Nowadays, efficiency, flexibility and transparency are key drivers of sustainable competitiveness. The focus is very different, depending on the industry and application: While customers opt for maximum efficiency and reliability with low energy and maintenance costs where production machines are concerned, test bench providers are successful when they offer maximum flexibility with interfaces, sensors and actuators. Flexible transport systems, image recognition and machine learning are important building blocks in machine construction. Modern test benches, on the other hand, require dynamic, integrated control systems and precise, synchronous and calibrated measured data. Operators of machines and plants want to expand their investments in a sustainable manner and to extend them with new drive and safety technologies, condition monitoring for new maintenance concepts or energy measurement as a basis for consumption optimization and optimized control strategies.

In this area, we present our concepts and solutions for machine construction, test bench technology, production machines and structural monitoring. As a technology provider, Beckhoff provides you with modern tools that give you the decisive edge in product development and time-to-market. The focus is on PC-based control technology, combined with high-quality measurement, drive and safety technology to create modern, high-performance DAQ systems.

Applications

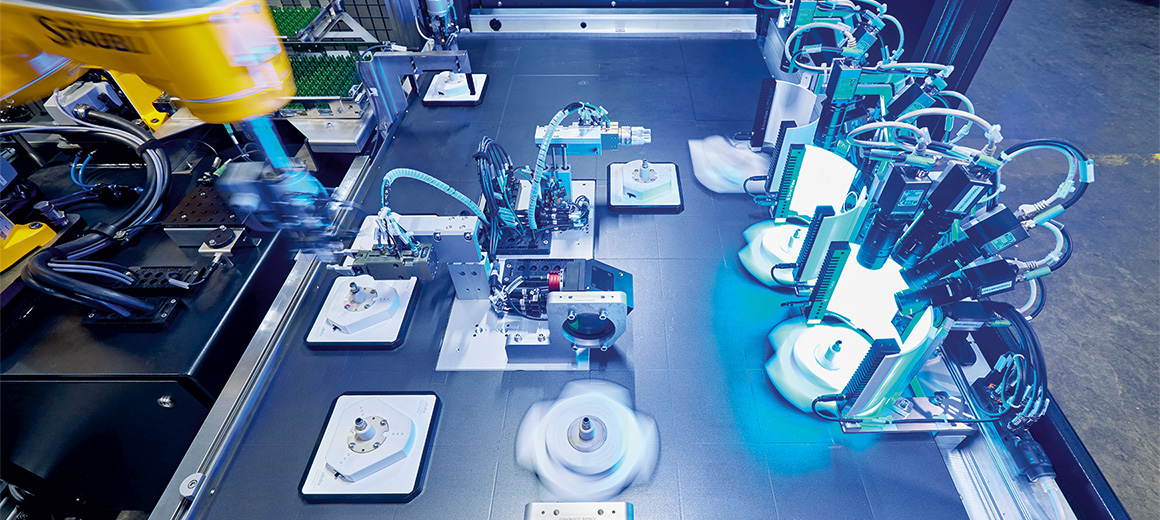

Machine building

System-integrated measurement technology reduces costs for machine manufacturers and enables new business models

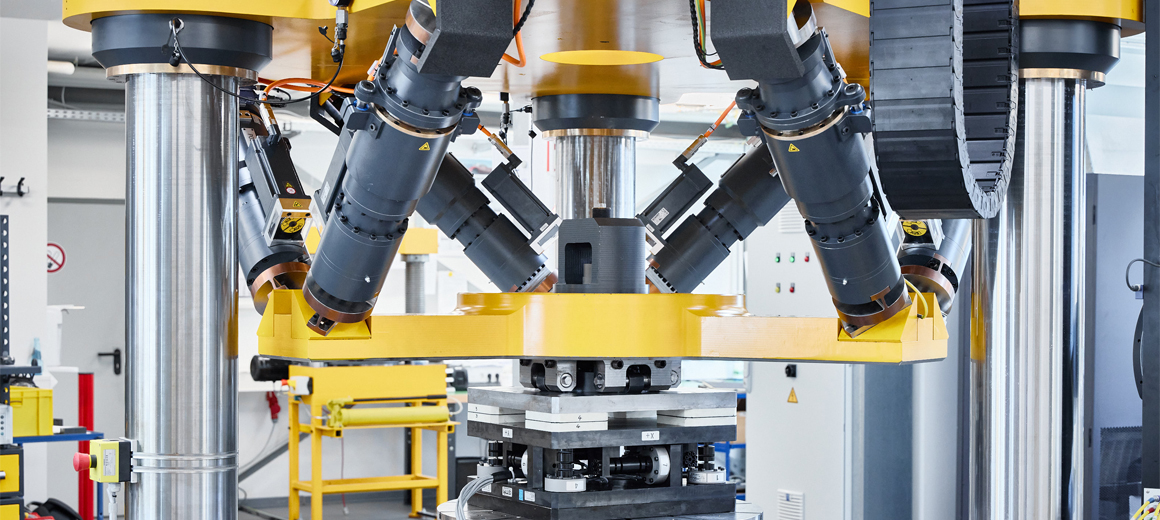

Test stands

System-integrated measurement technology: benefits for test stands in research, test and lab facilities

Production measurement technology

Secure product quality reliably and quickly with production-integrated measurement technology

Energy and power measurement

IoT-enabled solutions for consumption transparency in machines and power distribution systems

Condition monitoring

Measuring and monitoring – as a controller-integrated solution or as retrofitted condition monitoring

Retrofits and controller extensions

Technological extension of existing systems with measuring and control systems, drive and safety technology.

Scalable IIoT systems

IIoT systems combine measurement and control technology with simple engineering and HTML5 visualization

Structural monitoring

Distributed synchronous signal acquisition with IIoT connection and flexible interfaces for the continuous monitoring of civil engineering structures and infrastructure

Machine learning – for all areas of automation

Beckhoff offers a machine learning (ML) solution that is seamlessly integrated into TwinCAT 3.

Beckhoff technology highlights for the measurement and testing technology

The PC-based control principle

Regardless of whether measurement and testing technology is used in the production environment or in dedicated test equipment: most of the times, it is designed to solve new types of measurement tasks, collecting data or checking setpoints. Often, this requires special equipment that needs to be installed and connected to the control level. This results in a great deal of commissioning work as well as the complex maintenance of the systems and – associated with this − high costs.

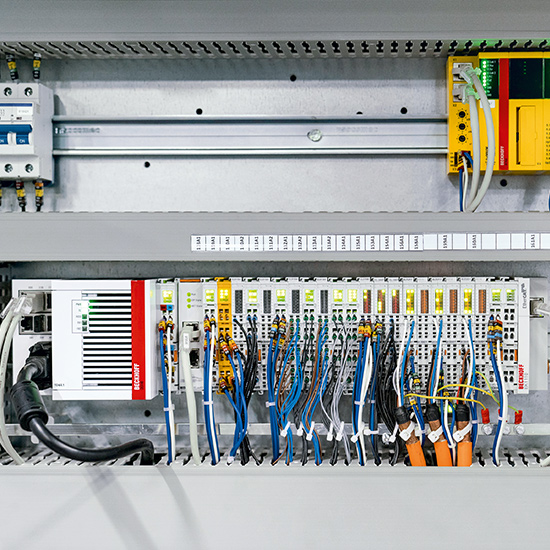

Beckhoff recognized as far back as the 1990s that the universal PC is an ideal instrument for solving a wide range of control tasks. Any problem that can be solved by programmatic computing power can in principle be run on one central PC (or possibly on several) and then acts on the environment via actuators, e.g., motors or valves. The PC receives the information via flexible I/O systems placed close to the central controller (or even installed in it) or also detached as remote I/Os. This approach is easily transferable to tasks that are required in the metrological environment. Regardless of whether five, 500 or 50,000 measuring channels are to be recorded, these requirements are everyday tasks for PC-based control. Even the massive accumulation of measured data and the complex calculations or "eternal" file storage in gigabyte dimensions based on it do not pose a challenge. Based on fast consumer-driven developments, the so-called Industrial PCs (IPC), equipped with components that are available in the long term, are able to meet any programmable challenge. (For example, see the C60xx and C69xx series and the CX2xxx series for mounting on the DIN rail.)

The extraordinarily high computing power of modern PCs is also advantageous: control cycles or measurement tasks can be carried out even with extensive measured data in the fastest sequence – even with so-called short cycle times down to the 50 µs range – i.e. 20,000 cycles per second. The IPC platform can be scaled very easily in terms of performance, from the small controller, which performs 10 control cycles with 10 measuring points per second, to computing machines that calculate 10,000 channels 10,000 times per second. One of the decisive factors is that there are no technological limits to communication with the environment. This applies to:

- External local communication: the connection of actuators, sensors, input/output devices, light barriers, limit switches, position encoders, probes, etc. Such data is transported today via digital bus systems (keywords: Ethernet, EtherCAT, PROFIBUS, GPIB, USB, RS422, etc.). Even if Mbytes of data are to be transported per second with nanosecond accuracy, this can be solved with PC-based control.

- Internal communication in the controller: measuring devices often require special software for communication, for data processing or visualization, for model calculation, for simulations or for data analyses in order to be able to predict results (keywords: MATLAB®/Simulink®, HMI, PCI etc.). These, too, can run on appropriate operating systems and, in accordance with the PC-based control principle, do not require an extra control platform, which would cause additional installation expenditure (time, cost, space, engineering) and runtime costs (electricity, care, maintenance).

- Higher-level communication: measuring and testing devices often need to communicate with higher-level systems in order to send results, fetch measurement jobs or simply update themselves. This is not a problem for a PC-based controller, as all modern ways are available on the operating systems down to real time: Ethernet, USB, serial protocols, OPC UA, cloud connection, MQTT, and more.

The programming of such PC-based control systems is carried out with modern development environments of all kinds. Here, too, state-of-the-art tools can be used, as we are in the environment of the current IT technology. More often than not, no separation of the programming and target device is necessary; instead, the programming takes place live, directly on the executing IPC. The Beckhoff TwinCAT automation software is the ideal platform for the connection and processing of measurement tasks.

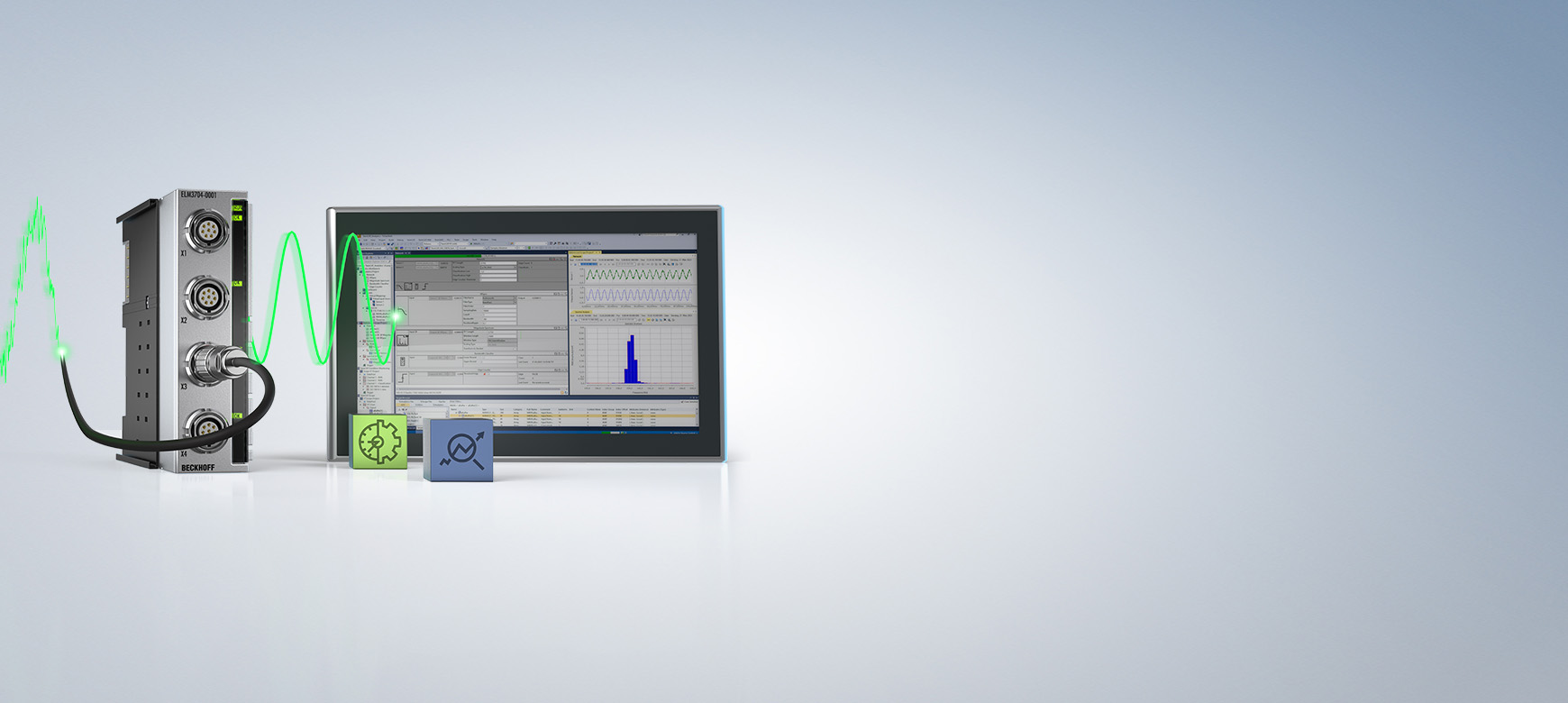

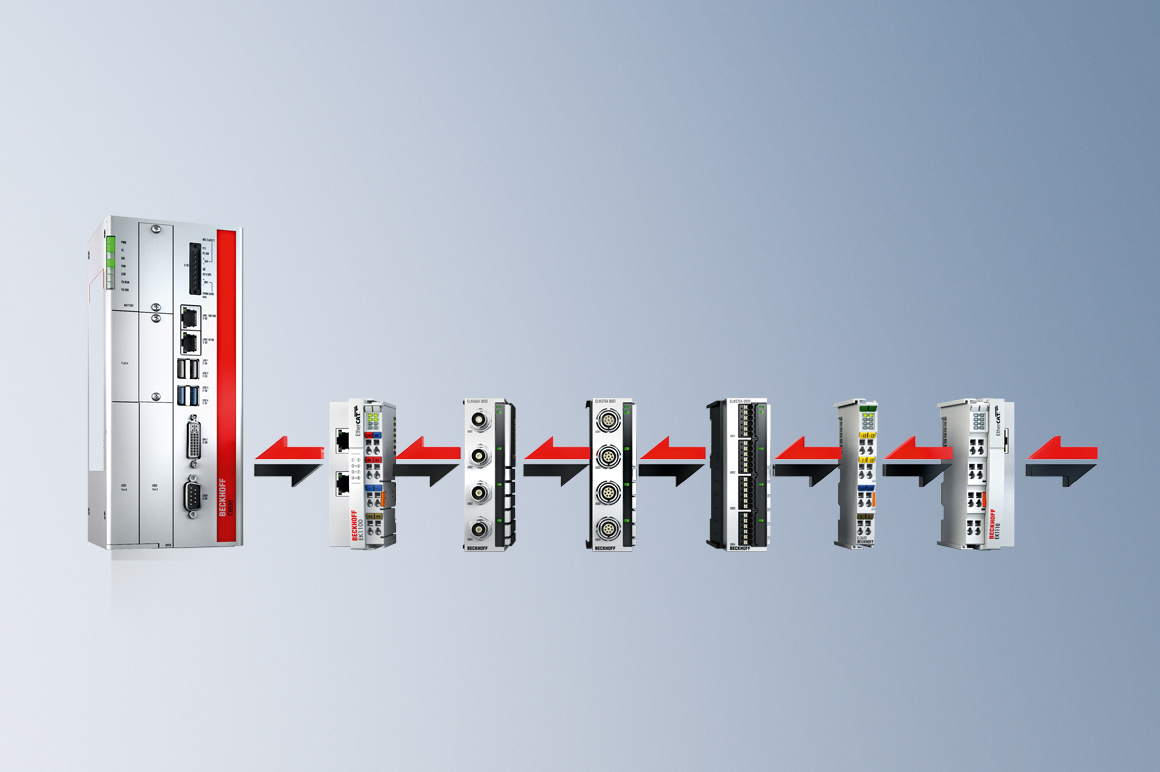

Modular DAQ system from Beckhoff: Fully integrated, from data acquisition to analysis

For the first time, Beckhoff enables the direct integration of high-quality measurement technology in already existing automation systems in a production machine, plant, test bench or quite simply wherever a programmed controller controls processes. The advantage: commissioning times and plant complexity are reduced because measurement technology and the associated software no longer need to be implemented in separate stations. The cross communications required up to now can also be omitted.

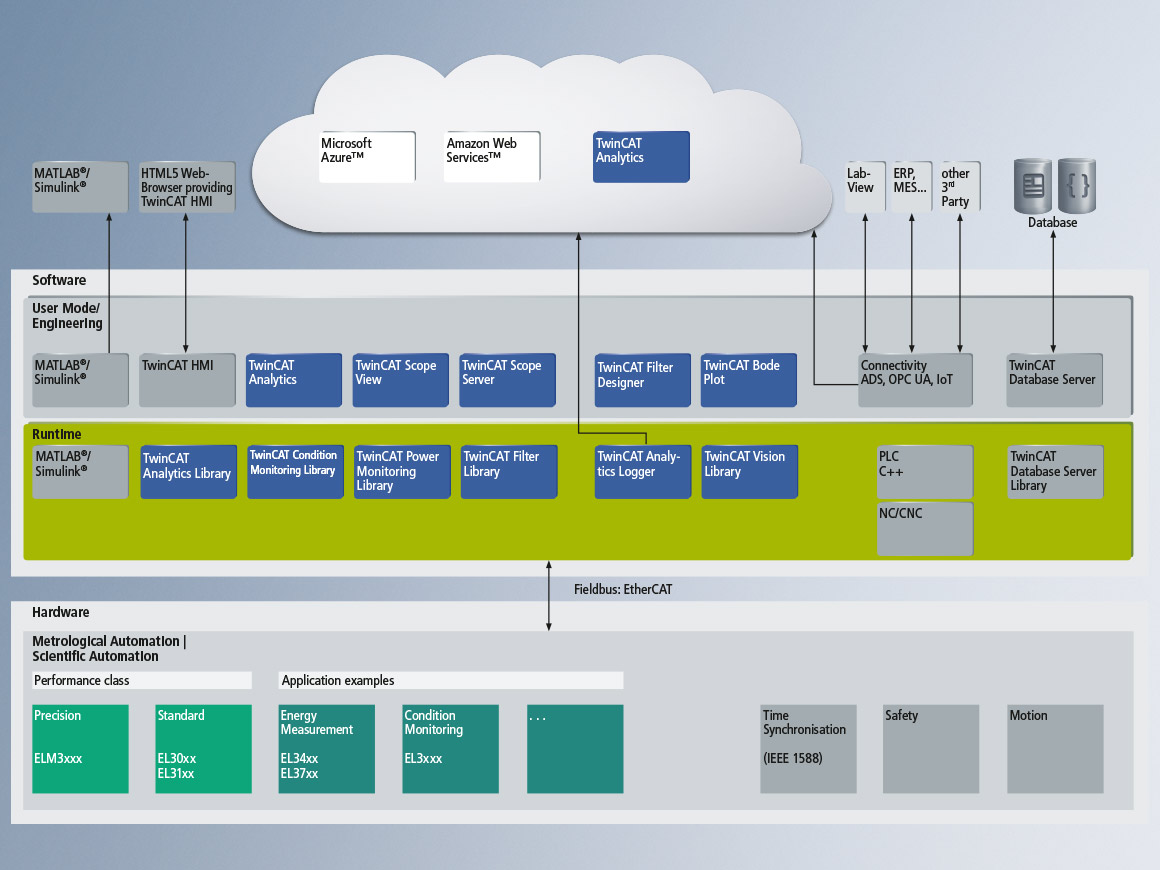

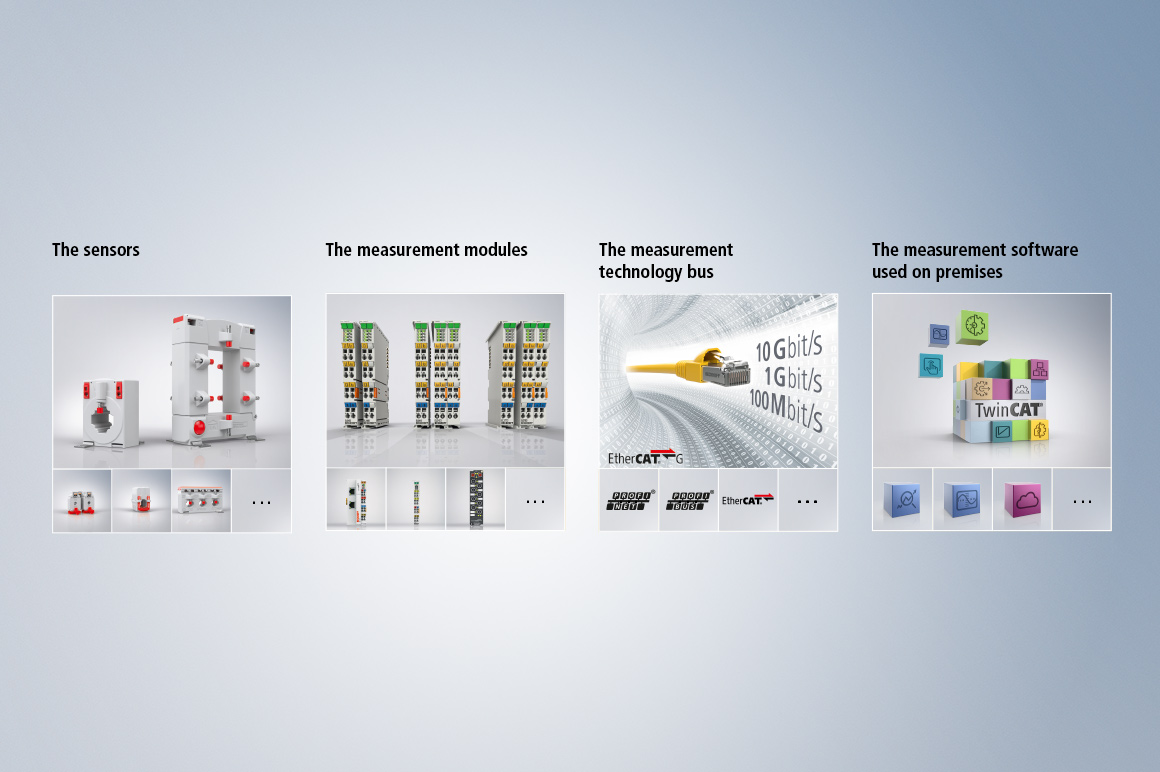

The entire measuring chain is covered, from sensor to data processing:

- Sensors at the lowest hardware level are connected to I/O modules in IP20 and IP67.

- High-performance fieldbus systems such as EtherCAT and EtherCAT G also transmit large amounts of data to the controller in synchronization.

- The TwinCAT software integrates engineering, PLC, motion control, safety, visualization, communication and measurement technology in one environment. It supports local operation, on-premises or distribution to remote stations.

- Modern cloud connectivity is already integrated in the controller, in the same way that any communication technology that has been implemented on PCs worldwide can also be implemented on a controlling Industrial PC.

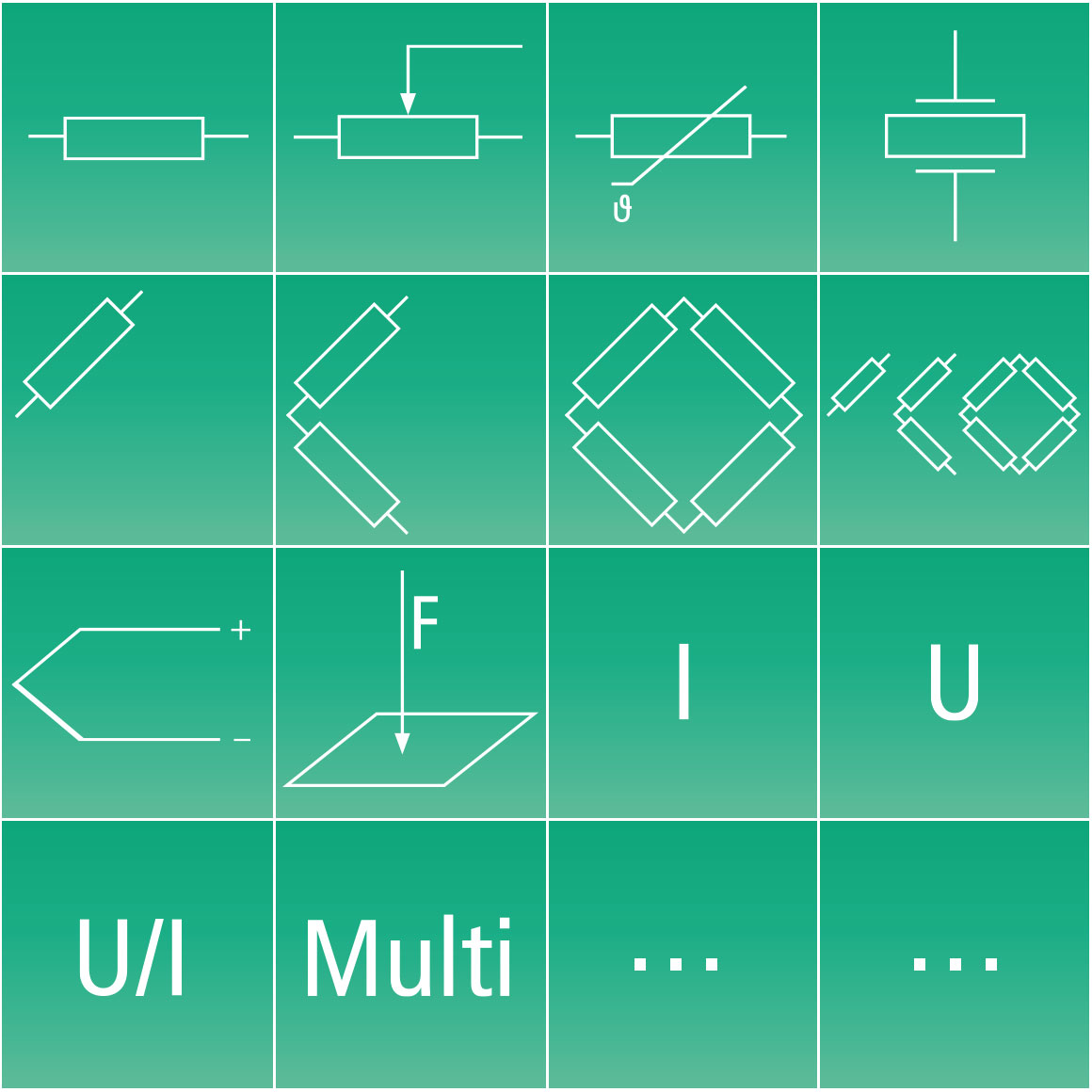

The Beckhoff I/O modules can be used to electrically connect most common sensors, e.g., for force, pressure, temperature, speed, frequency, torque, measuring bridges, vibrations, current, and voltage. For this purpose, our I/O modules are available in protection rating IP20 for installation in the control cabinet and IP67 for use directly on the machine. The ELM3xxx EtherCAT measuring terminals are equipped with a plug-in-compatible metal housing; a mixture of EL and ELM terminals on the DIN rail is thus possible without any problems.

Beckhoff prefers to work with EtherCAT and EtherCAT G as a measurement technology fieldbus. With a usable data rate of 100 Mbit, EtherCAT is sufficient for many hundreds of channels with 24-bit resolution and oversampling, synchronous sampling, timestamp with nanosecond resolution and cable redundancy. EtherCAT G is suitable for even more data-hogging applications with a data throughput of up to 10 Gbit. Alternatively, the measurement data can also be acquired with other fieldbus systems supported by us, such as PROFIBUS, PROFINET, EtherNet/IP and others.

The measurement technology software includes the TwinCAT on-premises software for use on the local control PC and the software for use in the cloud.

The TwinCAT on-premises software consists of the following modules:

- TwinCAT 3 for engineering, PLC, motion control, safety, visualization, communication and measurement technology

- TwinCAT Analytics: platform for in-process and post-process analysis

- TwinCAT Power Monitoring for grid analysis

- TwinCAT Condition Monitoring for signal evaluation

- TwinCAT MATLAB®/Simulink®: integration of MATLAB®/Simulink® models and algorithms for standard automation technology

- TwinCAT Connectivity the possibility to use cloud systems, data memories and third-party measurement software, such as LabView, based on open interfaces in TwinCAT

The measurement technology software in the cloud:

- TwinCAT IoT for communication to various cloud systems via communication protocols such as OPC UA Pub/Sub, AMQP or MQTT

- TwinCAT Analytics for the analysis of the complete process image of multiple machines in one central system for perfect data aggregation

- TwinCAT Analytics Cloud Storage Provider for the simple connection of cloud storage services of various public cloud platforms

Fast, open and firmly established as a measurement technology fieldbus: EtherCAT

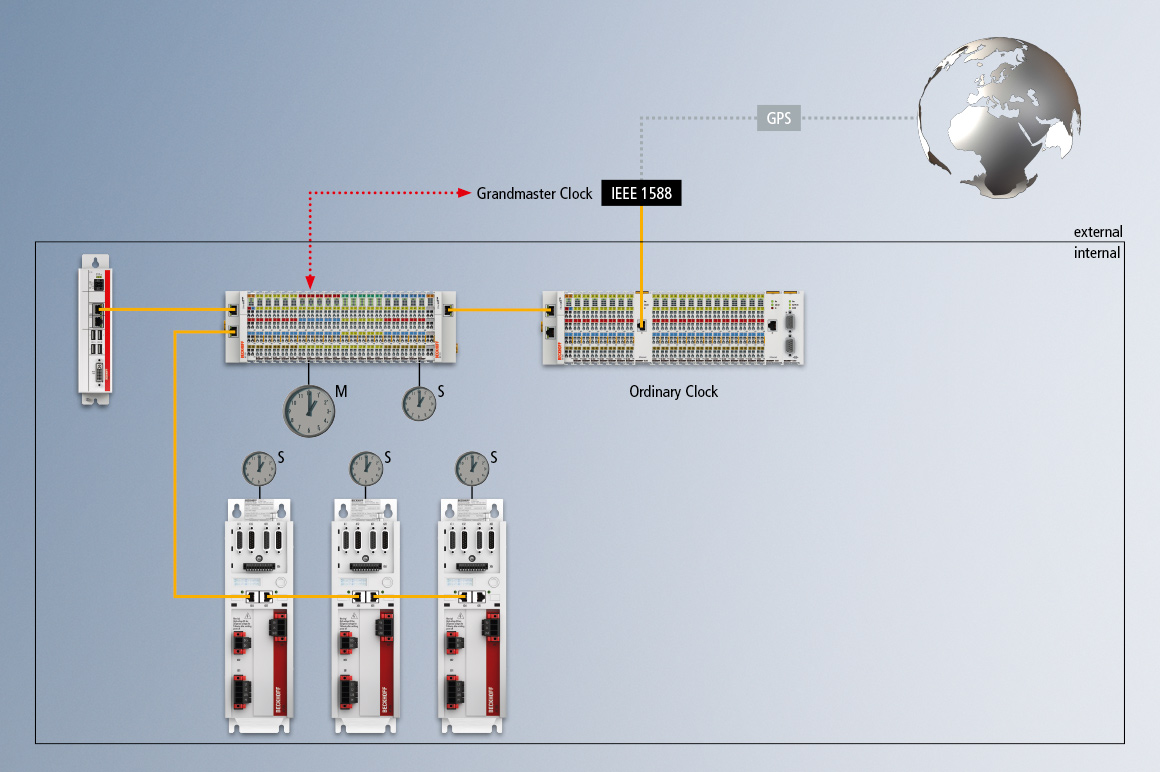

The direct integration of precise and, if necessary, fast measurement technology into the controller via EtherCAT ensures a simple system setup and reduces complexity. Other technological advantages include simple parameterization according to EtherCAT standards, synchronous scanning through Distributed Clocks (extending to external synchronization to any time source via IEEE 1588 PTP and others) and continuous diagnostics from the controller to the I/O level.

As a global standard, EtherCAT has now also established itself as a communication system in the field of measurement technology. With a data rate of 100 Mbit, EtherCAT covers large parts of what is required in measurement applications in laboratory or production environments. For particularly data-intensive applications, EtherCAT G provides bandwidths of up to 10 Gbit/s. This makes applications with thousands of channels easy to implement, even in the sampling rate range of 100 kSps and more per channel. High-performance measuring devices are not only available for EtherCAT, but also in particular infrastructure components from Beckhoff, such as the CU2508 port multiplier, which, if necessary, allows several EtherCAT segments to be simply arranged in parallel and thus multiply the possible data throughput. This is the basis for integrating up to 65,535 possible EtherCAT devices. It should not be forgotten that the PC-based control principle also allows the performance of the controller, which is flooded with data, to keep up. Here, the good scalability of our products has an advantageous effect at both I/O and control level!

EtherCAT is now so widespread in the world of highly specialized measurement technology that even unusual problems can be solved. Our components may not be available for all tasks, but a wide variety of EtherCAT devices are available on the market. The joining of forces of the EtherCAT manufacturers in the EtherCAT user organization ETG ensures through specifications and tests that all EtherCAT devices and masters harmonize with one another. The interoperability thus allows the mixing of EtherCAT devices on the bus level. Today, the ETG has more than 6,000 members worldwide – of which more than 100 are master manufacturers, so that almost every sensor or actuator now has an EtherCAT connection.

However, a glance at the Beckhoff website is sufficient to see that the great strength of our integrated measurement technology lies in particular in the mixability on the DIN rail with hundreds of other EtherCAT Terminals. In every measurement task, however complex, there are always "simple" digital or analog inputs/outputs to control – cost-effectively wherever possible. Our tried-and-tested automation portfolio has proven its worth here with its EL terminals, which can easily be mixed with the measuring terminals. Other EtherCAT I/O systems such as the EP/EPP system (IP67 waterproof) or the EJ modules for series use can also easily be connected to our measurement technology.

Regarding time synchronization, appropriately equipped devices from Beckhoff (terminals, boxes, modules) provide very high measuring accuracy. However, a measured value is often only usable when the time of measurement is also known. EtherCAT brings along precisely the right basis for this with the Distributed Clocks system: Appropriately equipped devices support the high-precision time synchronization of all inputs and outputs, typically with time uncertainties of well below 1 µs, both relative in relation to the devices in a network and absolute in relation to a higher-level global reference time. The latter in particular is fundamental if several controllers are to be temporally networked: the Beckhoff EtherCAT master in TwinCAT can adjust to an external time, which enters the EtherCAT system via PPS or PTP and other ways. Worthy of note here are the TwinCAT TF6225 function and the EL6688 and EL6695 EtherCAT Terminals. As a result, all EtherCAT devices on this bus then also run in sync with the external time. This allows, for example:

- many distributed analog inputs to be acquired simultaneously;

- actuators such as valves or motors to be controlled precisely with respect to time if the process is to be acted upon on a test bench or in a production machine;

- processes that are merged on a device (terminal, box, module) to be recorded with a relative accuracy of up to 10 ns. One example of this is the EL1252, which acquires both of its inputs locally in the hardware. Relative processes at the inputs can thus be acquired with a precision that is greater by several orders of magnitude than when the terminals are distributed in the system;

- long-term measurements to be stored with comprehensible time stamps.

EtherCAT optimizes the measurement technology architecture:

- only one communication technology for machine control, measurement technology and safety

- optimally matched products and technologies

- fastest Ethernet fieldbus

- 500 compatible EtherCAT Terminals from Beckhoff

- easy integration of third-party products

- high measurement quality due to timestamping

- protection of investment: no versioning (only one EtherCAT standard since 2003)

Measuring precisely - no problem with EtherCAT

The combination of the TwinCAT control platform and the fieldbus EtherCAT is a high-performance system for local control and regulation. This performance is required for:

- high-speed processes

- fast-running production machines with many products per second

- fast material flows in wood or paper processing machines

- laboratory applications with control cycles in the µs range

- observation of dynamic signals in the kHz range, such as oscillations, noises and vibrations

- data-intensive image processing

- simultaneous monitoring of energy flows in distributed systems

Time synchronization is important here, internally – between the devices on the fieldbus – and, if necessary, externally to higher-level clocks. TwinCAT and EtherCAT can deliver both perfectly.

- Internal synchronization: The EtherCAT Distributed Clocks are the tool for controlling devices with a precision of <1 µs among one another, no matter how many there are and no matter how far apart they are. The clocks work with a resolution of 1 ns in the devices. This is the basis for XFC product technologies such as timestamping and oversampling. The time reference is the first Distributed-Clock-capable device on the bus after the master – usually an EtherCAT Coupler. The EtherCAT master in TwinCAT primarily "only" provides for the distribution of the reference time; the devices readjust themselves. The master is required to do a little more work when the Distributed Clocks are combined with EtherCAT features such as Hot Connect (connecting/disconnecting segments during operation) or cable redundancy in ring operation.

- External synchronization: The comprehensive capabilities of TwinCAT come into play as soon as the EtherCAT system is to be readjusted to a higher-level time, because now the external time stamp must be received and incorporated into the local EtherCAT system. TwinCAT is capable of that, regardless of whether the external time information comes to the TF6225 via an Ethernet network (e.g., IEEE1588 PTP or NTP), via a bridge terminal such as the EL6695, from another EtherCAT network, or as a purely binary pulse per second (PPS) signal, e.g., from a third-party controller or a GPS. Of course, TwinCAT can also be the time source for other systems – if these can also be readjusted.

In summary, TwinCAT, EtherCAT and our I/O components are the right solution at the industrial level for problems requiring synchronicity and precise timing.

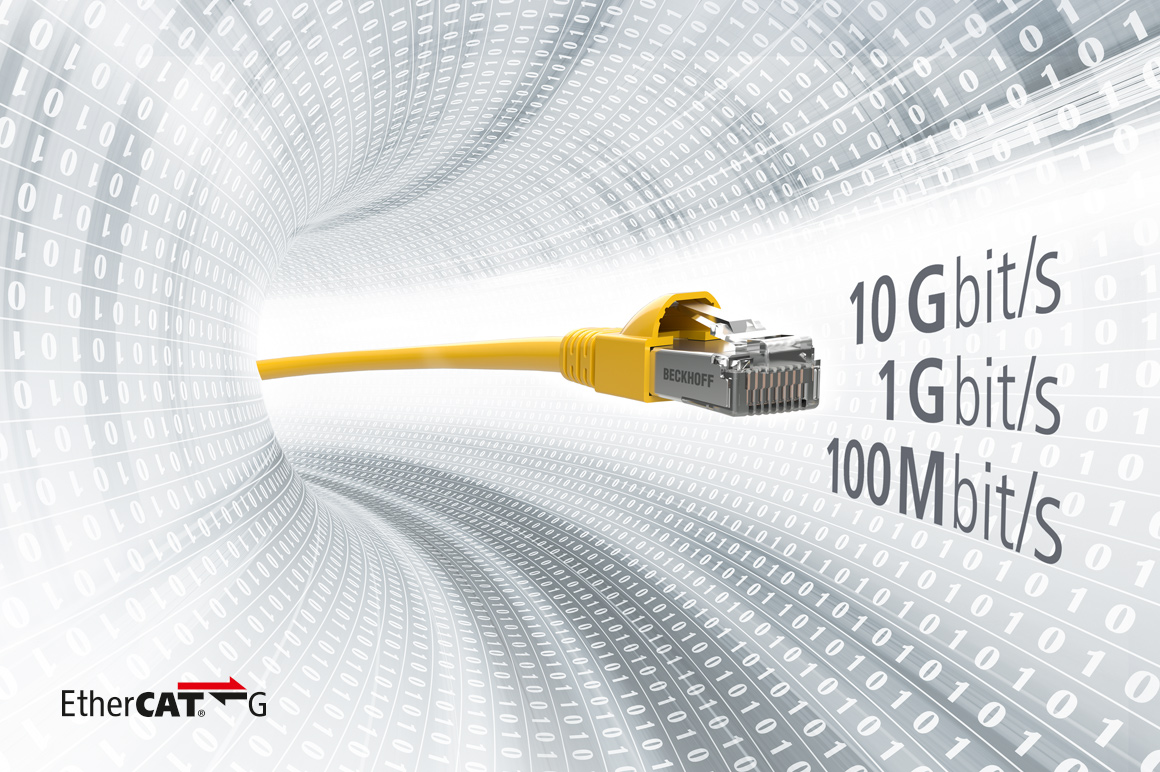

EtherCAT G: the scalable system from 100 to 10,000 Mbit/s

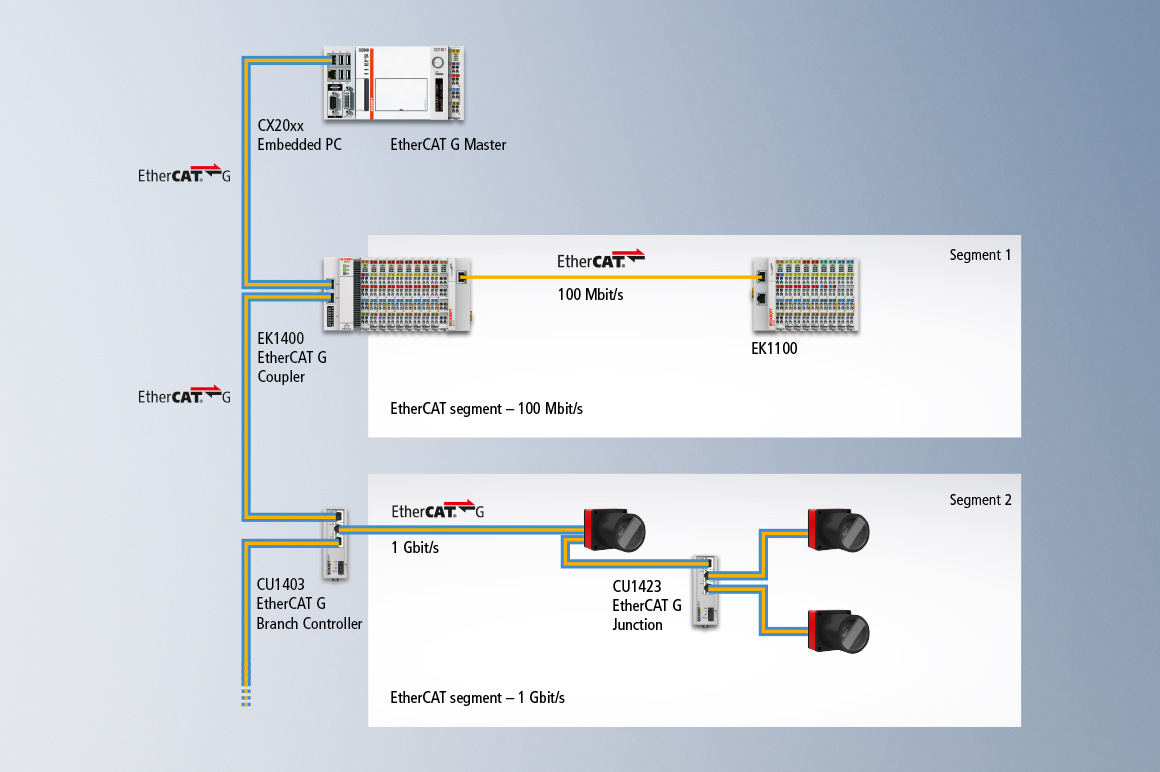

EtherCAT G is the continuation of the EtherCAT success principle with a 100 Mbit/s data transfer rate in the now technologically available speeds of 1 Gbit/s and 10 Gbit/s. This enables completely new application scenarios for automation tasks with integrated measurement technology: even more measuring channels and even greater data throughput are possible.

The EtherCAT protocol remains unchanged:

- The telegram sent by the EtherCAT master passes through all devices.

- Each EtherCAT slave reads the output data addressed to it "on the fly" and places its input data in the forwarded frame – now at 1 or 10 Gbit/s.

- The telegram is delayed only by hardware throughput times.

- The last device in a segment (or junction) recognizes an unused port and sends the telegram back to the master, thereby exploiting the full-duplex property of the Ethernet physics.

All other properties of EtherCAT are also fully preserved with EtherCAT G/G10. Devices with three or four ports (junctions) enable flexible topologies, exactly as required by the machine architecture. Optional machine modules can still be plugged in or unplugged via Hot Connect, as required. Network-wide diagnostics help to reduce machine downtime and thus increase availability. Of course, the integrated concept of Distributed Clocks continues to provide synchronization accuracies of better than 100 ns between devices. The management mechanisms such as CANopen over EtherCAT (CoE), File Access over EtherCAT (FoE) and Beckhoff ADS over EtherCAT remain usable.

The branch concept for the interaction between 100 Mbit/s and 1 or 10 Gbit/s EtherCAT networks is also fundamental. Existing and globally available devices with standard 100 Mbit/s EtherCAT can thus connect to Gigabit-speed networks. This makes EtherCAT fundamentally sustainable and transport-capable for all communication tasks in the coming years, even if existing systems are extended or upgraded to EtherCAT G/G10.

Universal properties from 100 Mbit to 10 Gbit:

- real-time Ethernet down to the I/O level

- flexible topology

- outstanding diagnostics

- synchronization accuracy better than 100 ns even with distributed systems

- very simple parameterization/configuration

- low system costs

- maximum performance

- functional safety can be integrated

- IEEE 802.3 compliant

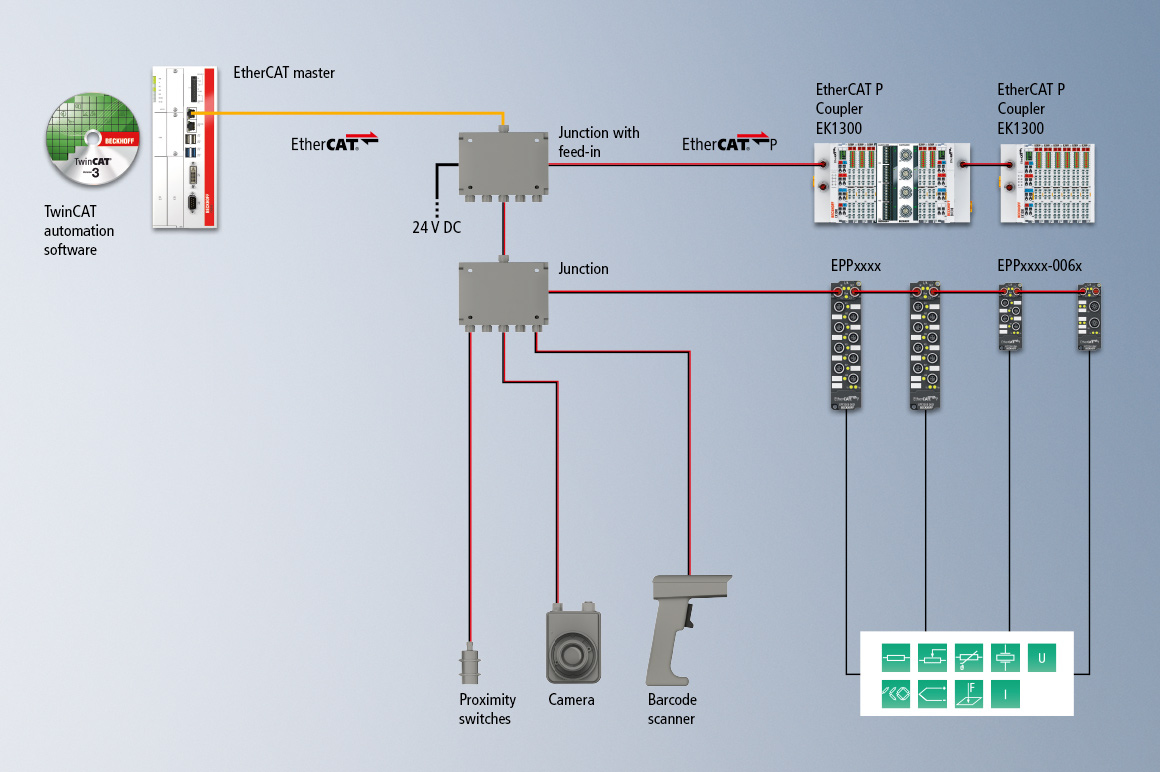

EtherCAT P: the sensor, actuator and measurement bus

Do you want to install small and large measurement devices outside the control cabinet distributed in the system and with high-performance querying? Thereby, using as few cables as possible? Still addressing the devices directly via EtherCAT? Exactly for this purpose, Beckhoff developed EtherCAT P in 2015.

EtherCAT P, the One Cable Automation fieldbus, combines communication and power in a 4-core standard Ethernet cable. The 24 V DC supply of the EtherCAT P slaves and the connected sensors and actuators is integrated: US (system and sensor supply) and UP (peripheral voltage for actuators) are electrically isolated from one another with a current of up to 3 A each for the connected components. All of the benefits of EtherCAT are retained, such as free choice of topology, high speed, optimum bandwidth utilization, the processing of telegrams in passing, highly precise synchronization, extensive diagnostics, and more.

The currents of US and UP are directly coupled to the cores of the 100 Mbit/s line, resulting in a very cost-effective and compact connection. EtherCAT P offers benefits both for connection of remote, smaller I/O stations in the terminal box and for decentralized I/O components locally in the process. A dedicated plug family was specially developed for EtherCAT P, in order to prevent potential damage caused by incorrect connection with standard EtherCAT slaves. It covers all applications from the 24 V I/O level through to drives with 400 V AC or 600 V DC and a current of up to 64 A.

The combination of EtherCAT P and decentralized measurement technology leads to new synergies: with little wiring work, high-quality measurement data can be collected from every section of a plant – up to temporary or even mobile measuring stations, which are only placed where they are currently needed. In the case of the EtherCAT measurement terminals, the EK1300 EtherCAT P coupler is to be used for control cabinet mounting. EtherCAT P is disclosed in the ETG and can therefore be implemented by all interested device manufacturers.

The high-speed fieldbus with the "one cable advantage":

- optimized for direct connection of EtherCAT P devices in the field

- less wiring work combined with time savings

- fewer sources of error

- smaller sensors and actuators due to elimination of the separate supply cables

- simple connection of components

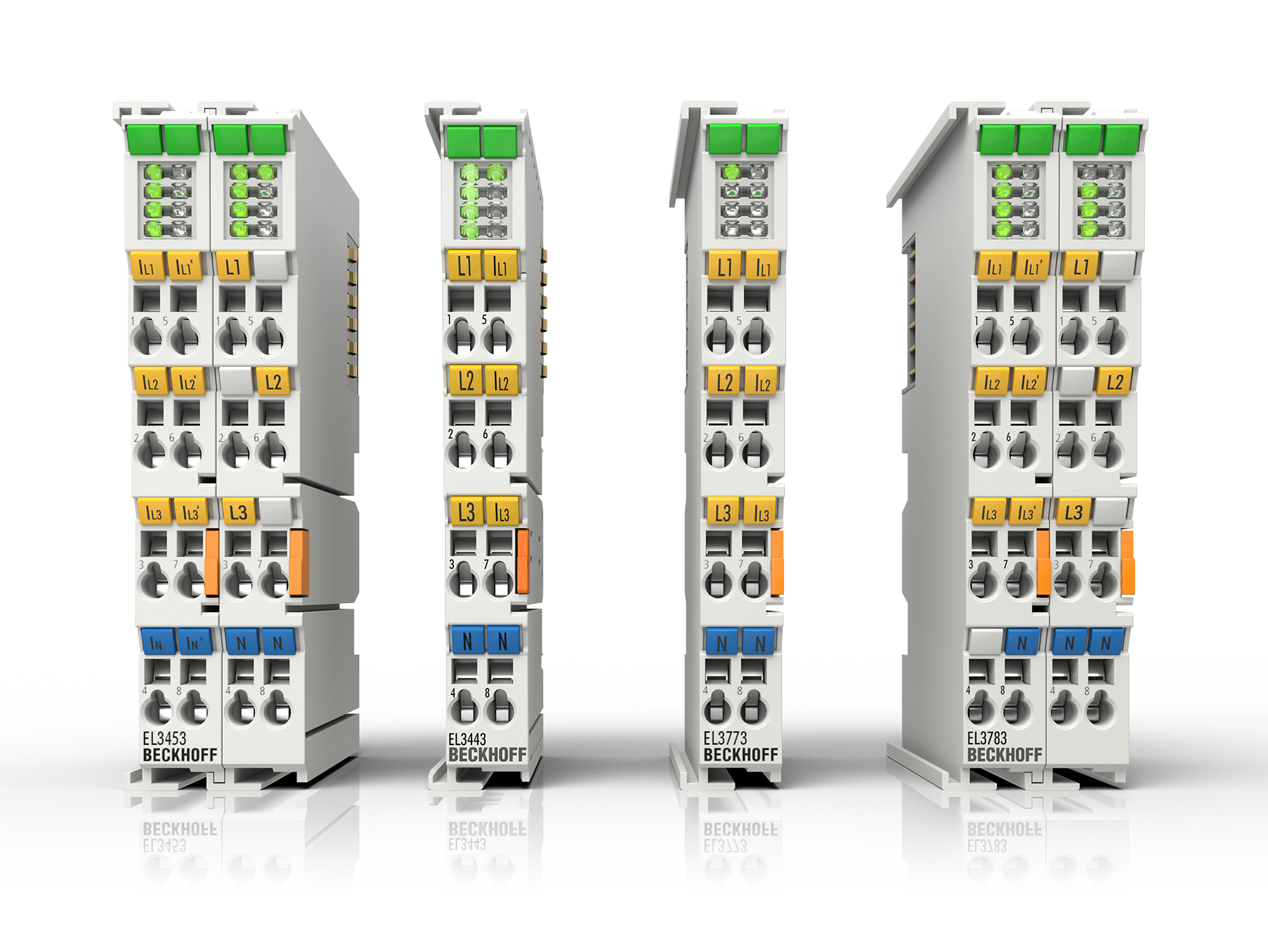

Modular power monitoring in hardware and software

What do you understand by power monitoring? How about power measurement to construct a convenient energy management system? Regardless of whether this monitors a building or a single machine, the values recorded are suitable for many things – including, of course, for a consumption estimate or, based on it, a cost-benefit calculation. With fast power requirement values of individual units, together with information about their current task, it is easy to estimate predictive maintenance and ultimately avoid unintentional downtime. If you are interested in one of those topics, take a look at the EL3443 power measurement terminals and their siblings: the EL3446 for distributed power measurement or the EL3453, which is suitable for the measurement of voltage systems up to medium voltage.

Under power monitoring, Beckhoff combines high-performance Industrial PCs, energy measurement technology, current sensors, and PLC libraries to provide customers with the maximum depth of detail for their power measurement task. This high-end power measurement technology is used, for example, at transfer points of wind turbines or on motor test benches, where short-term peak currents and/or voltages are also important. Do you need access, for example, to the actual current and voltage curves of the sine wave? Would you like to check whether they are really sinusoidal, or would you like to close a control loop in the µs range? PC-based control from Beckhoff offers suitable solutions for these tasks.

Entirely in keeping with the principle of PC-based control, the measurement recording begins with our power monitoring oversampling terminals. Oversampling describes the capability of the XFC (eXtreme Fast Control) technology to record multiple readings within a PLC cycle, thus increasing the effective sampling rate to up to 20 kSps. The simultaneously recorded instantaneous values for current and voltage, for example from a 3-phase alternating current system, are transmitted directly to the PLC in the Industrial PC without further processing - and thus without loss of information. A powerful processor is available here, which can handle even very complex analyses easily and efficiently with the help of the function blocks from the TwinCAT library.

The TwinCAT TF3650 Power Monitoring function provides the following functions for the evaluation of raw current and voltage data:

- calculation of RMS values for current, voltage and power

- function blocks can output instantaneous or average values as well as maximum and minimum values

- frequency and frequency spectra can be determined, such as harmonics in the network and their load in the form of the Total Harmonic Distortion (THD)

- All blocks are available for single-phase and 3-phase systems.

- The TwinCAT products TE1300 Scope View Professional or TF6420 Database Server are suitable for displaying or permanently storing the data.

The EL3773 and EL3783 EtherCAT Terminals are designed to be used as power monitoring terminals for the detection of the state of a 3-phase AC voltage system and include the following functions:

- On each phase, voltages up to 288 Veff/410 V DC or 690 V with an extended range of 130 % and currents up to 1 Aeff/1.5 A DC or 5 Aeff, again with an extended range of 130 %, and a resolution of 16 bits are recorded as instantaneous values.

- The six channels are measured simultaneously according to the EtherCAT oversampling principle with a temporal resolution of up to 50 µs.

- The "Extended Range" feature provides the user with a technical measuring range of 130 % of the specified nominal full scale value. In order to measure synchronously with other EtherCAT devices, the terminals support the Distributed Clocks function.

The system can also be synchronized to external clocks via additional terminals, such as the EL6688 for IEEE 1588 PTP.

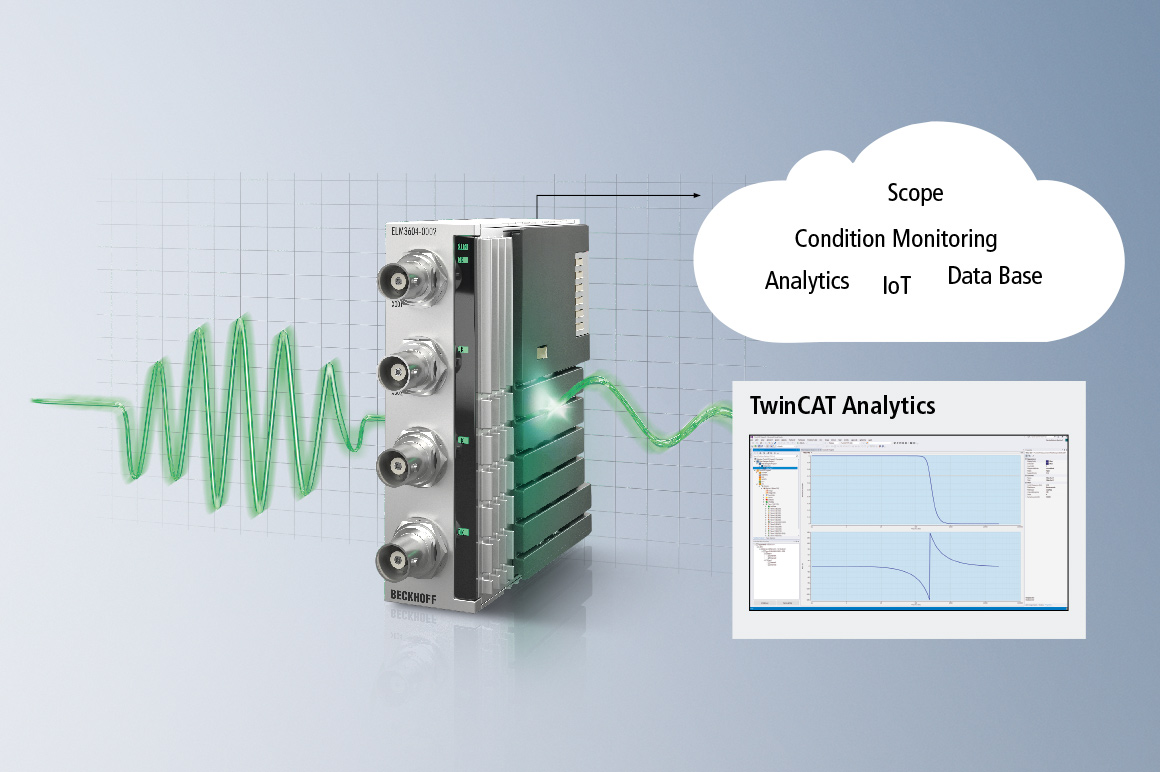

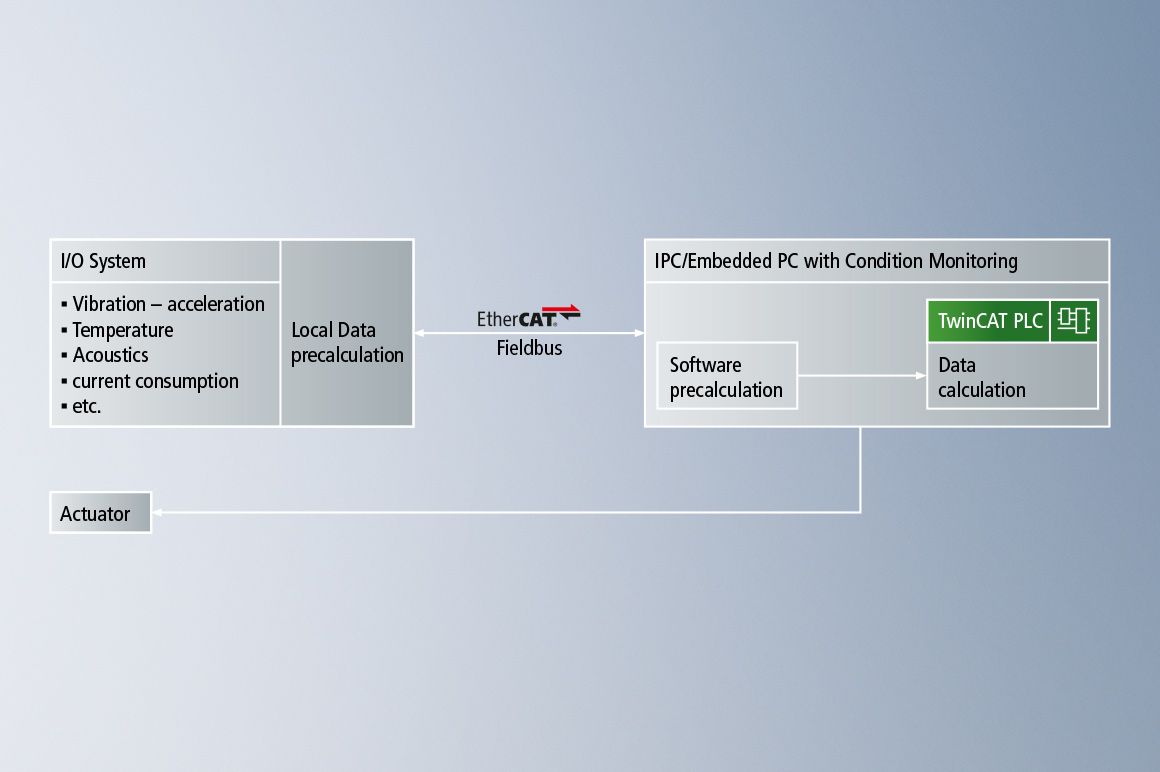

TwinCAT integrates condition monitoring into the controller

With TwinCAT 3, Beckhoff offers an extensive program of tools and functions. For example, the TwinCAT TF3600 Condition Monitoring library provides a modular toolkit of mathematical algorithms for the analysis of measured values. The library's functions are primarily relevant to analysis, statistics and classification. In addition to spectral analysis via FFT or using, for instance, an envelope spectrum, it is possible to calculate key statistical values such as the kurtosis or the crest factor. Combining these algorithms with limit value monitoring is, e.g., ideally suited to monitoring roller bearings. The great strength of the TwinCAT/EtherCAT system is the possibility to centrally collect and evaluate raw data at thousands of samples per second from all conceivable measurement points. EtherCAT as a powerful fieldbus, paired with measuring modules from the ELM series, enables a direct and clear view of the live data of the sensors. This allows an immediate live raw data analysis and, if necessary, the correlation of the channels with each other in real-time in the TwinCAT control software. However, the system becomes even more powerful when the raw data are also recorded with the TF6420 TwinCAT database and evaluated in post processing. TwinCAT Analytics, for example, makes this possible. Thus, based on historical data, analyses for live condition monitoring can be developed and easily loaded back into the real-time system.

The Beckhoff condition monitoring approach, which is based on raw data, has already been successfully implemented in many machines and wind turbines. If component-related threshold values are exceeded, the condition monitoring system triggers alarms that inform the system operator about wear, imbalances or impermissible operating states. These alarms can be reported for further processing directly to the system controller or other operator systems. Of course, the continuous machine monitoring can take place online. Trends in the characteristic values are analyzed here and translated into recommendations for action, for example for the planning of maintenance intervals.

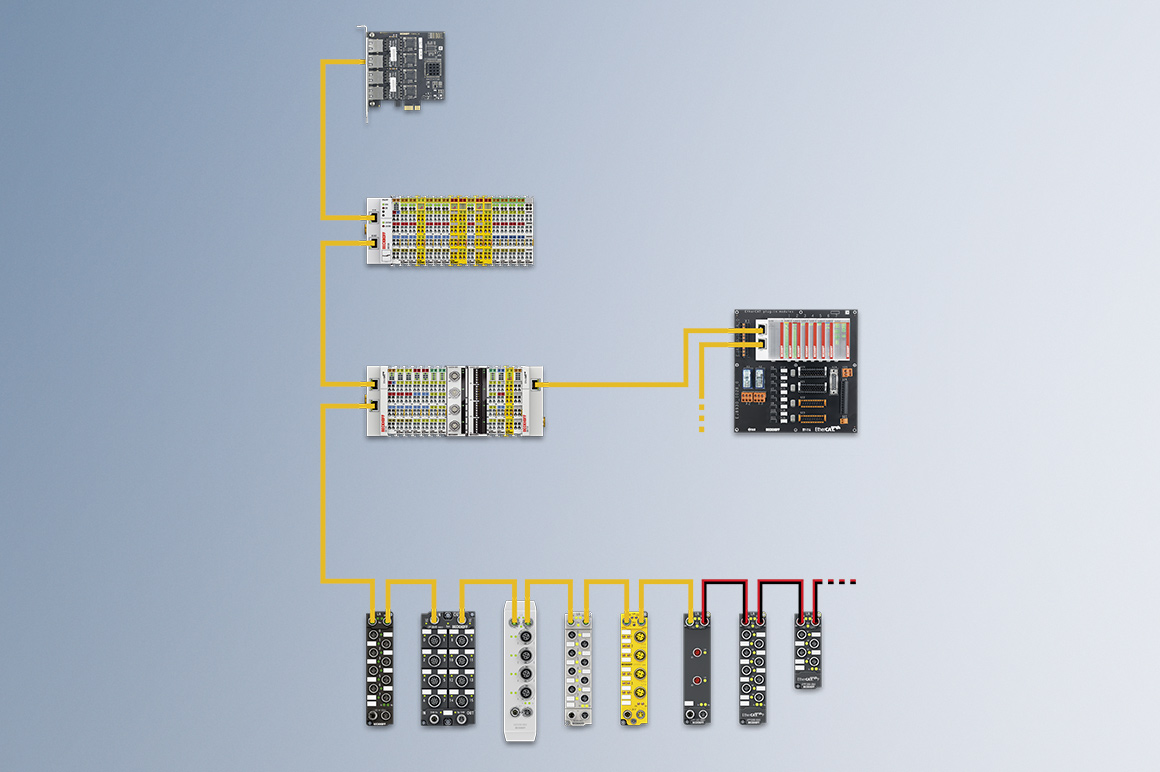

Decentralized and central I/O solutions – depending on environmental conditions

Outside or inside? The place of use doesn't matter! We offer our measurement technology in different designs and different accuracy classes. The focus is on stationary use: fixed and supplied with 24 V DC in plants or test facilities.

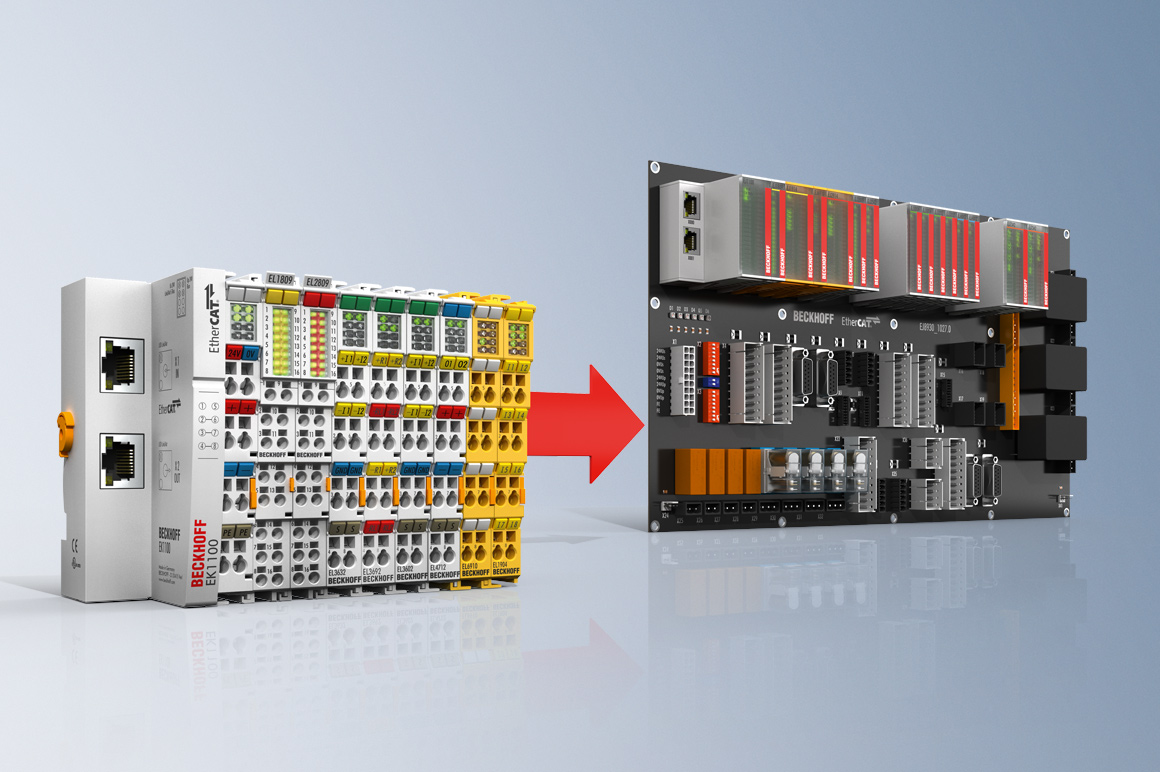

Beckhoff has been producing modular I/O devices since 1995. It started with the world's first modular terminal system, the so-called KL terminals, which can be connected to various fieldbuses via Bus Couplers (BK, BC). The system is still available today and continues to be expanded. The big leap in communication speed was made in 2003 with the introduction of the EL terminals based on EtherCAT communication. Suddenly, there was no longer a lower I/O level among the Bus Couplers. Instead, every single I/O function was directly addressable at the fieldbus level. This radically reduced commissioning times and diagnostic complexity. Both systems meet the demand for stationary I/O components mounted in the control cabinet with IP20 protection. This means that the devices are protected against being touched, but not against water or dust. The signals from the field, from sensors or actuators, must therefore be fed into the control cabinet by cable. Conversely, the advantage is that the devices, which are sometimes complex, are centrally concentrated and well protected. This can be particularly advantageous in measurement applications when environmental influences and EMC interference are prevented by the control cabinet. The ELM series follows this concept; the high-precision (100 ppm and better) and fast (up to 50 kSps per channel) measuring modules are even double-protected by their metal housing. Additionally, for large-scale applications, the EJ system can also be addressed via EtherCAT. It consists of even smaller modules in IP20, which are mounted on customer-specific backplanes in the control cabinet.

If I/O devices are required outside the control cabinet, our IP67 box modules are available for communication with various fieldbuses, including EtherCAT. With the protection rating IP67, i.e. waterproof and dustproof, the modules are suitable for free installation in a suitable place in the plant. Depending on the requirements, series are available with plastic, stainless steel or die-cast zinc housings.

Since the I/O devices in these series may not cover every application’s unique requirements, we also offer the necessary infrastructure components for networking.The extraordinary range of communication-compatible standard I/O components in the different series enables any plant planner to choose the right solution for the various applications with regard to installation location, cost considerations, communication speed, and accuracy. Thus, you get everything from a single source – in one system.

Further information:

- IP20 │ Bus Terminals: KL/KS/KM

- IP20 │ EtherCAT Terminals: EL/ES/EM

- IP20 │ EtherCAT plug-in modules: EJ

- IP67 │ Fieldbus Box modules: IP/IL

- IP67 │ EtherCAT Box modules: EP/EPP/EQ/ER

Measurement technology and safety integrated in one system

As an experienced provider of automation solutions, Beckhoff offers many technologies that can easily be combined. Do you have "normal" automation tasks and want to integrate electrical measurement technology? Is personal safety an issue? Then you should consider TwinSAFE. With this integrated safety solution, the installation and maintenance of heterogeneous systems in the plant can be avoided if necessary. The safe I/O products are recognizable by their all-yellow color. By the way: If direct analog measurement, e.g., of a temperature, is to be part of the safety architecture, the TwinSAFE SC products combine analog measurement and safety requirements compactly in one device, either as an EtherCAT Terminal or Box. These I/O products are recognizable by their partly yellow coloring: the EL terminals, for example, have a yellow stripe on the side.

Beckhoff product highlights for the measurement and testing technology

System-integrated high-end measurement technology for industrial 24/7 operation provides trustworthy data

Confidence in the correct functioning of a machine is the pillar of any contract award. Therefore, measurement technology is indispensable today – regardless of whether the application is a production line, a packaging line, energy distribution or a laboratory setup. System-integrated high-end measurement technology provides for a lean control architecture and trustworthy data. Thorough pre-testing in the Beckhoff production department and high-quality calibration ensure the reliable and precise measurement function of the EtherCAT measuring terminals.

Low aging and thus long-term stable operation of the terminal, adjustability in the customer environment, self-diagnostics and outstandingly high temperature stability are the cornerstones of an industrial measuring device. Equipped with a sturdy metal housing, the high-end measurement modules bring high-quality measurement technology to the DIN rail in the control cabinet. Beckhoff measurement technology is often used in unmanned, unaccompanied applications where no one checks the wiring every day or monitors measured values for their plausibility. For this reason alone, the measuring hardware used is expected to test and validate itself within the scope of what is technically possible.

The ELM3xxx terminals are specially designed for industrial use: with short assembly times in the industry-standard control cabinet environment. An additional feature is comprehensive self-diagnostics, which ensures reliable long-term operation in typical unaccompanied low-maintenance systems. Thus, the EtherCAT measuring terminals automatically and immediately detect any incorrect measurements that might otherwise be mistakenly considered valid over a lengthy period of time. This increased operational and measurement reliability – continuously retrievable via EtherCAT as a diagnostic report – is realized by a comprehensive connection diagnosis, self-test and internal repeated tests as well as the continuous monitoring of temperature and input for the detection of overload. A completely new view of the well-known measurement uncertainty!

The ELM3xxx measuring terminals significantly expand the existing analog product range of the EL3xxx terminals by the area of lowest measurement uncertainty, commonly called measurement accuracy. A guiding value here could be ±100 ppm (±0.01 %), while "normal" analog input products (terminals in IP20 or boxes in IP67 design) are more likely to be in the range of ±0.3 % (±3000 ppm). An important aspect of this is, of course, "the fine print" of the specification: the specified ambient temperature range in particular significantly influences the comparability, both inside and outside our product range. Currently, the ELM3xxx series consists of 2 groups: the ELM3x0x basic line and the ELM3x4x economy line.

ELM3x0x | EtherCAT measurement terminals from the basic line

The high-performance EtherCAT measuring devices from the ELM3x0x basic line are designed to measure highly dynamic processes while maintaining high measurement accuracy – simultaneously across all channels and terminals. Orientation values for this class are a sampling rate of 10 kSps per channel and a measurement uncertainty of ±100 ppm at an ambient temperature of 23 °C. Individual terminals from the series may deviate from this, e.g., the ELM3602 terminals achieve a sampling rate of 50 kSps per channel. The ELM370x features multifunction channels with numerous integrated measuring ranges (±60 V to ±20 mV, ±20 mA, full/half/quarter-bridge strain gauge, IEPE, thermocouple, RTD, potentiometer). The ELM300x, ELM310x, ELM350x and ELM360x series offer reduced functions and thus price-optimized versions with different numbers of channels.

ELM3x4x | EtherCAT measurement terminals from the economy line

The measuring terminals from the ELM3x4x economy line are designed to measure processes with lower dynamics; at the same time, they are significantly cheaper. Orientation values for this class are a sampling rate of 1 kSps per channel and a measurement uncertainty of ±100 ppm at an ambient temperature of 0-55 °C. Therefore, they have enormous temperature stability, which is crucial for industrial use outside of temperature-controlled laboratories. In addition, the channels of these devices operate with the multiplex method, i.e. one after the other. The integrated 24 V sensor supply and the 24 V power contacts reduce the wiring work in the control cabinet. Versions with a standard signal input 10 V/20 mA (ELM314x) and a thermocouple input (ELM334x) are available in the economy line.

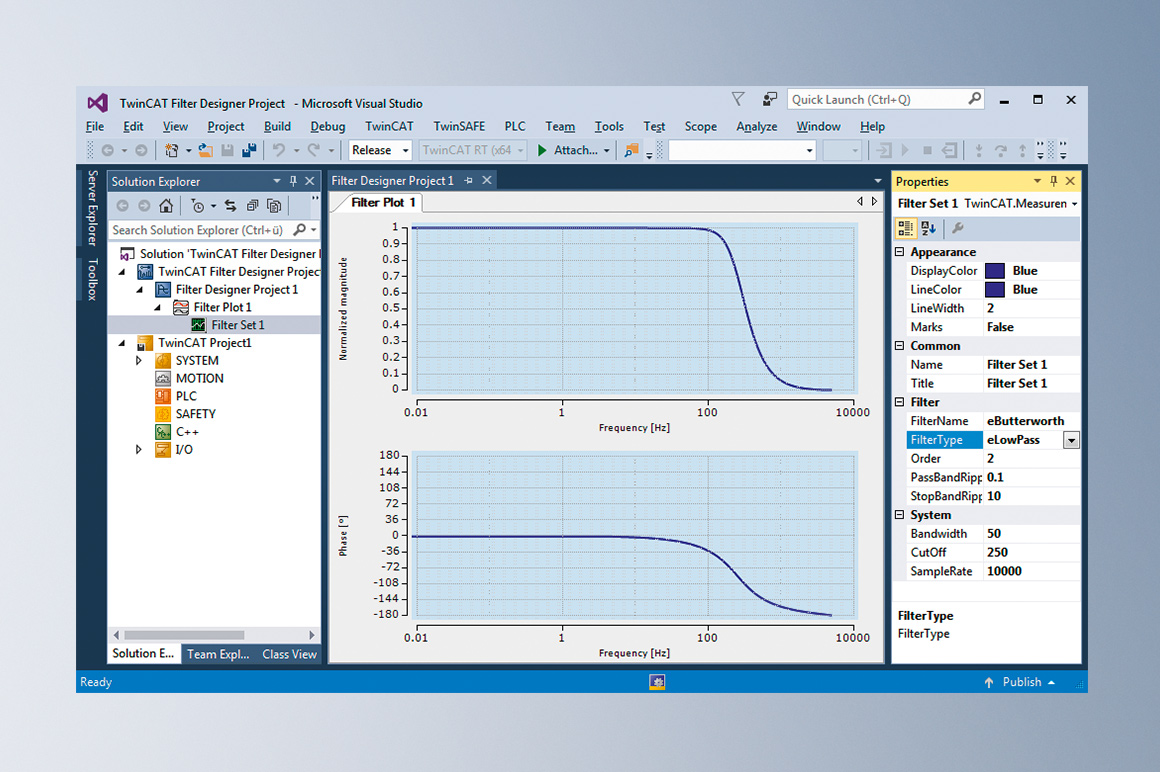

Both product lines support EtherCAT features such as Distributed Clocks time stamping in the ns format and fieldbus diagnostics. In addition, they have extensive functions for local data pre-processing, such as two-step digital filtering, true RMS calculation, and drag indicators. On top, they are able to locally calculate almost any digital filter up to the 39th order, which can be designed and loaded using the TwinCAT TE1310 Filter Designer.

Measurement technology system components

Ideally, the measurement terminals are supplied by system components such as the EKM1101 coupler and the ELM9410 power feed terminal. These supply devices are particularly designed for metrological requirements and thus stand out technologically from the standard components EK1100 and ELM9410: the outgoing voltages are regenerated, electrically isolated from one another, and are therefore particularly stable. In addition, they feature voltage and environmental monitoring, so that the operational capability of the connected ELM terminals is ensured.

Other accessories are available for the ELM series, such as the ZS9100-0003 shielding hood and the ZS9100-0002 shield connection terminal.

Reliable integrated measurement technology:

- up to 50,000 samples/s

- measuring accuracy of up to 25 ppm at 23 °C, depending on the measuring range

- metal housing for perfect heat dissipation and interference shielding

- extremely sturdy, ideal for harsh environments

- plug front end for different application requirements: LEMO, BNC, Push-in

- pre-treated in production for long-term high-quality measured values

- integrated connection and function diagnostics

- optionally with calibration certificate

Worthy of note are the ELM2xxx Multiplexer terminals, with which analog signals can be switched and fed to the measuring terminals in any complexity. This significantly reduces costs and installation space where large numbers of channels are involved.

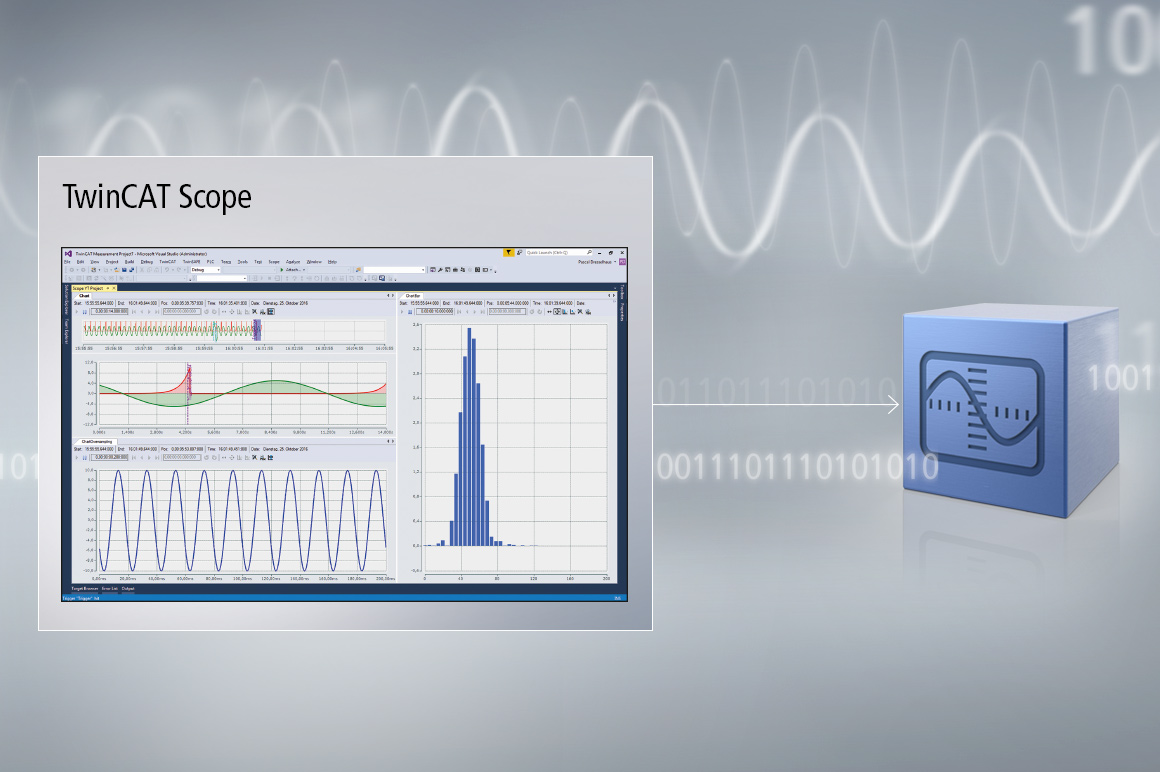

For the graphic display of all measuring signals

The highlight of the TwinCAT measurement product family is the powerful TE1300 TwinCAT Scope software oscilloscope. The charting tool, integrated as an independent project in Visual Studio®, can graphically display measuring signals in the single-digit µs range. In addition to conventional functions such as trigger, chart synchronization and cursor, TwinCAT Scope View offers multi-core support, in order to enable the full computing power of the corresponding system to be utilized for the display of high-frequency signals, including oversampling values. Several wizards integrated in the product simplify the already intuitive operation of TwinCAT Scope View. In addition to a project wizard, there is a wizard for selecting and transforming physical units and another for converting data to other file formats, such as csv or tdms. With the latter, it is also possible to discard unnecessary data and to specify a time period for the export. In addition, data recording and export can be fully automated via the PLC. A basic version of the scope is already included in the free TwinCAT XAE engineering environment and can be extensively tested there. The extended licensed Professional version includes additional functions such as long-term recording.

Seamless interaction with other TwinCAT products was the focus of the development of TwinCAT Scope. In addition to templates for motion applications, bar charts in conjunction with the TwinCAT Condition Monitoring library, for example, are very useful for displaying the frequency responses of power or magnitude spectra. Even images from vision systems can be sorted by timestamp in the data stream and displayed. This way, all essential data from testing and measurement tasks can be bundled in the scope.

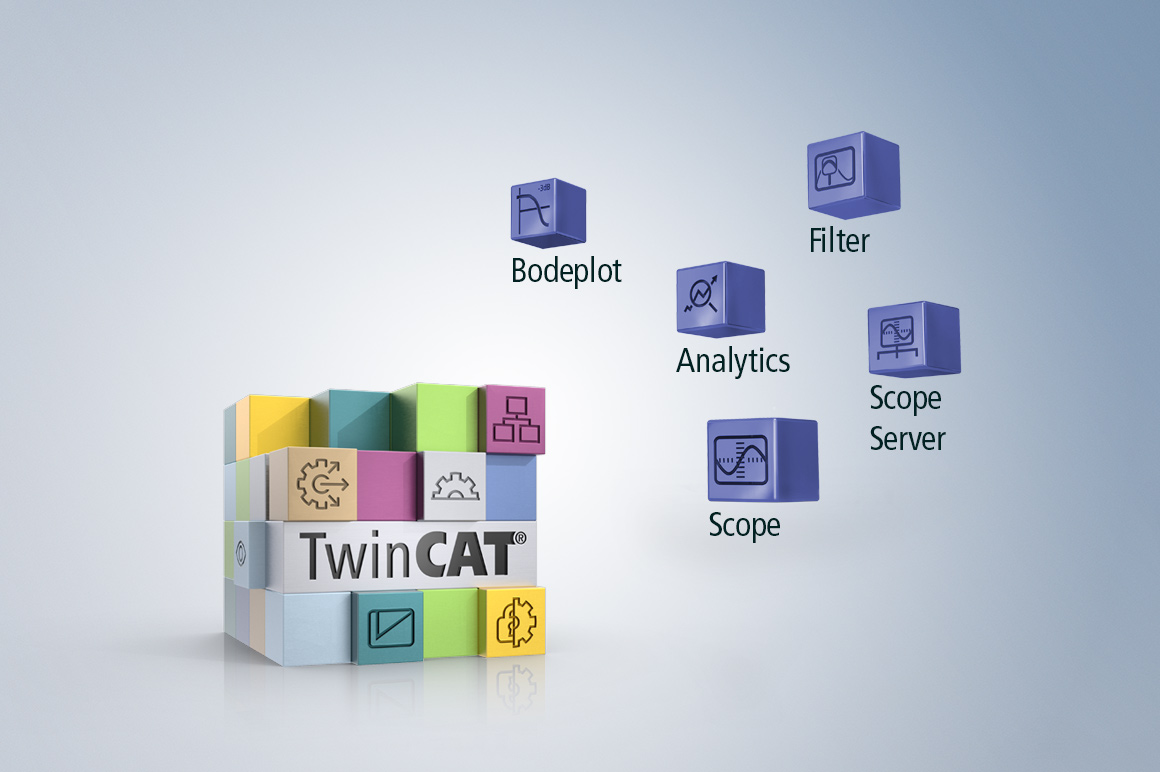

The scope is part of the TwinCAT 3 Measurement package, which also contains the respective latest versions of various measurement products such as Scope View, Scope Server, Bode Plot, and Filter Designer. Drive technology can be optimally adjusted with the Bode Plot, which is based on the TwinCAT Scope. Setpoints can be transferred to the drive and its reaction can be displayed graphically as frequency response and phase in order to optimize the drive parameters. This way, these systems can supply data for condition monitoring and analytics.

Software oscilloscope with multi-core computing power:

- high-end charting tool for high-resolution data

- free basic version integrated into TwinCAT XAE

- long-term and trigger-controlled recordings

- communication via ADS or in the OPC UA standard

- scope Control for integration into your own .NET-based HMI

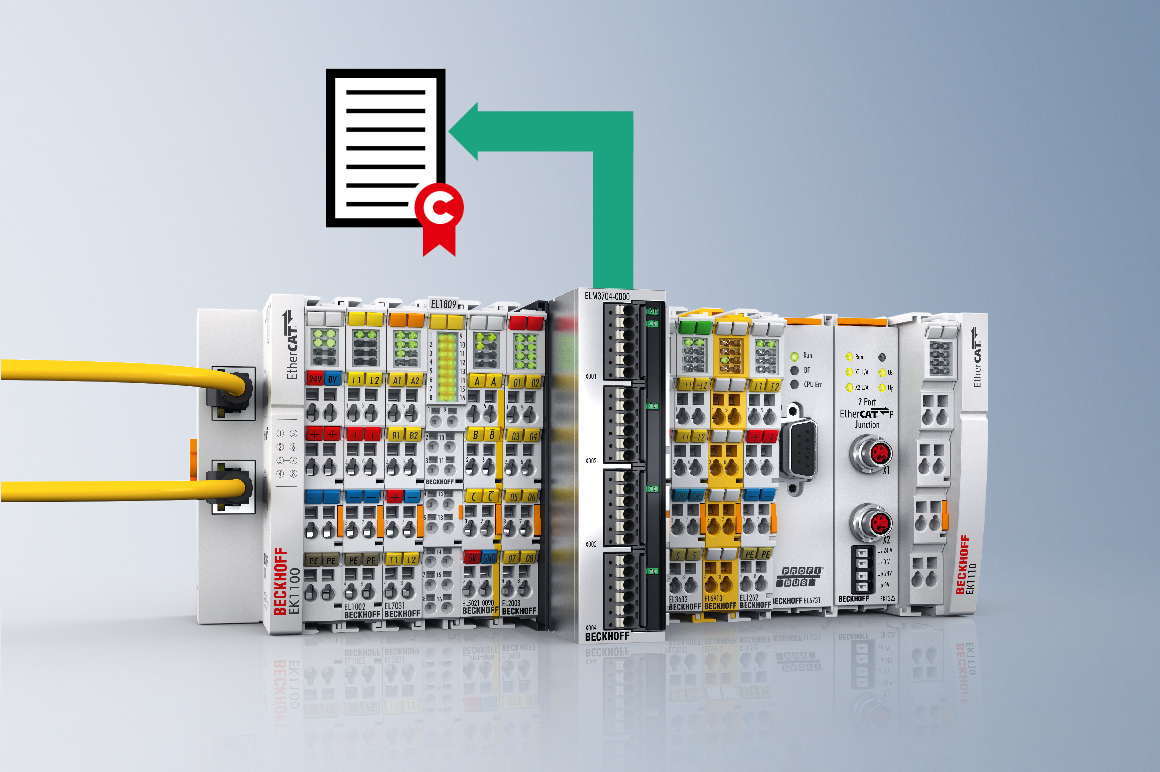

Calibration certificates prove measuring capability

Sophisticated production facilities and test benches require calibrated measurements: from sensor to cable to digitization. Beckhoff also provides competent support in such special cases by supplying some analog devices from the factory with a calibration certificate. The factory calibration, ISO 17025, and DakkS steps are available. Recalibration at our production site in Verl, Germany, is also available on request.

Basically, all our analog devices (input or output) are calibrated and tested in the Beckhoff Production Dept. The calibration, i.e. the written proof of measuring capability, is only carried out for appropriately designated devices. The respective calibration certificate is available for download as a PDF on our website.

This shows the strength of the extensive Beckhoff I/O portfolio: from the simplest digital input to standard 12 bit analog inputs to DAkkS-calibrated 24-bit measurement terminals with an uncertainty of <100 ppm, the most diverse requirements in a system and the EtherCAT universal communication system can be covered.

TwinCAT 3: the heart of PC-based control

TwinCAT consists of runtime systems for the real-time execution of PLC, HMI, motion, robotics, safety technology, measurement technology, vision and IoT applications, and is at the same time the development environment for programming, diagnostics and configuration. All main IEC 61131-3 programming languages are available for real-time applications. C/C++ and MATLAB®/Simulink® modules can be integrated in the IEC context via existing interfaces or operated independently in the TwinCAT 3 real-time environment.

Demanding tasks in the field of measurement data processing can easily be solved with TwinCAT; the system can easily be scaled with the number of channels and data quantity. It is one system and one interface for all purposes: from acquisition to processing to storage. Functions specifically designed for measuring tasks, such as TwinCAT Scope and TwinCAT Analytics, are available for TwinCAT.

Taking the example of wind turbines, the performance of TwinCAT has already been demonstrated thousands of times worldwide: complex subsystems have been dissolved and the control and condition monitoring tasks transferred to the central TwinCAT controller.

This model can be transferred to many other types of plant, from manufacturing to process technology to test systems – in fact, wherever specific systems work side by side and communicate intensively. TwinCAT can efficiently process extensive input data streams (I/O system, cameras, higher-level systems, etc.) and retroact on the plant as a control system in real-time via the actuators (drives, actuators, valves, etc.).

Flexibility through modularity with TwinCAT:

- support of all major industrial bus systems worldwide: suitable for the connection of measuring devices, drives or standard automation technology

- high-quality real-time platform that supports cycle times up to 50 µs (20,000 cycles per second) and more

- modular solution can be scaled and expanded according to requirements (see PC-based control)

- highly scalable computer platforms for all performance requirements

- all options for data storage and evaluation: locally on the machine, on the company's own network or in the cloud

- simplified code generation through templates

- simple replication of created code for series production

- support of many industrial communication standards

Integrated, seamless data analysis with TwinCAT Analytics

Competitive advantages can be generated by analyzing meaningful data. This explains why more and more data analysis tools are becoming available. However, they don't usually speak the language of the machine manufacturers and are conceptually limited to a few scenarios. In contrast, the TwinCAT Analytics family (TE35xx, TF35xx) has been developed for mechanical engineering. The TwinCAT Analytics engineering tools are seamlessly integrated into Microsoft Visual Studio®, which is well-known through machine applications. The familiar environment saves a lot of time during development. For instance, numerous algorithms are available that allow a direct linguistic reference to mechanical engineering and corresponding functions. Interaction with already well-known TwinCAT tools, such as TwinCAT Scope for data visualization, simplifies the handling of analytics.

TwinCAT Analytics is not limited to targeted fault-finding on machines, but also enables the permanent monitoring of one or more machines located in a network. Thus, the path to 24/7 monitoring is simple: readable PLC code can be generated from an analysis created in the configuration tool with one click. It can run in parallel with the machine in the TwinCAT Analytics runtime on an IPC or in a virtual machine. The generated code can be extended in well-known programming languages for individual analyses. Existing code can be adopted. TwinCAT 3 HMI can also be used to design a dashboard, creating added value for the end customer. In addition, TwinCAT Analytics works not only with live data, but also with historical machine data. Database access takes place via the TF3520 Analytics Storage Provider. Overall, TwinCAT Analytics is not just one product but a workflow that allows you to realize IoT technologies and Industrie 4.0 applications.

Data analysis generates added value:

- new business models based on data analysis

- fast and simplified error analysis

- machine optimization

- simple engineering integrated into TwinCAT XAE

- cost reduction through automatic PLC code generation for 24/7 monitoring

- virtually automatic data management

- maximum flexibility through IoT technologies

TwinCAT Analytics consists of several tools that can be executed during the engineering (TE3500, TE3520) or at runtime (TF35xx family, e.g. TF3510).

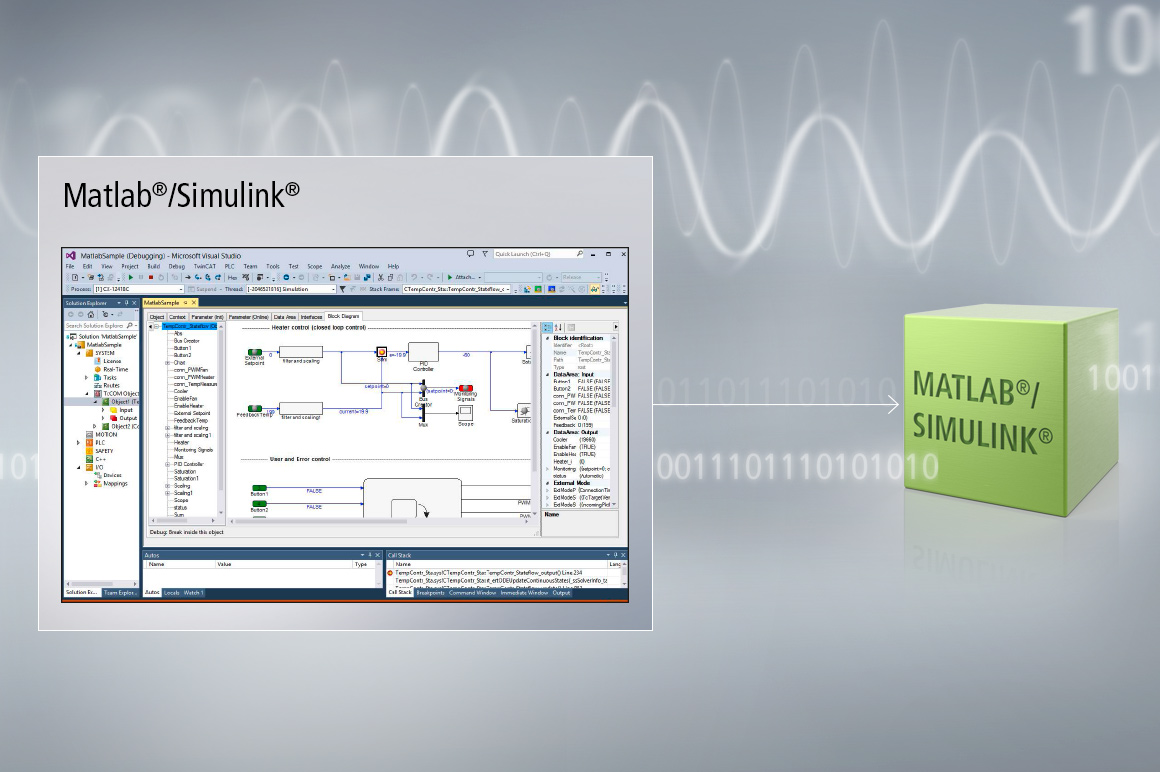

MATLAB® and Simulink® – strong partners in measurement and testing technology

MATLAB® and Simulink® set standards in measurement data analysis as well as in system modeling and simulation. Beckhoff supports the integration of both tools into its TwinCAT 3 engineering system with two products: Target for MATLAB®/Simulink® (TE1400) and Interface for MATLAB®/Simulink® (TE1410). When using Simulink® engineering, you can use TE1400 to generate instances of TwinCAT objects (TcCOM models) in TwinCAT 3. In TwinCAT, these modules can be triggered directly via a real-time task or via other TcCOM models. Embedded as a control in TwinCAT Engineering, the block diagram allows you to parameterize such a model in TwinCAT and monitor signals. It can be used to develop, for example, monitors that can be executed in real time or virtual sensors for deducing measurement values that cannot be read directly, or to simulate the behavior of non-existing components (hardware-in-the-loop) in real time. TE1410 supplies an ADS-based communication interface for exchanging data between TwinCAT and MATLAB®/Simulink®. It supports synchronous and asynchronous read/write procedures as well as module calls (read/write). You can also use this product to make MATLAB®-based analyses available as functions that can be called from within TwinCAT. Or you can use the product in connection with Simulink® for software-in-the loop simulation as part of model-based software development.

TE1400

- one-click TcCOM generation from within Simulink®

- multiply instantiable modules in TwinCAT

- block diagram as a control in XAE

- parameterisation and charting of (internal) model signals

- debugging in XAE possible

TE1410

- ADS client in Simulink®

- embedded target browser in the Simulink® block

- ADS client/server in MATLAB®

Reducing data flow with flexible tools – TwinCAT filter functions make it possible

Integrated measurement technology from Beckhoff delivers enormous quantities of raw data from the entire production plant and the entire test bench – centrally via EtherCAT if required. This data is the valuable basis for all who want to concern themselves with process analysis and, as a result, the optimization of the plant. The system supports both forms of analog value processing: central or decentralized.

- central:

Ideally, no data reduction and thus no information destruction takes place in the lower-level measuring devices; everything is processed centrally in the TwinCAT controller. The I/O devices send raw data unfiltered "upwards" via EtherCAT, if desired with thousands of channels and many tens of kSps, and with a high resolution. The data are then evaluated, correlated and stored centrally in TwinCAT. - decentralized:

Pre-filtering already takes place in the lower-level measuring devices, if necessary with a reduction in the sample rate in the I/O devices. This may be due to an interest in a low bus load, or because it is known from experience how the raw data should be filtered. For this form, we provide extensive and powerful functions in our I/O devices, especially in the ELM measurement terminals.

A basic tool for illustrating process-relevant information in the analog signals is a single filter stage in the frequency range low-pass, high-pass, etc. Depending on the desired execution location, the following can be selected with Beckhoff:

- decentralized:

- pre-installed, fixed filters in almost all analog input devices (EL, KL, EP series, etc.)

- the filter property is set via the device settings (CoE or register)

- decentralized:

- flexible, variable filters in the ELM3xxx measuring terminals

- filter construction with the TwiCAT Filter Designer

- central:

- flexible, variable filters in the controller, e.g., in the PLC or C/C++

- filter construction with the TwinCAT Filter Designer and real-time execution in the TwinCAT Filter Library

The TwinCAT Filter Designer was developed in order to adapt filters ideally to the respective measuring task. It is free of charge and part of the TwinCAT Measurement package, which also contains the respective latest versions of various measurement products, such as Scope View, Scope Server, and Bode Plot. Currently, selectable filter designs are Butterworth, Chebyshev and Inverse Chebyshev; possible filter types are low-pass, high-pass, band-pass and band-stop (more are being prepared). The Filter Designer offers the possibility to influence the filter coefficients via a tabular specification or graphically. Once the filter coefficients have been determined, they can be

- used in digital filter function blocks in the PLC, e.g., in TF3680 or C/C++,

- or transferred to the ELM measuring terminals by drag-and-drop.

The filter success can then be checked with live data in the TwinCAT Scope TE1300 or TwinCAT Analytics TE3500.

Simplified database connection for efficient measurement applications

Data from machines, systems or test stands, have a lot of value and must be protected. The TwinCAT Database Server (TF6420) does precisely that by handling the data traffic between TwinCAT and various database systems. It can write or read values during this process. The Database Server offers four functional modes. The Configure Mode allows for fast and easy configuration of a database connection without requiring any programming. The PLC Expert Mode was designed for PLC programmers who do not want to create their own SQL commands in the PLC; the Database Server does this automatically. The SQL Expert Mode features total flexibility, because user can combine their commands themselves and even trigger Stored Procedures on the database side. This mode is also available for C++. In environments with frequently changing measurement campaigns, a rigid table structure in a relational database is particularly difficult to manage, which is why the Database Server offers support for classic relational databases like Microsoft SQL, Oracle, MySQL or SQLite, and in addition a NoSQL Expert Mode for connection to so-called NoSQL databases such as MongoDB in addition. For this purpose, no predefined scheme is required, which increases the flexibility of the application significantly.

Convenient database integration without programming

- direct link from the real-time context to the database

- supports relational and NoSQL databases

- easy configuration in TwinCAT Engineering

- PLC code generation for easy implementation in the controller

- various PLC function blocks for all user groups available

Easy realization of the combination of Beckhoff devices and LabVIEW™ systems

In many laboratory applications, LabVIEW™ is set as the program language, recipe management system and HMI. If a Beckhoff TwinCAT system is to communicate with its real-time and with a standalone LabVIEW™ system, the TF3710 is the right choice. Using the TF3710 function, the test bench operator can access the TwinCAT data of the Beckhoff measurement technology hardware and generate additional measurement functions via the familiar user interface. The communication between TwinCAT and LabVIEW™ is bidirectional: TwinCAT data can be streamed to LabVIEW™, processed and displayed. LabVIEW™ data such as a start event or an external measuring signal can be transmitted from LabVIEW™ to TwinCAT.