Syntegon: “The XTS is a huge gain for high-performance packaging systems”

Syntegon Technology, formerly Bosch Packaging Technology, is a global leader in process and packaging technology for the food and pharma industries. As part of the company’s Food Division, the company’s location in Beringen, Switzerland, specializes in fully automated packaging systems for the confectionery industry. It is also home to Syntegon’s innovation center for horizontal packaging systems, sealing technologies and top-load cartoners. The linear transport system XTS from Beckhoff has already been proven as a major innovation factor in approximately 100 packaging installations.

The Syntegon team in Beringen has been working with the Beckhoff experts since 2011 and was one of the first XTS customers, as Kurt Gleichauf, head of technology and packaging, explains: “As a technology and innovation leader in our industry, we recognized the benefits of the intelligent transport system from Beckhoff early on. Today we have already installed roughly 100 packaging systems with XTS technology, and by the end of 2022 we will exceed 200 of these systems as a result of the strong demand.”

“Having Syntegon, a former Bosch company, as a partner is very important to us. With many XTS systems installed in industrial production environments, we are constantly learning new things. The feedback we receive from globally operating manufacturers is very valuable. Accordingly, we are constantly advancing the product in line with Syntegon’s requirements,” adds Uwe Prüßmeier, Senior Product Manager Motion, XTS and XPlanar, Beckhoff Automation.

Highly flexible mover and product control

XTS is particularly useful in the area of supply systems for primary and secondary packaging machines, says Kurt Gleichauf. Other than in a conventional conveyor chain, the intelligent transport system allows for the flexible control of each XTS mover as a separate servo axis and thus of each individual product. In addition, the product spacing can be regulated with exceptional flexibility. The system accelerates the products individually with the goal of optimizing the entire product flow, which enables it to achieve steady speeds of up to 1,500 products per minute in high-performance applications.

Syntegon in Beringen sells fully automatic packaging systems all over the world to confectionery manufacturers who want to benefit from the system’s high level of flexibility as the industry is subject to many rapidly changing trends to which manufacturers must respond at a moment’s notice. Besides the traditional seasonal changes, social trends like the rising number of single-person households, the on-the-go lifestyle of young people and “free from” nutritional concepts have a major impact on the way products are packaged. For manufacturers, this means that they must churn out many different products in a wide range of combinations and package sizes.

Handling many different cereal bars efficiently

One example of this product diversity are cereal bars, which are offered in many different flavors as well as in single-serve portions for individual sale, and as variety packs with a mix of flavors, or as multi-packs or family-packs. The packages might contain one, two or more bars in a single pouch. The bars can vary in length and width and may be sold in different box sizes and shapes depending on the retailers’ requirements. To accommodate such a variety of products, having high-speed packaging systems with quick format changeover capabilities is a must.

While in traditional supply chains the movers must be changed individually and manually for each format, the XTS handles this with the push of a button via its corresponding software functionality. This results in tremendous time savings that have a very positive impact on the overall machine efficiency, says Kurt Gleichauf.

Handles sensitive products as well

Besides flexibility and speed, the gentleness with which the XTS handles products is a major factor for many confectionery manufacturers. Syntegon’s two-in-one cookie packaging system is a prime example of this feature, explains Kurt Gleichauf: “The clever application of the XTS with its individually controllable movers enables us to package cookies stacked as well as standing on edge on the same system. The time required to convert from stacked to slug packaging is probably record-breaking with only a few minutes. And the number of items per package can be changed at any time by pressing a button on the HMI. With such a future-proof solution, confectionery manufacturers have everything they need to accommodate short-term special offers quickly and easily.”

The key feature of the two-in-one system is the way it “layers” the cookies, which can be supplied lying flat on a conveyor belt or via a shaft. The movers mounted on the XTS carefully stack the cookies or turn them upright so that they can be fed into the tubular bag machine while standing on edge. The two-track version of the two-in-one system is the fastest model because it employs two XTS systems that work independently of each other. For example, while one lane packages stacks of two cookies each, the other lane can package slugs of 12 cookies each. According to Kurt Gleichauf, this solution is the only one of its kind on the market.

Leveraging the XTS technology, the products are subject to very little mechanical stress. With the individually controllable movers, even highly fragile products such as cereal bars or chocolate-covered cookies can be moved through the packaging process with exceptional gentleness. “Despite the very gentle handling, there will always be crumbs, dust and sticky residue when you package cookies and cereal bars. That’s a stress test for any system – especially for the high-tech components we use. The experience with our installed base has shown that the XTS from Beckhoff is very robust even under these difficult conditions and operates trouble-free over the long term,” says Gleichauf.

XTS minimizes machine footprint

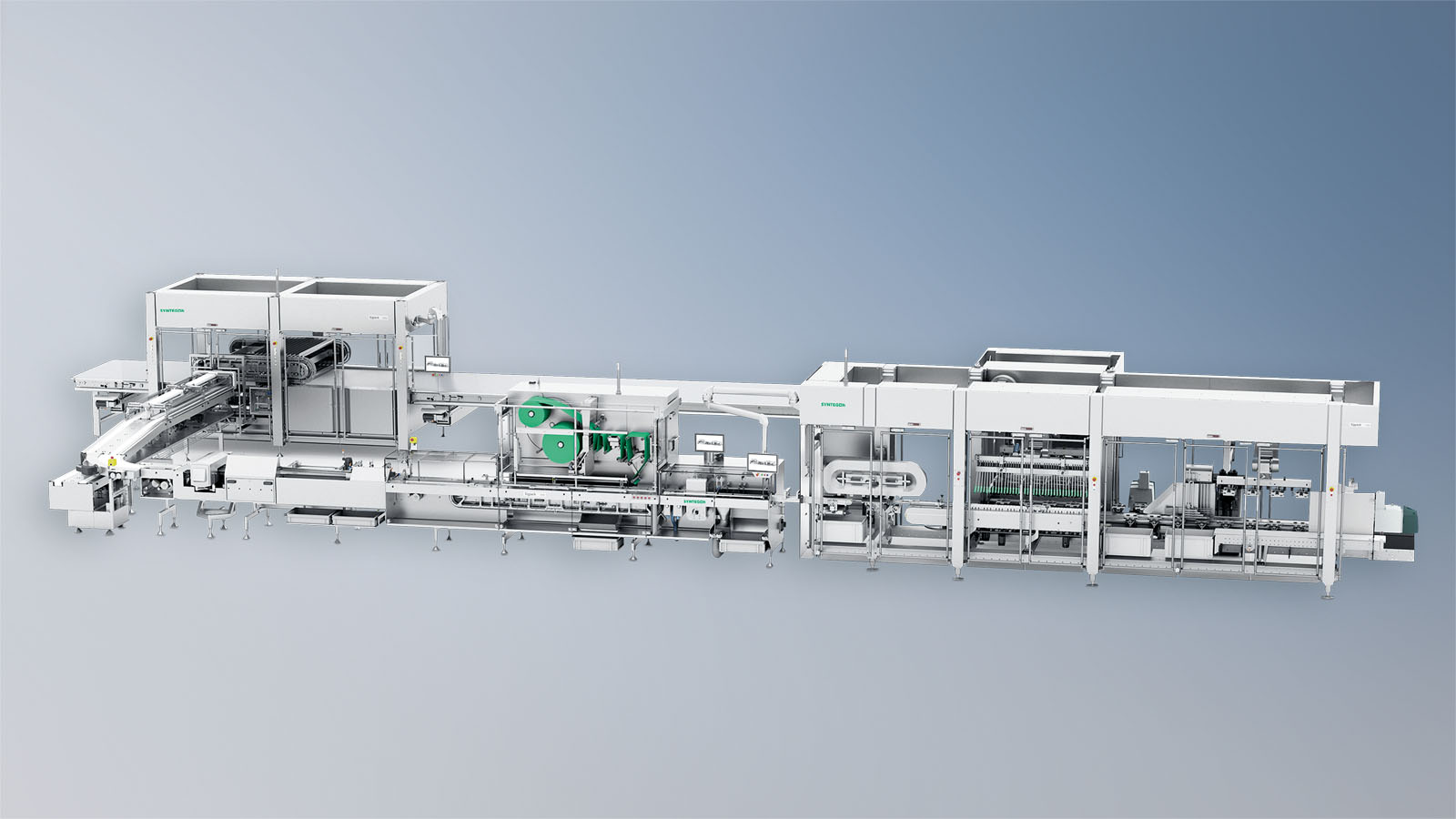

Another benefit of the XTS is its very compact design. Particularly in existing plants, the floor space available for new installations is often limited. At customer Tunnock’s home plant in Scotland, for example, Syntegon was able to shorten the footprint of the company’s new installation for packaging caramel wafer biscuits by four meters. Only the 2.5-meter-long Sigpack FIT feeder module for the Sigpack tubular bag machine had to be installed. At the core of the compact Sigpack FIT is a 1.5-meter-long XTS with 40 product movers.

Since 2017, Syntegon has deployed the XTS for primary as well as secondary packaging applications. The Sigpack PFI feeder module operates adaptively and without the need for vacuum technology, and the XTS can rotate each individual product into the correct position even at top speeds. Since the product handlers of the XTS movers, which cover the products from above, are 3D-printed, they can be easily adapted for new products and quickly replaced. With the help of the XTS, the Sigpack PFI feeder could be implemented in such an extremely compact and flexible way while featuring very gentle product handling.

Robotics applications even for sensitive baked goods

Besides the intelligent XTS transport system, other shared projects with high innovation potential are the HMI 4.0 user interface which runs on a multi-touch Panel PC and the control of robotics applications via TwinCAT . While robotics were rather rare in food handling applications in the past, the market for them is currently growing by 19% annually. The reasons for using robots to achieve a higher level of automation are manifold, ranging from many personalized products, strict hygienic regulations (FSMA) and labor vs. investment costs to the shortage of skilled workers. Many technical innovations further support this trend. Moreover, standardized robotics solutions and reduced complexity in kinematics, controllers and vision systems deliver lots of benefits and make it easier to implement robotics in production lines."

Baked goods generally require very gentle yet complex handling, which in the past was done mostly by people who loaded products into the packaging machines manually,” says Andreas Schildknecht, product manager for robotics at Syntegon in Beringen. “At the same time, today’s diversity of products and shapes results in very tough requirements in terms of format flexibility and quick format changeovers, which is why outstanding efficiency and productivity must be ensured.”

The use of pick-and-place robots, especially of fast and easily scalable delta robots in cells of four, makes it possible to automate even larger production capacities today. Syntegon built its most extensive robot project so far in cooperation with Beckhoff and by using TwinCAT software. It involves 69 robots that convert a stream of 6,000 cookies into 3,000 center-filled sandwich cookies and load them into trays, which are then fed into various packaging machines for different package styles and sizes. The trays are filled with two to four products and packaged in stand-up pouches with roll closure, display cartons, or tubular bags. This allows the manufacturer to optimally serve all customer segments, from single-person households to large families.

Syntegon combines its broad portfolio of primary and secondary packaging machines with its handling competencies involving flat and robotic feeders. The installation ensures that the fragile, high-quality products are packaged gently and while being touched by as few machine components as possible. The installation demonstrates the broad application spectrum of robot-based solutions. Special attention was paid to designing the robots with easy accessibility for cleaning and maintenance. The efficient design and the production strategy’s reflection in the control software as well as the use of storage technology make the entire system exceptionally effective. And the design of the delta robots with their reduction to what’s absolutely necessary makes them almost maintenance-free and reduces operating costs and planned downtimes. “Robots perform complex tasks without being complicated for the operator. That’s the key to success, to high flexibility and efficient manageability of a food company’s production operations – today and even more so in the future,” sums up Andreas Schildknecht."

Conclusion

No other manufacturer in the packaging industry has implemented as many XTS applications as Syntegon. The intelligent transport system from Beckhoff gives us the flexibility we need to solve any problem in the most effective and innovative way possible. The supply systems for primary and secondary packaging applications are unique on the market and in high demand among our customers,” adds Kurt Gleichauf.