One Cable Automation (OCA): the cabling philosophy for decentralized automation technology

One Cable Automation aims to provide efficient and optimal cabling for devices, machines, and systems, along with their associated peripherals. This is accomplished through the basic principle of combining power, signal, and data communication in a single connector. Cutting down on cable routes not only significantly reduces the complexity of the entire cabling process, but also saves space, time, and costs.

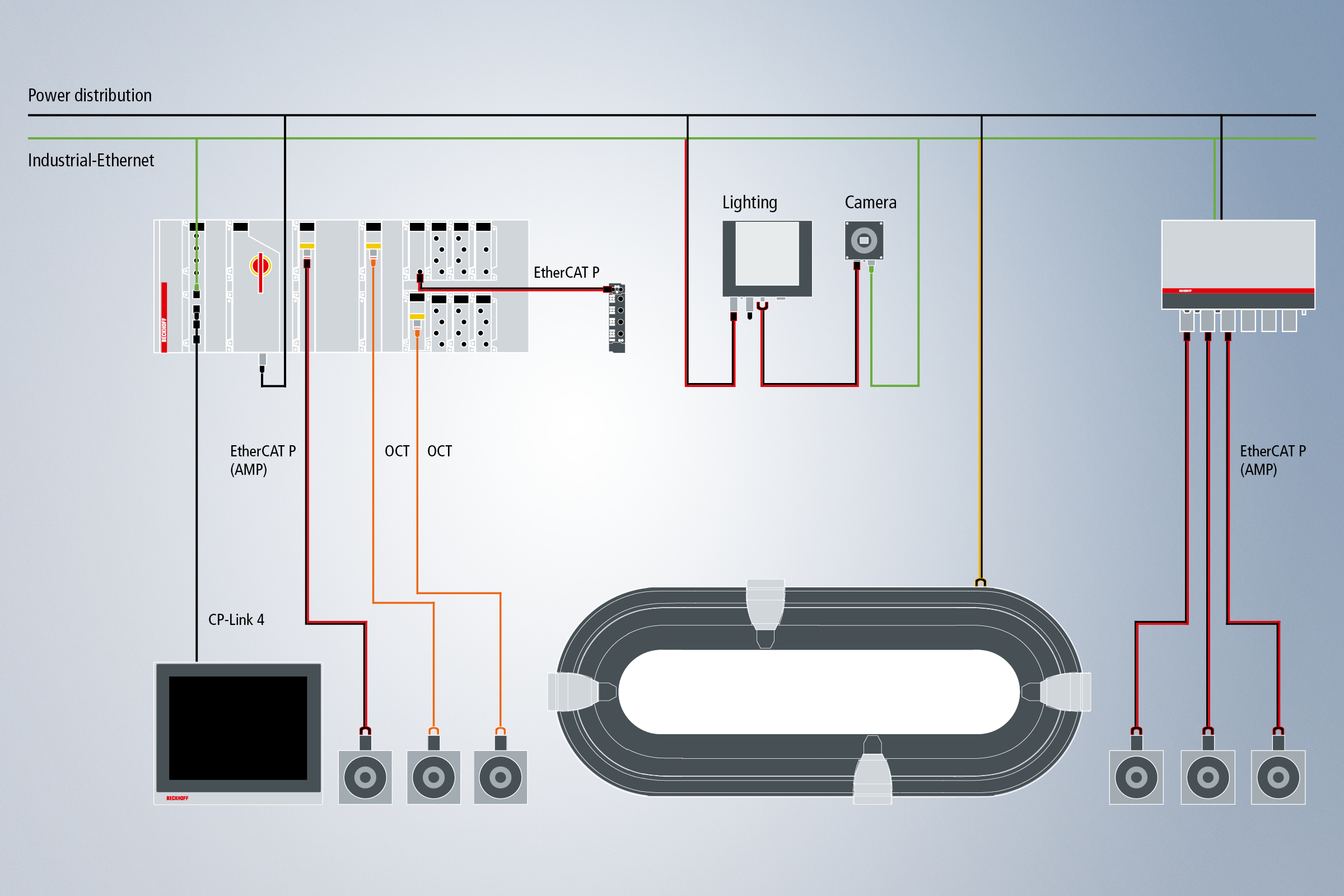

OCA is a comprehensive cabling philosophy that comprises specific technology for single-cable solutions. Its benefits can be observed at virtually every level and across all devices. Whether with EtherCAT P, the ultra-fast one cable solution for control cabinet-free automation, OCT for motion applications, or CP-Link 4 for remote operating units, OCA offers innovative cabling solutions for the entire field level.

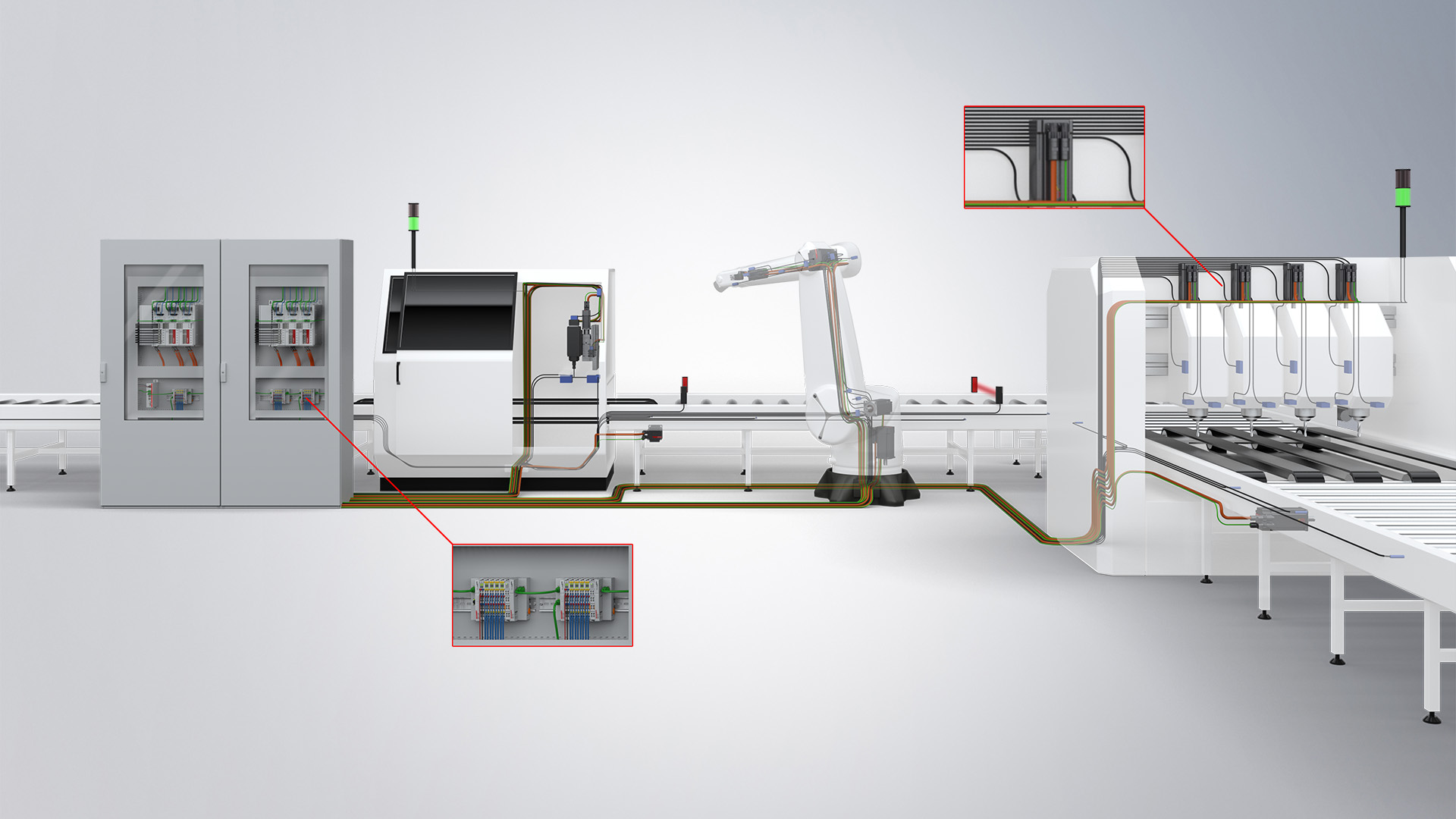

Central machine cabling

In machine systems with conventional cabling, lines from the sensors and actuators are routed centrally to a main control cabinet. Large cable cross-sections are usually used to compensate for voltage losses due to long distances between the central control cabinet and the sensors and actuators. This results in large bundles of cables both in and in front of the control cabinet, which means a lot of work during commissioning and an increased likelihood of errors.

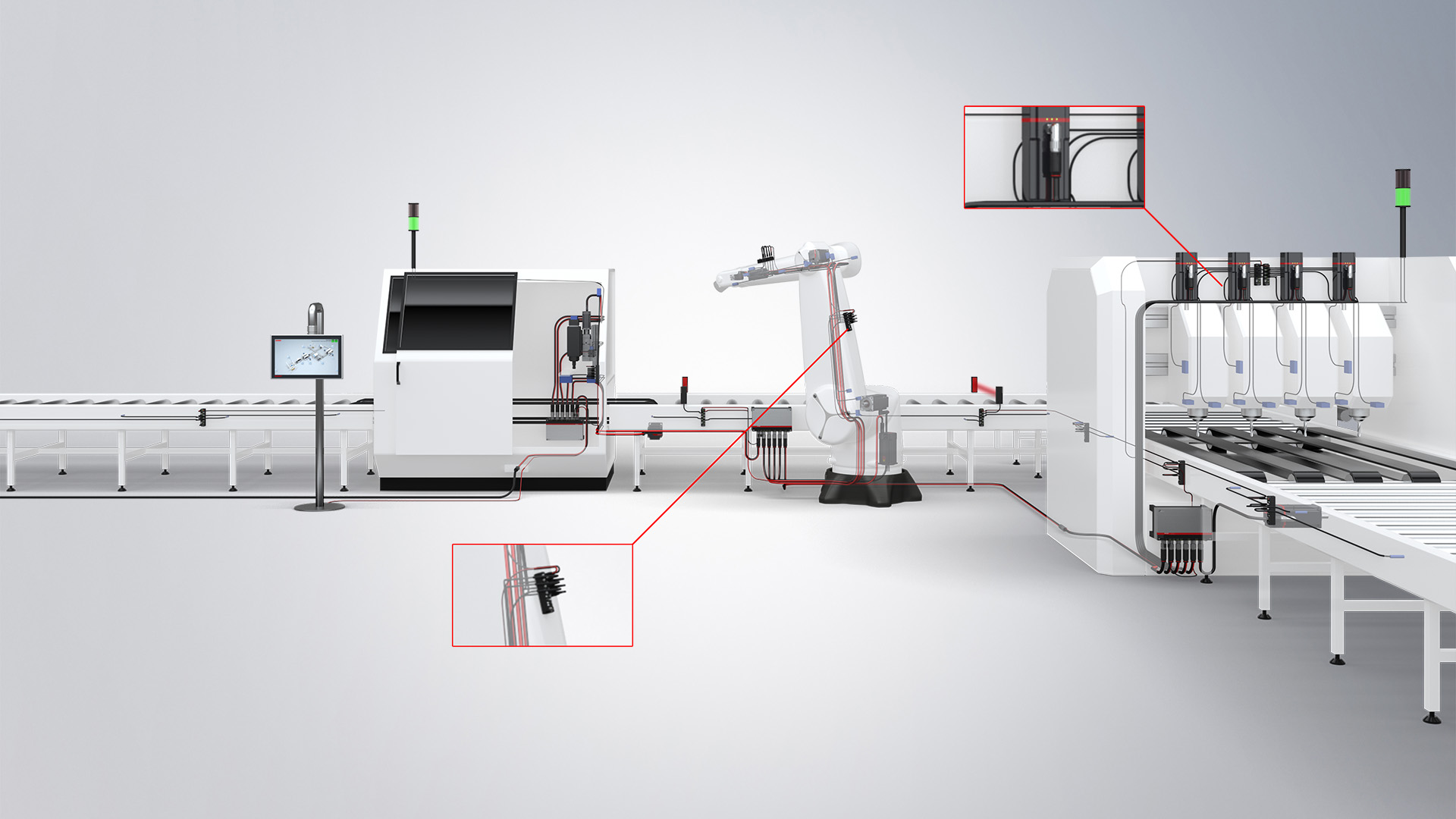

Control cabinet-free machine cabling thanks to OCA technology

Cabling work is demanding in systems with a central control cabinet, and this can be significantly mitigated by using OCA technology and hybrid cables. The control cabinet is completely eliminated by relocating decentralized connection points directly into the individual devices of the system. This future-proof technology is ideal for ensuring space-saving, well-organized, and maintenance-friendly distribution of data and power cables, as well as for connecting sensors and actuators.

Consistently flexible and standard-compliant quality with OCA

OCA enables an almost total freedom in terms of topology design while also guaranteeing all required security standards for all communication models:

- simple proprietary fieldbus systems (OCT/Hiperface DSL©)

- current Industrial Ethernet infrastructure (EtherCAT and EtherCAT P)

- future high-speed communication (EtherCAT G and EtherCAT G10)

Each automation device can be integrated with one sole connector system.

With OCA technology, innovative connection and cabling solutions can be implemented for every automation application. This includes applications with or without a control cabinet, fixed installations, in drag chains, and in robotics. Beckhoff offers a complete portfolio of compatible connection technology.

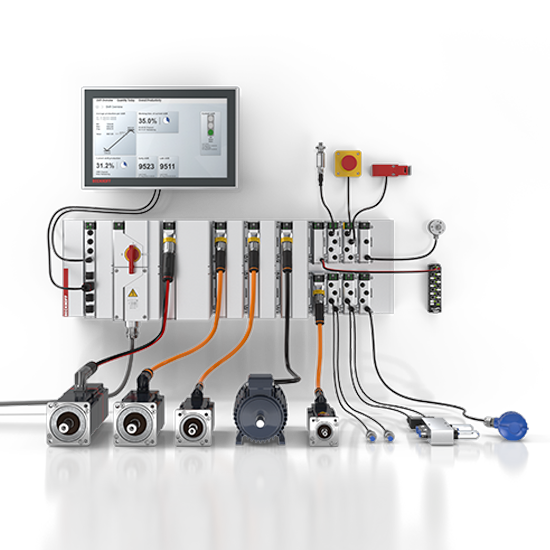

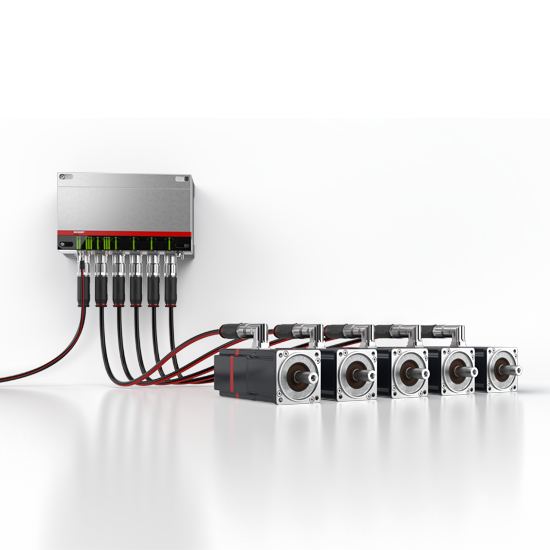

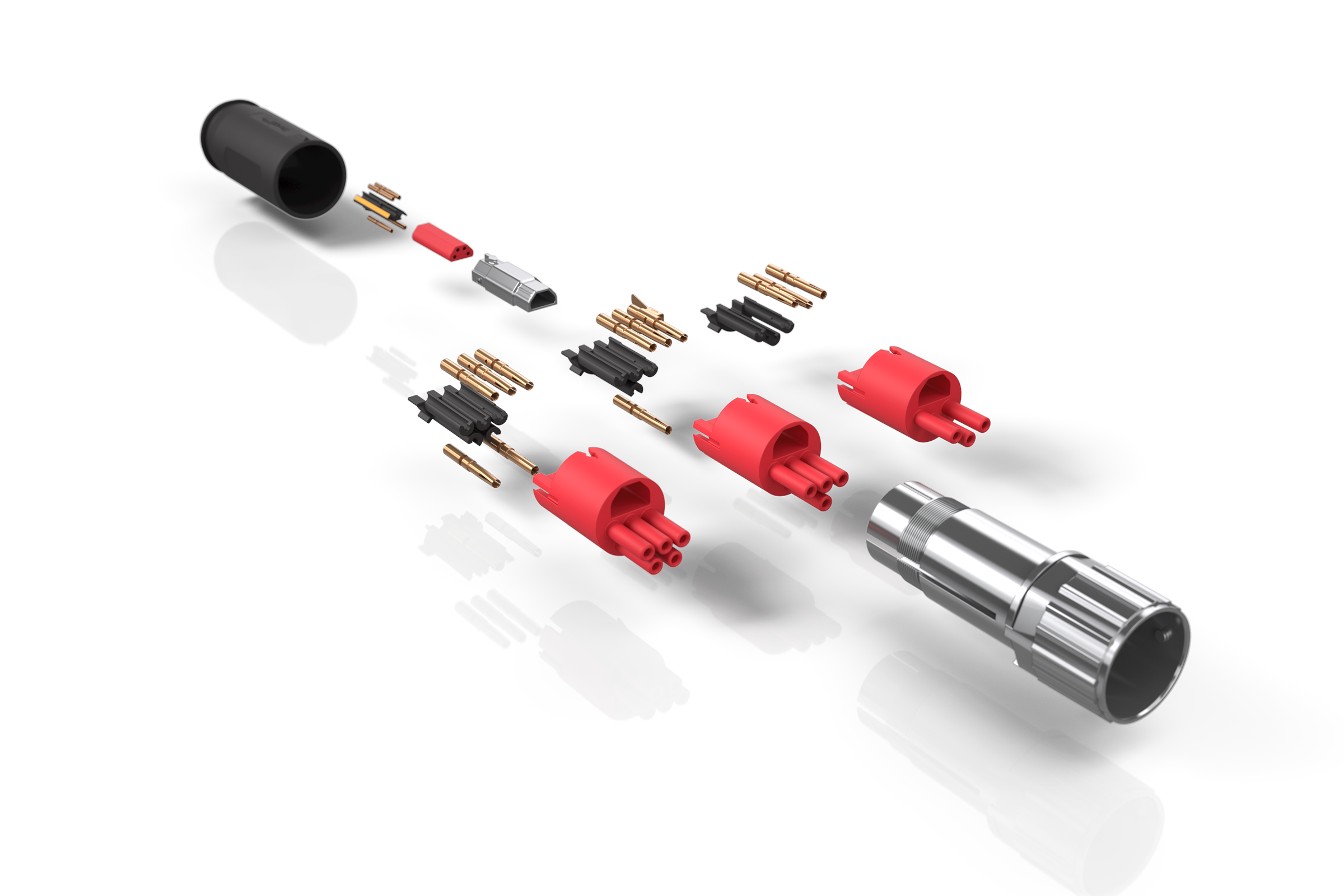

The concept of OCA technology is based on the ability to connect components, terminal boxes, and machine modules with just a single cable, which combines communication and power supply in one connector. The hybrid connectors are available in application-specific sizes and performance classes. In this context, common parts management covers almost every variant of decentralized connection technology:

The hybrid connector series is available with between 2 and 7 power contacts from 24 V DC in the I/O level up to drives with 400 V AC or 630 V AC/850 V DC and up to 72 A. It offers an integrated connection concept for EtherCAT/Ethernet and EtherCAT P technology, with connectors/flanges available in the standard sizes of B12, B17, B23, and B40.

The poka-yoke principle ensures that the plug connector can only be assembled in the correct configuration, while the bayonet fitting assures fast cabling and installation.

One connector for all applications. The simple design and modularity of the connector system allow a variety of decentralized automation devices to be networked with the same connector, unlocking a whole host of potential savings. The system boasts not only a smaller footprint, but also requires less storage space, has shorter installation and laying times, less potential for errors, and lower maintenance and procurement expenditure.

Connectors in accordance with the IEC standard

Beckhoff hybrid connectors are among the first products to comply with the future IEC 61076-2-118 standard. The primary aim of establishing a global standard like this is to ensure security for the user, not only with regard to supply chains and second-source strategies, but also in terms of the level of product reliability defined by established and widely adopted standards.

All the advantages of One Cable Automation at a glance

- reduced complexity in the cabling process

- simplified commissioning

- space-saving, straightforward, and smaller footprint

- lower material and labor costs

- high level of modularity for system adaptations or extensions

- improved operational uptime as cabling is less prone to faults

- faster maintenance

- more energy-efficient systems and machines

OCA – The one cable solution for all automation sectors

EtherCAT P

The one cable solution – One step closer to automation without control cabinets.

CP-Link 4

The continuous development of the industrial control panel connection technology allows the control panel to be located away from the PC.