Performance boost in converting with PC-based control and EtherCAT

To ensure that an online order arrives in perfect condition, the parcel must be well protected during shipping. CMD Corp. from Appleton, Wisconsin, developed a system producing mailing bags for the fast-paced e-commerce business. Control technology from Beckhoff integrates all stations along the line – regardless of whether for intermittent or continuous operation – into an optimized workflow.

CMD understands that flexible automation and repeatable results are essential in the packaging industry. So the OEM provider strives to meet these requirements by continuously exploring new technologies for use in their highly customized plastic converting solutions. CMD thus lives up to its name, which is an acronym for Custom Machinery Design.

For a contract manufacturer in the e-commerce sector, the company started designing a new mailer packaging machine. A high throughput machine with an intuitive operator interface was a top priority, according to Scott Fuller, Product Line Manager, Intermittent Motion Products at CMD. “This new machine is much faster and more automated, which was key for our end user customer,” says Fuller. The end customer will produce bags for online retailers primarily to ship e-commerce items in plastic bags. Another customer need: bags that would work with automated product loading.

Next-level automation

In the new streamlined converting process, the 1400-GEC machine unspools two rolls of film, registers the print on those two rolls and applies a continuous longitudinal seal. Then it runs the rolls through a series of cross-directional punches and seals, slits the material in up to five individual lanes of bags, depending on order specifications, and adds perforation for easy separation. Before loading the finished bags into cases, ready for use as specified by the customer, the system performs a vision test while blowing air into the open end of the bag and measuring its shape profile.

“This machine incorporates entirely new automation processes. It transitions from continuous motion to intermittent motion and back to continuous in the outfeed, while handling various tasks in each phase,” Scott Fuller explains. “That makes it distinct from the machines we've designed before.”

The support of all this functionality in real time required a control system with significant processing power. In addition, the development team faced tight lead times on this project. It was essential to finish on schedule while also delivering a smoothly working, reliable solution.

Powerful programming tools

As an end-to-end engineering and runtime platform, TwinCAT automation software combines everything from PLC and motion control to integrated safety and IoT. When programming the new operator interface, TwinCAT HMI allowed CMD to leverage modern web design standards, such as HTML5, JavaScript and CSS. The resulting responsive interface increases user-friendliness with a more intuitive HMI.

When programming the machine control with TwinCAT, CMD benefited from close cooperation with the software experts in Beckhoff's Special Projects Team (SPT). The SPT framework builds on industry standards such as ISA-TR88 and PackML and the associated libraries in TwinCAT. It simplifies the programming of communication between individual machines within a production line. The advantage for programmers is that they do not have to start from scratch for every project, but can reuse existing code or easily customize it to new requirements.

Efficiency throughout the line

A CX2033 Embedded PC serves as the sole machine controller for the entire line. A dual-core AMD Ryzen™ processor supplies extensive performance capabilities to the DIN rail-mounted controller from Beckhoff with room to grow in the future. “If you're working with a resource-constrained system, your HMI will be laggy to the touch. So, putting the HMI server on a CX2033, which offers ample computing resources, enables the touch panel to operate very responsively,” explains Software Engineer Adam Benson from CMD.

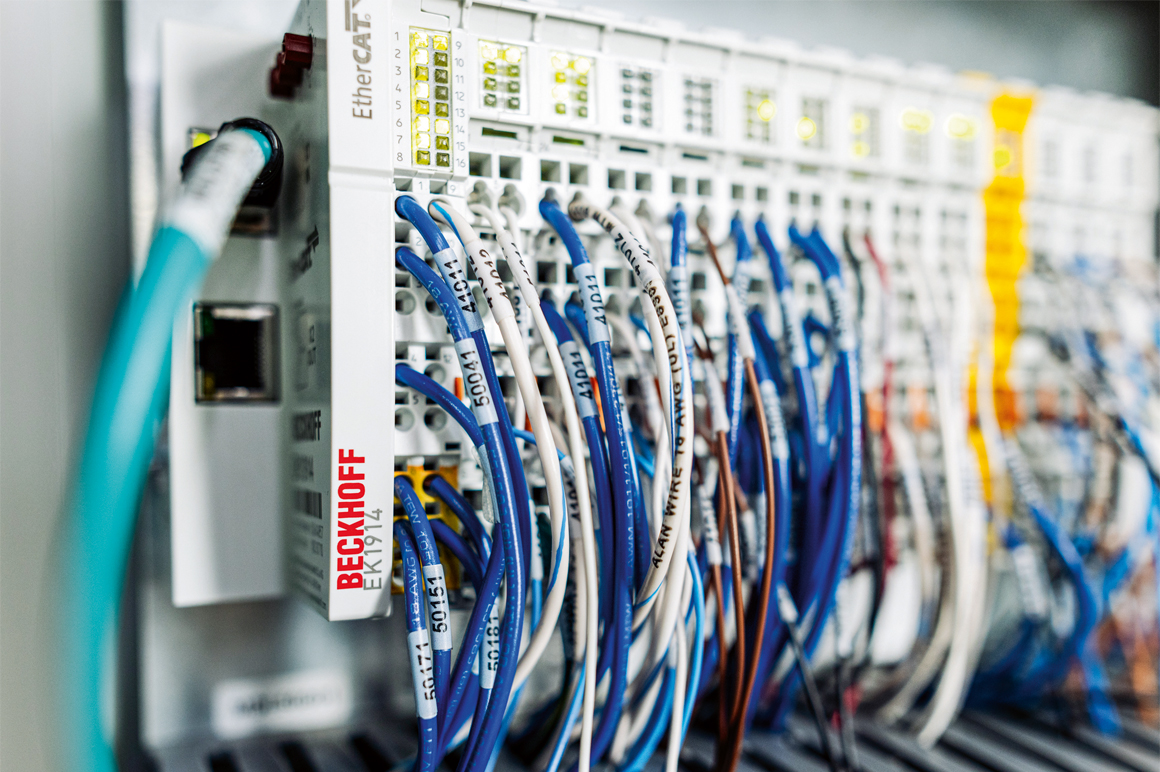

EK1914 EtherCAT couplers integrate communication along the entire line with their digital standard and safety I/Os. Besides EtherCAT Terminals for standard signals, the I/O segments of the various stations also include TwinSAFE terminals for functional safety. This allows CMD to conveniently allocate safety functions, such as an e-stop, to each tool in the machine line.

The high level of synchronization provided by EtherCAT also enhanced the powerful drive technology from Beckhoff in CMD’s motion-intensive application. The machine features the AX8000 multi-axis servo system and AM8000 servomotors controlling fourteen axes. “The AX8000 drives are very compact for the power they provide,” CMD Electrical Engineer Jason Plutz says. “And by using the integrated Safe Torque Off functionality, we eliminated two large contactors, saving significant panel space.”

CMD leveraged camming motion control in TwinCAT 3 software with two of the axes on the bag packaging machine. The bag opener, initially positioned in the intermittent movement section, was relocated downstream to enhance efficiency through the camming functionality. Using an extrapolation of continuous web processing, the bag opener is precisely cammed to achieve the desired motion at just the right moment.

Well-positioned for the future

By harnessing the software framework from Beckhoff, CMD boosted their code reusability to 90%. Employing TwinCAT HMI also helped the team create a more intuitive operator interface in a way that supports outstanding customization. “The new operator interface resembles our legacy HMI, but has a much cleaner, more user-friendly design,” says Software Engineer Adam Benson.

Running the entire machine with an EtherCAT-networked CX2033 Embedded PC accelerated CMD’s cycle times. “Having everything scan at one high speed is a huge benefit. You don't have to worry about communicating between process stations that function at different speeds because everything updates at the same time,” Jason Plutz explains. This enabled the CMD team to reach their target throughput rate of 200 feet or approximately 60 m of plastic sheet per minute. This translates to 100 bags per minute per lane, resulting in an impressive total of 300 to 500 bags produced every minute.

Looking ahead, the CMD team intends to scale up to the CX2043 with a quad-core AMD Ryzen™ CPU for even greater machine control horsepower. Beckhoff's nearly endless Industrial PC portfolio is built for scalability, enabling performance adjustments without requiring reengineering.