synhelion and can be fed back into the process at any time. “The ceramic storage tank for the process heat extends over two levels of the solar tower,” says Adrian González, explaining the dimensions of the plant, “and also fulfills an important function – ensuring continuous operation independent of solar radiation.” Instead of the heliostats, an electric heating system can also be used, which draws its energy from photovoltaic systems or wind turbines, for example. “This is particularly relevant when there is an oversupply of renewable energy in the distribution grid,” says Iesse Schneider, the programmer responsible for the plant, explaining the flexible approach to energy supply.

Synthetic crude oil requires sophisticated control technology

Since fall 2024, the Synhelion plant has been producing synthetic crude oil (syncrude) which is almost identical to its fossil counterpart. The entire manufacturing process is controlled and monitored by around 1,000 sensors and actuators networked via EtherCAT, with TwinCAT as the process control system and a C6030 ultra-compact Industrial PC. “Despite the many sensors and even more data points, the cycle time of the TwinCAT runtime remains well below 10 ms and gives us more than enough flexibility for tests and expansions,” says Adrian González. The plant in Jülich is the industrial-scale test system which Synhelion is using to test, validate, and optimize the process control of various end products on even larger plants. As a result, the process control technology needs to be flexible and easy to expand. “With PC-based control and the scalable hardware, the control technology and I/O level can be adapted very flexibly to actual requirements and additional measuring points can be retrofitted at any time,” adds Wilm Schadach, Branch Manager at Beckhoff Monheim.

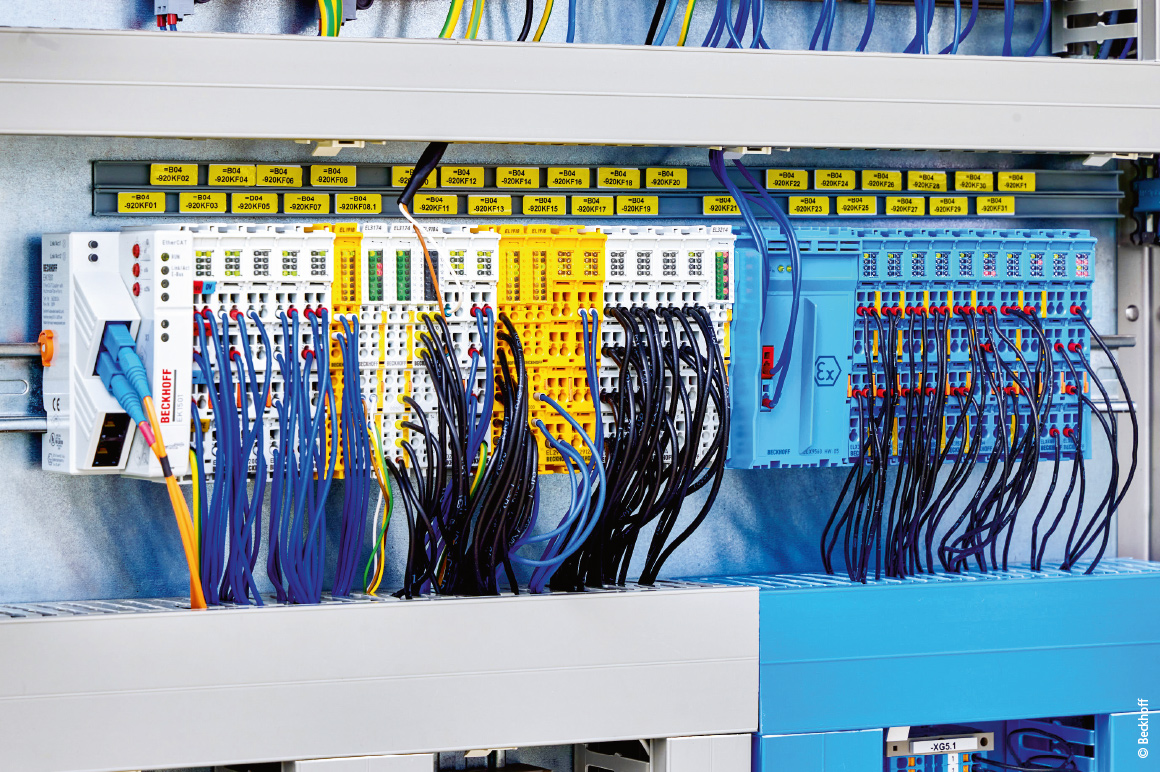

Although the process does not place any extreme demands on performance, the large number of different sensors and actuators alone was seen as critical at the beginning of the planning phase. “The comprehensive range of EtherCAT Terminals and the flexible topology options of EtherCAT really helped us to collect the I/Os that are distributed over four levels, integrate them into the controller, and map them in the HMI,” says Iesse Schneider. The ability to integrate the sensors and actuators in hazardous areas (ATEX) directly into the EtherCAT communication via ELX terminals was also a great advantage. “Numerous EtherCAT Terminals from the ELX series are used in the project,” adds Sebastian Böse, who works in process industry management at Beckhoff. Almost 600 terminals were installed in total, spread over 27 control cabinets on six levels. The 37 different terminal types include various EtherCAT Terminals with communication interfaces for Modbus TCP, Profinet®, and HART.

There are also numerous safety functions that have been implemented using TwinSAFE SC and TwinSAFE Terminals. “In total, around 40 functions – some of which are SIL2-rated – were implemented on the basis of IEC 61511,” says Iesse Schneider. EtherCAT and Safety over EtherCAT (FSoE) play an important role here. The initial approach was to use one EL1918 TwinSAFE Terminal with TwinSAFE Logic as the safety controller. However, as it was not possible to map all of the plant’s safety functions with the terminal’s maximum of 512 function blocks, the function blocks – numbering more than 700 in total – were distributed across four EL1918s. These receive the information from the sensors and actuators via FSoE and communicate with each other.

Reliable data logging with open control

In parallel with process control, data logging takes place via EtherCAT at different intervals. “This can be conveniently configured for each data point in TwinCAT and the data can be saved. EtherCAT also gives each process value a precise timestamp,” says Sebastian Böse. Intelligent logging strategies ensure that the data is only saved if the process value changes, for example. In total, the plant has around 50,000 data points, which TwinCAT provides via an OPC UA server. “The openness of PC-based control and OPC UA is also an advantage here,” adds Adrian González. It enabled Synhelion to install a third-party data logger on the C6030 ultra-compact Industrial PC, which retrieves the data on site. This has the advantage that if the communication connection fails, the data is always recorded and is not lost. “For test facilities, this is extremely important,” says Adrian González.

EtherCAT’s wide range of diagnostic options also made the work easier and quickly uncovered the typical errors that occur during commissioning of large plants of this kind. Using the extensive diagnostics, Synhelion was able to quickly rule out communication errors and concentrate on the configuration of the devices. “EtherCAT is a backbone that you can rely on,” says Wilm Schadach.

TwinCAT HMI Server (TF2000) communicates with the industrial PC via ADS and displays the information in the control room on a main workstation, four small monitors, and a large process overview monitor. If required, additional monitors can be added for data visualization. The TwinCAT HMI is a perfect platform for complete plant control and goes far beyond simple HMI solutions. In future, the process library will facilitate tasks that would otherwise have to be performed by a separate SCADA system.

Scaling is facilitated by technologies such as MTP and NOA, which allow the process control technology of individual modules to be flexibly integrated into existing plant structures. Sebastian Böse comments: “Beckhoff already provides a large selection of HMI and PLC function blocks for the development of MTP-compliant modules. In addition, the amount of development work required is reduced significantly by means of automatic code generation.” With a view to future projects, MTP is a very exciting prospect for Adrian González: “In the medium term, we see ourselves as a company that licenses its technology and makes it available to other fuel suppliers. A general contractor can then add Synhelion’s modules to its plant and integrate automation into its control technology using MTP and NOA based on our P&ID diagrams and controls.”