The combination of e-commerce, cost pressure, and staff shortages are driving a real trend in intra- and production logistics toward the increasing use of automated guided vehicles (AGV) and autonomous mobile robots (AMR). This is where our flexibly configurable PC- and EtherCAT-based control technology offers the ideal solution for automating your autonomous vehicles and mobile robots.

Your head start in mobile robotics with Beckhoff:

- save valuable installation space with one of the most compact controls for AGVs on the market

- benefit from all technologies – control, robotics, motion control, drives, I/Os, navigation, and safety – integrated into a single platform

- enjoy investment and life-cycle protection as well as flexibility thanks to Beckhoff’s control system architecture, openness and EtherCAT

- take advantage of comprehensive industry expertise based on decades of cooperation with end users

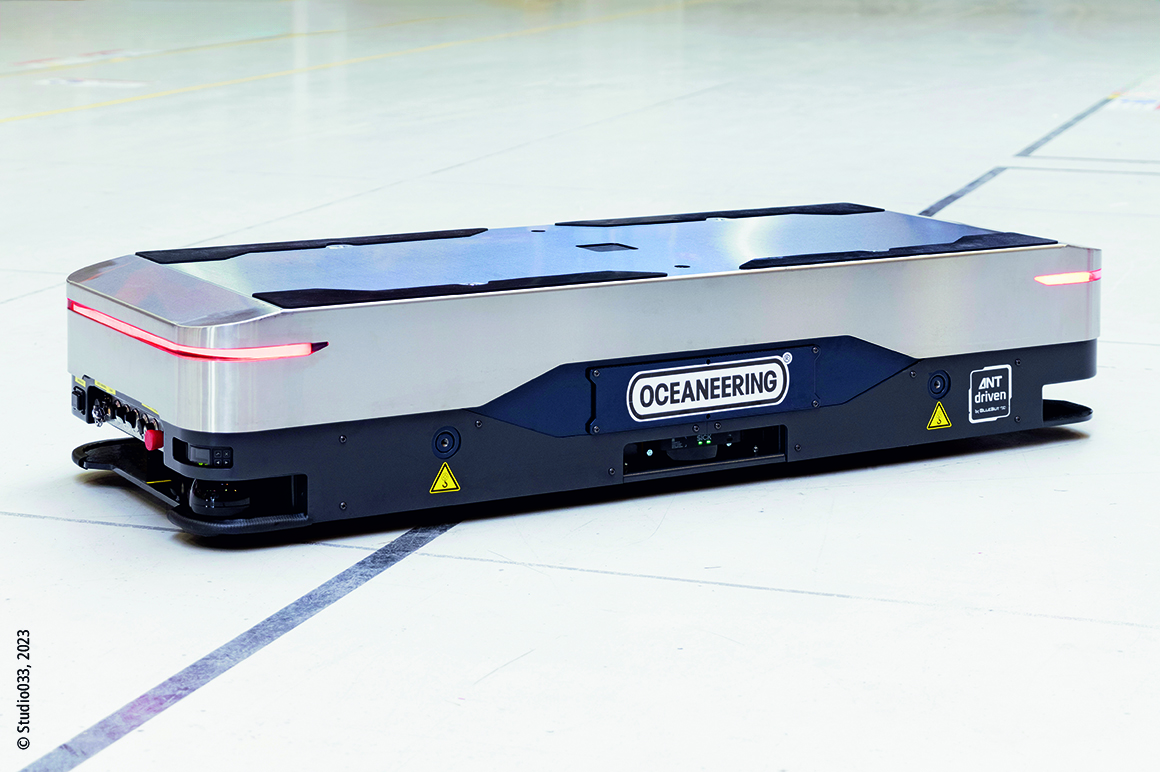

Compact components for the automation of AGVs

PC-based control for high-performance AGV and AMR

The market for automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) is experiencing exponential growth. This expansion in terms of both the variety and quantity of applications is driving a corresponding increase in the demands on the automation technology. No matter how diverse your tasks may be, Beckhoff's open and flexibly configurable platform, which provides complete protection from system-obsolescence, allows you to automate all aspects of your AGV using a single high-performance industrial PC or embedded PC – including robotics, safety, battery management, and navigation. How can all functions be integrated into the smallest of spaces and what cost-saving opportunities does PC-based control bring to the table? What methods can be used to reduce the number of different controls?

Beckhoff in use

These AGV and AMR manufacturers are already benefiting from the unique advantages of our open, system-integrated automation platform.

Boston Dynamics

Stretch from Boston Dynamics is taking mobile robotics to a new level in terms of autonomy, flexibility, and safety. Boston Dynamics relies on automation technology and integrated safety technology from Beckhoff to translate its expertise into an autonomous truck unloading robot for intralogistics.

Further information

Warehouse and distribution logistics

Scalable with high performance: PC-based control for control and drive technology tasks in warehouse and distribution logistics.

EtherCAT

Outstanding performance, flexible topology and simple configuration characterize the real-time Ethernet technology.

Compact drive technology

The small drives in the low-voltage range offer solutions for both conventional operation and operation without a control cabinet.