Products

EJ11xx | EtherCAT Coupler

The EtherCAT Couplers are the link between the EtherCAT protocol at fieldbus level and the EtherCAT plug-in modules.

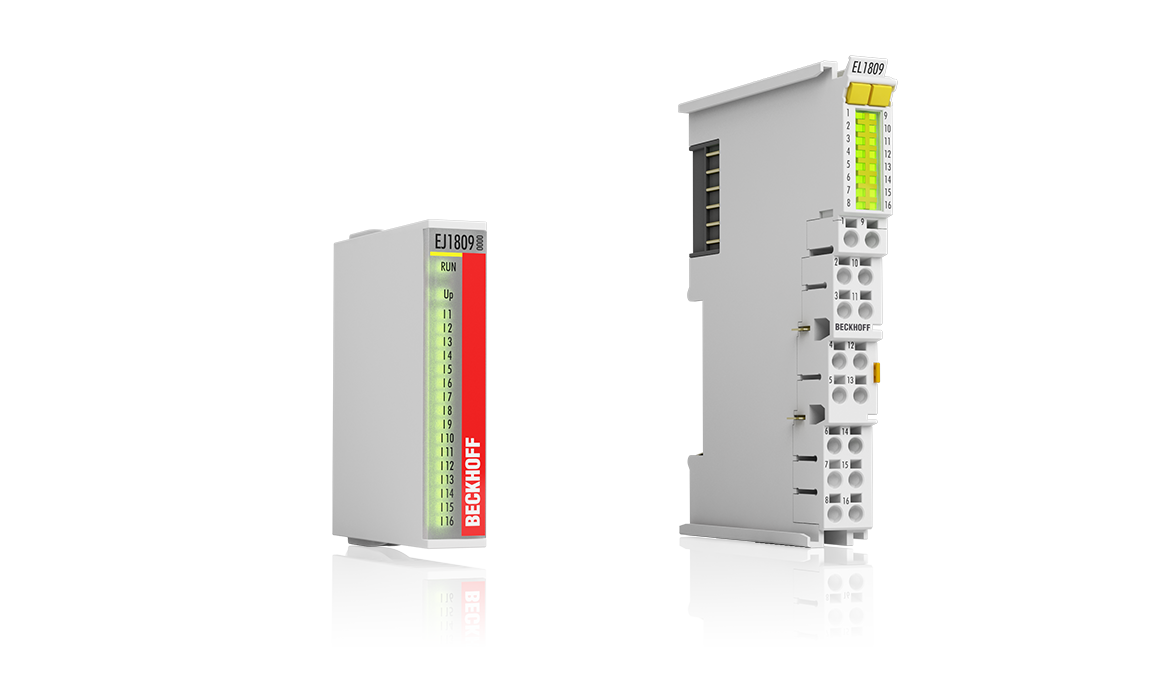

EJ1xxx | Digital input

The EJ1xxx EtherCAT plug-in modules enable the acquisition of binary signals from the process level.

EJ2xxx | Digital output

The EJ2xxx EtherCAT plug-in modules generate binary signals and forward them to the process level.

EJ3xxx | Analog input

The EJ3xxx series EtherCAT plug-in modules process a variety of analog signals.

EJ4xxx | Analog output

The EJ4xxx EtherCAT plug-in modules output analog signals with the levels 0…10 V, ±10 V, 0…20 mA and 4…20 mA.

EJ5xxx | Position measurement

The EJ5xxx EtherCAT plug-in modules are intended for the evaluation of complex signals from absolute and incremental encoders.

EJ6xxx | Communication

With the EJ6xxx EtherCAT plug-in modules, the EJ system becomes a universal gateway between different systems.

EJ7xxx | Compact drive technology

The EJ7xxx series EtherCAT plug-in modules enable the direct connection of various drive technologies.

EJ9xxx | System

The EJ9xxx EtherCAT plug-in modules complete the I/O system with power supply unit, brake chopper and placeholder modules.

EJxxxx-0090 | TwinSAFE SC

The TwinSAFE SC technology enables the user to use standard signals for safety tasks in any networks or fieldbuses.

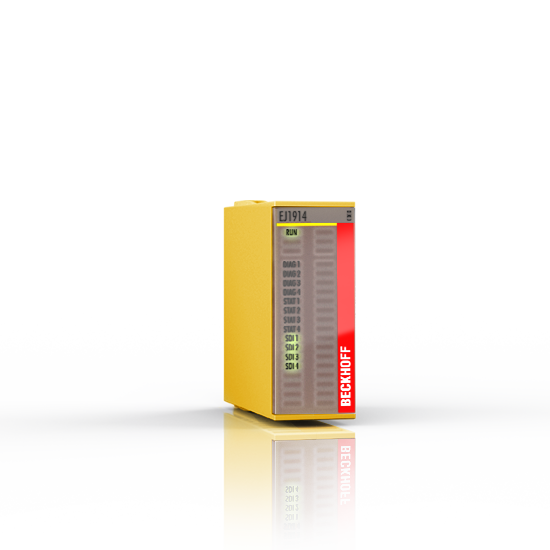

EJx9xx | TwinSAFE

With the integration of TwinSAFE, the high performance of EtherCAT is also available for safety technology.

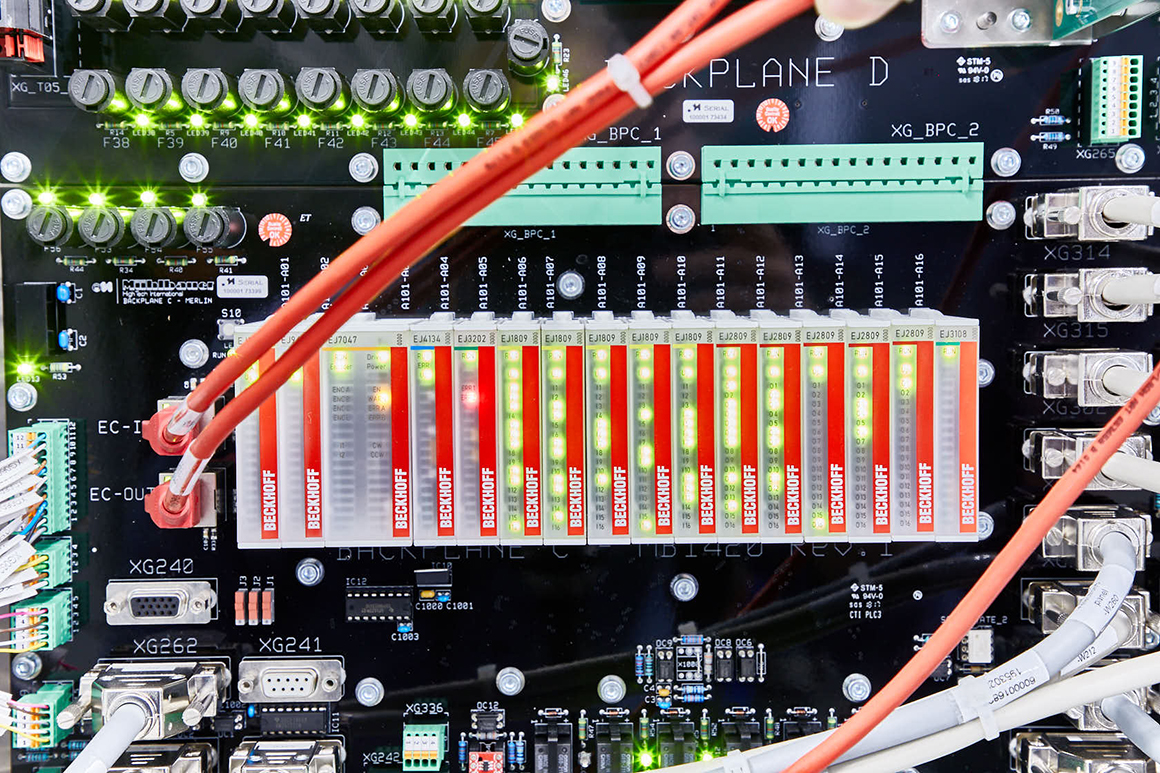

Signal distribution board

An application-specific signal distribution board is used to plug in the EJxxxx EtherCAT plug-in modules.

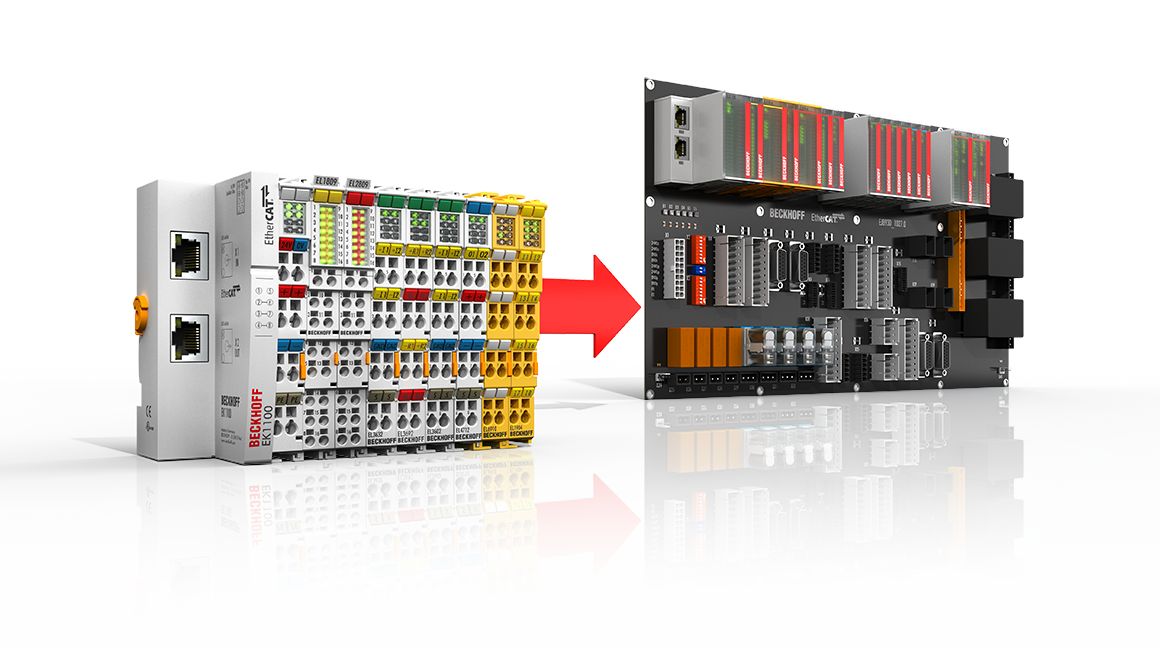

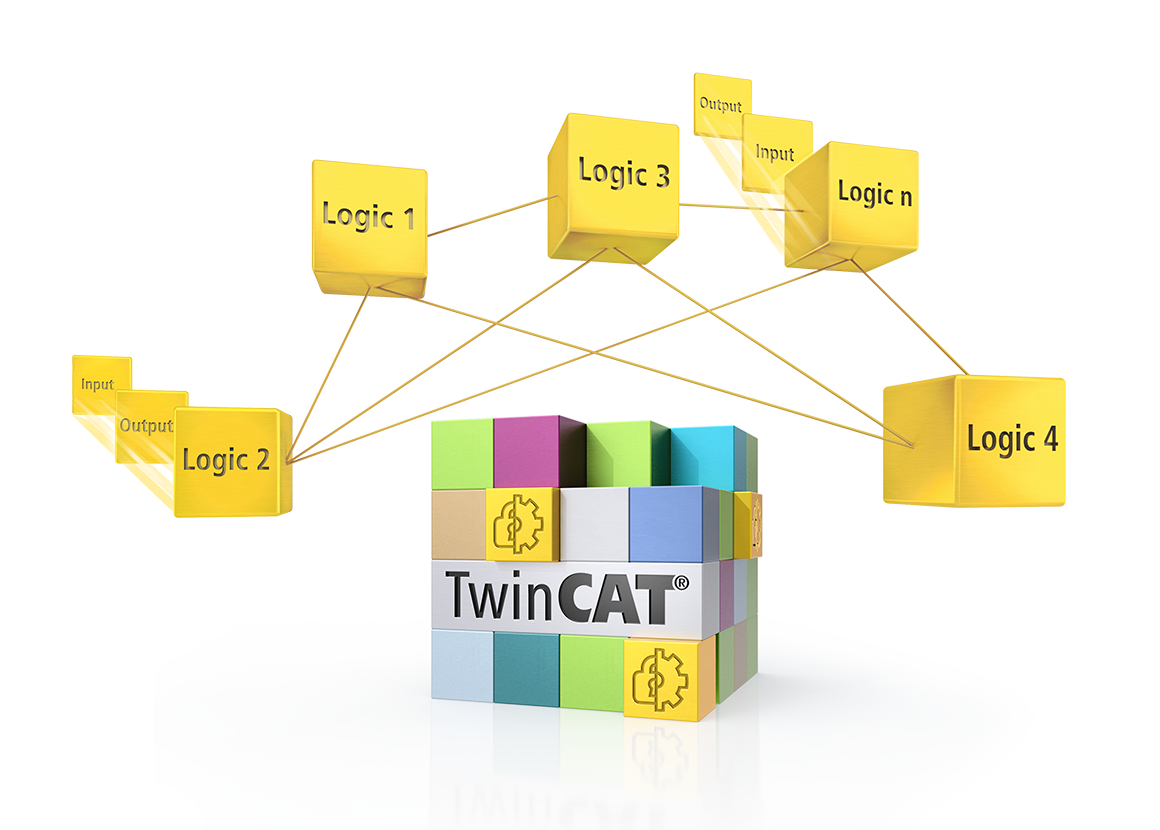

I/O expertise for series production: the EtherCAT plug-in modules

With the EtherCAT plug-in modules from the EJ series, Beckhoff, a specialist for PC- and EtherCAT-based automation solutions, provides the possibility of making serial productions with medium and high quantities much more efficiently. The EJxxxx EtherCAT plug-in modules are electronically based on the well-known EtherCAT I/O system and their design allows them to be directly plugged to a circuit board. The circuit board is an application-specific signal distribution board that distributes signals and power supply to individual plug connectors in order to connect the controller to further machine modules. Elaborate manual wiring of single wires, common in conventional control cabinet construction, is replaced by simply plugging in prefabricated cable harnesses. Unit costs are lowered and the risk of incorrect wiring is reduced to a minimum by coded components.

Advantages at a glance

Plug-and-work

The EtherCAT plug-in modules are not only electronically based on the well-known EtherCAT Terminals but also provide their wide range of signals, including functional safety (TwinSAFE). The electromechanical design enables the modules to be plugged directly into an application-specific signal distribution board with outsourced wiring level. This circuit board distributes signals and power supply to individual application-specific plug connectors in order to connect the controller to further machine modules. The combination of I/O modules, signal distribution board and pre-assembled cables implements the plug & work idea consistently.

Compact design

The EJ modules are extremely compact, measuring just 12 x 55 x 66 mm. Compared to the EtherCAT Terminals they are almost 50% smaller in relation to volume, thus optimizing the machine footprint. In conjunction with coding holes in the signal distribution board, coding pins on the underside of the EJ modules offer the option of providing protection against incorrect connection. The risk of errors can thus be considerably reduced during assembly and service.

Optimized for serial applications

The EJ plug-in modules and the plug level for sensors and actuators can be placed flexibly on the signal distribution board. The development of a signal distribution board is carried out by the user or as a customer-specific solution by Beckhoff. With the circuit boards in the EJ system, a prefabricated and pluggable EtherCAT I/O system is available. Communication, signal distribution and module supply take place via the rear of the modules and PCB tracks on the signal distribution board.

At the same time, the wiring effort is reduced considerably: All connection types with pre-assembled cables and coded plugs can be placed on the signal distribution board specific to each customer. The error probability is reduced due to the lack of conventional wiring and work processes are simplified.

The EtherCAT plug-in modules offer an alternative to the classic control panel with single-core wiring in the control cabinet, as they massively reduce the assembly effort, the system installation time and the testing effort and no longer necessarily require the use of electrical specialists in the assembly.

Cost reduction

The manufacturing process is accelerated as far as possible and the risk of wiring errors is reduced with the EJ system. This saves working time and thus costs. It allows production at different locations worldwide with a minimum of risk, since errors are avoided by concept through automation and coding.

The EtherCAT plug-in modules offer an alternative to the classic control panel with single-core wiring in the control cabinet, as they massively reduce the assembly effort, the system installation time and the testing effort and no longer necessarily require the use of electrical specialists in the assembly.

Integrated safety

Like the familiar EtherCAT I/O system, the modular TwinSAFE system was also adapted in the design of the EJxxxx EtherCAT plug-in modules. Modules are thus available for securely recording, processing and outputting safety-relevant signals. As a dedicated safety controller, the EJ6910 represents the new generation of safety controllers. Besides Boolean values, analog values can also be safely processed with the help of certified function blocks, meaning that very complex safety applications can also be implemented.

Another highlight of the TwinSAFE system in the context of the EtherCAT plug-in modules is the integration of the TwinSAFE Logic functionality in all other TwinSAFE modules. The EJ1957 module with 8 safe inputs and 4 safe outputs can therefore be used, based on the integrated logic functionality, to implement a complete safety application using a single module. The modules with integrated TwinSAFE Logic can naturally continue to communicate with other TwinSAFE modules via FSoE.

The use of TwinSAFE EtherCAT plug-in modules implies certain requirements of the application-specific signal distribution board to be able to use this for safety applications. To do so, the design guide “EJ backplane for TwinSAFE modules” must be followed. The TwinSAFE application is programmed using the TwinCAT 3 Safety Editor.

EJ system in use

Wherever the Beckhoff EJ system is used, benefits can be gained for the user. The minimized wiring effort reduces installation costs. Coded modules and pre-assembled cable harnesses reduce wiring faults and subsequent costs for corrections. This enables the supply chain to be streamlined, which not only facilitates work preparation and order processing, but also reduces the risk of production down time due to interrupted supply chains. Tested components improve the quality of the machine due to increased availability. Prefabricated components reduce machine delivery times. Individual, compact solutions can also be used where space is limited.

With the signal distribution boards, the interconnection remains hidden from prying eyes – unlike a control cabinet, whose wiring and parts list can be copied without much effort. The know-how protection provided by the EtherCAT plug-in system is an advantage not be underestimated in international competition.