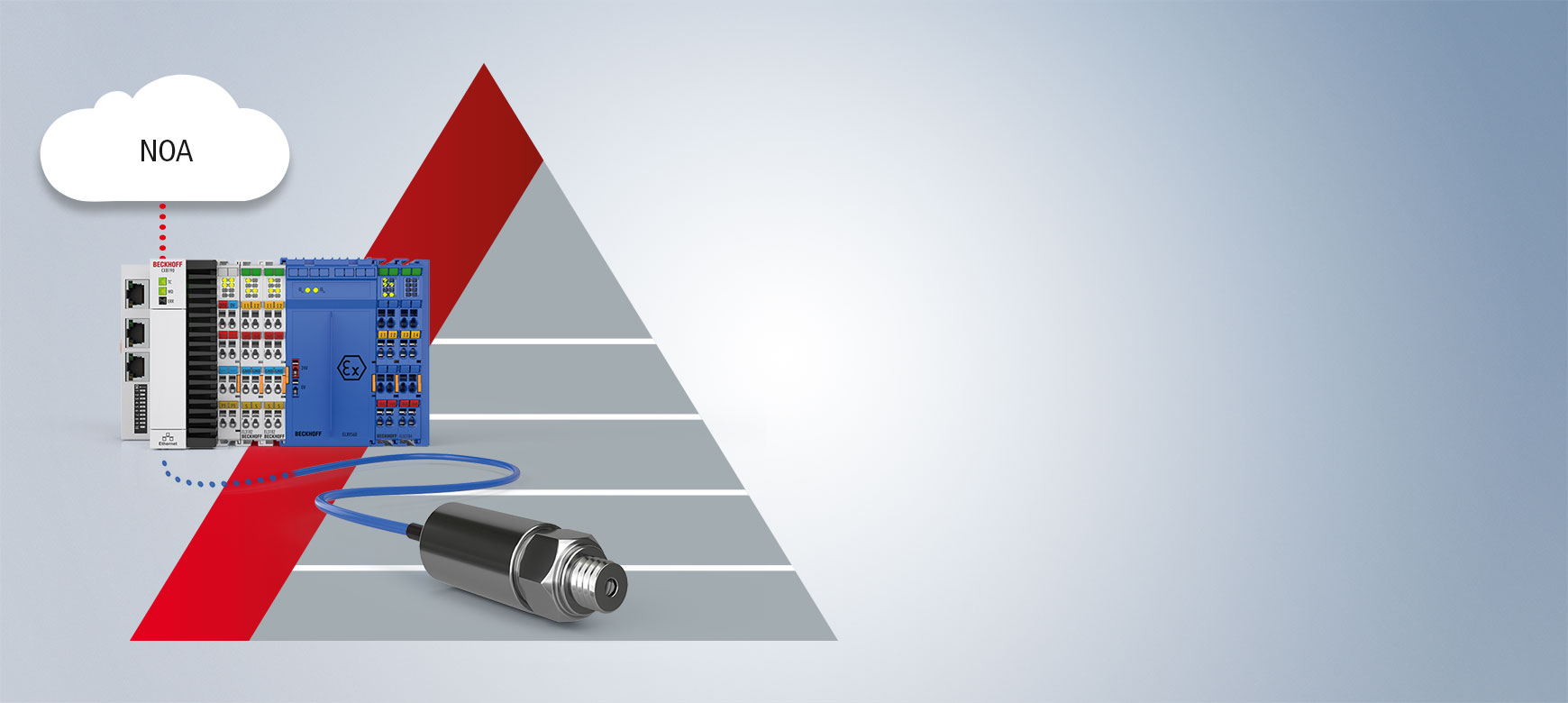

Implementing NOA with Beckhoff

Beckhoff has developed an NOA edge device specifically for reading out the additional operating data for the higher-level M+O. The edge device, which consists of a compact embedded PC, EtherCAT Terminals with HART functionality, and the relevant TwinCAT project, can be placed directly in the plant.

Functions of the NOA Edge Device from Beckhoff:

- independent second channel of a signal isolator is used

- the widely used HART protocol is implemented for field device communication

- conversion and translation of the read data

- parameters are mapped onto a defined data model

- standardized information models such as PA-DIM are implemented

- automatic adaptation of the OPC UA information model, depending on the connected device type

NOA concepts

The NOA concept offers considerable potential – particularly for brownfield applications. Existing plants need to be future-proofed by converting or upgrading them: costs can be reduced and output increased simply by monitoring and optimizing systems without changing the current process control methods. To this end, additional components are added to collect previously unused data from the field level. The Beckhoff NOA edge device was developed specifically for this purpose. Its compact design allows it to be integrated into existing plant structures while saving space. Beckhoff offers various solutions for recording field device data, depending on the infrastructure already in place. In each of the following scenarios, the NOA edge device does not allow feedback or modification of field device data.

With feed isolator

Many commercially available feed isolators (barriers) offer two independent interfaces for connecting to I/O systems. The first is typically used to connect to the control system to transmit measurement data from the field device. The NOA side channel can also be opened here by connecting an EL6184 EtherCAT Terminal as a HART master to the second interface.

Without feed isolator

If no feed isolator is used, the field device is connected directly to the I/O level of the control system. The EL6184 EtherCAT Terminal can be connected in parallel to the existing I/O modules to read vitality data. Thanks to its high internal resistance, the EL6184 communicates via the HART protocol without distorting the measurement data transmitted via the 4–20 mA signal.

Using Profibus remote I/O

If the field devices are connected to the control system via HART-enabled Profibus remote I/Os, central extraction of the NOA data is a practical solution. In this setup, the NOA edge device reads the field device data from the gateway via OPC UA and provides the data from all connected field devices in a corresponding information model (PA-DIM).

The NOA concept also offers advantages for greenfield plants. For example, vitality data can be transmitted directly from individual plant modules to the respective manufacturer, who can then provide appropriate spare parts or initiate maintenance work. This approach is particularly effective in connection with the Module Type Package (MTP).

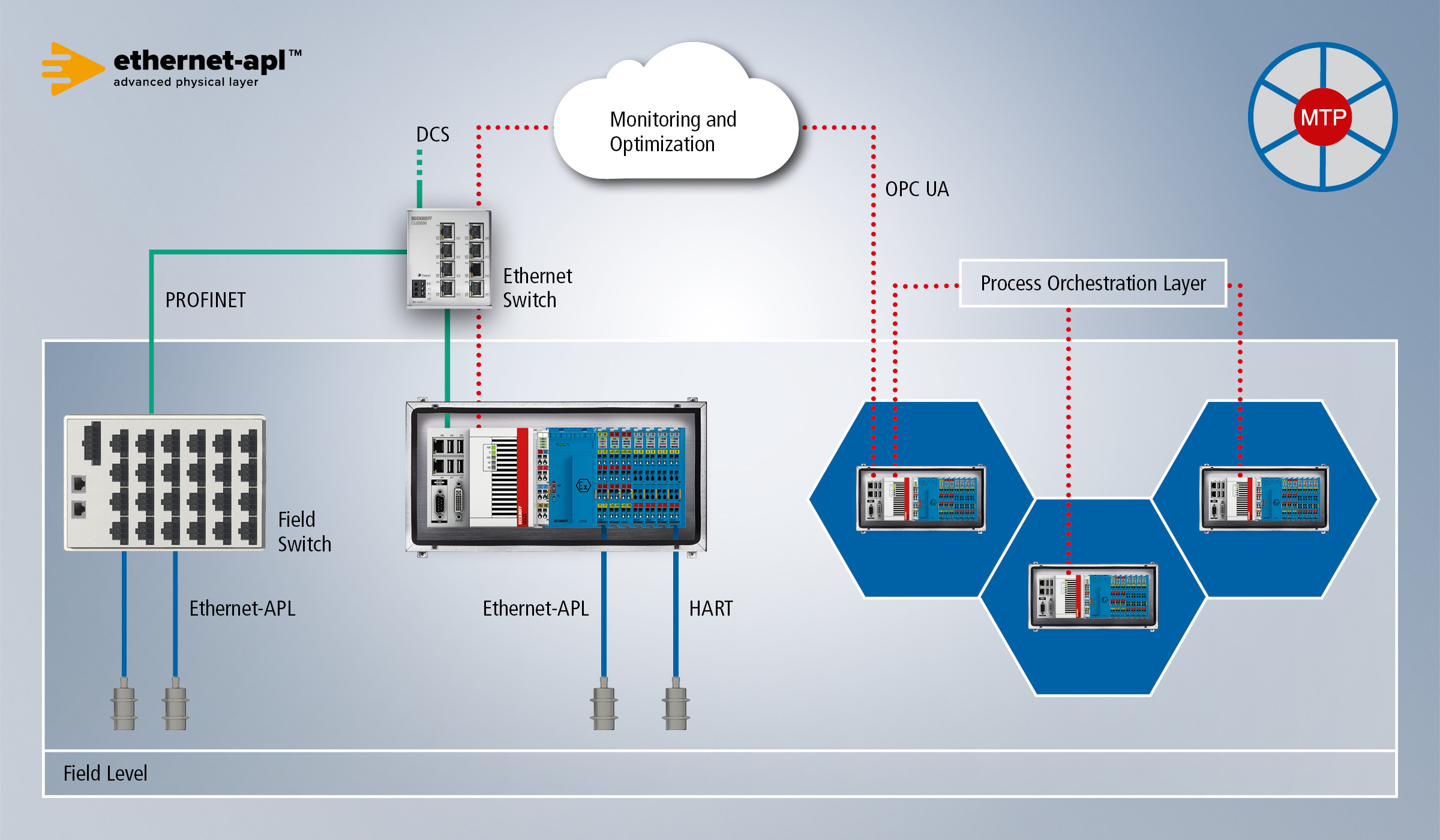

Additional monitoring sensors can be installed at the plant planning stage, providing more data for monitoring and optimization. New technologies such as Ethernet-APL make implementation simpler, as process and vitality data can be transmitted simultaneously via the Ethernet connection. Data processing and translation can be carried out in the TwinCAT automation software, regardless of the protocol used.

We also offer ideal solutions for your edge device applications outside the process industry.

More products and solutions for your plant

Ethernet-APL

ELX6233 EtherCAT Terminal enables complete data acquisition for the process industry with the Ethernet-APL communication standard.

Module Type Package (MTP)

TwinCAT MTP integrates the Module Type Package concept into the engineering environment and enables efficient development of modular plants.

ELXxxxx | Explosion protection (Ex i)

The EtherCAT Terminals from the ELX series with intrinsically safe inputs/outputs enable the connection of field devices up to zone 0/20.

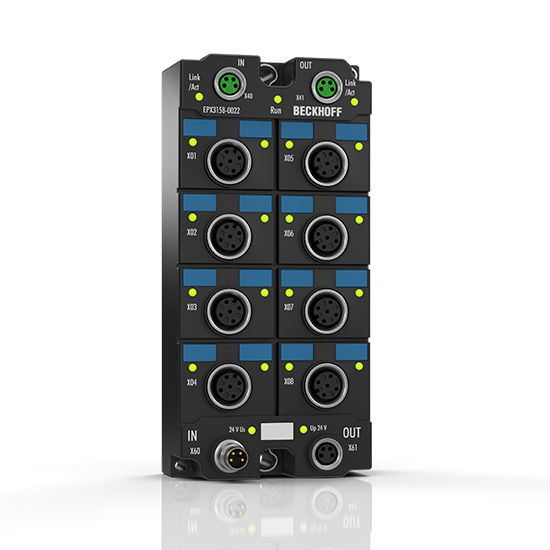

EPXxxxx | Explosion protection (Ex i)

The EtherCAT Box modules from the EPX series with intrinsically safe inputs/outputs enable the connection of field devices up to zone 0/20.