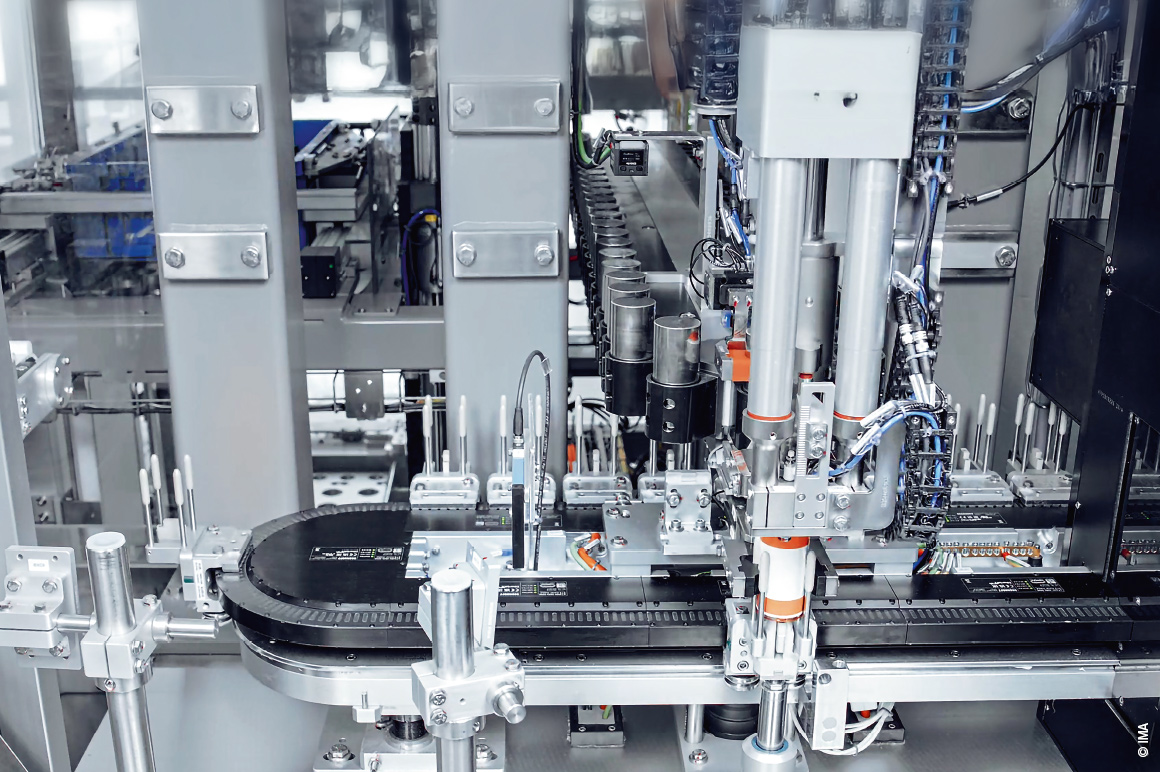

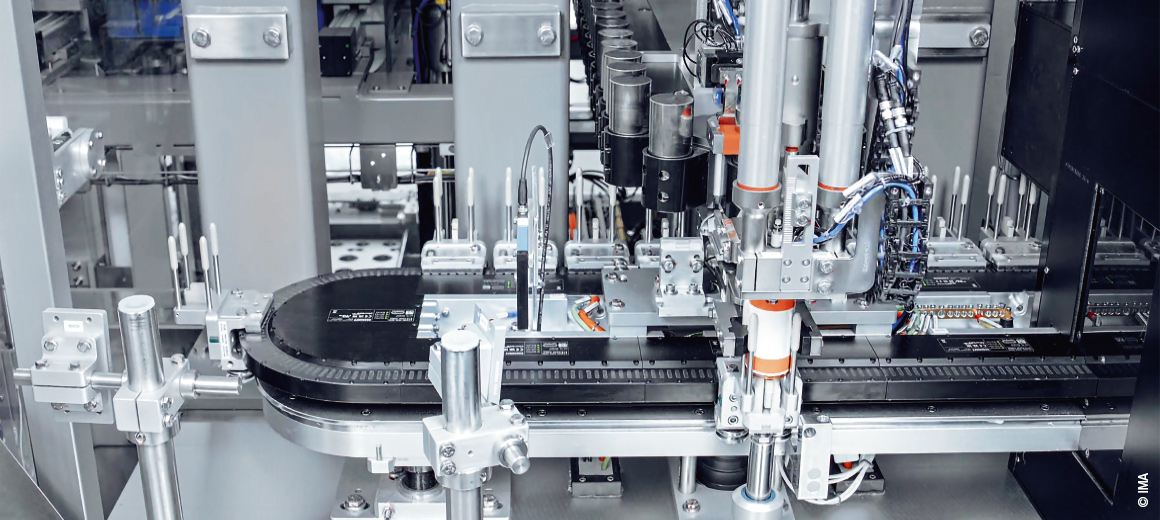

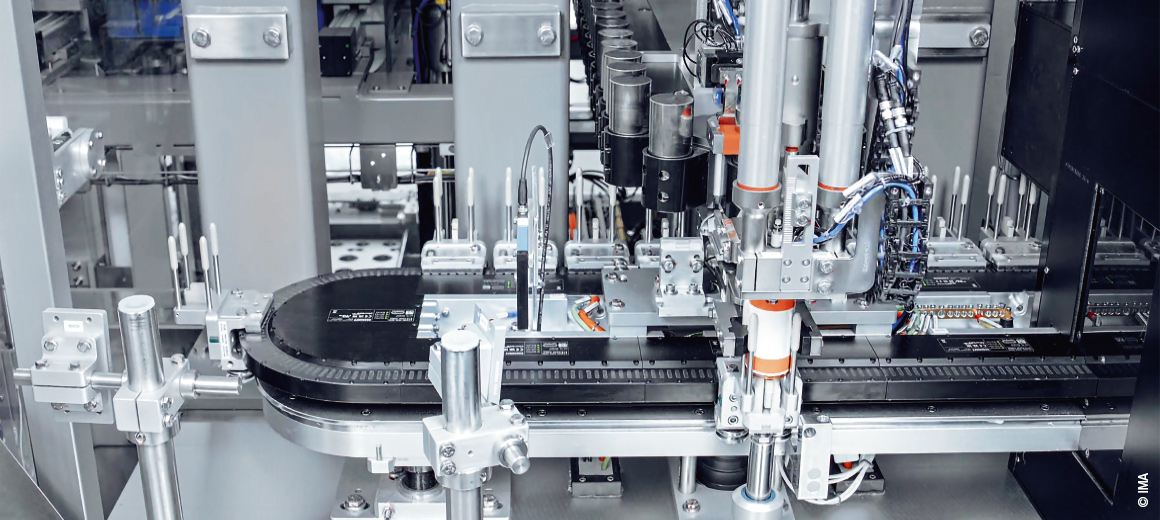

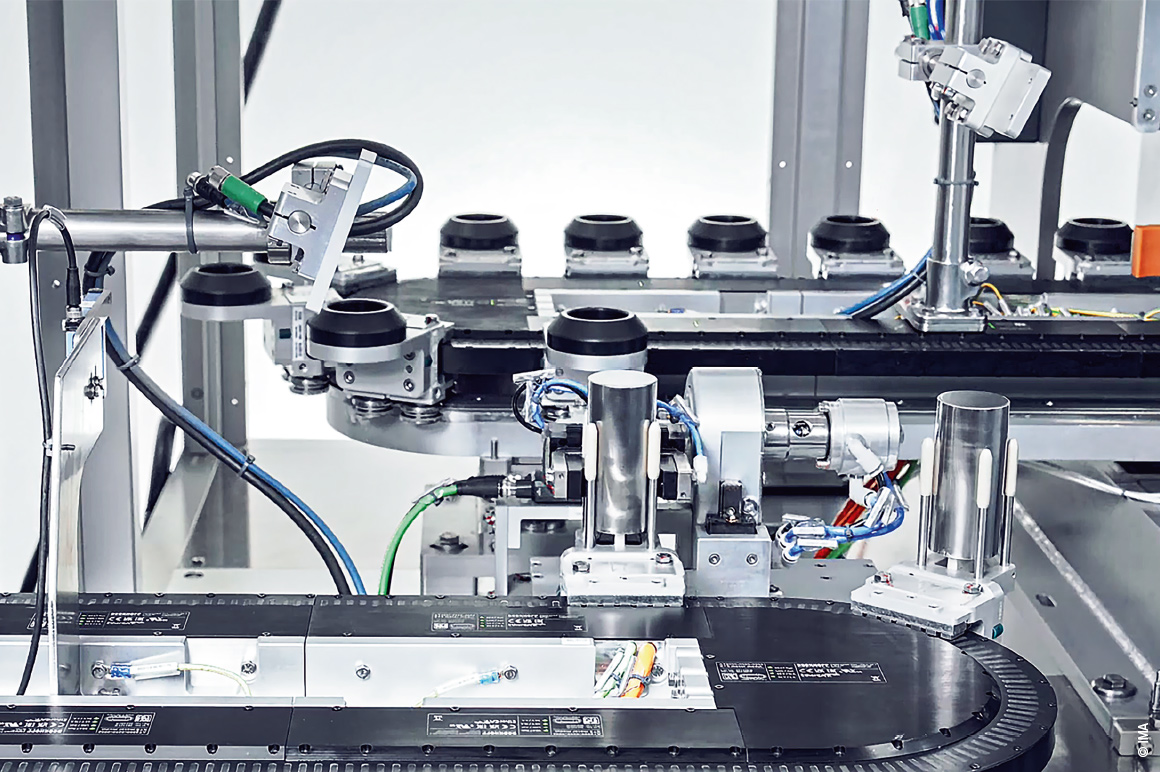

XTS in an assembly line for vehicle battery cells

IMA EV-Tech, a business unit of IMA Automation, has developed a new battery cell assembly line based on integrated Beckhoff technologies. The key element here is the XTS linear transport system, which features a high level of software functionality and a significantly more compact layout compared to conventional solutions. This results in an assembly line with high productivity and quality in operation combined with a minimized system footprint.

With more than 60 years of experience, over 7,400 employees, more than 3,500 registered patents, and an international network of factories and subsidiaries, IMA S.p.A. is a world leader in automated machines for the processing and packaging of pharmaceuticals, cosmetics, food, tea, and coffee. IMA EV-TECH was founded to strengthen its presence in the electric vehicle sector. This business unit of the IMA Automation division specializes in the development of technologies and complete assembly lines for electric vehicle solutions such as battery cells, hydrogen cells, electric traction motors, motor stators, and motor rotors. Fabio Tozzi, Sales Manager at IMA EV-Tech, comments: “The latest result is a high-performance system for assembling battery cells, which owes its development in part to the innovative contribution of Beckhoff automation solutions.”

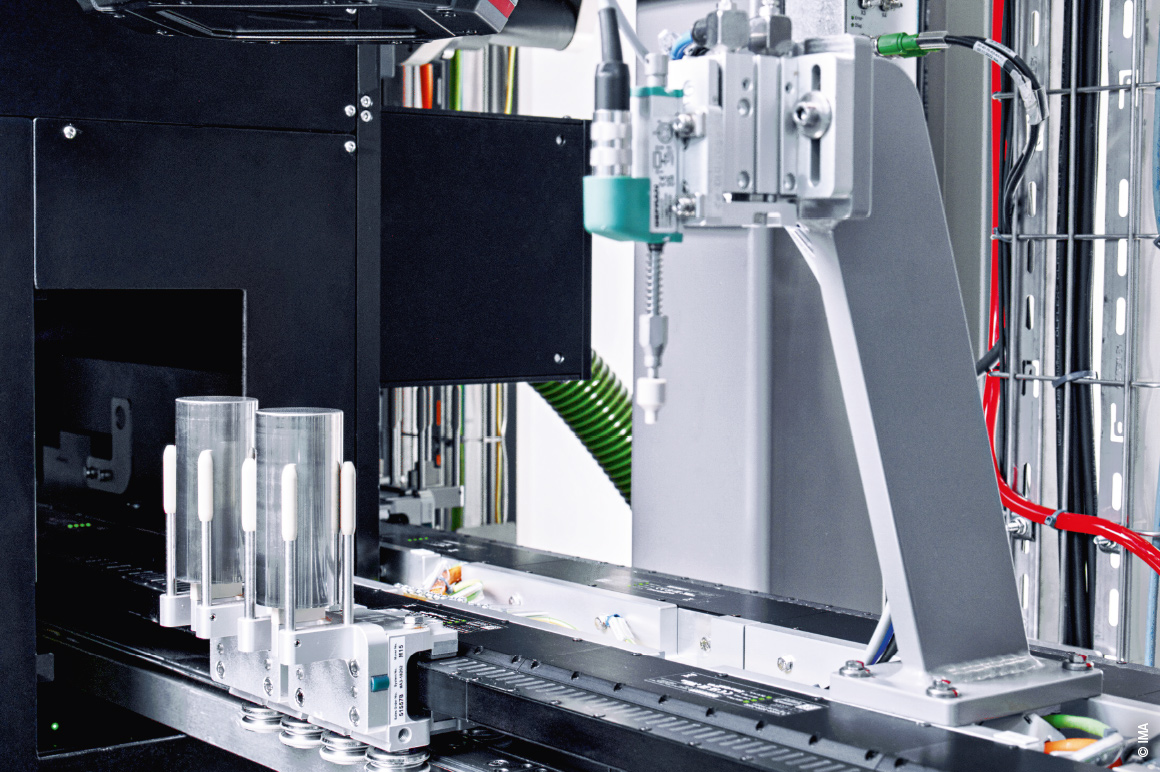

The individual battery cells look similar to small cylindrical cans. Although they are conceptually simple, producing them on a large scale is a rather complex process. The anode and cathode are separated by a polymer material and rolled together to form what is known as a jelly roll. The cell as a whole consists of this jelly roll and other elements in a cylindrical metal container that is hermetically sealed and filled with an electrolyte solution.

High performance and low space requirements with XTS

“The market is currently dominated by Asian manufacturers, especially from China and Korea,” explains Fabio Tozzi. “The lack of real competition at an international level has so far resulted in little technological development of the available solutions. In this environment, our assembly line stands out due to its high productivity and assembly quality, its small footprint and, above all, its very competitive total cost of ownership.” The XTS product transport system with its individual control of all movers plays a key role in this innovative solution. It enabled the individual phases of the assembly process to be decoupled and made it possible to overcome the limits previously imposed by a strictly sequentially controlled production process. In this way, it was possible to increase the speed and precision while reducing the working space.

XTS and PC-based control are nothing new for IMA, as the company has been working with Beckhoff for many years and uses products including embedded PCs, panel PCs, TwinCAT software, EtherCAT, and the corresponding I/O components as well as drive technology. In addition to these basic components of the Beckhoff automation architecture, IMA has already used XTS successfully in some of its recently developed solutions for the pharmaceutical sector and food and beverage industry, among others. “XTS is a system that offers very interesting application possibilities for our goals,” says Fabio Tozzi. “With the flexibility of PC-based control and the TwinCAT automation software in particular, XTS offers us a major advantage – namely the ability to manage the individual movers with special motion profiles. This has proven to be ideal for the specific characteristics of this application.”

Assembly line comprising five modules

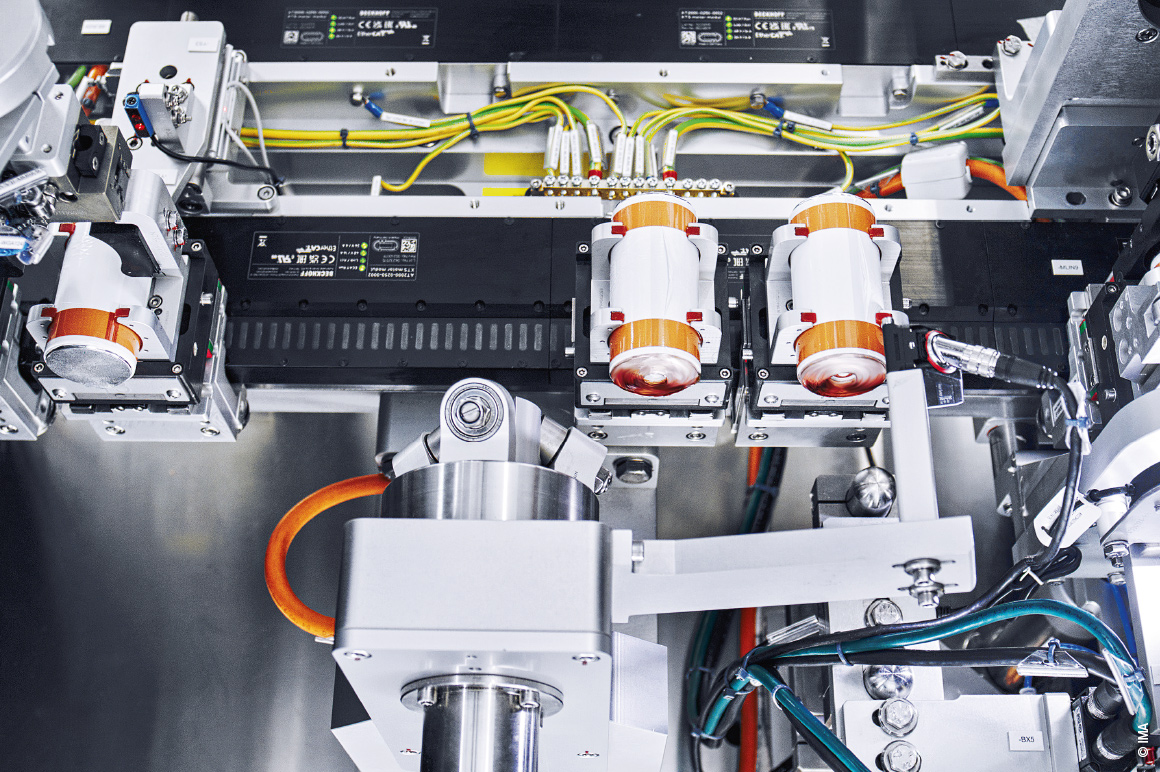

Each system section is equipped with a C6030 Industrial PC and a CP3916 multi-touch Control Panel, with an additional CP3918 Control Panel integrated in three sections. The entire control system is equipped with advanced servo drive technology for high performance and reliability, including the AX8000 multi-axis servo system, the AM8000 servomotors, and the AMP8000 distributed servo drive system. To make the process even more efficient, five enclosed XTS systems with a total length of approx. 43.5 m are provided for linear product transport within the system.

According to IMA EV-Tech, the application is characterized by a modular and efficient structure that enables orderly and easily scalable management of the production process. The division of the assembly line into functional sections corresponds to a clear operating logic, while the integration of industrial PCs and modern control panels ensures reliability and easy monitoring. The use of XTS also enables an approach that is geared toward maximum flexibility and precision in parts handling and complies with the latest standards of industrial automation.

Sophisticated cell assembly

Assembling battery cells involves a number of challenges, as handling, manipulation, and inspection must be managed with very high throughput and high demands on the quality of the end product. The system must therefore not only be fast, but also guarantee very high precision, which the XTS movers ensure with a positioning accuracy of ±0.25 mm.

The assembly phases are combined with functional and visual inspection processes, which are carried out using elements such as image processing systems and X-ray detectors. If these processes were carried out completely sequentially, some process steps – such as the aforementioned checks – could develop into potential bottlenecks due to the longer throughput times. This is where the flexibility of XTS comes into play, especially with the ability to place multiple cells simultaneously on multiple instances of slower workstations. According to IMA EV-Tech, this enables a significant increase in system throughput.

Another factor to consider is that production lines often have to operate in clean and dry rooms in order to prevent contamination from a wide range of sources and thus ensure the quality and durability of the battery cells. These are classified environments in which critical environmental parameters such as temperature and humidity – to prevent oxidation or corrosion – as well as particle concentration are strictly controlled. In this context, using machines that not only increase productivity but also require less space is a great advantage. For IMA EV-Tech, this is the only way to make optimum use of the available space and ultimately increase the profit margin.

For the new assembly line, IMA EV-Tech relies almost entirely on the Beckhoff ecosystem: IPCs, panel PCs, communication modules, I/Os, AX8000 servo drives, AM8000 servomotors and the AMP8000 distributed servo drive system, EtherCAT (with Safety over EtherCAT, FSoE), TwinCAT and, of course, XTS as the heart of the overall system. It was an obvious choice for Fabio Tozzi, especially as the openness of PC-based control did not rule out the possibility of integrating third-party devices, e.g., electrical inspection systems, specific controllers, or ad hoc handling systems. He adds: “The support offered by Beckhoff proved to be crucial. The direct contact with the Italian subsidiary and, if necessary, with the head office in Germany proved to be a key factor that led us to a genuine technological partnership. We also took part in training that enabled us to get to know the XTS system thoroughly and thus utilize its full potential.”

Particularly high system flexibility

Although the shape and size of the battery cells are defined as standard, the assembly line must also be able to process certain product variants. This requires additional steps, such as the incorporation of plastic elements. A system of this kind, to be able to adapt quickly to different production requirements, must work very efficiently. According to Fabio Tozzi, the XTS system and TwinCAT were the key elements in ensuring the success of the project in this context.

With the assembly line developed by IMA EV-Tech, new stations and devices can also be integrated if required. This increases system flexibility – so that, for example, new work processes can be added in the future or, alternatively, certain process steps can be selectively excluded. All of this makes it easier to manage product variants without compromising the overall performance of the line. “In parallel to the assembly line for cylindrical battery cells, we have developed assembly solutions for prismatic cells,” adds Fabio Tozzi. “Their shape and composition, which varies greatly in terms of size, process sequence, and components to be assembled, requires an additional degree of flexibility. Our aim is to provide the market with modular solutions that can be adapted to the needs of each individual customer and integrate all the necessary processes. At the same time, we want to further increase the performance of the systems and reduce the number of operators required to operate them. This is a factor that is particularly important with regard to relocating production activities from Asia to Europe or the United States.”