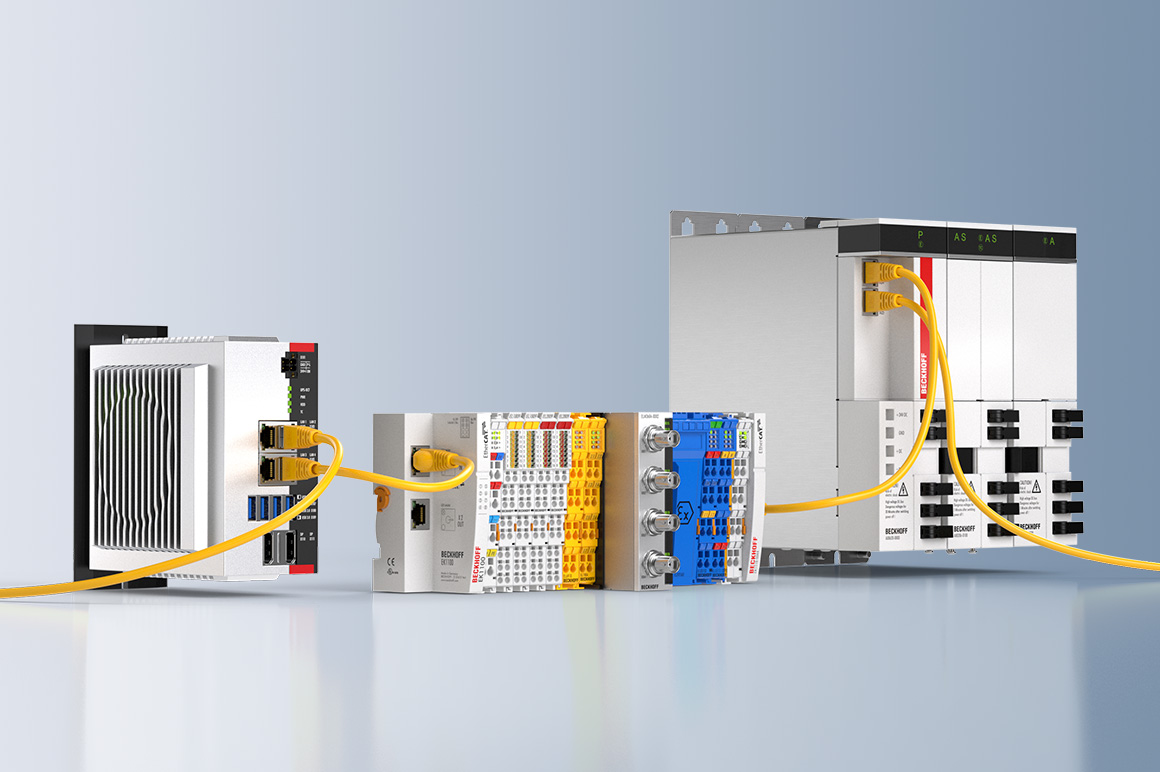

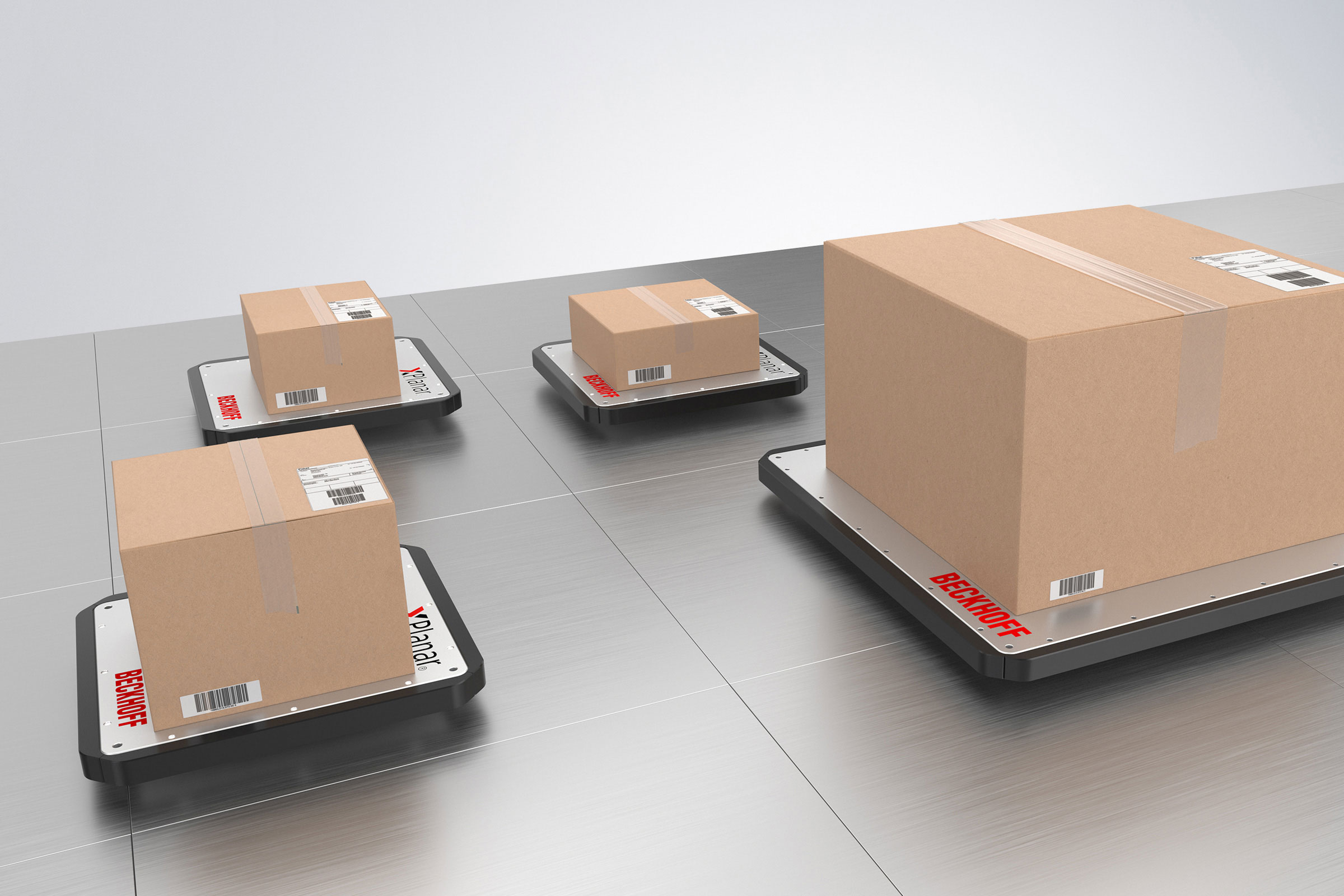

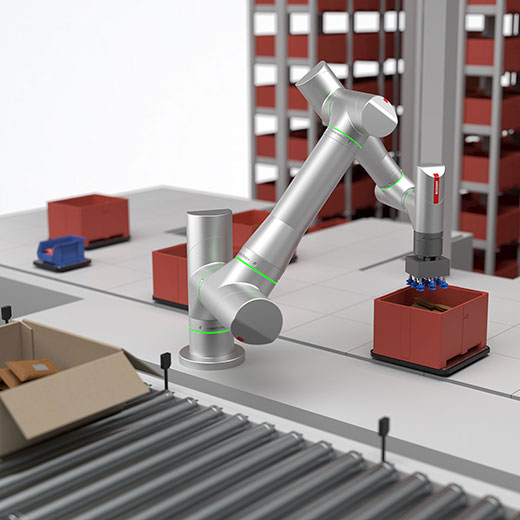

Control cabinet-free automation with the MX-System

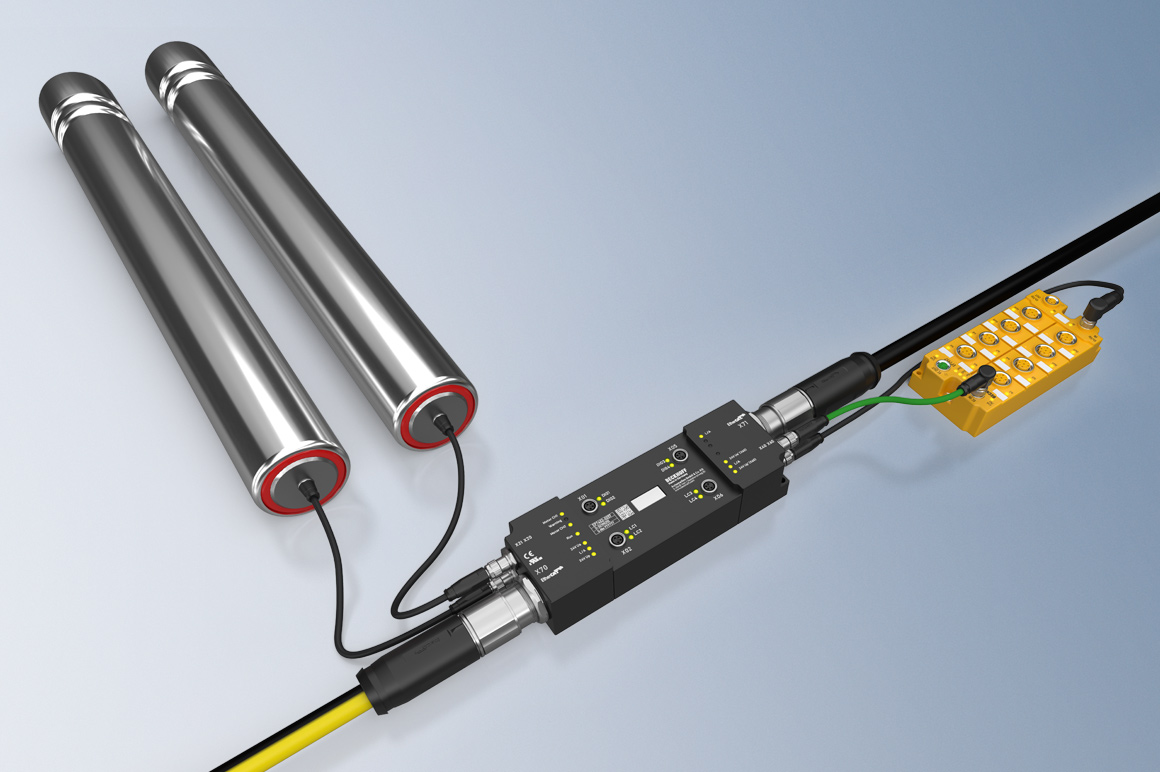

The MX-System is the first to provide completely control cabinet-free automation solutions in machine and system engineering. The combination of baseplate and function modules in this modular system combines all the tasks and properties of a control cabinet: power supply, fuse protection and power distribution, generation and monitoring of auxiliary voltages, sequence control with inputs and outputs, control of motors and actuators, and the connection level for the field devices. The consistently systemic approach greatly reduces the effort required for planning, machine installation, and maintenance. The system footprint is reduced, and system availability and flexibility are also increased.

The advantages of the MX-System for warehouse and distribution logistics:

- decentralization shortens cable routes, particularly in sprawling logistics centers

- exact scalability to logistics applications

- elimination of wiring errors and fast commissioning with the plug-and-play principle

- minimal downtime due to hot-swap functionality

- can be expanded flexibly with EtherCAT Box modules and integrated drive technology

- integrated diagnostics in each module for added system uptime