XTS with NCT

XTS movers become processing platforms with NCT

Hoofdkantoor België

Beckhoff Automation BV

XTS movers become processing platforms with NCT

Beckhoff achieves a further quantum leap in terms of machine flexibility with a new type of technology for the XTS: No Cable Technology (NCT) enables contactless, continuous power supply and synchronous real-time data transmission to the XTS movers. The XTS modular system has been expanded to include a special motor module and electronics that can be mounted on the mover. The hardware required for NCT is fully integrated into the motor module, so that the existing functions and compact design are retained. No additional connections or supply lines are required.

With NCT, processing steps and quality control are possible for the first time directly on the mover during the running process. Sufficient power and fast communication with the TwinCAT control system make the connection of sensors and actuators easy. Data communication with each mover is real-time capable and, in conjunction with EtherCAT, synchronizes system-wide events with µs precision so that a specific event can be triggered at an exact position. Especially in the areas of product handling, processing and measuring parallel to transport as well as machine adaptations for quickly changing production batches, NCT offers users new solution possibilities.

With the No Cable Technology extension of the XTS system, production companies can tap into the advantages of highly flexible systems with minimal effort in order to meet current market trends. The increasing number of variants with shorter product life cycles and limited production space require the most versatile use of the machine possible. To meet this challenge, the XTS offers numerous possibilities to replace complex external mechanics with individual movements of the XTS movers, and thus with pure software functionality. In addition to the previous purely passive product transport, NCT enables additional process sequences directly on the mover itself – both during movement and when at a standstill.

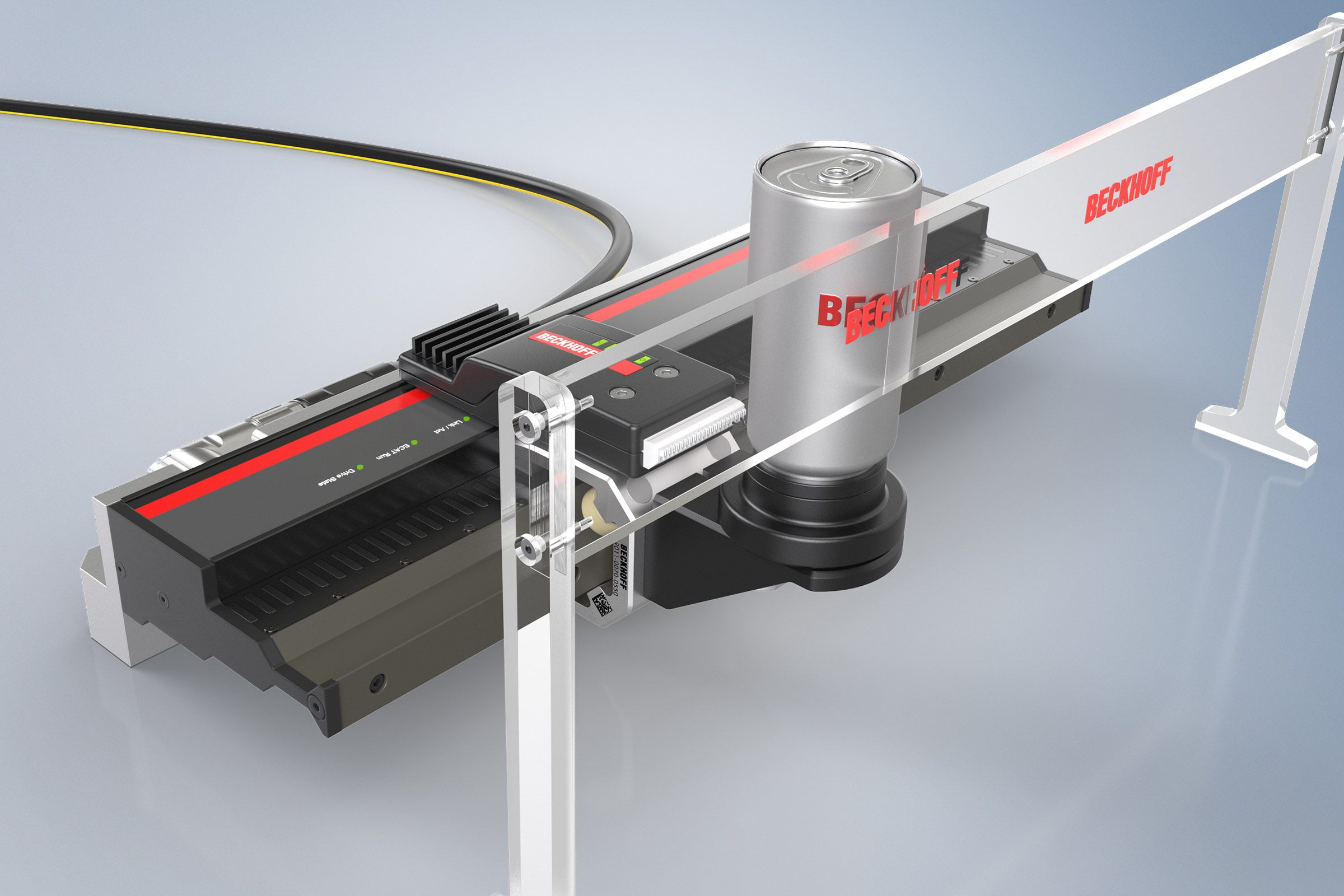

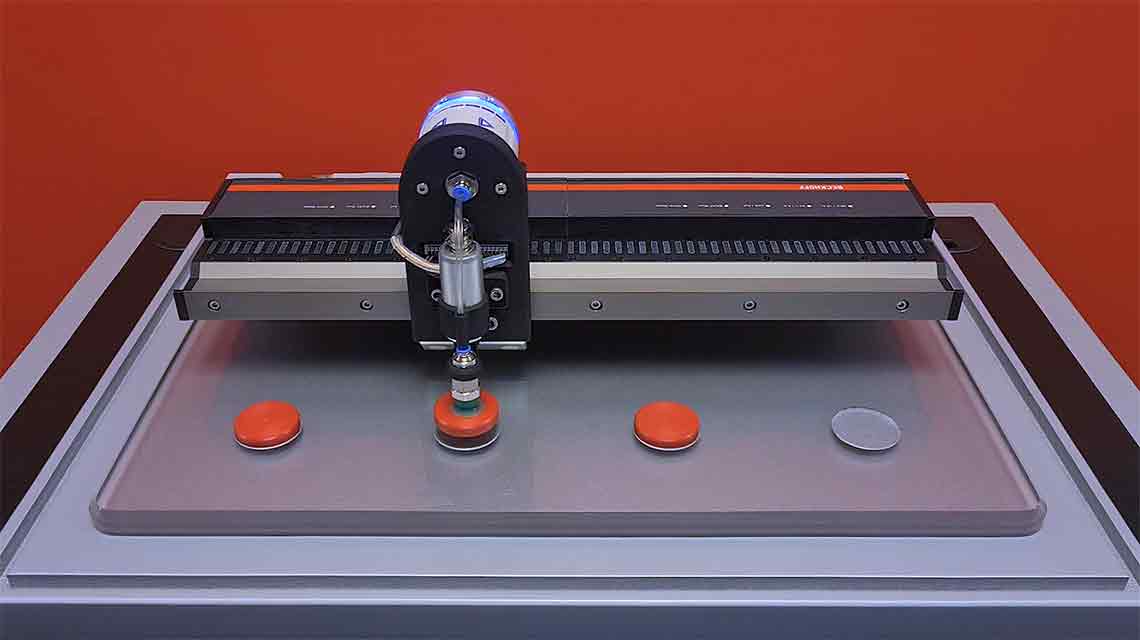

NCT transfers energy wirelessly to the mover. This energy is available to realize different motion sequences directly on the mover with the help of motors. The CNC-based motion sequence is synchronized with the positioning of the mover in real time. The central software approach in TwinCAT allows simple synchronization with external processing stations. In this way, the mover becomes an active part of the manufacturing process as a mobile processing station, e.g. by performing a product alignment by means of a rotary movement or by manipulating a product in order to position a carton or screw on a screw cap. The process times for feeding and removal at alternative processing stations are eliminated and the product flow no longer needs to be interrupted. Consequently, the efficiency of the machine increases and the production output increases.

Application examples:

With NCT, every mover becomes a moving handling system. By means of electric motor-driven grippers, electric lifting magnets, adhesive grippers or vacuum suction units, a mover can pick up, deposit, transfer, align and stack products.

Application examples:

Individual pick-up from an unsorted and irregular product flow as well as subsequent sorting, e.g. into good and bad parts or orderly product placement in the final packaging, is also possible. XTS achieves a particularly high sorting performance through a circulating travel movement, i.e. without movement against the product flow, as is necessary with robot arms.

The throughput is increased without further space requirement by a large number of movers with integrated product pick-up, e. g. vacuum cups or electric lifting magnets. Each mover can perform multi-axis movements and thus allows product alignment in the X, Y and Z directions, whereby one axis is already taken over by the travel movement of the movers. Additional degrees of freedom can be achieved by rotary movements. TwinCAT controls the interaction of the axes via CNC functions. This integration turns XTS into a flexible multi-robot system that increases sorting performance while reducing the required installation space to a minimum.

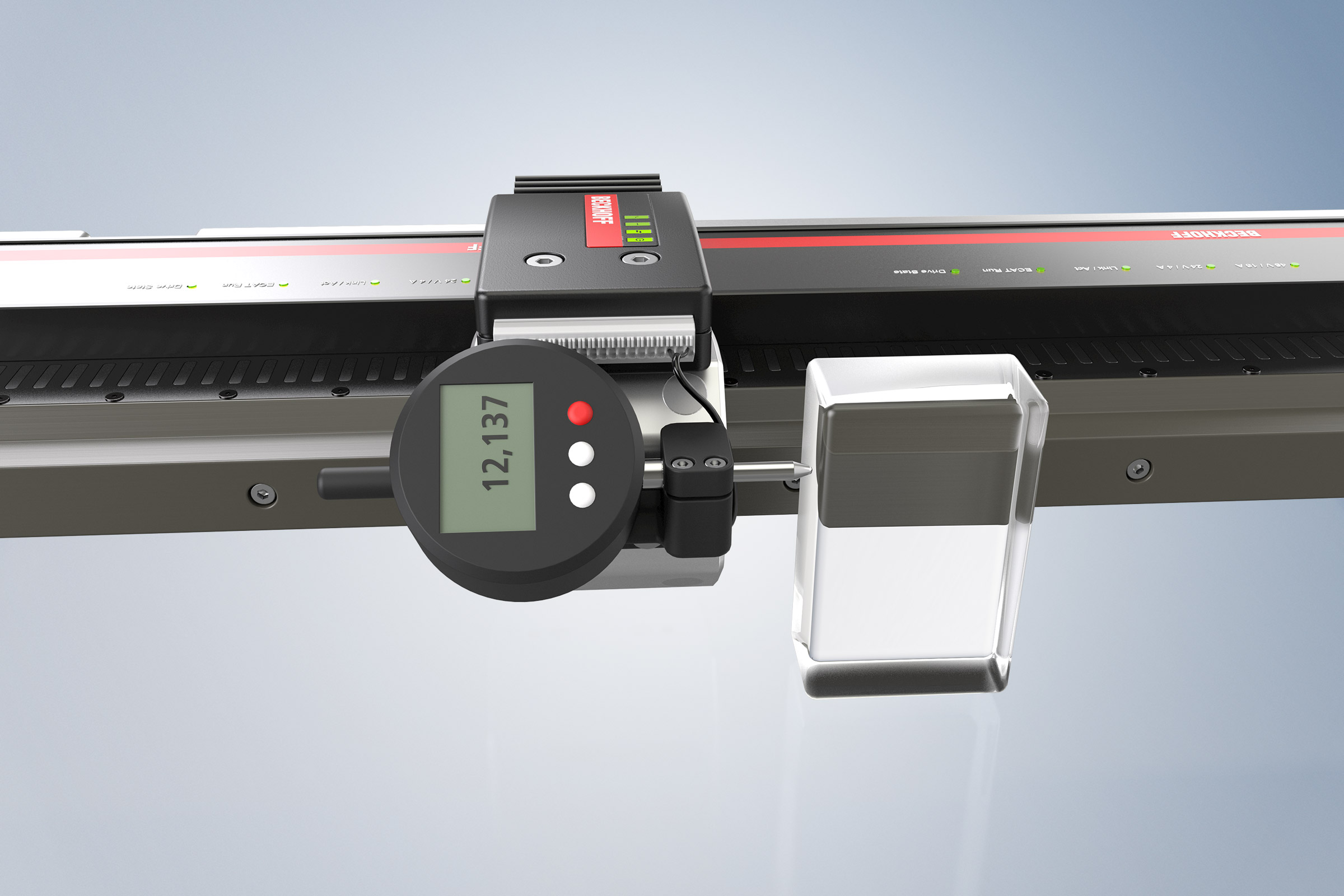

The supply voltage on the mover enables the temperature control of the product during transport. In addition to the generation of physical quantities, measurement tasks can be carried out not only inline during the ongoing production process, but also in process and in parallel to the processing station or during the transport movement. For this purpose, the mover is equipped with sensors for recording measured variables. For measurements at standstill, the mover can be fixed via a holding brake. The measured values can be directly and easily linked to the product, which supports its complete traceability from the order through the production process to delivery.

A fully monitored and controlled dosing process can be carried out, for example, with a load cell for recording the product weight, since a comparison of the target and actual fill quantity is carried out in real time on the basis of the transmitted process data. This 100 percent monitoring enables the early detection of abnormalities and thus the direct initiation of appropriate countermeasures. A filling station with a suddenly reduced flow rate can be recognized immediately by its filling curve, which is too flat; however, complete filling is still possible. It remains locked to the production process until the next maintenance to ensure product quality and production performance throughout the process. This "on the fly" quality assurance eliminates additional process steps and the product can remain on the mover throughout the entire production process. Overall, this significantly increases machine efficiency.

Application examples:

NCT offers the user integrated data communication and thus access to the electronics of the mover. Production data or system configurations can be stored directly in a memory, thus ensuring unambiguous mover, tool and product identification. The mover also offers condition monitoring of the tools on it.

The data communication of the mover also provides an open interface with direct linking to the TwinCAT control system. This enables the connection of standardized devices on the moving mover. One example is the cyclic reading of an ultrasonic sensor via an RS485 communication interface, which can be used for distance control. All in all, a broad product portfolio – sensors and actuators – can be integrated on the movers.

Application examples:

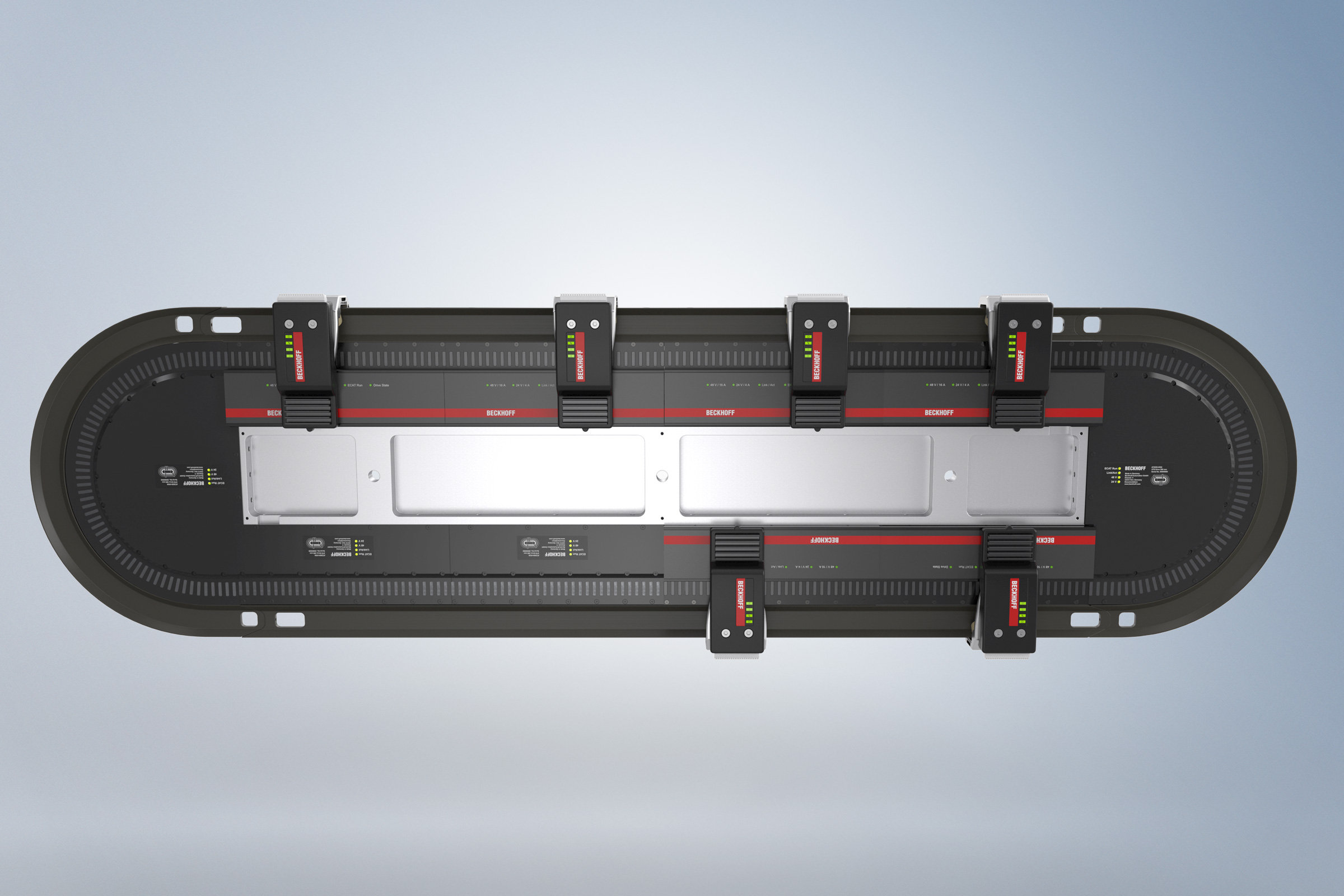

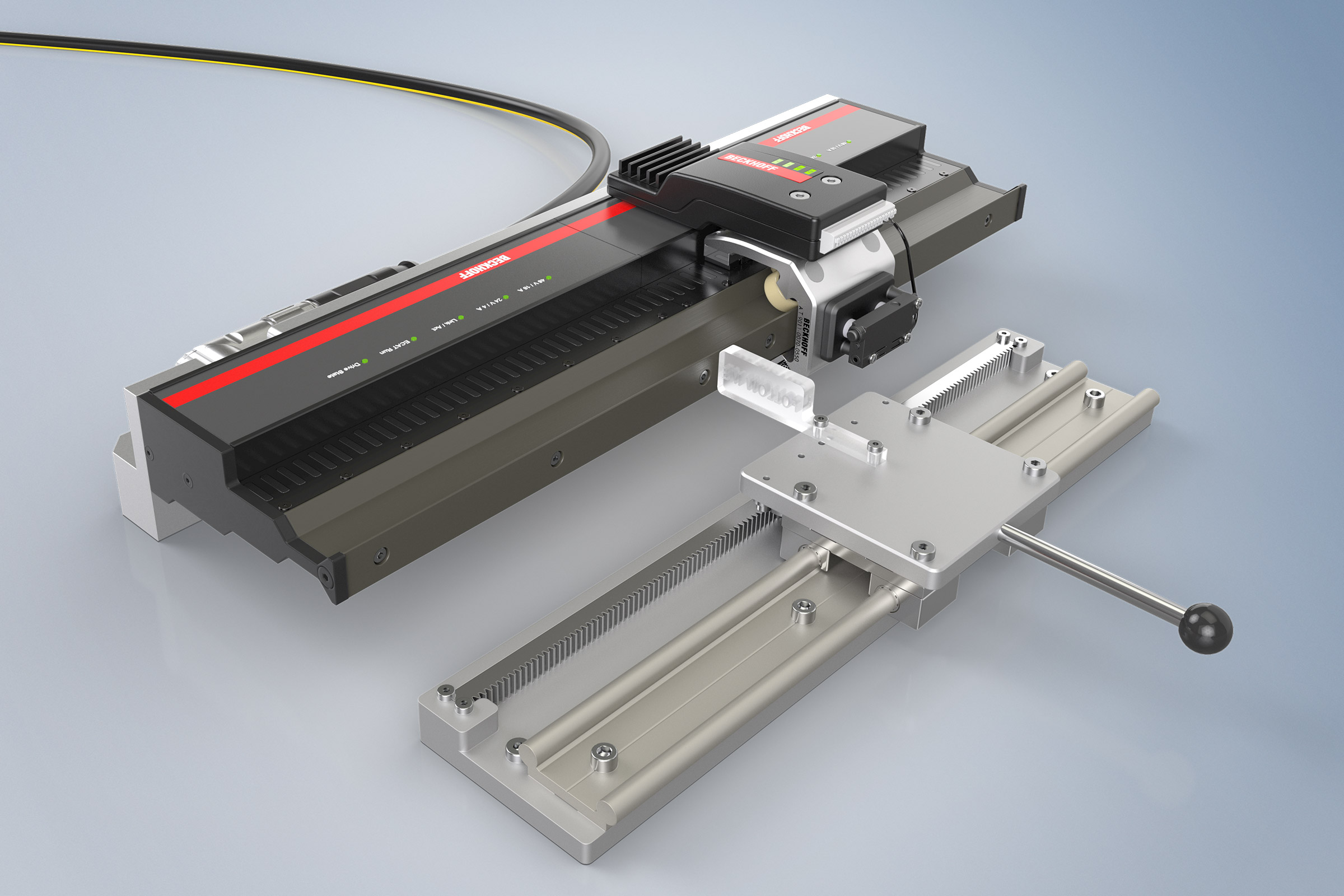

The AT2100 motor modules are elements for building straight XTS line sections with integrated NCT functionality. In combination with electronics mounted on the mover, a power supply and synchronous real-time data communication are available on the mover. This provides the basis for integrating sensors and actuators on the mover. In addition to product transport, active execution of processes is possible directly on the mover – both during mover motion and at standstill.

The AT2102 motor modules largely correspond to the AT2100 motor modules with integrated NCT functionality. In addition, they have a plug connector for the power and communication supply of the motor modules, to which connection cables of variable lengths can be connected. With a length of 250 mm, the motor modules with power supply represent the shortest variant of a power supply line. By adding motor modules without power supply, the power supply line can be extended.

The NCT electronics form the basis for an application-specific adaptation of the NCT technology in third-party applications. In combination with a housing unit, an XTS mover and the AT2100 or AT2102 motor modules, a regulated 24 V DC power supply and synchronous real-time data communication are available on the movers. The basic electronics used already offer a wide range of options for integrating sensors and actuators – digital inputs and outputs, analog inputs and PWM outputs. The basic functionalities can be complemented with application-dependent electronics. All functions can be controlled centrally via TwinCAT, ensuring high usability with short training times.

As a mechatronic XTS unit, the XTS starter kits with NCT functionality provide a plug-and-play solution for fast and effective introduction to XTS. With NCT, a power supply and synchronous real-time data communication are available on the moving XTS movers. The movers can be expanded into mobile handling and processing stations. In addition to the previous application that was purely for product transport, NCT also enables process sequences directly on the mover. The XTS starter kits with NCT functionality make it particularly easy to test the use of different sensors and actuators. Mechanical tests and the programming of your own motion profiles are simple to accomplish. The starter kit is available in two different lengths with different numbers of movers.