Generating sustainable growth with PC-based control

It really does pay to save energy. Not only is it good for our environment, but it also helps counteract the massive price increases for primary energy sources. Every kilowatt hour of unconsumed energy, every kilogram of unreleased CO2 counts. It is with this in mind that Beckhoff has been setting the wheels in motion across its production processes and existing buildings for quite some time now, with a firm focus on its ultimate goal of achieving carbon neutrality.

In terms of action already taken, Beckhoff implemented a successful energy management system in 2016 and was certified by TÜV Süd in line with ISO 50001 standards in the same year. The energy management system helps to steadily reduce the company’s costs and energy consumption by continuously recording all relevant consumption. Analyzing this information reveals potential for further measures to reduce energy consumption. In this way, Beckhoff not only demonstrates its compliance with legal requirements, but also lives up to its responsibility for climate and environmental protection. After all, less energy consumption automatically leads to a massive reduction in carbon emissions, which is set to be the major challenge for all companies going forward as we look to achieve a climate-neutral economy. Beckhoff is rising to this challenge and setting itself ambitious goals:

- to improve energy-related performance by 0.5% annually

- to create climate-neutral sites for Beckhoff Automation GmbH & Co. KG by reducing and offsetting carbon emissions

“We are committed to increasing the energy efficiency of our company,” says Johannes Beckhoff, who is responsible for general energy management in the energy team at Beckhoff in addition to his role as XPlanar product manager. In concrete terms, the commitment means continuously improving energy-related performance (energy consumption in kWh per 1,000 euros of sales) and making greater use of renewable energy sources in the long term. The ratio at Beckhoff Automation Germany in 2018 was 14.32 kWh/1,000 euros, and this key figure could be reduced to 13.35 kWh/1,000 euros by 2021.

In the meantime, the share of “gray energy” makes up less than 1% of the total energy demand (as of 2021) within the Beckhoff Group in Germany (Beckhoff Germany, Smyczek, Fertig Motors). And of the 11 million kWh of green electricity used, Beckhoff already produces around 10% itself through its own photovoltaic systems with an installed peak output of currently 1,081 kWp – and the trend is rising. At this year’s Hannover Messe, Hans Beckhoff announced the installation of further solar panels at the Verl site as the latest project. The aim here is to install modules with a total output of 509 kWp over 170 solar carports. Plans for another PV plant with 650 kWp on a production building are also under way. Once the planned expansions are complete, the installed PV capacity will amount to 2,240 kWp at Beckhoff, Smyczek and Fertig Motors. Furthermore, the heating systems in existing buildings were partially renewed and expanded with ceiling heating panels, cooling panels and heat pumps, or else completely converted to use district heating. Wherever possible, lighting is consistently converted to LED technology with a preference for demand-oriented, daylight-dependent control.

The measures implemented to date have been paying off for quite some time already: Evaluated in accordance with the internationally recognized “GHG Protocol Corporate Accounting and Reporting Standard”, the Beckhoff CO2 figures have already fallen massively between 2019 and 2020, from 23.7 t CO2e (CO2 equivalent) per million euros of sales to 14.9, corresponding to a reduction of 37%. Only 13,763 t CO2e were emitted in total, and Beckhoff offsets these unavoidable emissions via CO2 certificates from myclimate gGmbH. “Of course, the priority here is to focus on avoiding carbon emissions in the first place, followed by looking at ways to continuously reduce them,” emphasizes Anne Schaper, in charge with energy management at Beckhoff.

Transparent energy data opens up optimization potential

Energy monitoring plays a crucial role in reducing carbon emissions. After all, maintaining an awareness of the present situation is fundamental to achieving any goal. This is where Beckhoff has been relying on software from the Stuttgart-based company Optenda for many years now. “The first step in becoming aware of energy consumption and consequently being able to reduce it in a targeted manner is, of course, to measure it at as many loads as possible and then consolidate it centrally,” explains Johannes Beckhoff. Since 2019, all processes related to DIN ISO 50001 have been supported by Optenda’s Energy Monitor software at Beckhoff and Smyczek. The tool records the various energy flows at the company sites (electricity, heat, compressed air and nitrogen consumption) via PC-based control and an extensive range of measurement terminals and current sensors to make them transparent. The universal and system-integrated energy measurement technology lays the foundations for maintaining an overview of key production figures and for comparing the target and actual state of systems and buildings directly within the control system. In this way, impending damage to or inappropriate use of the facilities can be detected at an early stage and optimization potential can be identified more easily.

In-house efficiency measures such as the control of lighting times and operating times for room air conditioning can be quantified with MWh savings through monitoring. For example, optimization measures in Beckhoff-owned production buildings have demonstrably saved 210 MWh/a.

Continuous monitoring of production consumption enables non-conformities to be identified and rectified at an early stage, such as leaks in the compressed air network. Recording consumption at the production level makes it possible to quantify and monitor the energy consumption per product.

Complete measurement chain supports data transparency

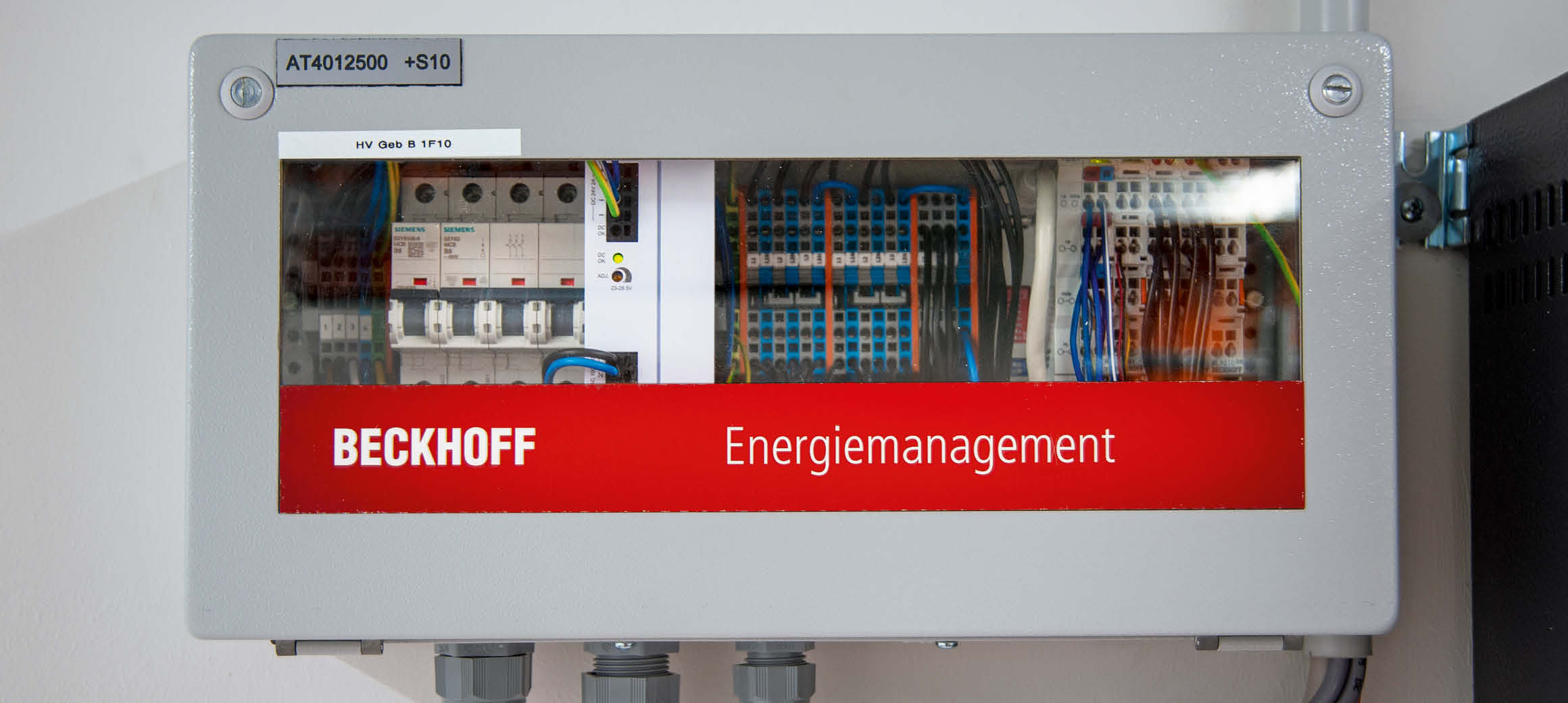

Continuous data monitoring is typically associated with considerable expenditure, because additional sensors are often integrated at a later stage, usually at high cost and sometimes with the help of special components; however, with the power measurement terminals, current transformers, overcurrent protection terminals and power supply units from Beckhoff, this can be achieved with standard components and correspondingly low expenditure – even in the case of retrofits.

As an automation specialist, Beckhoff enables the merging of relevant power supply components to form a transparent complete system. Only a combined application such as this could provide a comprehensive overview of the energy supply, from individual machines through to production halls and office buildings.

With the current transformers from the SCT series, Beckhoff has completed the power measurement chain that ranges from measuring the physical value to transmitting the captured data to the cloud. The broad portfolio of current transformers covers all relevant applications from 1 to 5,000 A. Users can select from two device types, each available in various designs and performance categories that are highly scalable and therefore suitable for a great variety of applications. The diverse SCT portfolio ranges from low-cost 3-phase transformer sets – including for building services – and standard industrial transformers for machine building through to solutions for test benches with particularly high accuracy requirements.

The concept of distributed power measurement offers a particularly efficient and inexpensive way of obtaining precise power measurement data even in more complex systems: its central element is the EL3446 6-channel current input terminal for up to 1 A AC/DC measurement current. It can be used to determine precise power values, even with spatially separated voltage and current measurement. A key feature here is that all relevant electrical data from the supply grid, including real measured values for power, can be determined with the EL3446 as a mere current measurement terminal. However, these terminals receive the voltage values required for calculating the power data via EtherCAT from a separate EL3443 3-phase power measurement terminal, which only needs to be installed once per network and is precisely synchronized in time by the distributed clocks function in EtherCAT. This concept of distributed power measurement minimizes the hardware and installation expenditure.

More transparency through OPC UA and PC-based control

TwinCAT 3 Building Automation offers a comprehensive package of function blocks for building automation. Communication via BACnet and OPC UA is integrated directly so that the control system can be integrated into a management and operating level. The openness of PC-based control allowed Optenda to connect their Energy Monitor with the existing Beckhoff measurement infrastructure in no time via OPC UA. “With more than 200 relevant data points, we soon noticed during the course of the project what a major advantage this is,” emphasizes Dennis Ulke, Manager Sales and Business Development at Optenda.

PC-based control links lighting, sun protection, window control, heating, ventilation and air conditioning on a central platform to achieve intelligent control of all technical systems. This reduces the number of individual physical data points and thus the risk of errors. In addition, all data is available in one system, which is a basic prerequisite for successful energy monitoring. Functions such as sun protection, thermal automation and daylight-dependent lighting control contribute significantly to energy savings. Added to this are HVAC functions from the TwinCAT package, such as summer night cooling, summer compensation, backup operation and time schedules. With the help of the HVAC modules, further energy-saving possibilities can be exploited by the occupancy-dependent control of building systems.

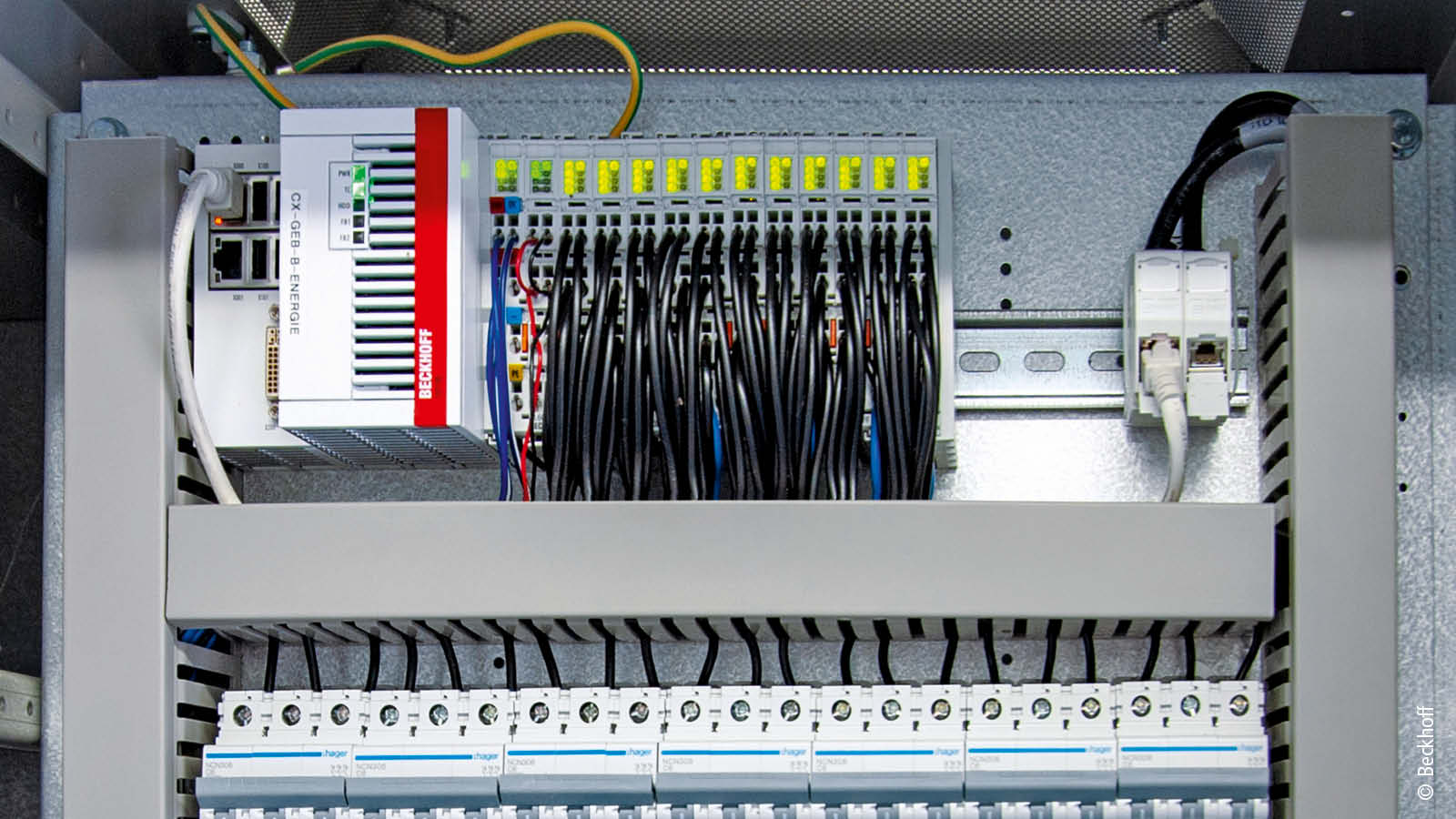

Various Embedded PCs from the CX9020, CX5100 or CX7000 series form the control center for energy monitoring. With its fanless ARM Cortex™-A8 processor (1 GHz clock frequency), the CX9020 Embedded PC is ideal for small to medium-sized projects in the field of building automation. The CX9020 can be used in conjunction with the TwinCAT 3 Lighting Solution for tasks such as operating the lighting of entire halls, and alongside TwinCAT 3 Building Automation for applications such as shading, lighting control and air conditioning for offices. The more powerful CX5100 Embedded PC is the optimal control platform for automating buildings with many data points. With this series, for example, more than 2000 BACnet objects can be controlled and managed with ease. The CX7000 Embedded PC is designed for small stand-alone solutions in buildings, such as a compact ventilation or room automation system. With its eight integrated multi-functional inputs and four multi-functional outputs, it makes for a very inexpensive compact controller.

Significant savings potential identified after just three months

Equipped with these components, Beckhoff was able to identify a large savings potential of 63 t CO2 within a ventilation and air conditioning system in its own properties and facilities shortly after consumption monitoring began. The user-friendly interface of the Energy Monitor clearly visualized the analysis and initial optimization potential while also ensuring the corresponding control of results later. “Three months after commissioning, savings of approximately 20,000 euros per year had been identified and achieved – and sustainably, too, since these savings continue over time. “If nothing had been done, on the other hand, the 20,000 euros in savings would have come as a constantly recurring cost. With rising energy prices, this would have become increasingly expensive, so it really is worth tracking down inefficiencies and eliminating them quickly. We are delighted that we can provide the ideal tool with our software,” says Dennis Ulke.

The Energy Monitor software not only records electricity consumption, but also all relevant consumption data from other forms of energy, such as heat and compressed air. It can be used to just as quickly reduce CO2 emissions for the respective energy type. This makes the whole balancing process, which is necessary to achieve carbon neutrality, considerably faster and easier, because efficient energy management means efficient carbon emissions management.