Implementation of a compact, web-enabled standard controller for industrial compressed air systems with PC-based control

U.S. expert for industrial compressed air systems, iZ Systems, offers energy audits and other services to reduce energy consumption. Using open PC- and EtherCAT-based automation technology, the company has developed a compact standard controller that enables remote monitoring and optimization of compressed air systems. This enabled food packaging manufacturer Pactiv to achieve enormous energy savings following an equipment upgrade and to secure these savings in the long term.

While many companies claim their products or services pay for themselves, iZ Systems can actually prove it. The Macon, Georgia-based company founded in 1990 by Dean Smith provides energy auditing services and control systems that quickly deliver a complete ROI from the resulting energy reductions.

For seven years now, iZ Systems has been providing these services to food packaging manufacturer Pactiv at its Macon facility, which focuses on molded fiber egg cartons. The partnership began with a project to replace the compressed air systems supplying low-pressure blowers, according to David Powell, maintenance manager for Pactiv. “With every blower we tested, the pressures would change too much even if a single nozzle was adjusted,” Powell says. “The iZ Systems team promised a blower system that would not change in pressure, even if you shut off all but one nozzle, and their system has worked flawlessly.” iZ Systems also installed its standard control system at Pactiv, which ensured the long-term optimization of the compressed air systems with its data acquisition and remote monitoring functions.

Open, transparent technologies deliver valuable insights

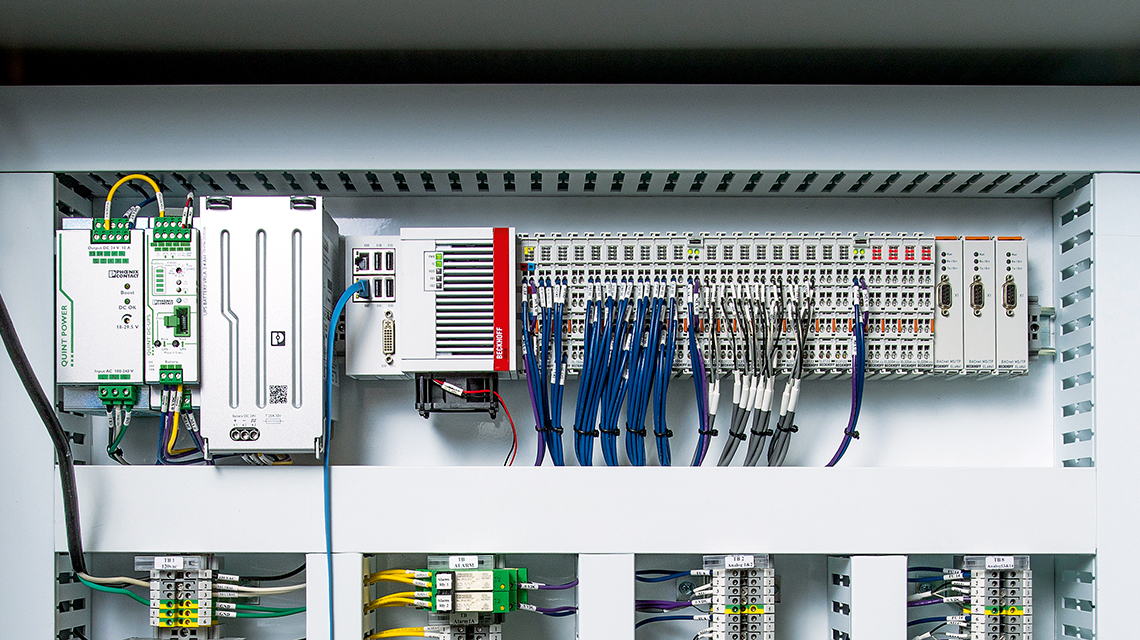

To ensure that customers’ systems achieve peak performance, iZ Systems must be able to monitor data remotely and make adjustments whenever necessary. In addition to its audits, the company accomplishes these goals through its turnkey iZ Compressed Air Automation and Data Acquisition System, which combines the automation controller, I/O and HMI in a single control cabinet and utilizes custom software. Leveraging the open control technology from Beckhoff, the system has been providing connectivity to clients’ diverse networks for years now.

When Beckhoff and iZ Systems first partnered about 15 years ago, TwinCAT automation software helped the company establish remote monitoring of its compressed air automation and data acquisition systems. Dean Smith, general manager and technical manager for iZ Systems, explains that interfacing horizontally via Modbus TCP to diverse compressor control systems within plants and vertically via OPC UA are important features that exemplify the system openness of PC-based control technology. Enabling data acquisition and monitoring in customer plants, PC Control creates transparency with regard to performance and potential optimizations.

Visualizing the numerous compressors and equipment spread throughout entire plants can easily clutter HMI, so iZ Systems has standardized on the CP2924 multi-touch Control Panel. The 24-inch widescreen panel is mounted into a control cabinet cutout to enable easy identification of field components, according to Allen King Jr., inside application project manager.

The go-to machine controller is a DIN rail-mounted CX5140 Embedded PC, which features a four-core, 1.91 GHz Intel Atom® E3845 processor. Measuring only 142 x 100 x 92 mm, the powerful Embedded PC reduces space requirements in the control cabinet, while providing advanced capabilities not available in traditional PLCs.

EtherCAT technology enables real-time communication. In addition to standard digital and analog I/O terminals, iZ Systems also uses EK1501 and EK1541 fiber optic EtherCAT Couplers along with EK1521 and EK1561 fiber optic junctions in most compressed air applications to communicate with field devices. “Fiber optic wire provides absolute isolation between our system, the processor, the machine and the compressor,” Dean Smith says. “Fiber optics by nature provides excellent immunity to electrical noise and interference, and the EtherCAT I/O hardware offered us a big step forward in this regard.”

Stratospheric energy savings, guaranteed

By implementing these open, PC-based solutions, the engineering team at iZ Systems was able to keep its promise to Pactiv. As a result of the blower equipment upgrades, Pactiv reduced its energy consumption for compressed air by 45%. “By using blower air, we replaced nearly 400 horsepower (300 kW) of compressed air with 50 horsepower (37 kW). This amounts to a cost savings of nearly $250,000 each year,” David Powell says. “The improvements to our air compressor design have stabilized our pressure, and the remote monitoring has given us peace of mind.”

More importantly, the systems with Beckhoff components achieve the utmost reliability. Secure communication with customer machinery via OPC UA allows iZ Systems to monitor any changes in performance and to initiate maintenance measures early on if required. Powell says this, along with excellent support, has been crucial for Pactiv: “The system alerts me when there are any abnormalities with the compressors, but iZ gets the warnings as well and their engineers are usually working to address the issue before I call them.”

Win-win solution for customer and end users

In addition to boosting reliability, iZ Systems has reduced control cabinet footprint by two-thirds on average by implementing Beckhoff controls. “Our old control cabinets were much larger because the previous PLC generated an excessive amount of heat, increasing our cooling requirements and energy consumption. With the Beckhoff hardware, heat generation is not a problem and we increased our own energy efficiency like we do for our customers,” Allen King says. In addition, the flexibility and scalability of Beckhoff components allows iZ Systems to build and stock standard control cabinets for future use, rather than designing a custom cabinet for each client.

By creating open systems that support multi-vendor architectures, iZ Systems has the unique opportunity to apply energy-saving solutions from one industry to another. Dean Smith concludes: “We try to make the initial acquisition cost attractive to the client while guaranteeing major energy reductions, and the Beckhoff platform has made a huge difference in our ability to meet these goals.”