Linear motors, made in Germany

AL8100 series linear motors are suitable for highly dynamic and powerful linear axes for 48 V DC and are available in a 50 mm width (AL812x). This product series boasts a large portfolio of primary parts which differ in their number of coils and matched winding types. The product portfolio is supplemented by secondary parts in varying lengths (AL852x), thus enabling a wide range of different applications to be achieved.

Modular coil concept

The AL8100 series has a modular coil concept, so that each primary part consists of identical segments. As a result, the linear motors are generally very short, and a precisely symmetrical assembly is created that establishes screw-on compatibility between all linear motors in a series. In addition, the design increases the flexibility and the adaptability to customer requirements. Within the maximum of 45 coils, any length can be produced in steps of 3 with no great effort.

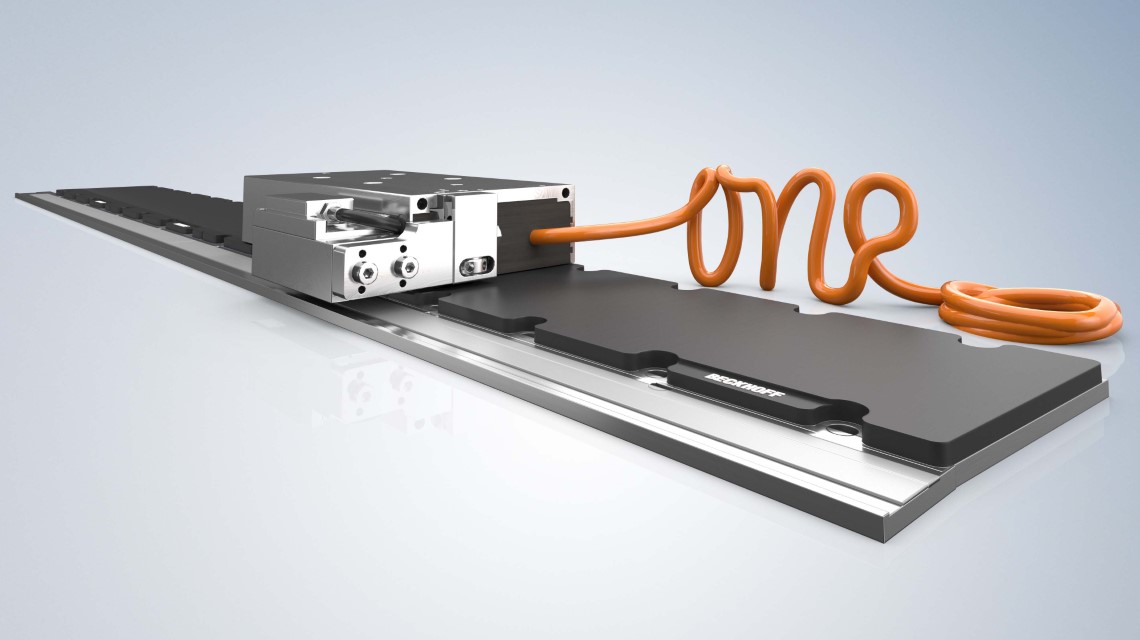

One Cable Technology

In addition to the standard version, the AL8100 series are also available with One Cable Technology. The OCT solution for linear motors eliminates the need for feedback lines, similar to the established OCT solution for rotary motors. This not only reduces the number of cables, but also offers a whole host of other advantages, such as reduced cabling effort, simplified mechanical installation, and fast commissioning thanks to an electronic name plate.

The AL8100 linear motor series is optimally matched to the powerful servomotor terminals in the robust ELM72xx metal housing. The connection is made directly without additional accessories, such as the connector box.

Apart from the wide availability and flexibility, the fact that the AL8100s are developed and produced in Germany guarantees constantly high manufacturing quality and short delivery times for these products, which create durable and highly reliable applications with linear motor technology.

Properties

- in-house development and production: made in Germany

- modular coil concept

- accelerations up to 30 g

- no mechanical wear

- no backlash, resulting in tight control behavior

- high-precision positioning

- even, immediate force, low cogging

- very low thermal resistance, therefore more available power

- protection from thermal overload through integrated temperature sensors

- operation on ELM72xx is easier due to default values

AL812x

- speeds of 1.3 m/s to 6 m/s

- peak forces of 100 N to 650 N

- Reset all filter values

- Results: