PC-based control used for forming steel plates in one of China’s largest shipyards

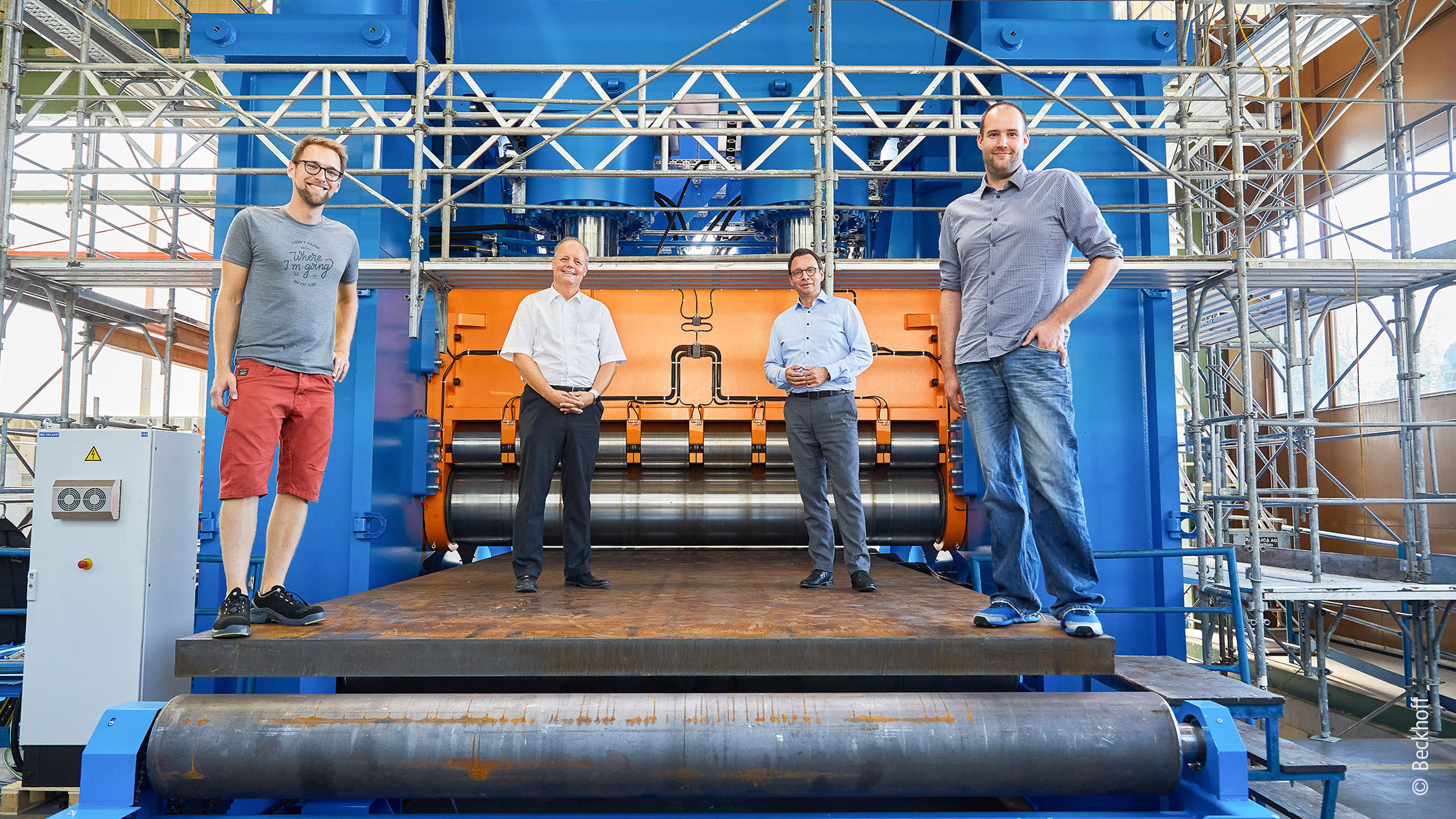

Haeusler AG, based in Duggingen, Switzerland, is a leading specialist in large-scale facilities for forming metal plates. At the end of 2020, a giant 1,245-ton straightening machine was delivered to one of the largest shipyards in China. The company explains that this plant, the largest of its kind in the world, is used in the production of oil tanker hulls. In this context, PC-based control technology from Beckhoff ensures that the enormous forces for precisely forming steel parts are guided in the right direction.

Haeusler is a special purpose machine manufacturer that was founded in 1936 and employs around 120 staff today. Since then, the company has developed a wide variety of machines and production lines, including customer-specific designs, for processing sheet metal for use in applications such as wind turbine towers, pipelines, the Ariane rocket, shipbuilding or enclosures within power plants and reactors. After an 18-month design and construction period, the latest RI 4000 X 87 straightening machine was delivered to the Chinese customer. The company’s numerous shipyards produce a wide range of different vessels – from oil tankers, cargo ships and passenger ships right up to speedboats.

80 years’ experience with straightening machines

Haeusler draws on more than 80 years’ experience in developing customer-specific straightening systems. The result of this expertise is the RI machine series, which is fitted with five, seven, nine or 11 straightening rollers, depending on the technical specification. This includes the latest, gigantic forming system, which, standing at 12 m high, coming in at a dead weight of 1,245 tons and equipped with five large straightening rollers, can apply up to 19,000 tons of force during the forming processes. It is capable of machining 120-mm-thick, 4-m-wide and 12-m-long high-strength steel plates (1,000 N/mm2 yield strength) weighing up to 45 tons. Haeusler explains that the capacity to process these huge metal plate dimensions provides significant advantages compared to traditional straightening solutions.

Machining this kind of steel plate is simply not comparable with that of typical metal sheets that are just a few millimeters thick. Here, it is more a matter of evenly aligning the plates as a rule – which are sometimes slightly wavy after manufacturing – for the subsequent work steps. Another task is to homogenize the stresses occurring in the sheet through several passes of cold rolling. For these purposes, the RI series offers a number of advantages, such as special individual roller adjustment for optimal straightening of both thin and very thick sheets. The direct roller drive provides automatic speed compensation and integrated overload protection.

Intelligent machine control optimizes machining results

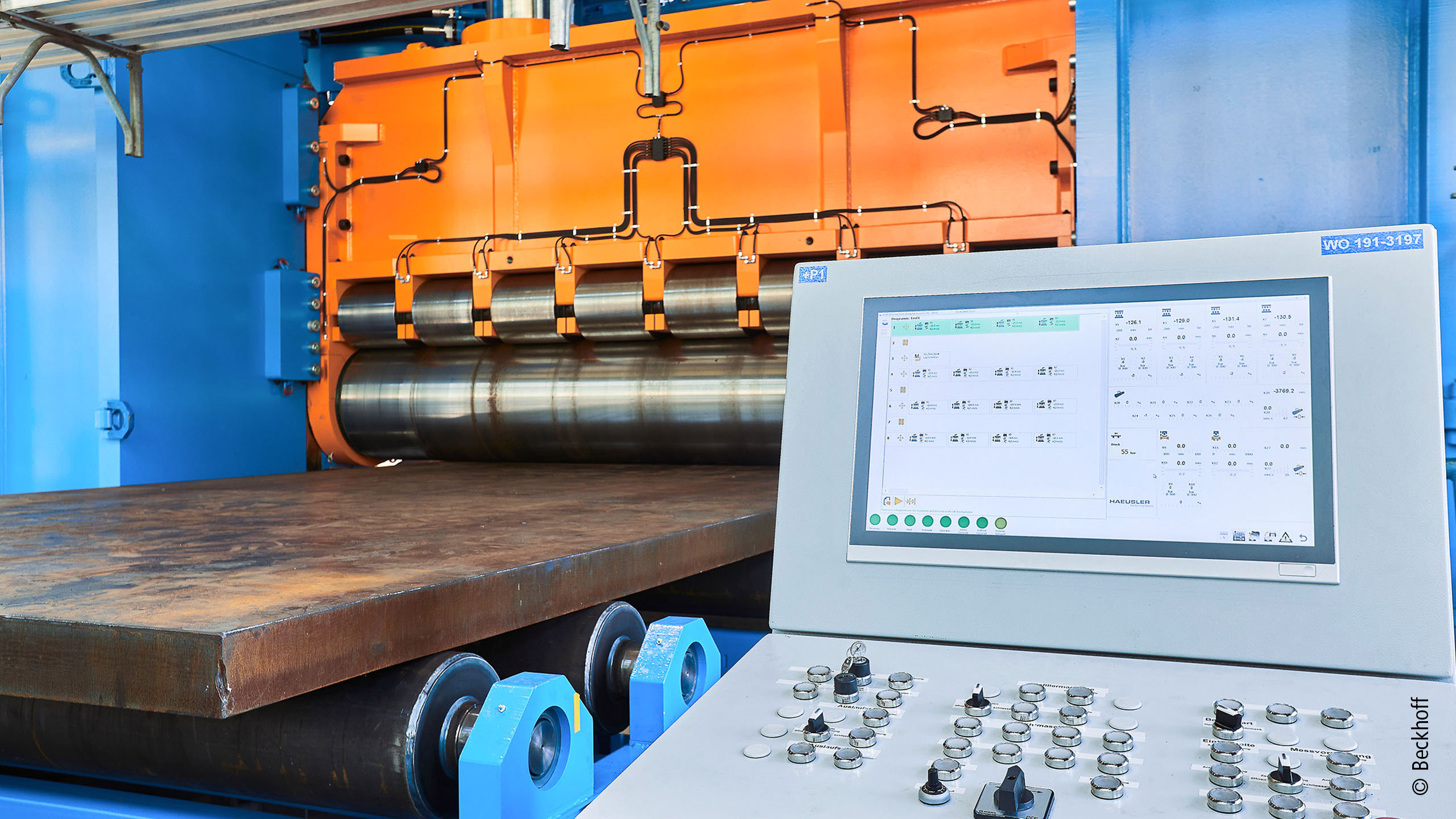

Another feature of the RI series is its intelligent machine control system, according to Haeusler. PC-based control technology from Beckhoff allows users to achieve optimum machining results within a short amount of time. The modular components are distributed and networked with the high-performance EtherCAT communication system, which can be ideally adapted to the special requirements of the straightening machine. Patrick Stadler, deputy head of the electrical department at Haeusler, explains that “The strength of Beckhoff lies in the breadth of the portfolio and in particular in how open PC-based control and EtherCAT technology is. This means that if third-party components such as position measuring systems are required, they can be integrated without a huge amount of effort. What’s more, a second control computer was installed in the plant for a downstream measuring application, which enables quality inspections to be performed after straightening. Using the EL6695 EtherCAT bridge terminal, both controllers could be connected to allow real-time data communication with minimal effort. We also use ADS to transfer process parameters between the controllers via TCP/IP and to the HMI that we developed ourselves, and we appreciate how open the interface is in this respect, too.” As another example, Patrick Stadler mentions a highly precise laser used for measuring the flatness of the straightened steel plates: “The laser has an RS422 interface and could be easily integrated with the EL6021 serial interface and the corresponding TwinCAT library without painstaking project planning.”

The overall control of the latest machine is implemented via two C6920 control cabinet Industrial PCs. These are connected via the efficient CP-Link 4 one-cable solution to a CP2919 (19-inch display) or CP2924 (24-inch display) Control Panel as a convenient multi-touch HMI built into an operator panel. TwinCAT with the TwinCAT PLC Hydraulic Positioning (TS5810) library is used as the control software. It forms the basis for the entire axis controls and coordinates immense forces, according to Patrick Stadler: “A complex hydraulic system is fed from an 8,000-liter oil tank, which transfers up to 3,500 liters of oil per minute. Hydraulic torque control of seven axes simultaneously has been implemented, with torques of up to 10 million Nm. The system is supplied with up to 2,500 A power (at full load), the majority of which is used for the hydraulics.” Patrick Stadler also sees another advantage in the TwinCAT OPC UA Server (TS6100): “With this OPC UA interface, we provide the end customer with the option to efficiently integrate the machine into their shop floor management.”

The I/O level distributed across several control cabinets within the plant includes nine EK1100 EtherCAT Couplers, nine EK1122 EtherCAT junctions and more than 150 EtherCAT Terminals. These include 36 EL1008 digital input terminals and 28 EL2008, EL2024 or EL2088 digital output terminals. Four EL2535 2-channel pulse width current terminals are also used. Haeusler benefits from the wide range of terminals available for analog value acquisition. For example, the EL3413‑0001 power measurement terminal, which is suitable for up to 600 V AC, can be used to directly integrate particularly powerful machine components. The analog value acquisition is supplemented by 27 analog EL3152, EL3162 and EL3255 EtherCAT input terminals, and seven EL4032 and EL4034 analog output terminals. Other I/O terminals used are the EL5152 incremental encoder interface, the EL6021 (RS422/RS485) serial interface, the EL6080 EtherCAT memory terminal and the EL6695 EtherCAT bridge terminal.