System portfolio to support energy management in accordance with ISO 50001

Transparent energy monitoring reduces both machine standstills and the need to oversize the corresponding components to assure plant availability. Preventive maintenance and ultimately a considerably increased production efficiency are also benefits here. With its portfolio of integrated power measurement, Beckhoff simplifies energy management while at the same time optimizing the availability of machines and plants. Due to the continuous, system-integrated power measurement, deviations from the standard state can be detected quickly, thus enabling targeted intervention. For example, if a machine's power consumption continuously increases, this may indicate bearing wear, while decreasing power consumption may indicate quality problems. By monitoring the power supply, erroneous behavior can be attributed to a potential phase failure in the power grid. The reaction speed is reduced and possible downtimes are avoided.

In addition to EtherCAT Terminals, the power measurement portfolio also includes current transformers which have optimum compatibility with the I/Os and a software library for monitoring with TwinCAT. Suitable accessories are available for additional safety in the control cabinet. This results in a complete package: all components can be procured from a single source.

A comprehensive system portfolio

There is a wide variety of requirements for energy management in the machine environment and in the energy economy, ranging from pure grid monitoring and process control through to high-end power monitoring. The power and energy measurement terminals focus on different aspects and are therefore designed for a wide range of applications.

The portfolio for power and energy measurement technology also contains products designed for medium voltage. Voltages in the medium voltage level can simply be connected to our terminals with a measuring range of up to 130 V AC via standard voltage transformers with a 100 V or 110 V output.

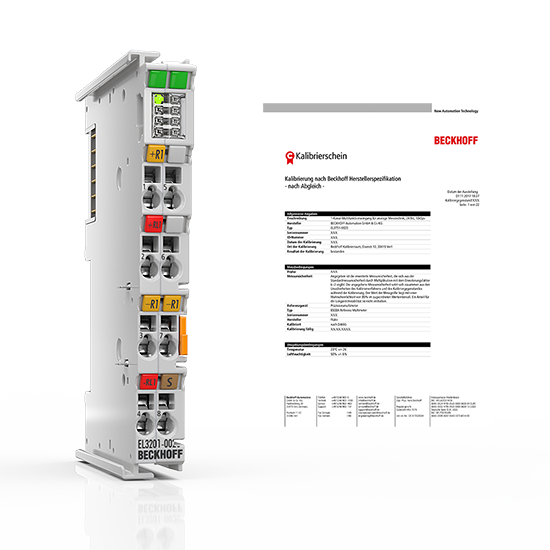

Calibrated terminals are necessary for some applications if, for example, information on the measuring behavior and uncertainty is to be gained for quality reasons. Calibrated terminals with the identifier "-0020" are also available.

| EtherCAT Terminal | Area of application | |||

|---|---|---|---|---|

| EL3423 | Simple threshold checking for voltage, frequency and phase with output of warning and status bits with IoT and energy management projects | |||

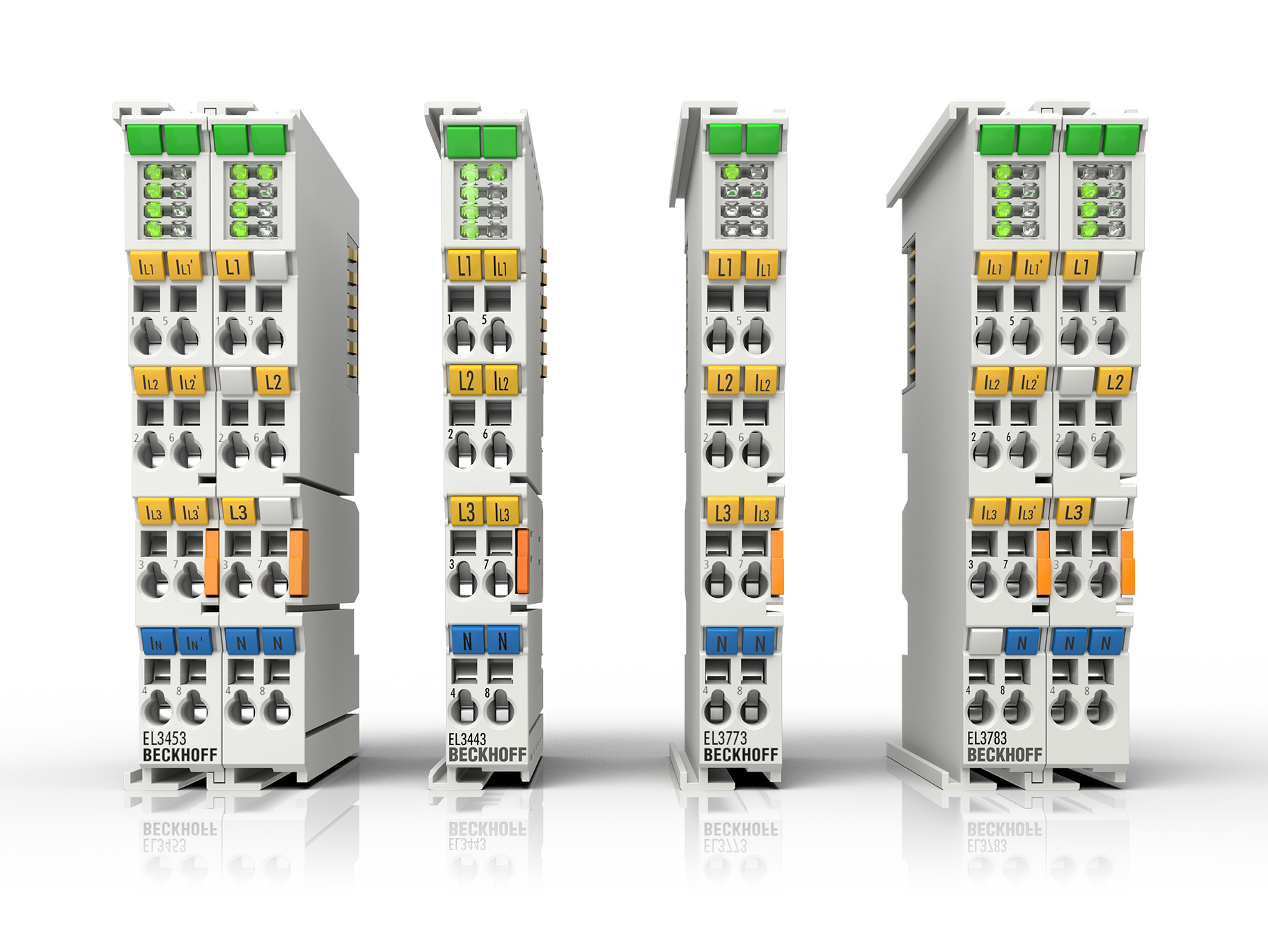

| EL3443, EL3453 | High-feature applications for 3-phase networks, internal preprocessing of current and voltage values, provision of up to 600 values for network analysis in the controller | |||

| EL3773, EL3783 | Network monitoring with oversampling function, simultaneous measurement of current and voltage on all channels at up to 10 ksps | |||

| EL3446, EL3444 + EL3443 | Distributed power measurement with as many EL3446/EL3444s as required and one EL3443 per network. With spatially separated current/voltage measurement, real power data can be determined | |||

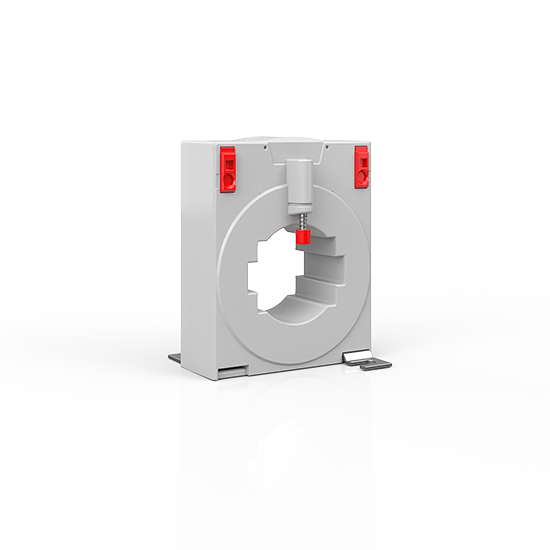

With the SCT current transformers, Beckhoff, as a system provider, enables implementation of reliable power sensors as an integral part of the PC-based controller directly in the field and completes the measuring chain, from recording the physical measurement value to data transmission to the cloud.

Users can choose between different concepts, each of which are highly scalable thanks to different designs and performance classes and are therefore suitable for any application, for current intensities from 1 to 5,000 A, and from ring-type and split-core current transformers up to 3-phase transformers. The SCT series is extremely diversified and offers low-cost transformer sets for building services, standard industrial transformers for mechanical engineering and solutions for test benches with particularly high demands in terms of accuracy.

The intended use is the deciding factor when choosing the variant. While data acquisition can be implemented cost-efficiently and with high measurement accuracy using the ring-type current transformers in new systems in particular, the split-core current transformers are the ideal straightforward retrofit solution as they are easy to attach.

SCT5564 | Ring-type current transformer for differential current

The SCT5xxx ring-type current transformers are all-current sensitive and thus suitable for detecting type B/B+ differential currents. As residual current monitors (RCM), their selectable settings make them flexible platforms for differential current measurement which are suitable for many applications. These devices can be used when planning an industrial plant or when expanding the plant with new, modern DC-based loads or high switching frequencies, which can increase the leakage current in the plant. In combination with the EL3444 EtherCAT Terminal, an additional form of power measurement can be implemented.

The TwinCAT Power Monitoring function is a PLC library for the evaluation of raw current and voltage data, which is generally provided by the EL3773 and EL3783 EtherCAT Terminals. Function blocks are available for calculating RMS values for current, voltage and power. These can be output as instantaneous or average values. Maximum and minimum values are also available on the function block. Frequency and frequency spectra can be determined, e.g., harmonics in the network and their load in the form of the total harmonic distortion (THD).

All blocks are available for single-phase and 3-phase systems. The TwinCAT products TE1300 TwinCAT 3 Scope View Professional and TF6420 TwinCAT 3 Database Server are suitable for displaying or permanently storing the data.

The TF6735 TwinCAT 3 IoT Communicator app offers a simple solution for monitoring and analysis of TwinCAT process data on mobile end devices.

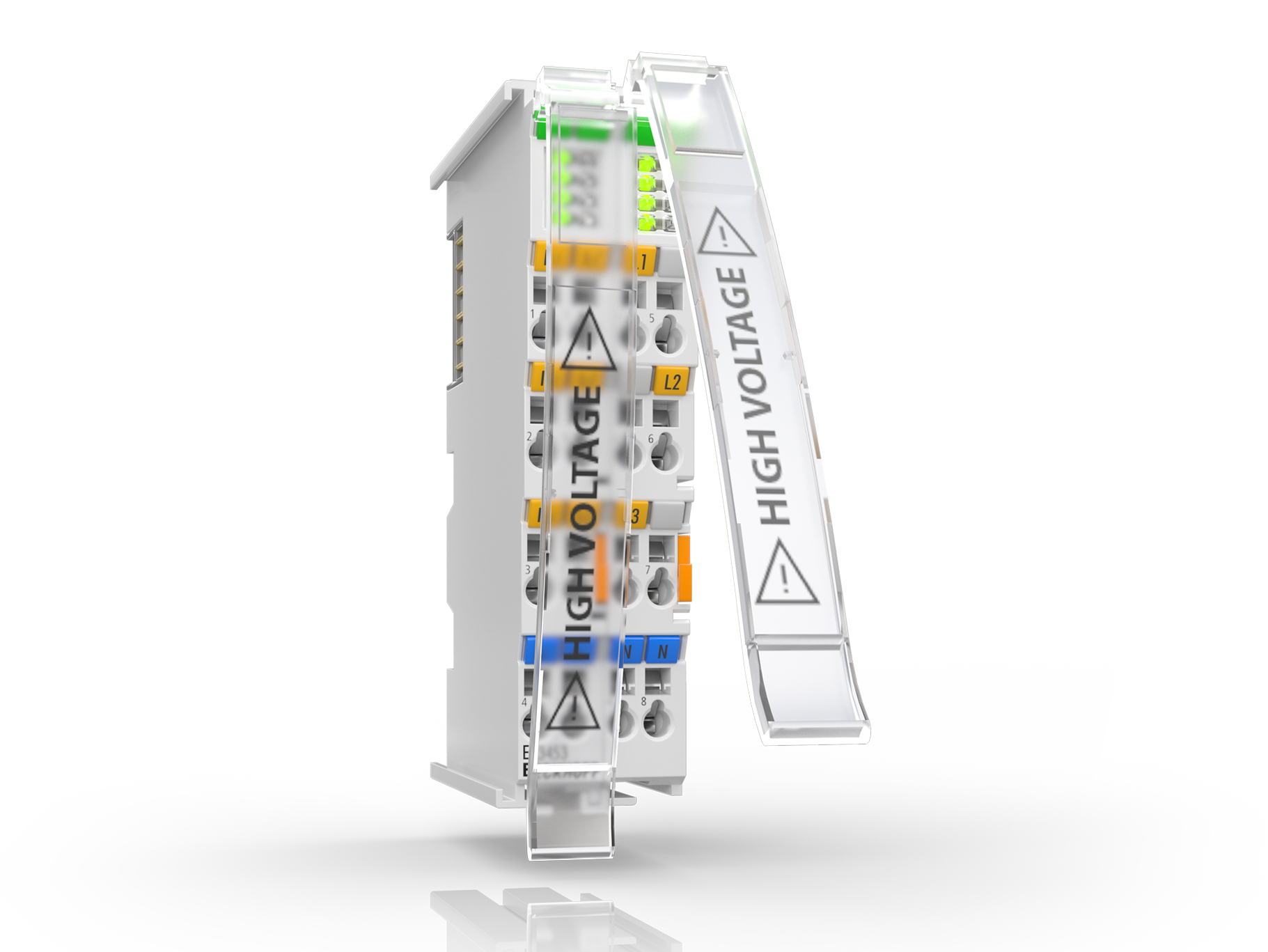

Standard signal voltages in the I/O system are generally ≤ 48 V. For power measurement, the signal voltage is often ≥ 230 V, so additional safety must be assured to prevent injury to persons. For this purpose, Beckhoff offers various options for marking the power measurement terminals.

- Marking via additional I/O station by means of EtherCAT Coupler. Voltages < 48 V and < 690 V are separated

- Marking by EL9080 separation terminal with signal color

- Marking by BZ3201 plug-in labeling cover with "HIGH VOLTAGE" marking

In order to simplify the assessment of current performance values for the user as much as possible, Beckhoff has developed the power quality factor (PQF). This guide value enables you to assess the voltage quality in the environment of a plant on the basis of a single numerical value without having to analyze frequency, voltage, THD/harmonics and symmetry separately. For example, if an error occurs on a machine and the PQF drops to zero at the same time, it can be concluded that it is probably not the machine itself, but a change in the power supply that caused the error. Using this method, the signs and effects of a fault can be rectified more quickly, as can, most importantly, the causes. At the same time, a falling PQF can be used as an early warning system.

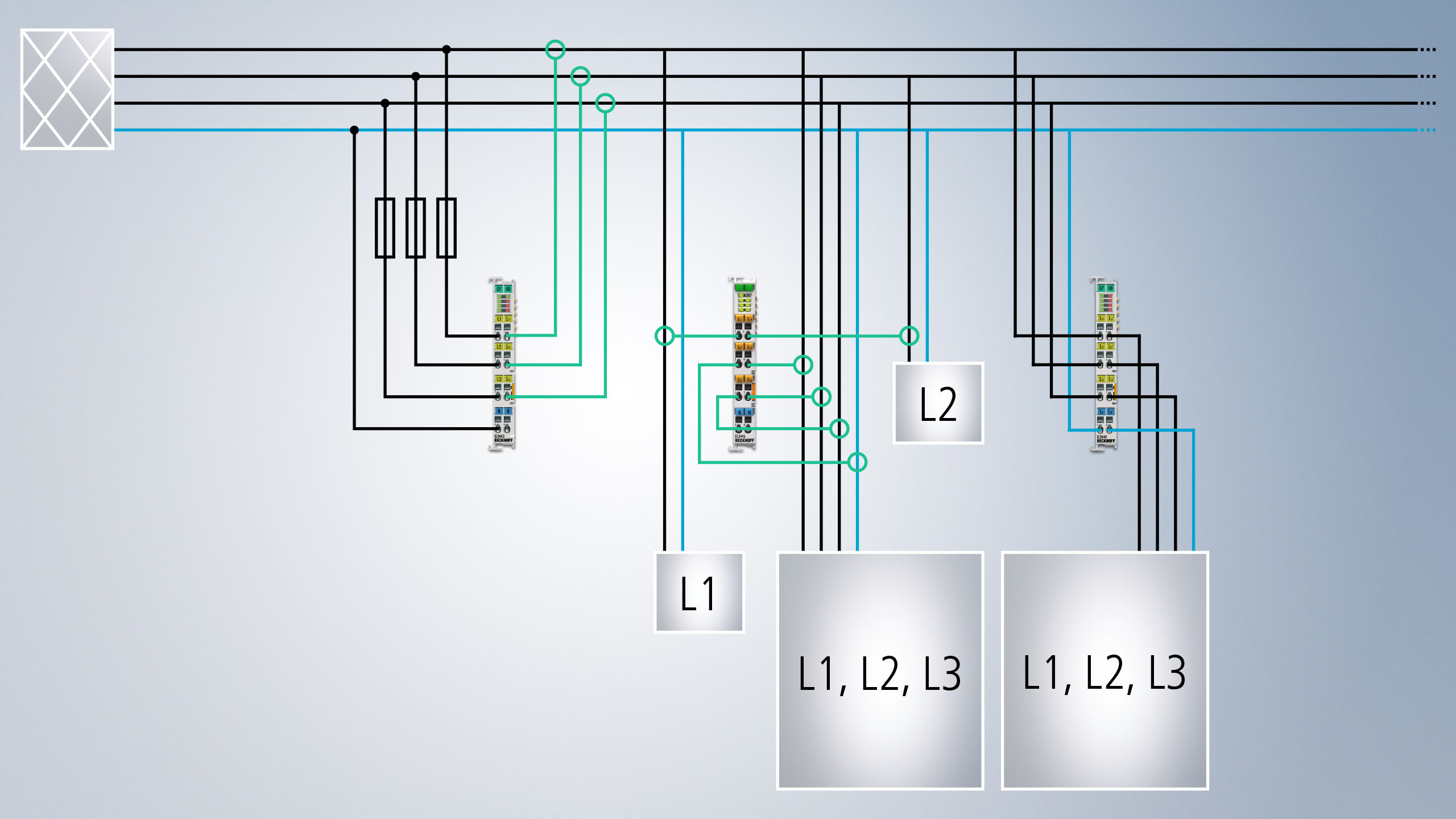

Effective power values can even be ensured for spatially separated voltage and current measurement with Beckhoff, using the distributed power management function of the EL3444 and EL3446.

On the one hand, the EL344x can be used in normal applications as standard current measuring terminals for 0 to 1 A (EL3446) or 10 A (EL3444) ranges. At the same time, they offer a world first: based on the EtherCAT-supported distributed clocks system, the EL344x enable power data, including calculation of the apparent, active and reactive power components, to be determined, despite locally separated measurement of current and voltage. The voltage measurement is only performed once: the signal is distributed to all current measurement terminals, time synchronization is performed by the distributed clocks of EtherCAT. The number of current measurements can be selected as desired; power calculation is performed by linking local current measurement values with the voltage values distributed via the EtherCAT network. The wiring work for the voltage distribution is eliminated. Equally, the channel price for the power measurement is reduced significantly without the sampling rate having to be lowered as the number of measuring points increases.

Scalability for all areas of application

Scalability is the chief principle at Beckhoff: this also applies to the EtherCAT Terminals for energy measurement, which cover applications ranging from simple network monitoring to power monitoring. They are scaled by different levels of performance in terms of measuring accuracy, measuring speed, and internally calculated values. Beckhoff provides a comprehensive range of EtherCAT Terminals for this that is highly scalable in terms of both price and performance.

Products

EL3423 | EtherCAT Terminal, 3-channel analog input, power measurement, 480 V AC/DC, 1 A, 24 bit

The EL3423 EtherCAT Terminal enables the measurement of relevant data for an efficient energy management system. The voltage is measured internally via direct connection of L1, L2, L3 and N. The current of the three phases L1, L2 and L3 is fed via simple current transformers. The measured energy values are available separately as generated and accepted values. In the EL3423 Terminal, the effective power and the energy consumption for each phase are calculated. In addition, an internally calculated network quality factor provides information about the quality of the monitored voltage supply. The EL3423 offers basic functionality for mains analysis and energy management.

EL3443 | EtherCAT Terminal, 3-channel analog input, power measurement, 480 V AC/DC, 1 A, 24 bit

The EL3443 EtherCAT Terminal enables the measurement of all relevant electrical data of the supply network and carries out simple pre-evaluation. The voltage is measured via direct connection of L1, L2, L3 and N. The current of the three phases L1, L2 and L3 is fed via simple current transformers. All measured currents and voltages are available as root-mean-square values. In the EL3443 terminal, the effective power and energy consumption for each phase are calculated. The RMS values of voltage U and current I as well as the active power P, apparent power S, reactive power Q, frequency f, phase shift angle cos φ and harmonic are available. The EL3443 offers extended functionality for mains analysis and energy management.

EL3444 | EtherCAT Terminal, 4-channel analog input, current, 10 A AC/DC, 24 bit, distributed power measurement, electrically isolated

The EL3444 EtherCAT Terminal enables the measurement of all relevant electrical data of the supply network and carries out simple pre-evaluation. Since the EL3444 itself has no voltage inputs, the voltage measured values are transmitted via EtherCAT by an EL3453 to be installed once per network. The current of up to six galvanically isolated phases is fed in directly. All measured currents and voltages are available as root-mean-square values. In the EL3444 terminal, the effective power and energy consumption for each phase are calculated. The RMS values of voltage U and current I as well as the active power P, apparent power S, reactive power Q, frequency f, phase shift angle cos φ and harmonic are available. The EL3444 offers extended functionality for mains analysis and energy management.

EL3446 | EtherCAT Terminal, 6-channel analog input, current, 1 A, 24 bit, distributed power measurement

The EL3446 EtherCAT Terminal enables the measurement of all relevant electrical data of the supply network and carries out simple pre-evaluation. Since the EL3446 itself has no voltage inputs, the voltage measured values are transmitted via EtherCAT by an EL3443 to be installed once per network. The current of up to six phases is fed via simple current transformers. All measured currents and voltages are available as root-mean-square values. In the EL3446 terminal, the effective power and energy consumption for each phase are calculated. The RMS values of voltage U and current I as well as the active power P, apparent power S, reactive power Q, frequency f, phase shift angle cos φ and harmonic are available. The EL3446 offers extended functionality for mains analysis and energy management.

EL3453 | EtherCAT Terminal, 3-channel analog input, power measurement, 690 V AC, 0.1/1/5 A, 24 bit, electrically isolated

The EL3453 EtherCAT power measurement terminal is an advancement based on the EL3413. With up to 690 V AC, the voltage inputs are optimized for the direct monitoring of high-capacity generators, as in the wind power industry, for example. No upstream voltage transformer is required. The four current inputs are electrically isolated so that the terminal can be used in all common grounded current transformer configurations such as 2- or 3-transformer configurations with star or delta connection incl. neutral conductor current measurement. The EL3453 can be used for simple grid analysis up to the 63rd harmonics analysis. Alternatively, all readings can be combined in a power quality factor for simplified diagnostics. Like all measured terminal data, the harmonic content can be read via the process data. The EL3453 offers the “ExtendedRange” feature enabling the use of the full technical measuring range, which equals 130% of the specified nominal measuring range.

EL3453-0100 | EtherCAT Terminal, 3-channel analog input, power measurement, 130 V AC, 0.1/1/5 A, 24 bit, electrically isolated

The EL3453-0100 EtherCAT power measurement terminal is an advancement based on the EL3413. The adapted voltage measuring range to 130 V is optimally suited for connecting medium voltage transformers, for example. The four current inputs are electrically isolated so that the terminal can be used in all common grounded current transformer configurations such as 2- or 3-transformer configurations with star or delta connection incl. neutral conductor current measurement. The EL3453-0100 can be used for simple grid analysis up to the 63rd harmonics analysis. Alternatively, all readings can be combined in a power quality factor for simplified diagnostics. Like all measured terminal data, the harmonic content can be read via the process data. The EL3453-0100 offers the “ExtendedRange” feature enabling the use of the full technical measuring range, which equals 130% of the specified nominal measuring range.

EL3483 | EtherCAT Terminal, 3-channel analog input, mains monitor, 480 V AC, 24 bit

The EL3483 EtherCAT Terminal enables the monitoring of relevant electrical data of the supply network. The voltage is measured internally via direct connection of L1, L2, L3 and N. The internal measured values are compared with threshold values preset by the user. The result is available as digital information in the process image. The EL3483 checks for the correct phase order L1, L2, L3, phase failure, undervoltage and overvoltage, and possible phase asymmetry. An error bit is set in the case of an incorrect phase order or the failure of a phase. Should, for example, an asymmetry or voltage error occur, only a warning bit is set initially. In addition, an internally calculated mains quality factor provides information about the quality of the monitored voltage supply. The EL3483 offers basic functionality for mains monitoring and analysis.

EL3483-0060 | EtherCAT Terminal, 3-channel analog input, mains monitor, 480 V AC, 24 bit, with analog values

The EL3483-0060 EtherCAT Terminal enables the monitoring of relevant electrical data of the supply network. The voltage is measured internally via direct connection of L1, L2, L3 and N. The internal measured values are compared with threshold values preset by the user. The result is available as digital information in the process image. The EL3483-0060 checks for the correct phase order L1, L2, L3, phase failure, undervoltage and overvoltage, and possible phase asymmetry. An error bit is set in the case of an incorrect phase order or the failure of a phase. Should, for example, an asymmetry or voltage error occur, only a warning bit is set initially. In addition, an internally calculated mains quality factor provides information about the quality of the monitored voltage supply. The EL3483-0060 offers basic functionality for mains monitoring and analysis. In addition, the -0060 version also outputs current RMS values of the voltage in the process image.

EL3773 | EtherCAT Terminal, 3-channel analog input, multi-function, 500 V AC/DC, 1 A, 16 bit, 10 ksps, oversampling

The EL3773 and EL3783 power monitoring terminals are designed for state monitoring of 3-phase AC voltage systems. For each phase voltages and currents are sampled as instantaneous values with a resolution of 16 bits:

EL3783 | EtherCAT Terminal, 3-channel analog input, multi-function, 690 V AC, 1/5 A, 16 bit, 20 ksps, electrically isolated, oversampling

The EL3783 EtherCAT Terminal is a power monitoring I/O terminal used for state monitoring of a 3-phase AC voltage system. For each phase, voltage up to 400/690 Vrms and current up to 1 Arms/5 Arms are sampled as instantaneous values with a resolution of 16 bits. The six channels are measured simultaneously based on the EtherCAT oversampling principle with a temporal resolution of up to 50 µs and then passed on to the control system. With the processing power available there and in combination with the TwinCAT Function TF3650, true RMS or power calculations as well as complex user-specific algorithms can be calculated via the voltage and current characteristics. Through the oversampling principle, the terminal is able to measure at significantly shorter intervals than the cycle time of the control system. AC and DC parameters must be connected and measured with a common reference potential.

EL3783-0100 | EtherCAT Terminal, 3-channel analog input, multi-function, 130 V AC, 1/5 A, 16 bit, 20 ksps, electrically isolated, oversampling

The EL3783-0100 EtherCAT Terminal is a power monitoring I/O terminal used for state monitoring of a 3-phase AC voltage system. For each phase, voltage up to 400/690 Vrms and current up to 1 Arms/5 Arms are sampled as instantaneous values with a resolution of 16 bits. The six channels are measured simultaneously based on the EtherCAT oversampling principle with a temporal resolution of up to 50 µs and then passed on to the control system. With the processing power available there and in combination with the TwinCAT Function TF3650, true RMS or power calculations as well as complex user-specific algorithms can be calculated via the voltage and current characteristics. Through the oversampling principle, the terminal is able to measure at significantly shorter intervals than the cycle time of the control system. AC and DC parameters must be connected and measured with a common reference potential.

Current transformers

The SCT current transformers are reliable power sensors at field level in the PC-based control architecture.

TF3650 | TwinCAT 3 Power Monitoring

The TwinCAT Power Monitoring function is a PLC library for the evaluation of raw current and voltage data, which are usually supplied by EL3773 and EL3783 EtherCAT Terminals. Function blocks are available for the calculation of RMS values for current, voltage and power. These can be output as instantaneous or average values. Maximum and minimum values are also available on the function block. Frequency and frequency spectra can be determined, such as e.g. harmonics in the grid and their load in the form of the Total Harmonic Distortion (THD).

BZ32xx | Insertable label cover, 11.5 mm x 104.5 mm, pluggable, transparent

The slide-in label covers enable clear labeling of the individual channels or text-based functional description of the terminals. The labels are inserted in the designated slots. For connecting the individual channels the label cover can be tilted upwards.

EL9080 | Separation terminal

The EL9080 separation terminal is used for the separation and marking of different potential groups (e.g., 230 V AC/24 V DC). It is inserted between two potential groups, and indicates the separation through an orange colored cover. The E-bus is passed through in the usual way to the adjacent terminal.

ELxxxx-0020/-0030 | Calibration certificates

The calibration certificates provide information on the exact measurement deviation of analog EtherCAT Terminals.

EL3403 | EtherCAT Terminal, 3-channel analog input, power measurement, 500 V AC, 1 A, 16 bit

The EL3403 EtherCAT Terminal enables the measurement of all relevant electrical data of the supply network. The voltage is measured via the direct connection of L1, L2, L3 and N. The current of the three phases L1, L2 and L3 is fed via simple current transformers. All measured currents and voltages are available as root-mean-square values. In the EL3403 version, the effective power and the energy consumption for each phase are calculated. The root-mean-square value of voltage U, current I and the effective power P, apparent power S, reactive power Q, frequency F and phase shift angle cos φ can be derived. The EL3403 provides a comprehensive network analysis and an energy management option.