In the midst of the mobility revolution and the subsequent expansion of electric vehicle production facilities, Beckhoff technology has been steadily finding its place in battery manufacturing and electric motor production for several years. Thanks to our many years of experience in body construction, tire production, and process, assembly, and handling technology, our customers can always rely on our in-depth technical expertise. As a close partner of automotive OEMs and machine builders, we also actively promote the standardization of machine communication in working groups such as the VDMA Battery Production group. A large number of references from a wide range of sectors across the automotive industry confirm the effectiveness of our control solution.

Current applications

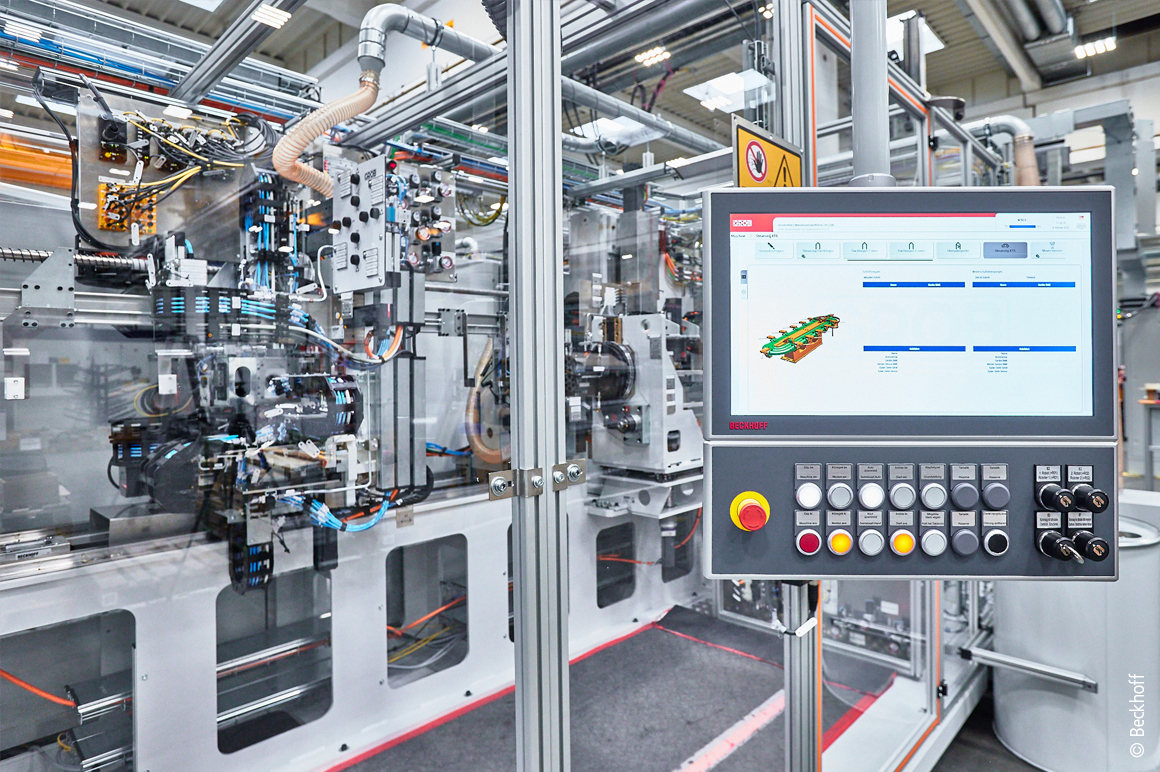

Flexible control technology increases efficiency in hairpin stator production lines

The machine tool manufacturer GROB is actively addressing the rapidly increasing significance of electromobility by implementing high-volume production and assembly systems. The decisive factors here are minimum cycle times and correspondingly fast process sequences, as enabled by PC- and EtherCAT-based control and drive technology from Beckhoff. A sophisticated production machine for hairpins, from which the stator winding rims of electric motors are formed, illustrates the advantages of this optimally scalable automation solution – e.g., with TwinCAT 3 on a C603x ultra-compact Industrial PC as the central control and with the XTS transport system.

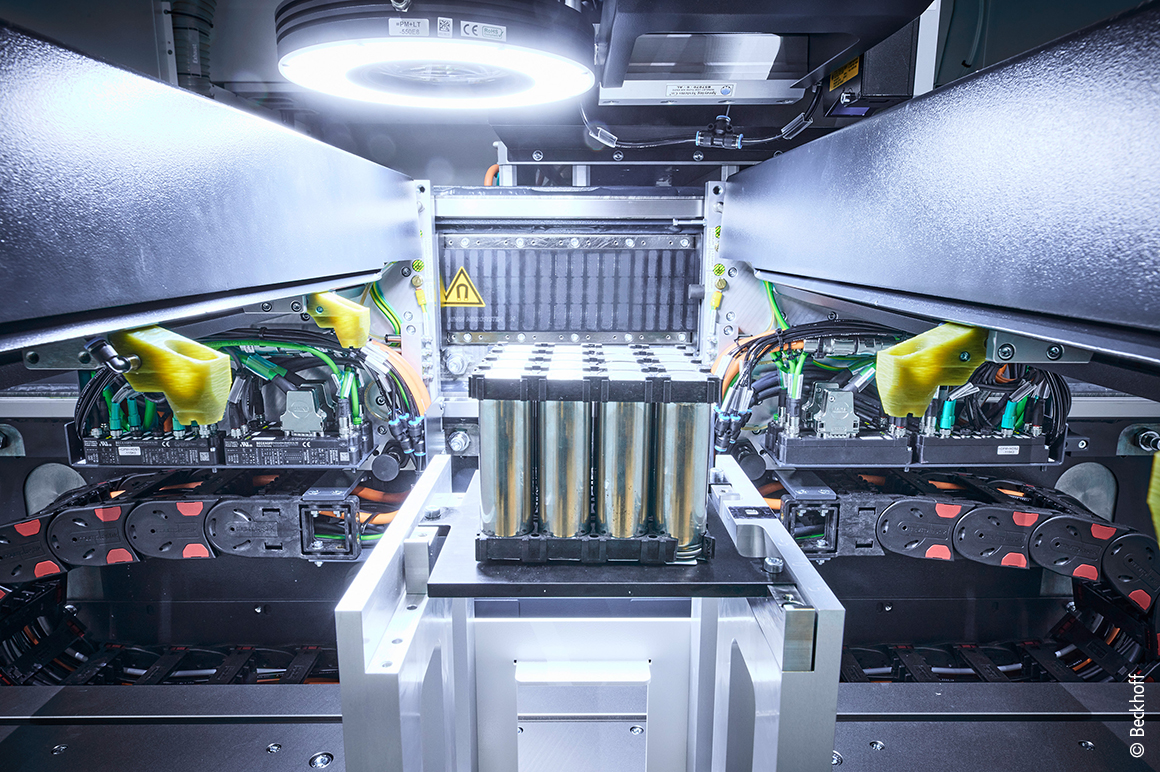

Automation for highly precise and efficient production of lithium-ion battery modules

The rapidly growing electromobility market calls for particularly efficient manufacturing processes when it comes to the production of lithium-ion battery systems. This is where the BLS 500 laser welding system from Manz makes for an ideal solution, as it allows individual battery cells to be precisely contacted and connected to form battery modules. A high level of efficiency is ensured by means of a graphical programming tool and a virtual commissioning tool from Manz, as well as rapid PC-based control technology from Beckhoff and the continuous OPC UA communication this facilitates.

PC-based control and EtherCAT in battery swap stations for electric vehicles

Chinese automaker NIO aims to provide high-quality smart electric vehicles combined with an optimal user experience. The NIO Power energy service system makes a valuable contribution in this regard, using PC-based control from Beckhoff to ensure safe and efficient operation of NIO’s second-generation battery swap stations.

Safety belt assembly with short time to market and increased system throughput

When it comes to building special machines for the demanding automotive industry, Sodecia’s Global Tech and Automation Center (GTAC) successfully applies principles from series production. The modernization of an assembly plant for seat belts is a prime example of the advantages of the PC- and EtherCAT-based control and drive technology from Beckhoff that is used as standard by the automotive specialist.

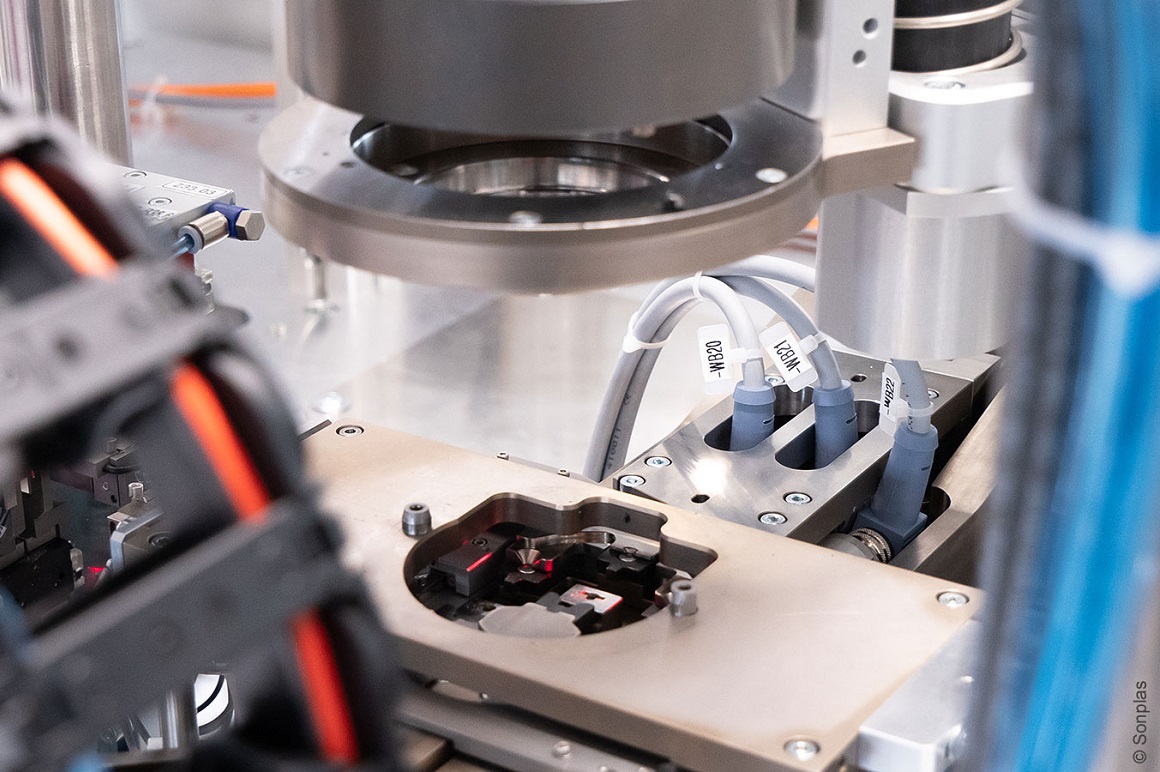

TwinCAT achieves high clock rates in the pre-assembly of stators

As new trends in mobility continue to emerge, the special machine manufacturer Sonplas is one of many companies that has been sharpening its focus on projects from the field of e-mobility in recent years. The company’s areas of activity include developing machines for rotor and stator assembly of electric motors. When it comes to the pre-assembly of stators, Sonplas relies on PC-based control from Beckhoff and benefits from the short cycle times of TwinCAT for maximum output and efficiency.