Products

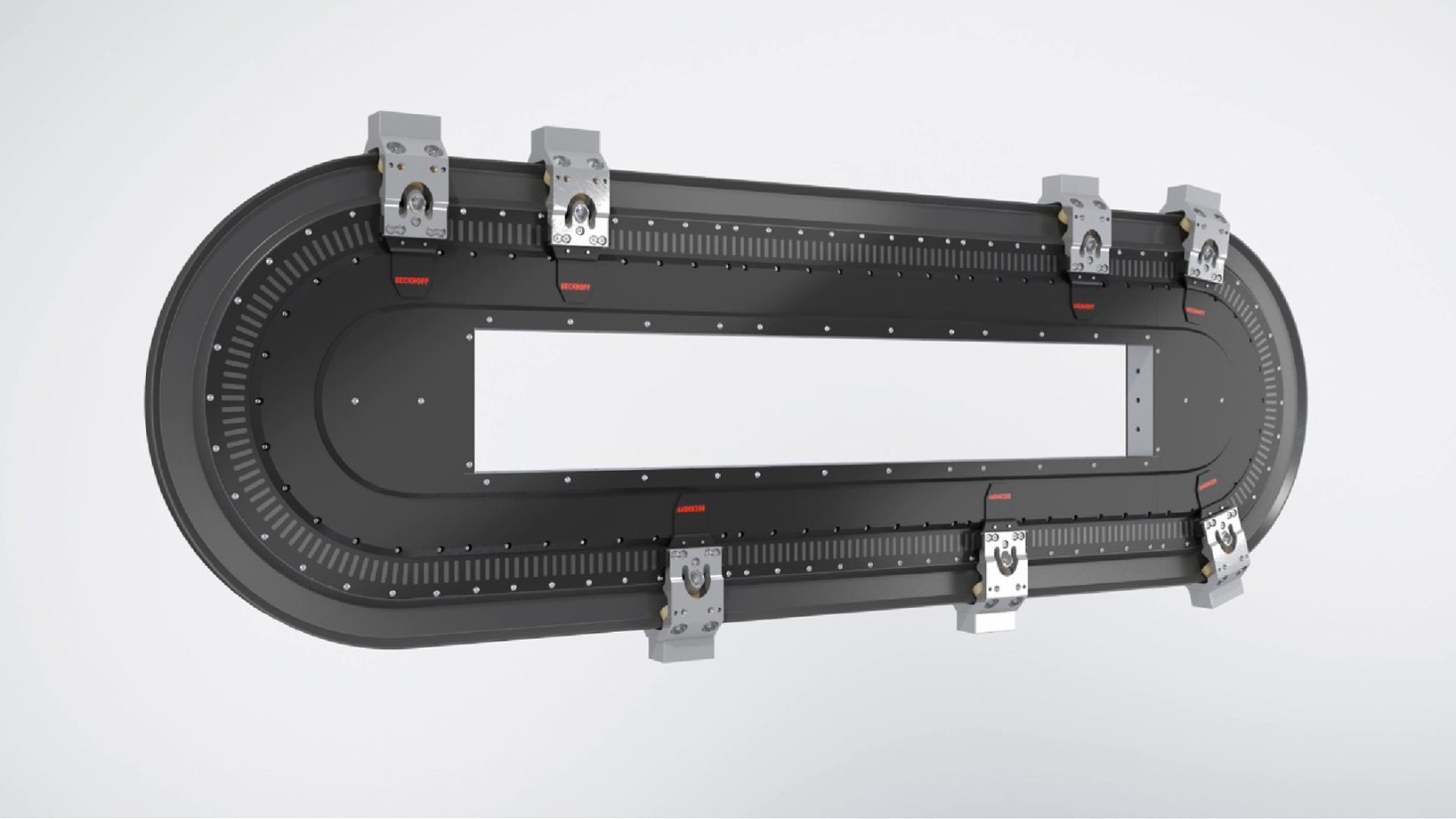

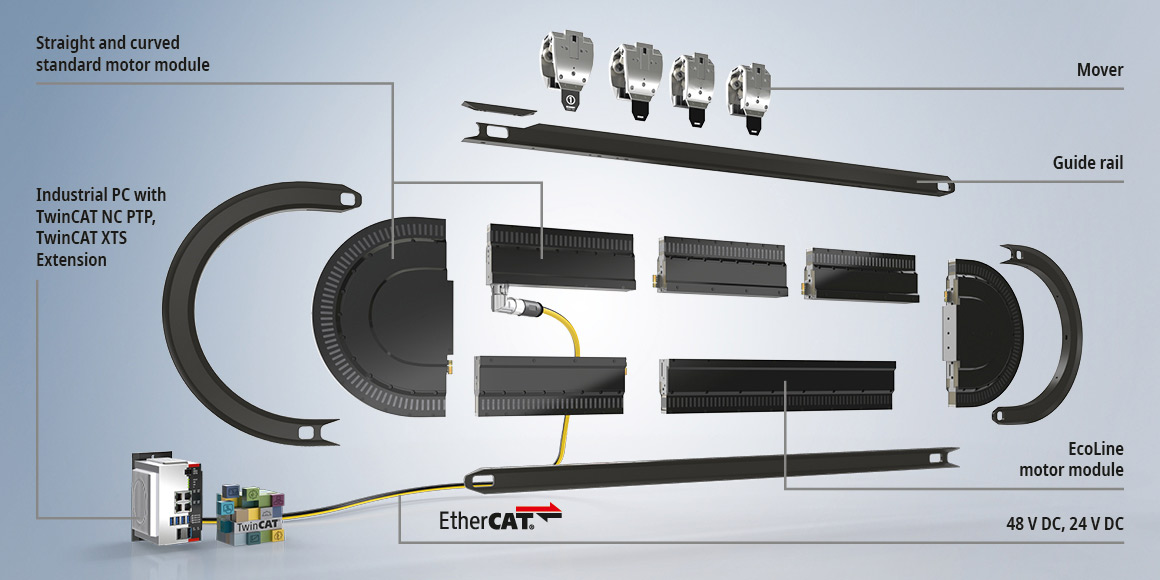

AT2xxx, ATH2xxx | XTS motor modules

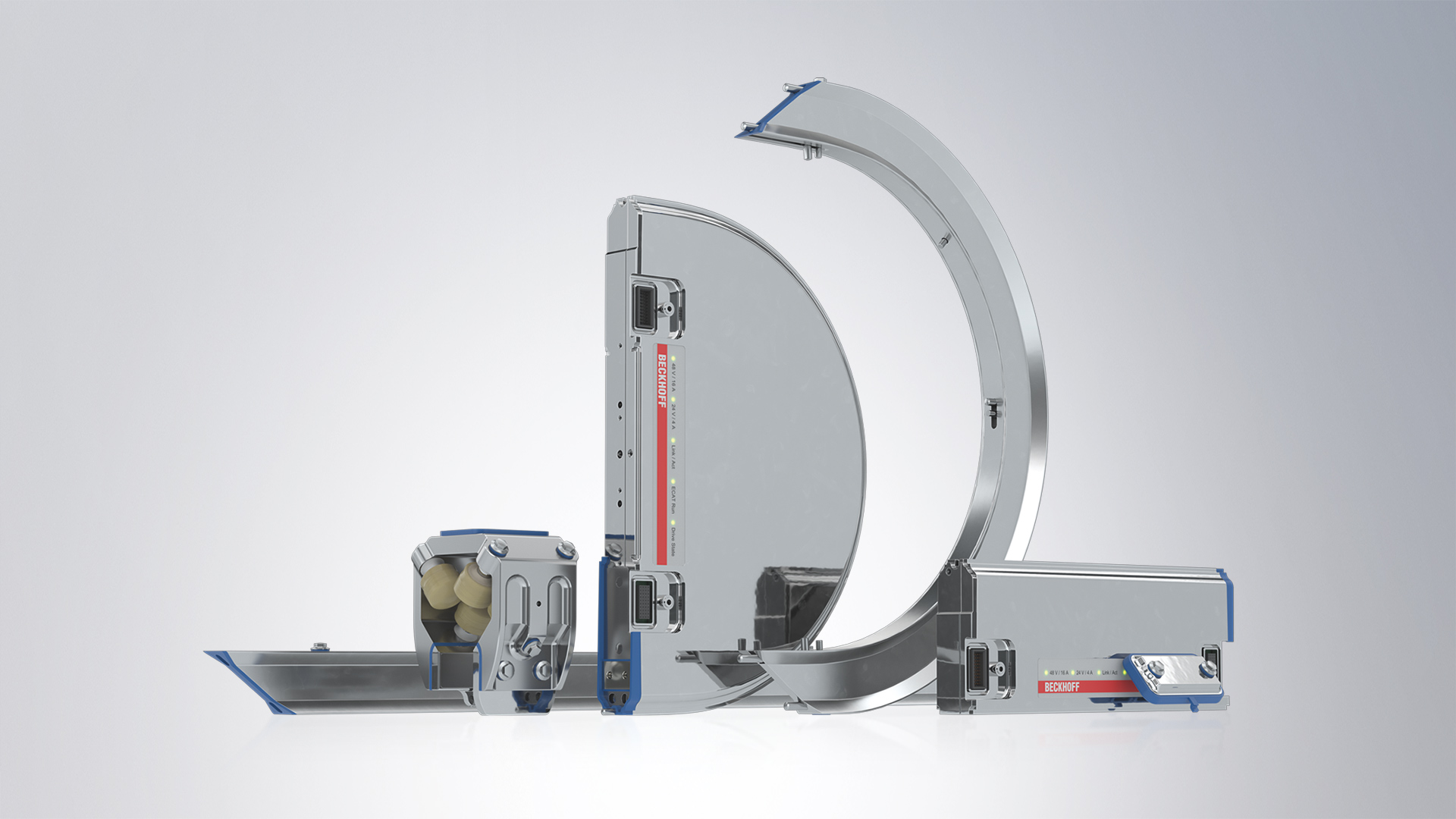

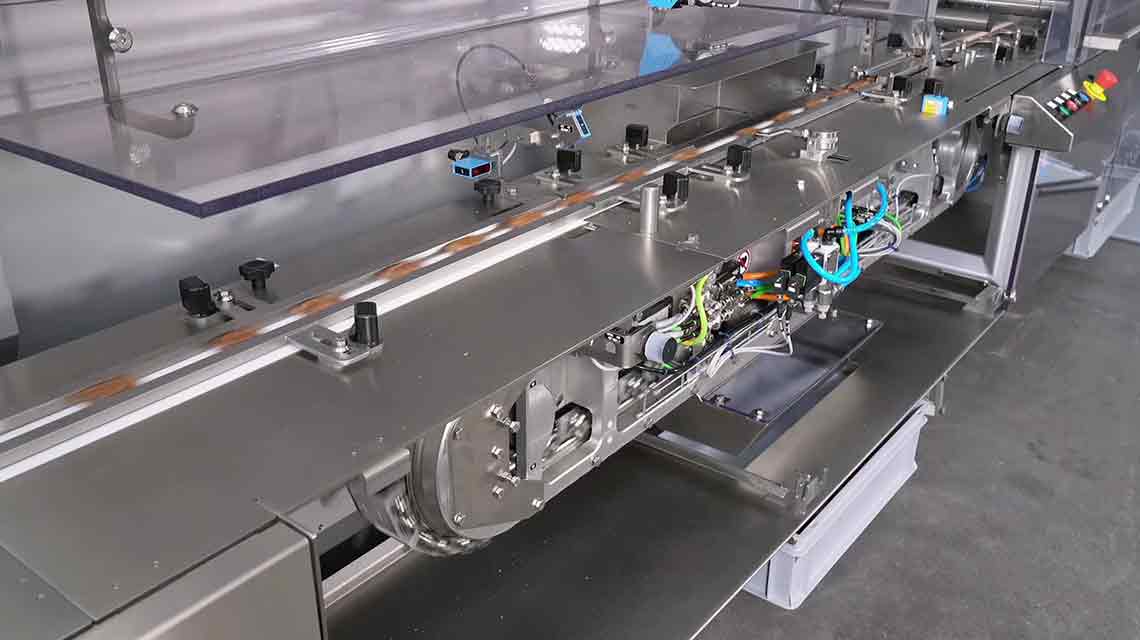

In the XTS motor modules, all active components are combined in a compact mounting space.

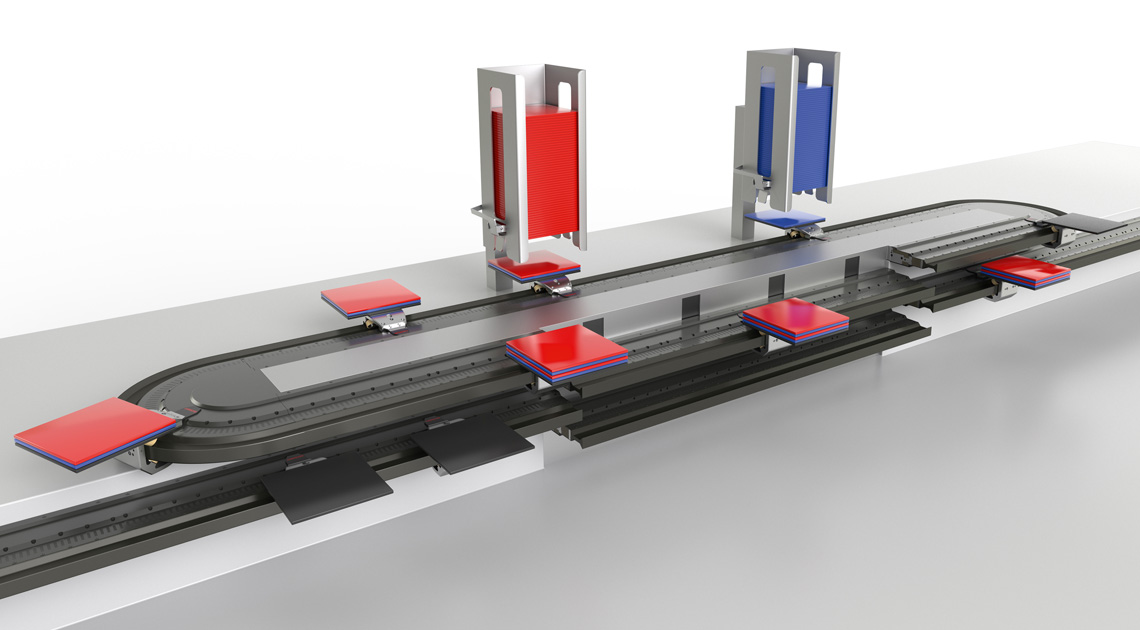

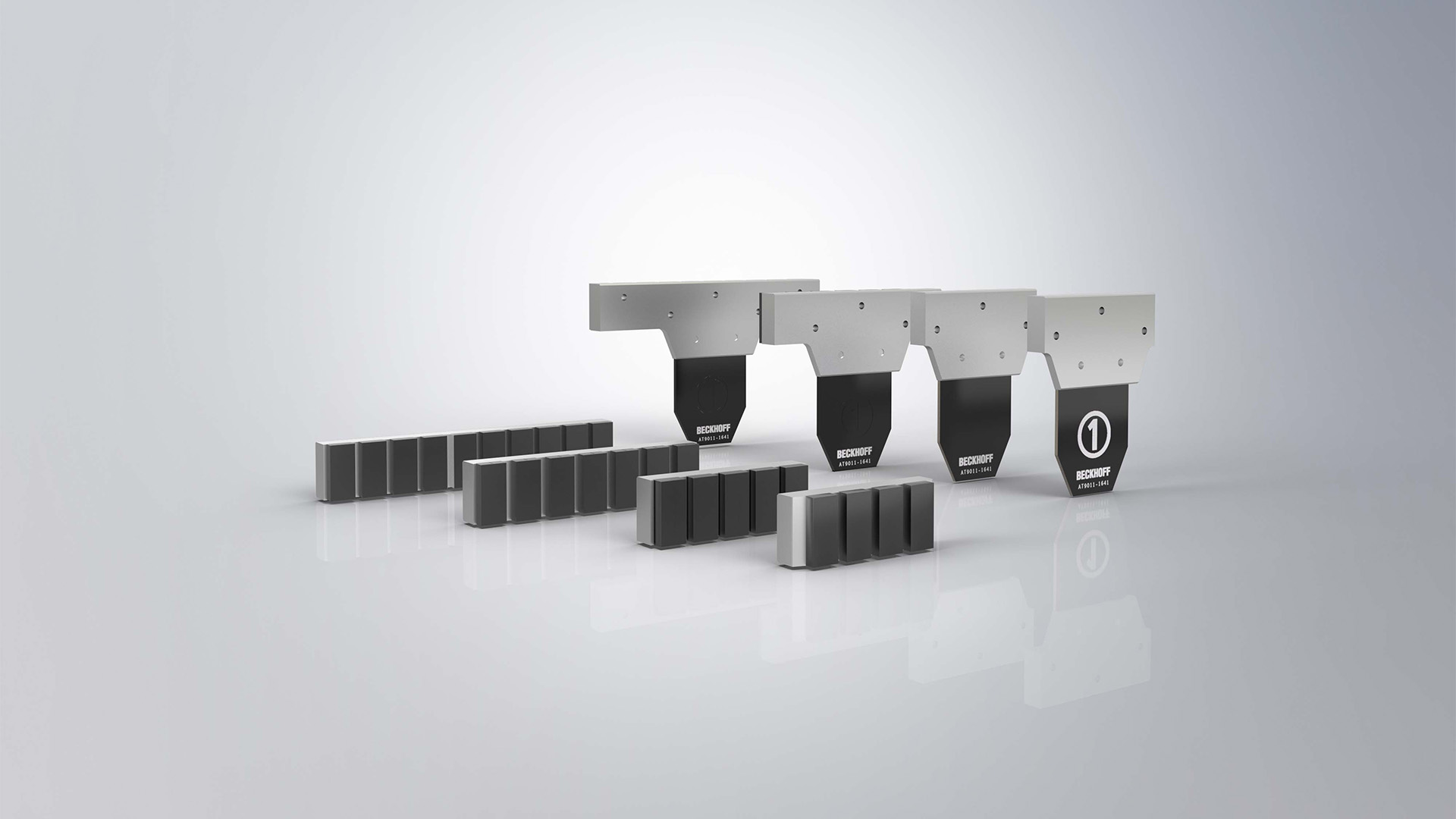

AT8x00, AT9xxx, ATH9xxx | XTS guide rails and movers

The guide rails and movers form the passive components of the XTS for a linear motion along a track.

XTS software

The TwinCAT 3 XTS extension enables simple configuration, simulation and operation.

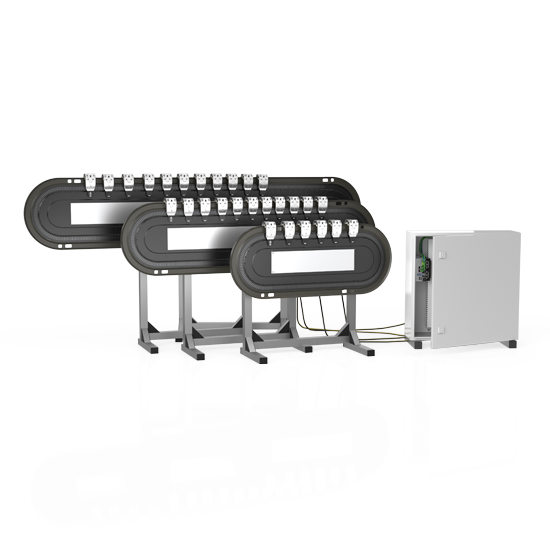

XTS starter kits

The all-round package from system assembly to commissioning enables a quick and simple entry.

The linear transport system from Beckhoff

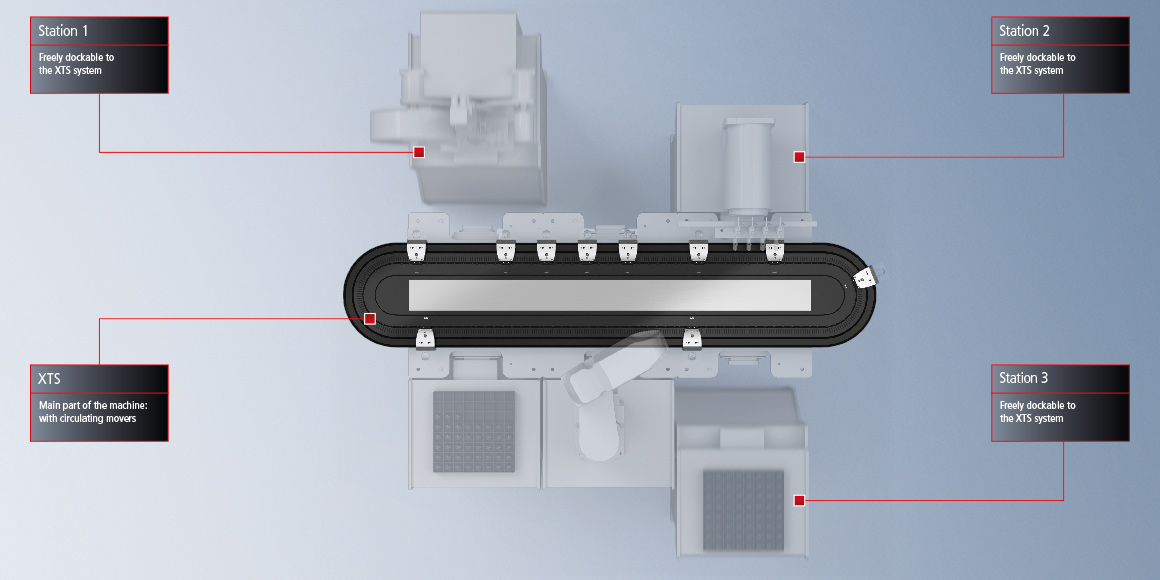

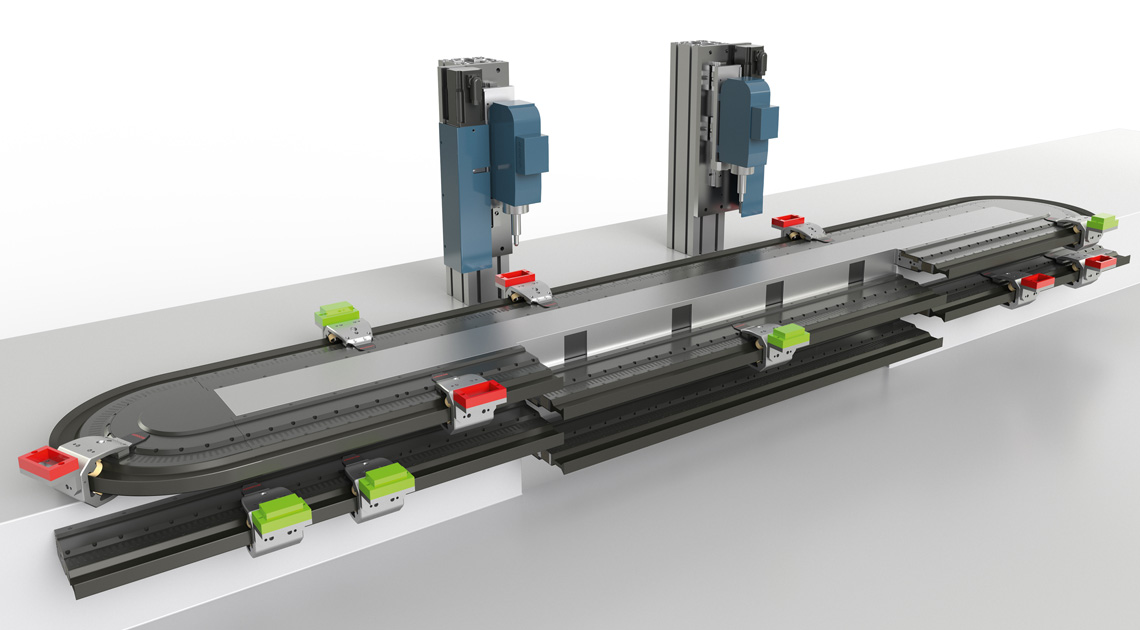

With the XTS linear transport system, Beckhoff offers a proven drive solution in which magnetically driven movers move along a travel path of fully integrated motor modules. An Industrial PC with the TwinCAT automation software enables the independent control of the movers with individual motion profiles. This results in many system-related benefits: The transport system is ready for operation immediately after assembly, as power electronics and displacement measurement are included in the XTS motor modules and the movers are completely passive. Due to different geometries of the motor modules, both an open and a closed travel path can be created and the machine footprint can be reduced by individual track layouts. The XTS not only replaces conventional conveyor belts, but also enables an innovative design of the entire machine. With the flexible motion profiles, simple to highly complex processes can be realized and the entire manufacturing process can thus be optimized.

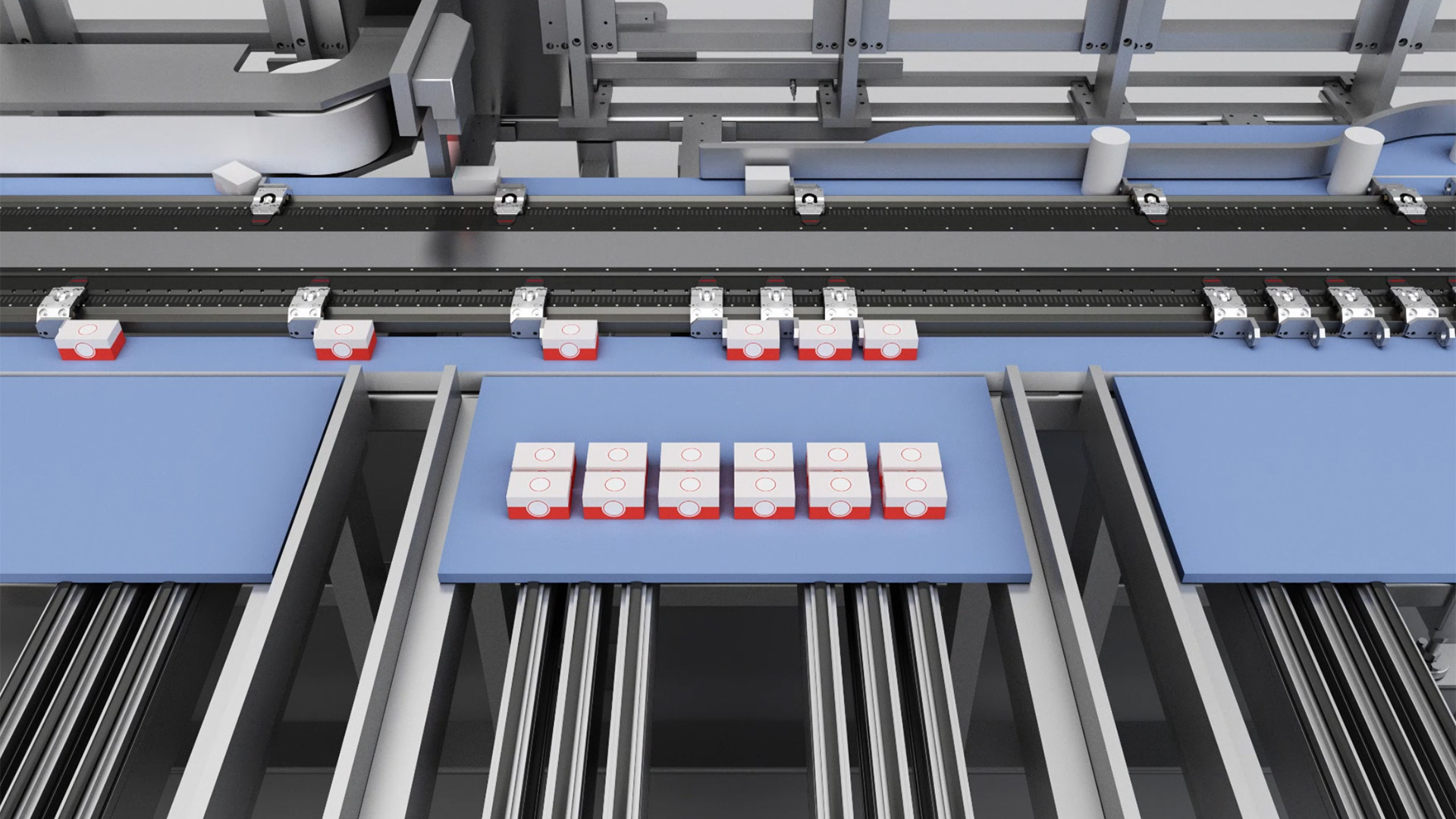

Software functions enable flexible motion sequences

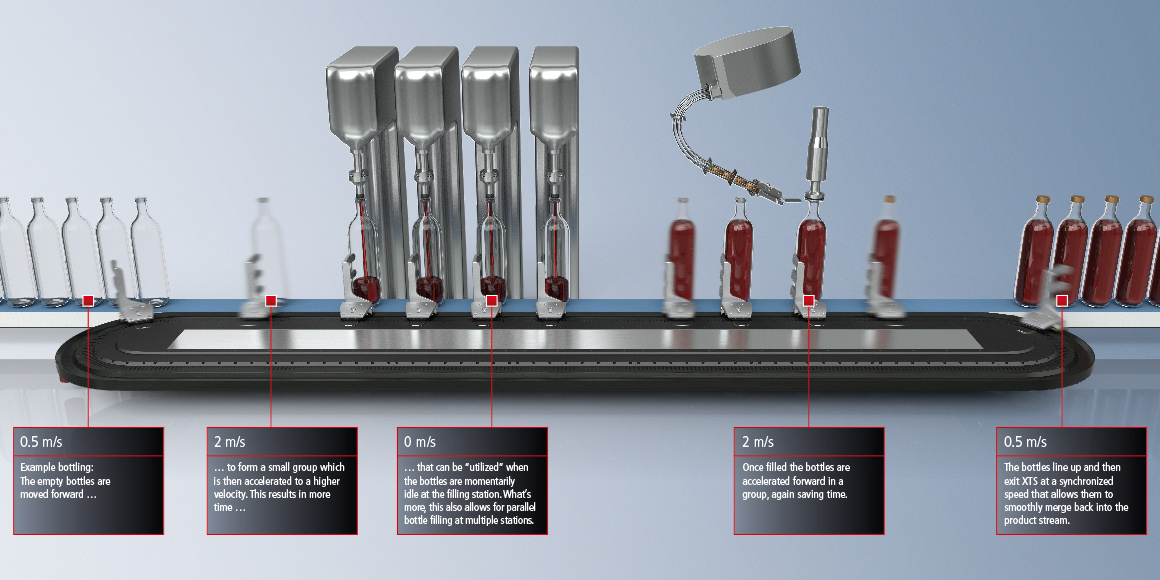

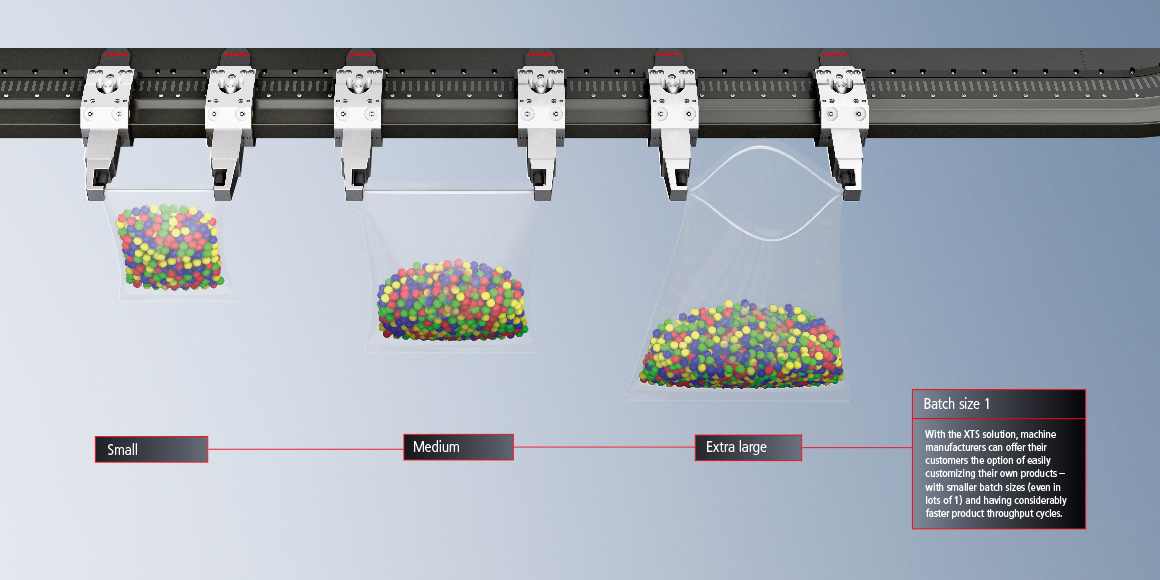

Each mover can be controlled independently of other movers and with freely movability for individual product transport on the travel path. As a property of the individual mover, the dynamics can thereby change at any time on the fly according to the respective requirement. If necessary, the movers can be synchronized to external process sequences or other movers. Group formation in motion with any number of movers as well as a moving buffer store are also possible. The individual movers are mapped as “normal” servo axes with all common motion control functions such as flying saw, electronic gearing, and cam plate. Functional enhancements in TwinCAT handle typical XTS requirements, such as automatic accumulation, centrifugal force limitation, and collision and jerk avoidance. All of these and other application-specific motion functions can easily be implemented without the complexity of the motion leading to a high complexity in the engineering.

Alternative solutions open up innovation potentials

The innovation potentials of XTS are by no means limited to highly complex motion sequences. In fact, the system offers finely scalable adaptation options with regard to the application requirements, e.g. in relation to the geometry, the number of movers, and the functional scope. This starts with simple applications, such as the purely linear motion of a mover and the extension by a second mover to create an XY motion. With the closing of the modular geometry consisting of motor modules and guide rails, an endless linear system with any installation position is ultimately created. The application possibilities can be further increased through the combination of several XTS systems, the use of comprehensive TwinCAT function blocks and the integration of robotics. If all this is consistently used together with Condition Monitoring and object-oriented controller programming, the result is a highly intelligent machine or production module in the spirit of Industrie 4.0.

The ideal solution for each application

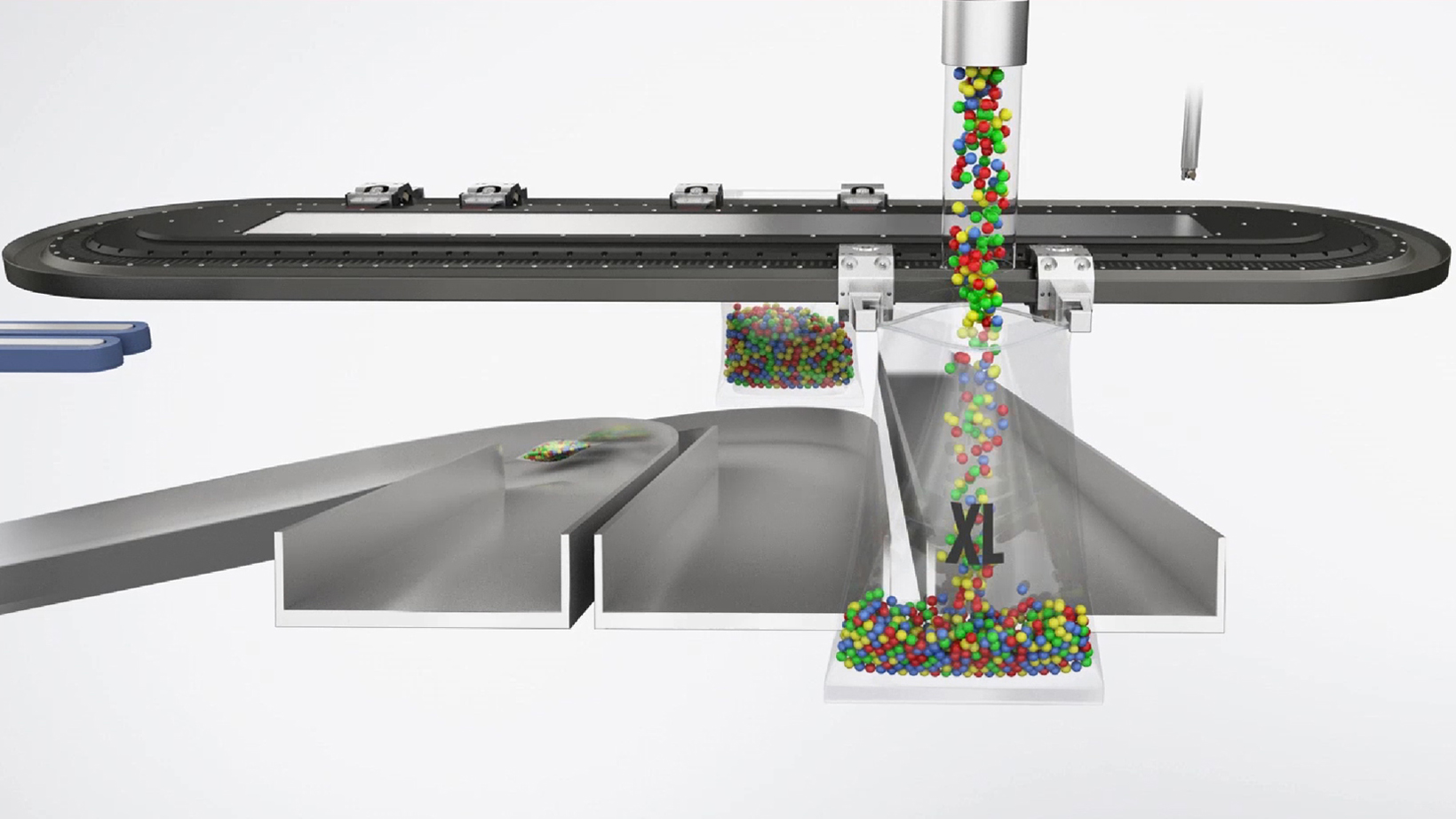

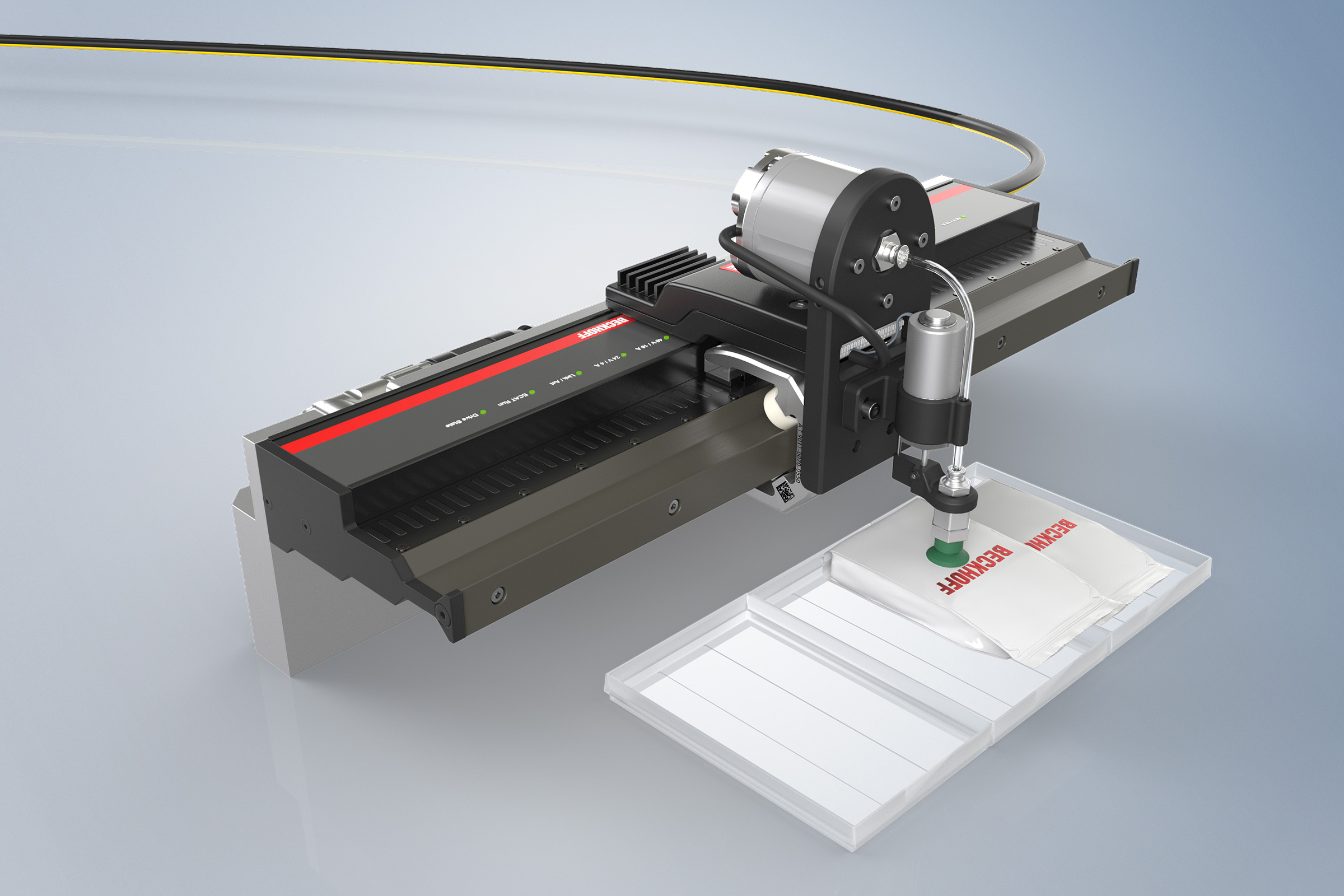

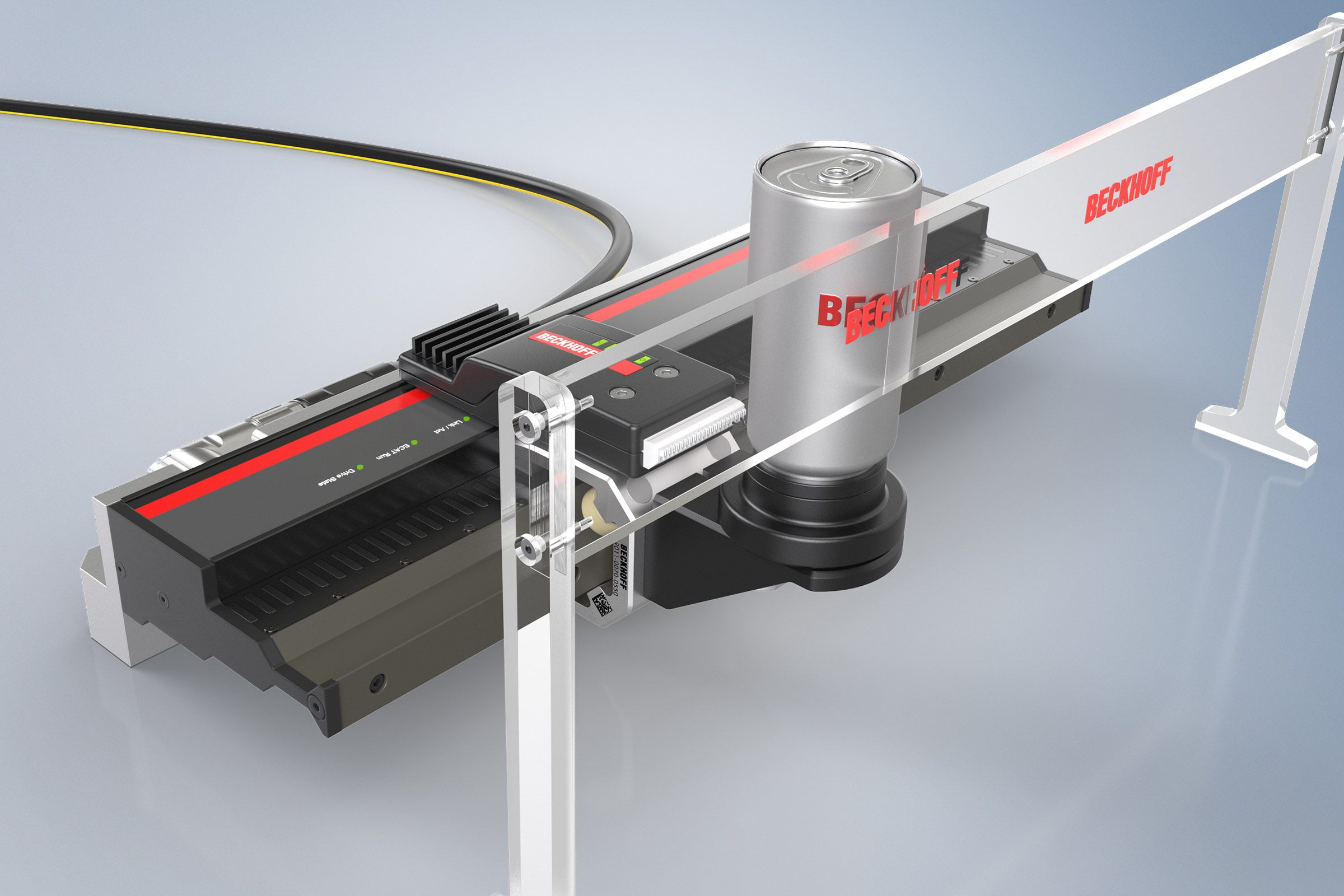

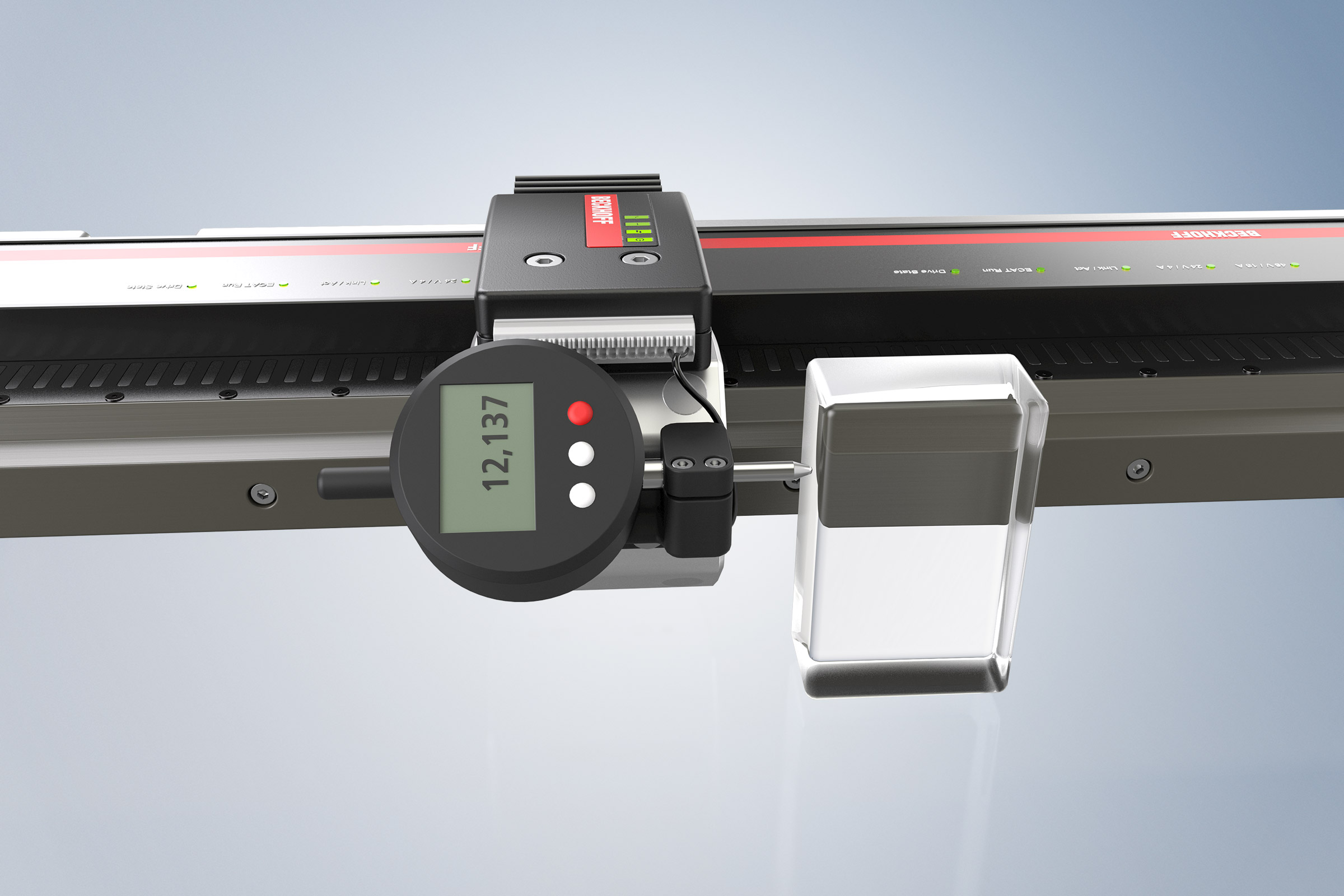

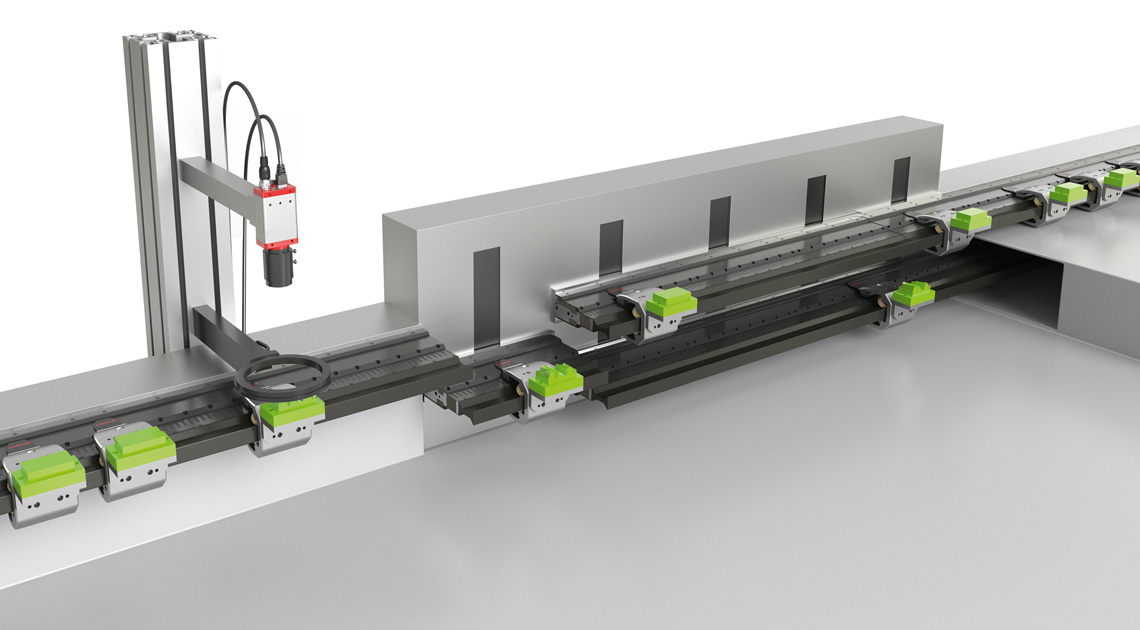

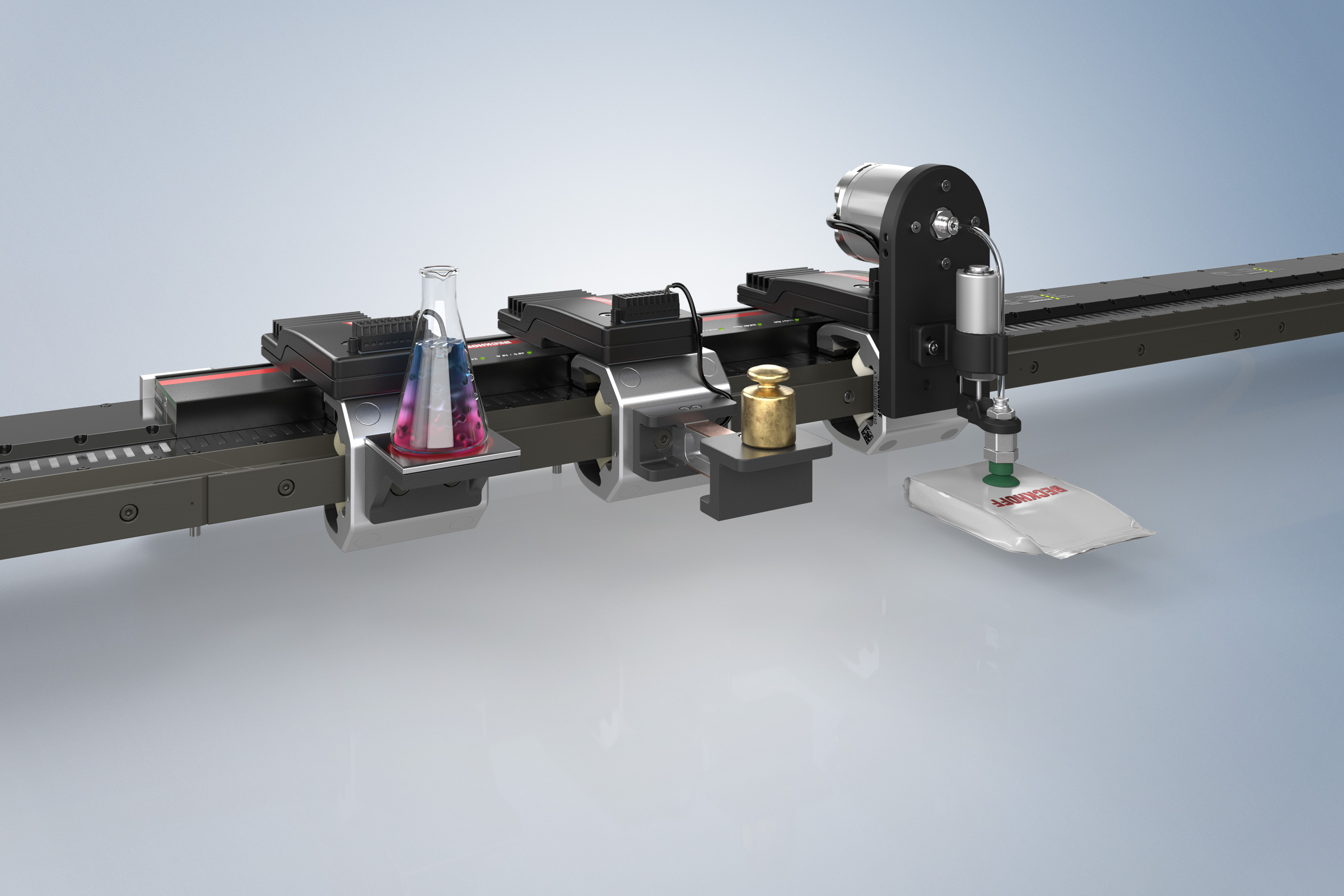

The No Cable Technology (NCT) extension of the XTS system is the basis for a new leap in terms of machine flexibility. For the first time, a power supply and synchronous real-time data communication are available on the moving XTS movers, with which the individual XTS movers can be expanded into mobile handling and processing stations. In addition to the previous pure product transport, NCT enables additional process sequences directly on the mover itself.

XTS with NCT enables new solutions

NCT makes it possible to process and check the quality of products on the mover while the process is running. Sufficient power and fast communication with the TwinCAT control system enable easy connection of sensors and actuators. The data communication is real-time capable and can synchronize system-wide events with µs accuracy in connection with EtherCAT. This opens up new solution options for the user, especially in the areas of product handling, machining and measuring in parallel to product transport, as well as adapting production machines for rapidly changing production batches.

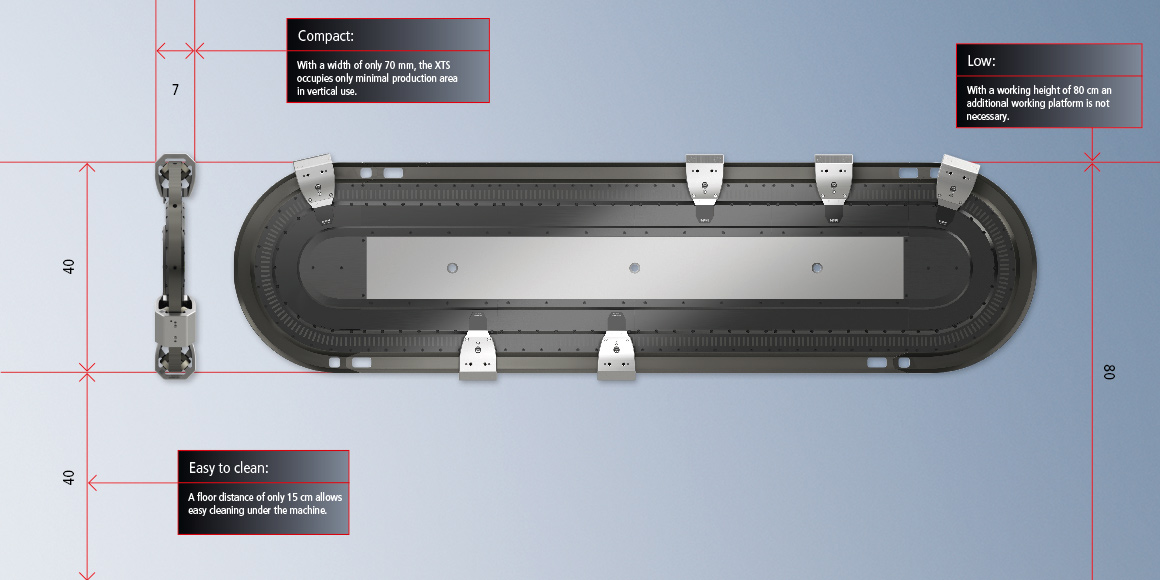

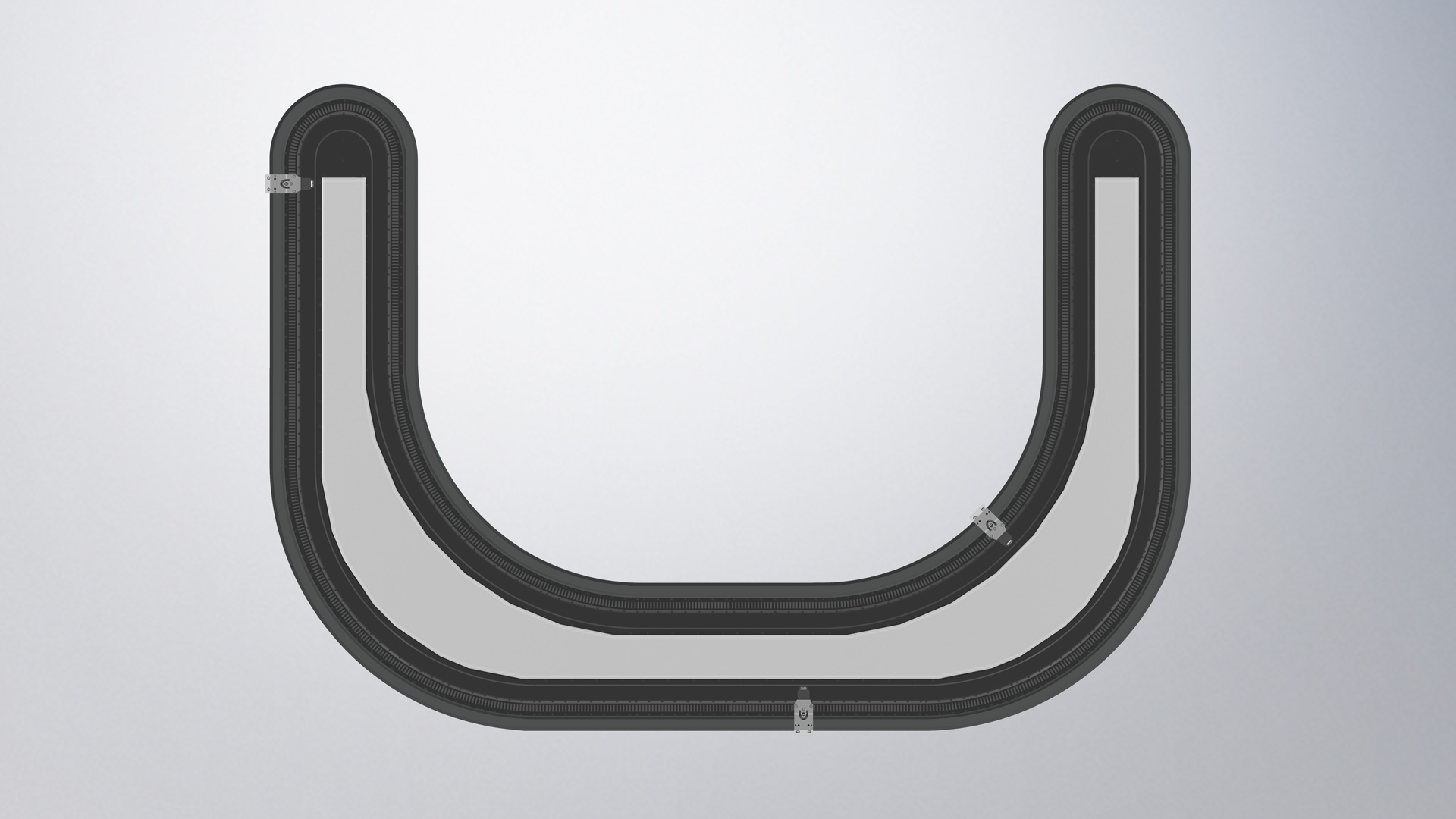

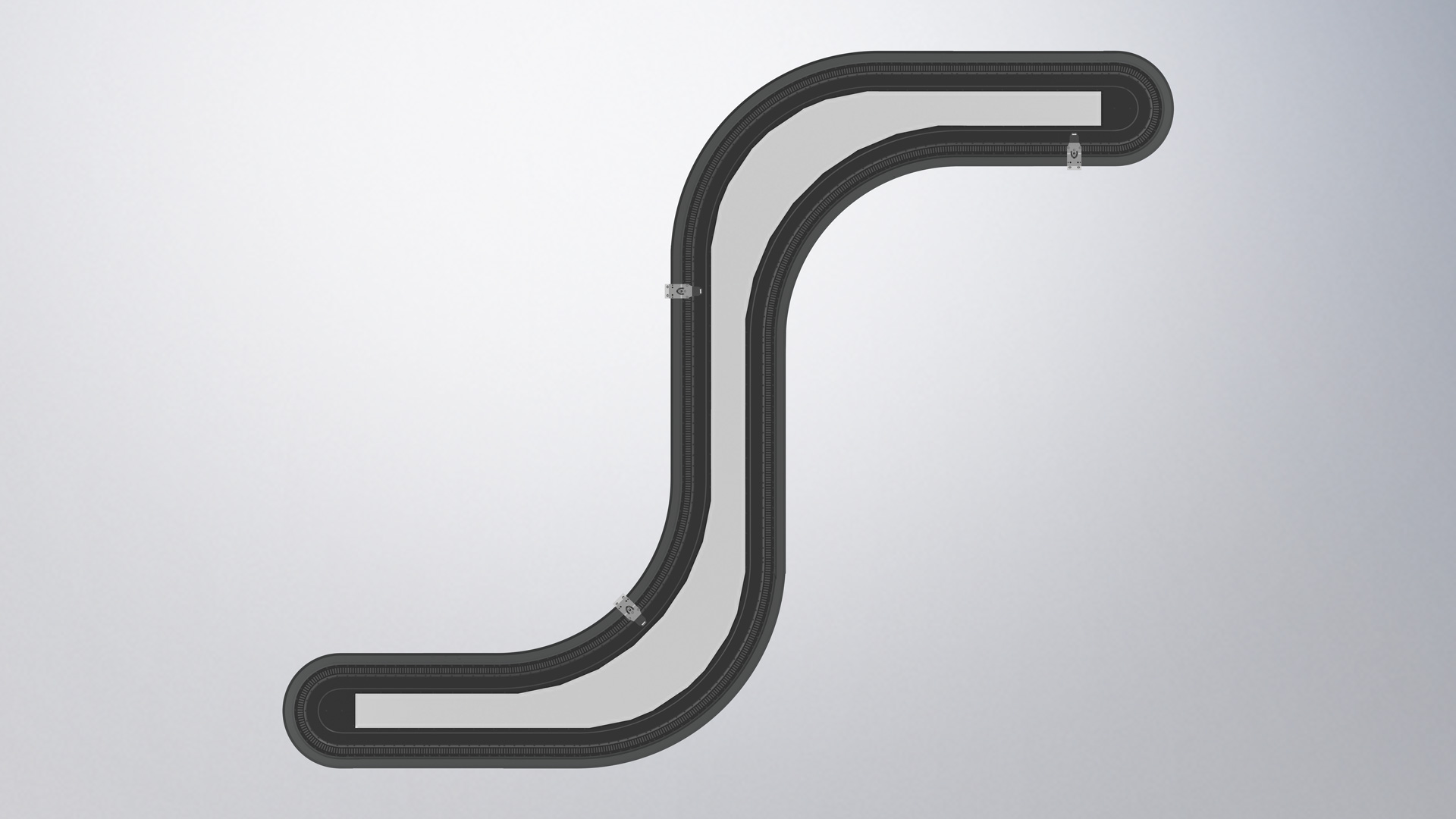

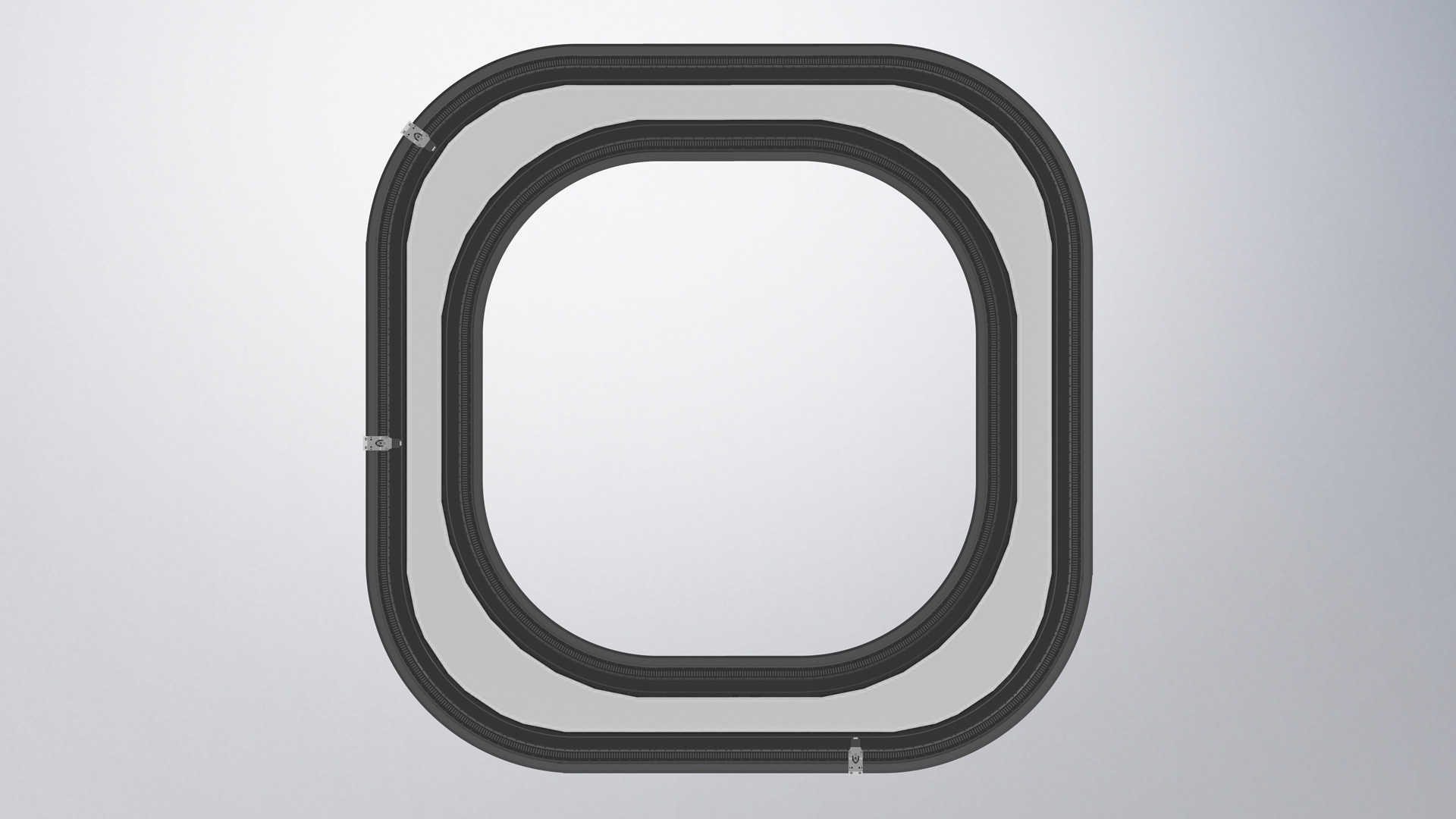

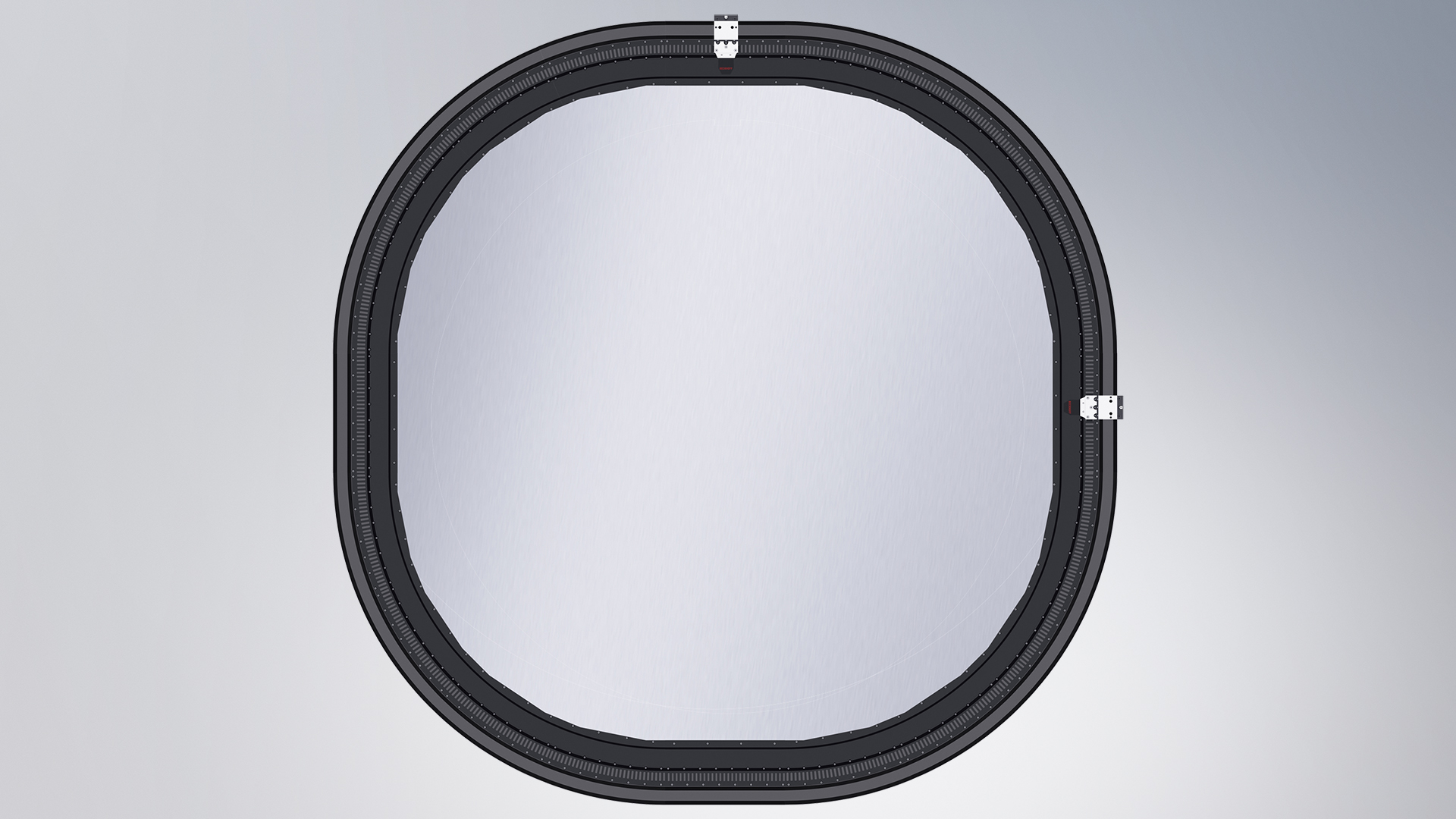

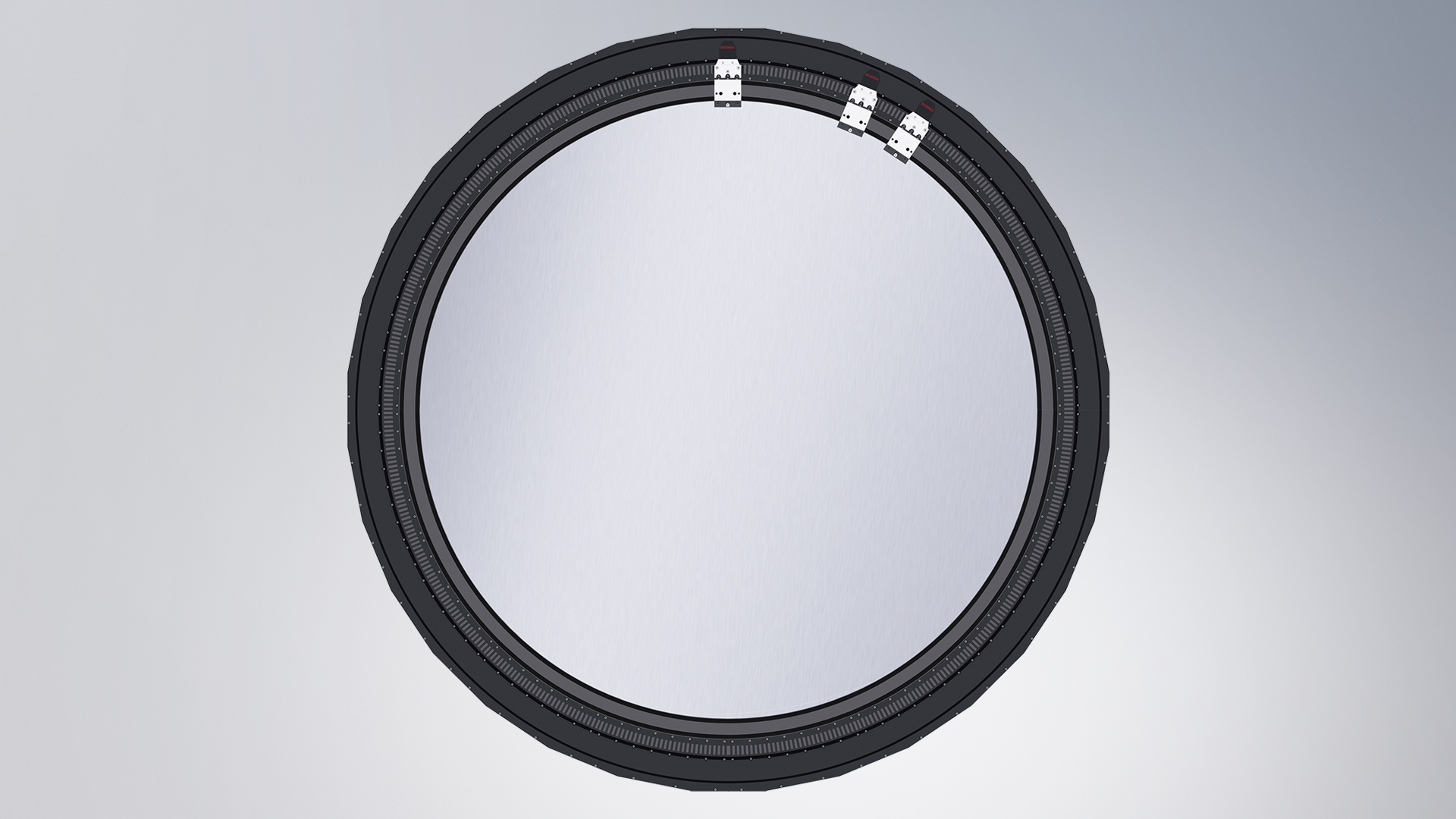

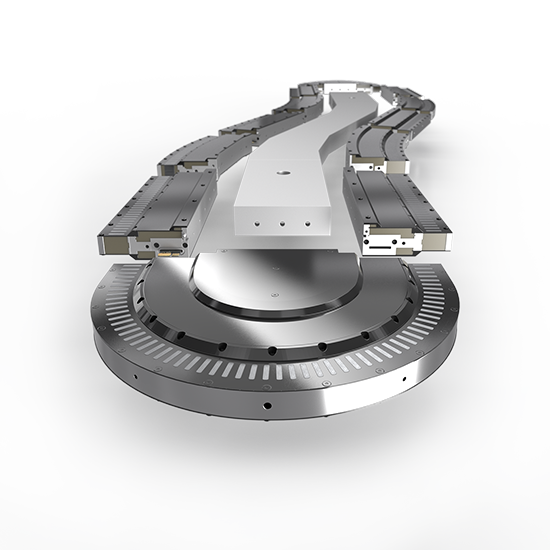

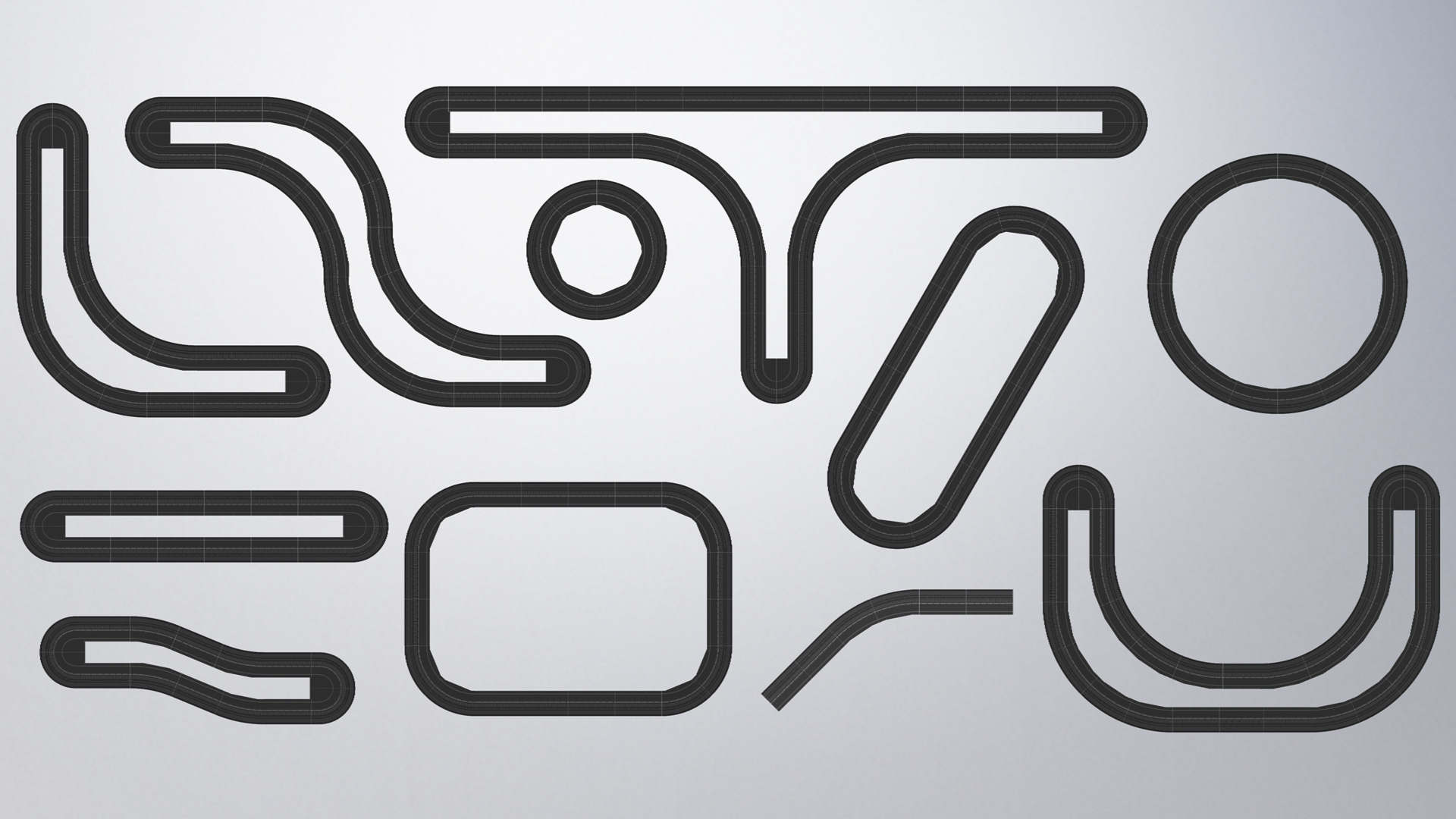

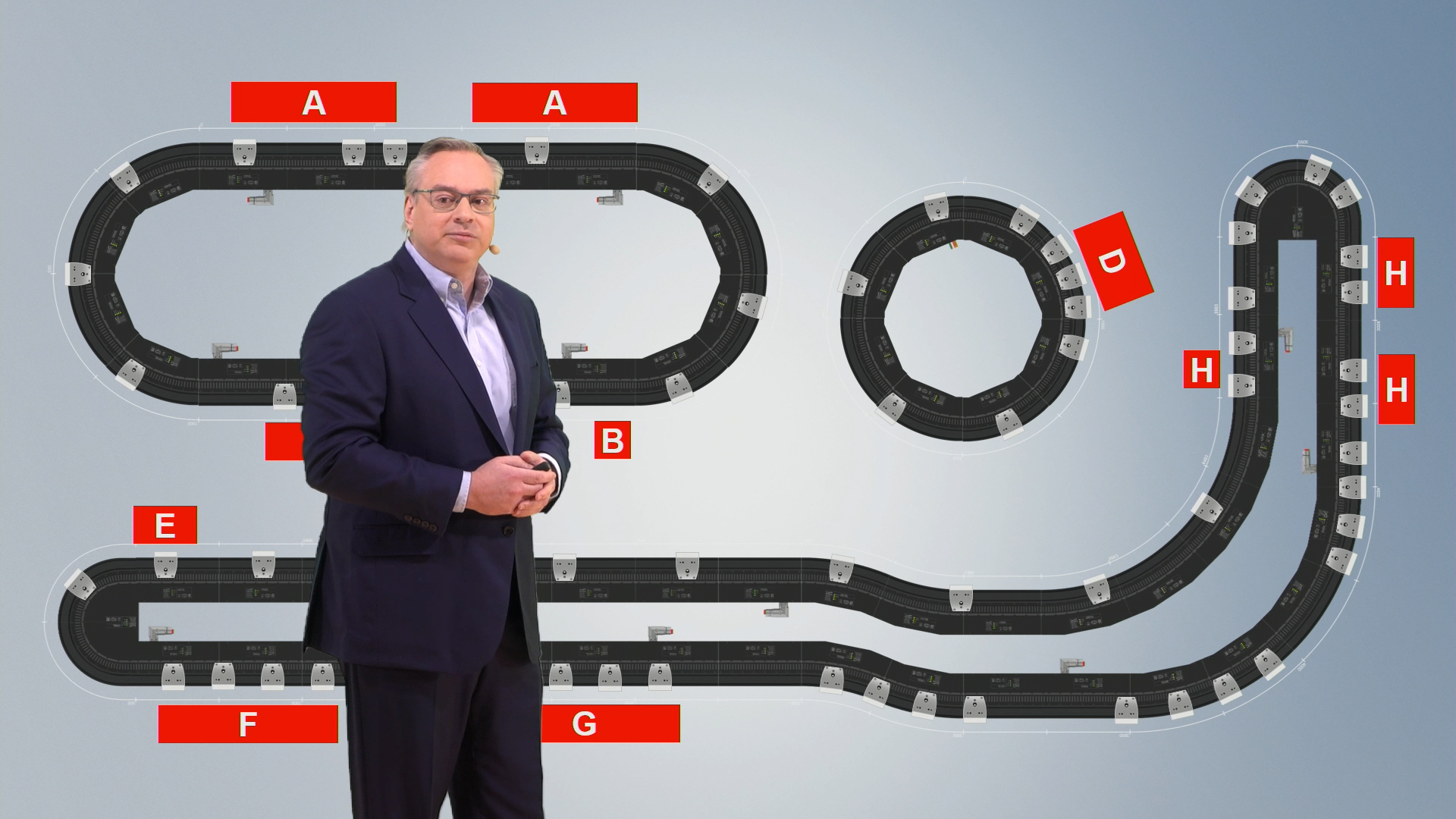

Using the XTS modular system, the XTS system can be perfectly adapted to the machine layout and/or the conditions in the hall. Motor modules with different radii (22.5°, -22.5°, 45° and 180°) and straight motor modules with different lengths (250 mm, 249 mm and 233 mm) are available. The customized routes enable more efficient use of the available installation space. This represents a viable solution especially in cases of limited production space and increasing product removals. It helps to overcome the challenges many producers face in terms of reducing the system footprint and increasing the modularity of the production system.

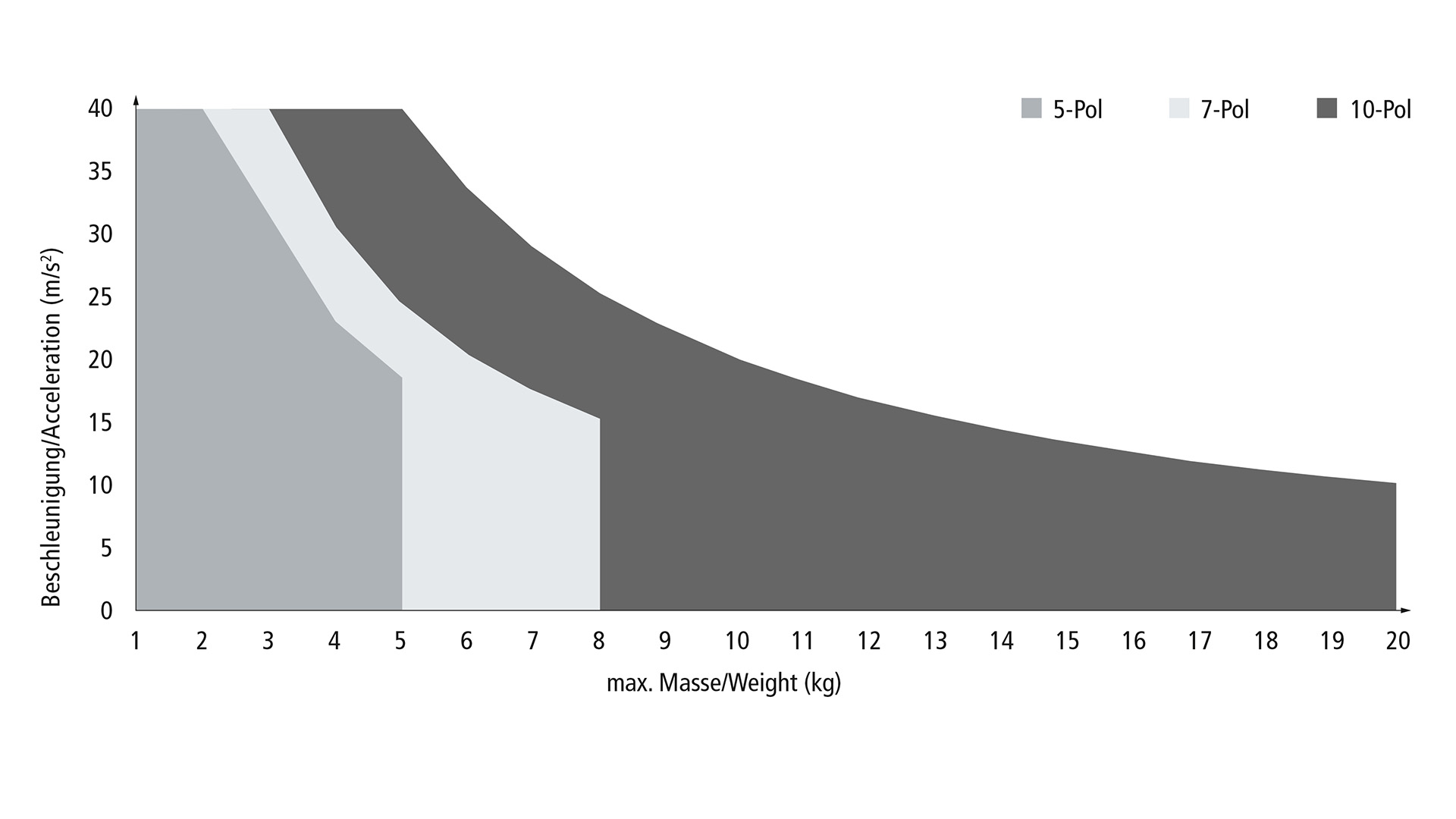

The XTS magnetic plate sets are part of the movers and generate a linear travel movement with the help of the magnetic travelling fields of the fully integrated XTS motor modules. Four performance classes are available, depending on the number of magnetic poles. These enable a minimum mover spacing of 50 mm or a maximum peak force of 210 N. Masses of more than 10 kg/mover can be transported with this peak force. A further increase in performance is possible through the mechanical coupling of several movers. In addition, the dynamics of the movers can be increased by larger forces while the mass remains constant. This leads in turn to an increase in production output.

Optimum time-to-market is becoming increasingly important due to the greater demands facing the plant development process, such as higher variant diversity and increased production output, in combination with ever shorter plant life cycles. The reduction and parallelization of the individual phases in the plant development process are essential.

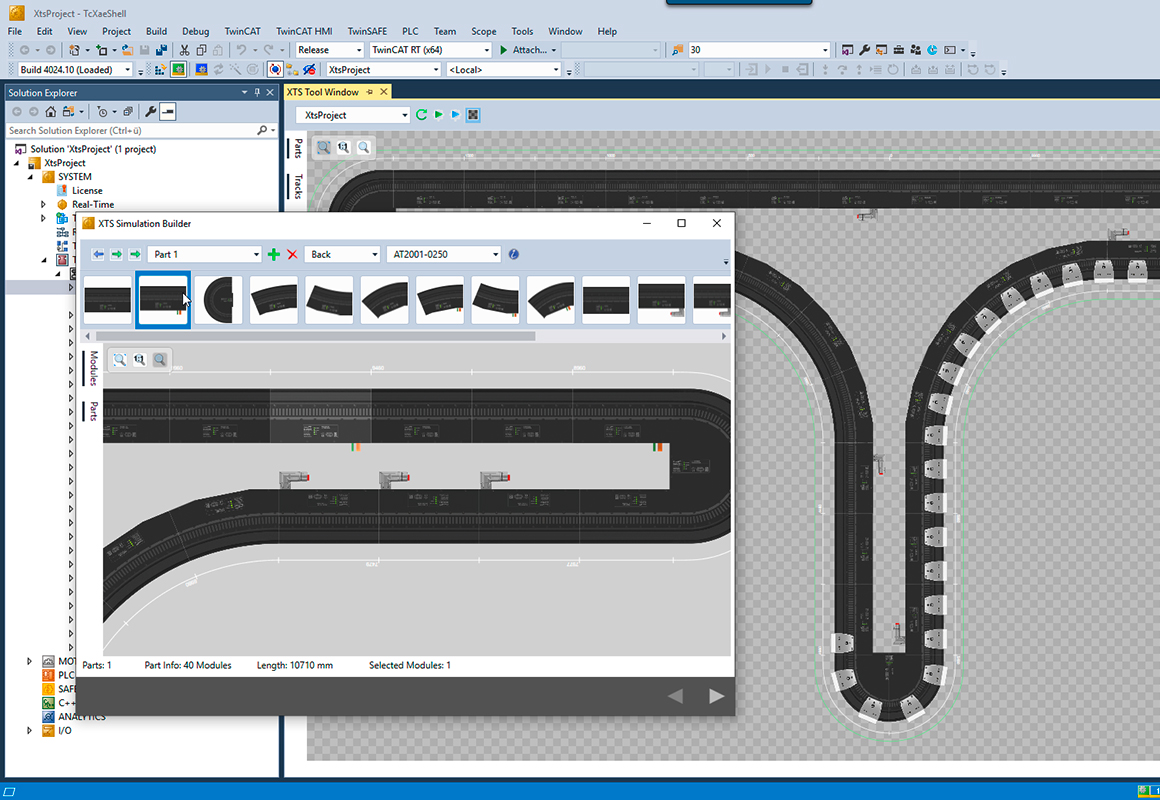

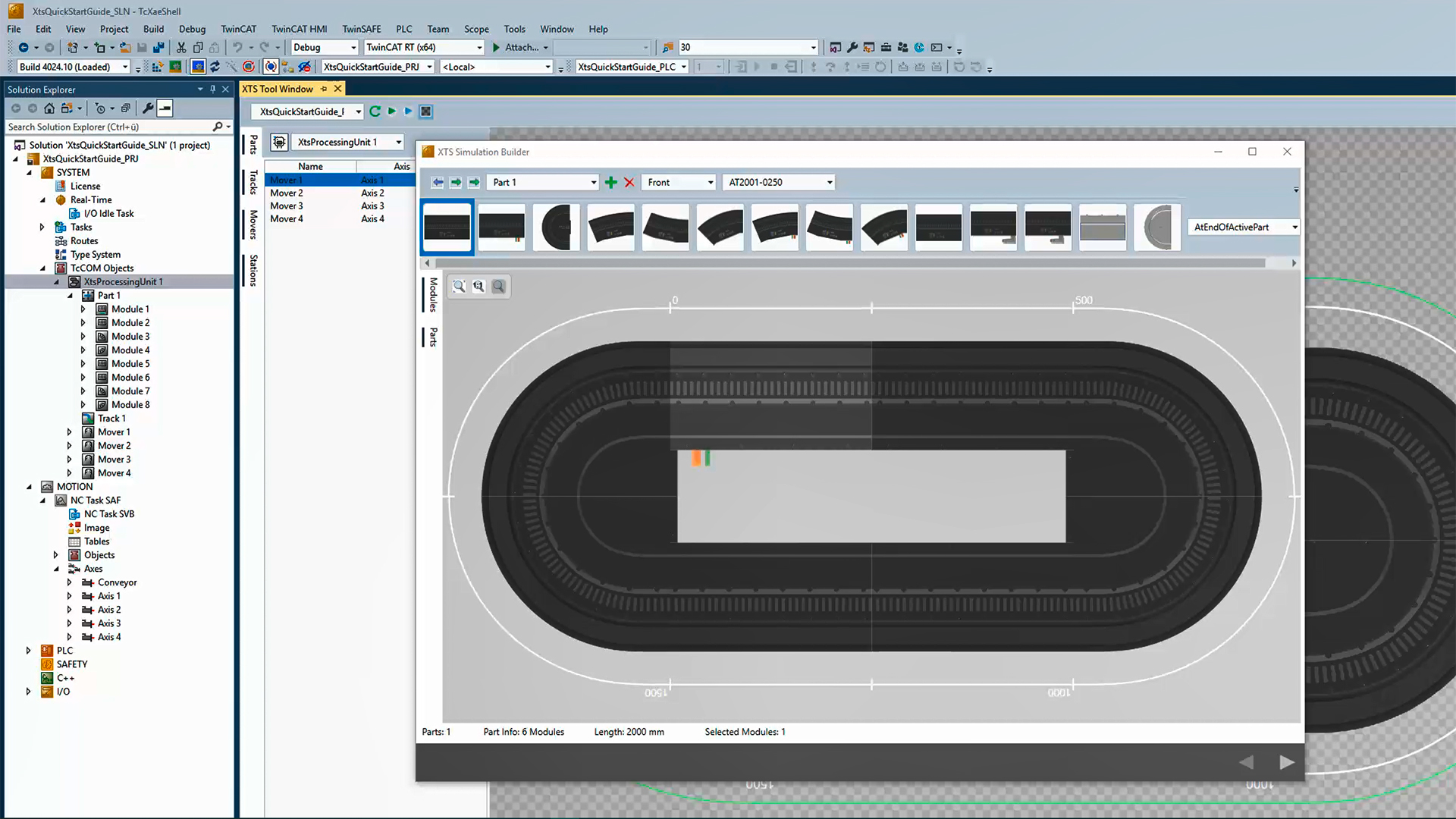

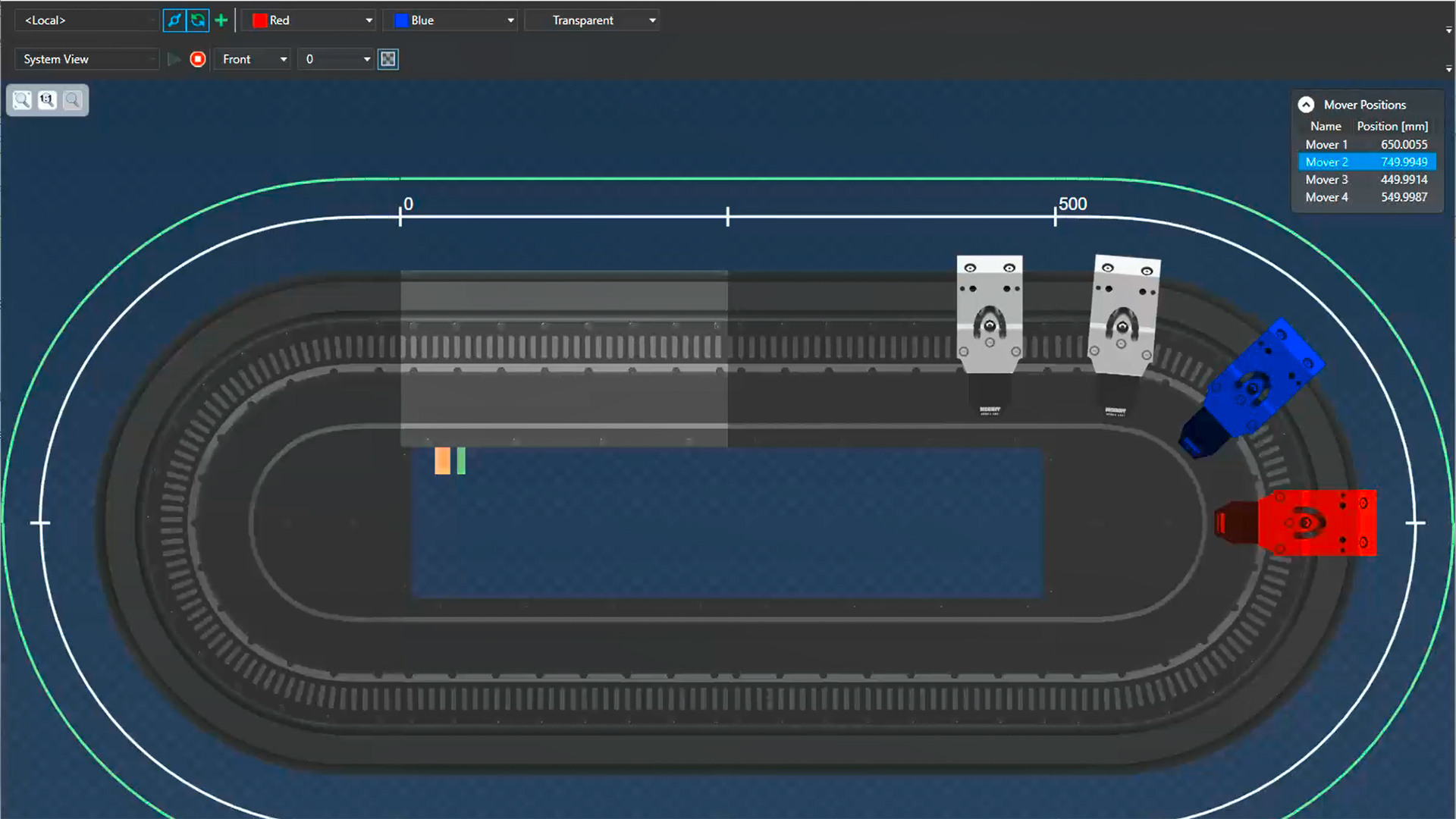

Integrated XTS simulation functions simplify plant design

The XTS simulation provides users with a software tool capable of achieving significant reductions during the design phase. The simulation enables the configuration of the desired routes from the XTS modular system without hardware and test setups as well as the validation of the subsequent integration into (existing) plant concepts and verification of application sequences. During the development process, all of the parameters (e.g. XTS path, number of XTS movers, etc.) can be modified and adapted to achieve the optimum solution.

Parallel software development reduces time-to-market

The complete integration into the TwinCAT automation software provides an additional benefit. Users can work in a familiar development environment, which they also utilize for the subsequent implementation. In addition, the program code developed for the simulation can also be used for the real hardware. This reduces costs and enables early implementation of the software without having to complete parts of the hardware. Overall, the time optimization and parallelization of the Plant design phases by using XTS simulation creates a significant competitive advantage.

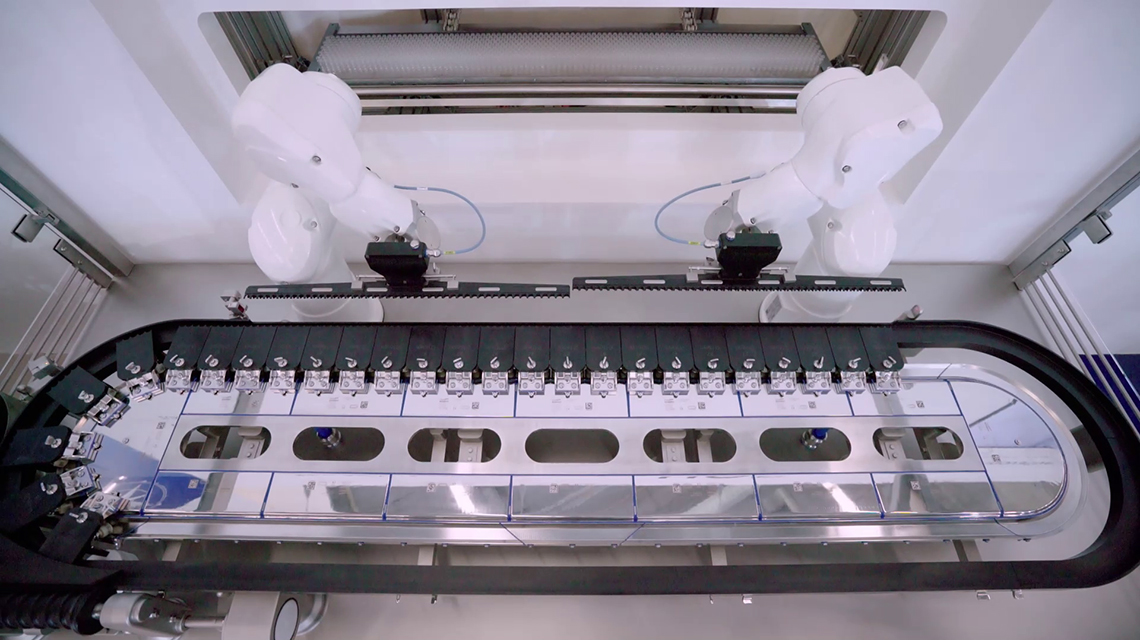

The eXtended Transport System in the stainless steel XTS Hygienic version has tapped into a wide range of new applications. It offers advantages over classic transportation solutions, in particular in the primary area of the food and pharmaceuticals industries, as well as the manufacture or filling of liquids. With the high protection rating IP69K and the hygienic design with no concealed edges or undercuts, simple cleaning is also possible in hygienically demanding environments. The electropolished stainless steel 1.4404 AISI 316L with a roughness depth of less than 0.8 µm and the high-pressure cleaner-resistant seals made of VMQ silicone can easily withstand harsh environmental conditions.

As central components of the mechatronic system, the motor modules in the XTS Hygienic can also be quickly mounted and dismounted. The connection of the modules is particularly simple due to the lateral plug contacts for the power and communication transmission. The electronic connection contacts can be implemented with or without a power supply cable. The power supply points or the number of power supplies can be adjusted without dismounting the motor modules.

The modularity of the motor modules is completed by two system solutions for guide rails and movers. Depending on the application requirements, suitable Beckhoff stainless steel guide rails are attached directly to the motor modules with a minimum of mounting effort. This structure can then be driven on by two hygienic design mover types: a stainless steel mover for particularly hygienically demanding environmental conditions and a mover made of anodized aluminum which can transport larger payloads with higher dynamics than the stainless steel variant. The second system solution consists of using a guide rail routed in parallel with the motor modules and a mover. A cover for the mounting surface of the rail interface for the motor modules as well as magnetic plate sets for the movers are available for this.

XTS enables a high degree of flexibility for parts transport in machines and plants through the independent control of movers with different motion profiles. Due to different geometries of the motor modules, both an open and a closed travel path can be created.

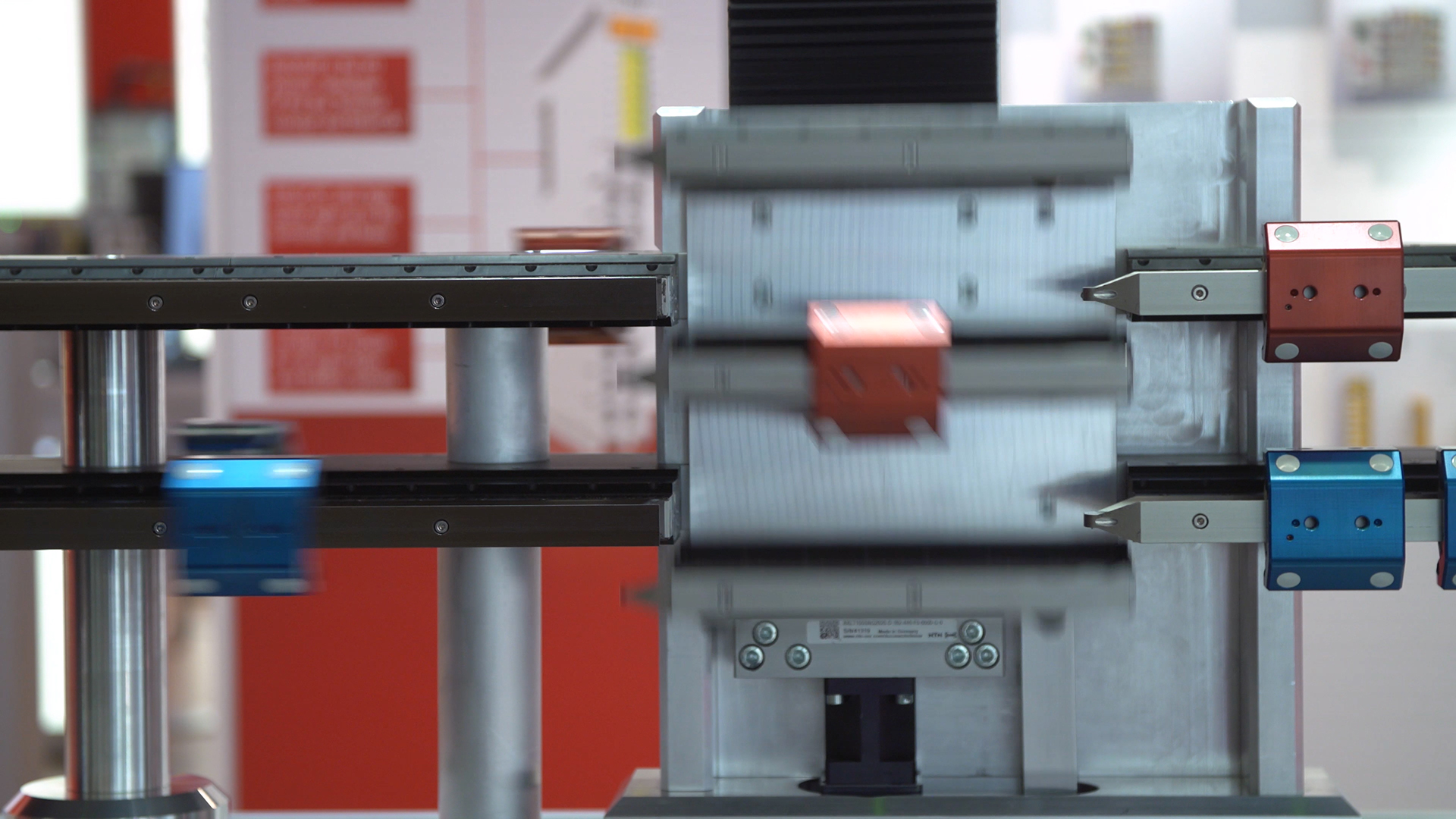

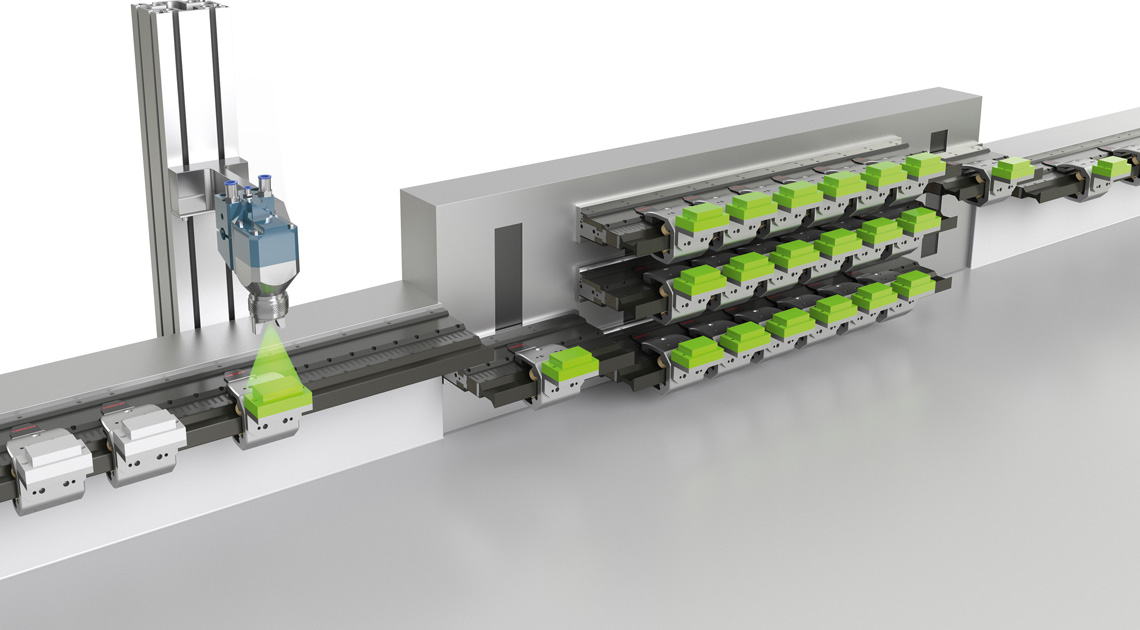

With the help of the XTS software function Track Management, an XTS structure can be divided into individual, spatially separated track sections. These can comprise just one or any number of consecutive motor modules. The track sections in turn form building blocks from which a variety of connected travel paths can be defined. By using a suitable mechanism, such as a spindle axle or a linear motor, the track sections can be moved with the movers on it. The exchange of movers between different XTS systems becomes possible. The motor modules and movers retain their full functionality at all times, so that even the moving track sections remain fully usable sections. The Track Management is part of the existing TwinCAT 3 XTS Extension TF5850.

Application examples

- insertion and removal of movers without interrupting the running product stream

- software-based tool change

- individual quality control

- integration of optional workstations

- sorting out of faulty products

- maintenance intervals detached from the production process

- manual workplace

- product buffer through the arrangement of several XTS tracks above one another

- secondary product stream, for example, a coating process in which the workstations can be passed through several times without changing direction with the help of a closed travel path

- Freely configurable order of products enables, for example, the combination of different products into packages.

Individual support for fast project implementation

Beckhoff provides individual support services to implement projects quickly and secure a competitive edge. Local XTS product specialists support the perfect integration of the XTS into innovative plants. Their cross-industry know-how supports the integration on various levels – from conceptual development to implementation and employee training.

Extensive experience enables the perfect integration of XTS

Beckhoff's extensive experience with over a thousand different XTS applications enables the direct and simple implementation of prototypes. Beckhoff already supports its customers during the conceptual design phase with a feasibility assessment and determination of possible cycle times. Optimization approaches are developed jointly to enable users to take full advantage of the benefits of XTS technology. The user can thus concentrate on its core competencies, while at the same time gaining initial experience with XTS technology. The skills acquired in this process can also be the basis for the independent implementation of further projects.

Pre-assembled function modules as plug-and-play solutions

With a pre-assembled function module, customers receive a ready-to-operate and tested XTS system: Motor modules, guide rails and movers are available as a complete unit with a matching control cabinet. The tested overall system significantly reduces potential sources of error. Beckhoff can also assist with on-site electrical installation and the development of application software according to customer specifications. For the user, this results in an easily integrated overall solution with calculable costs.

XTS in practical applications

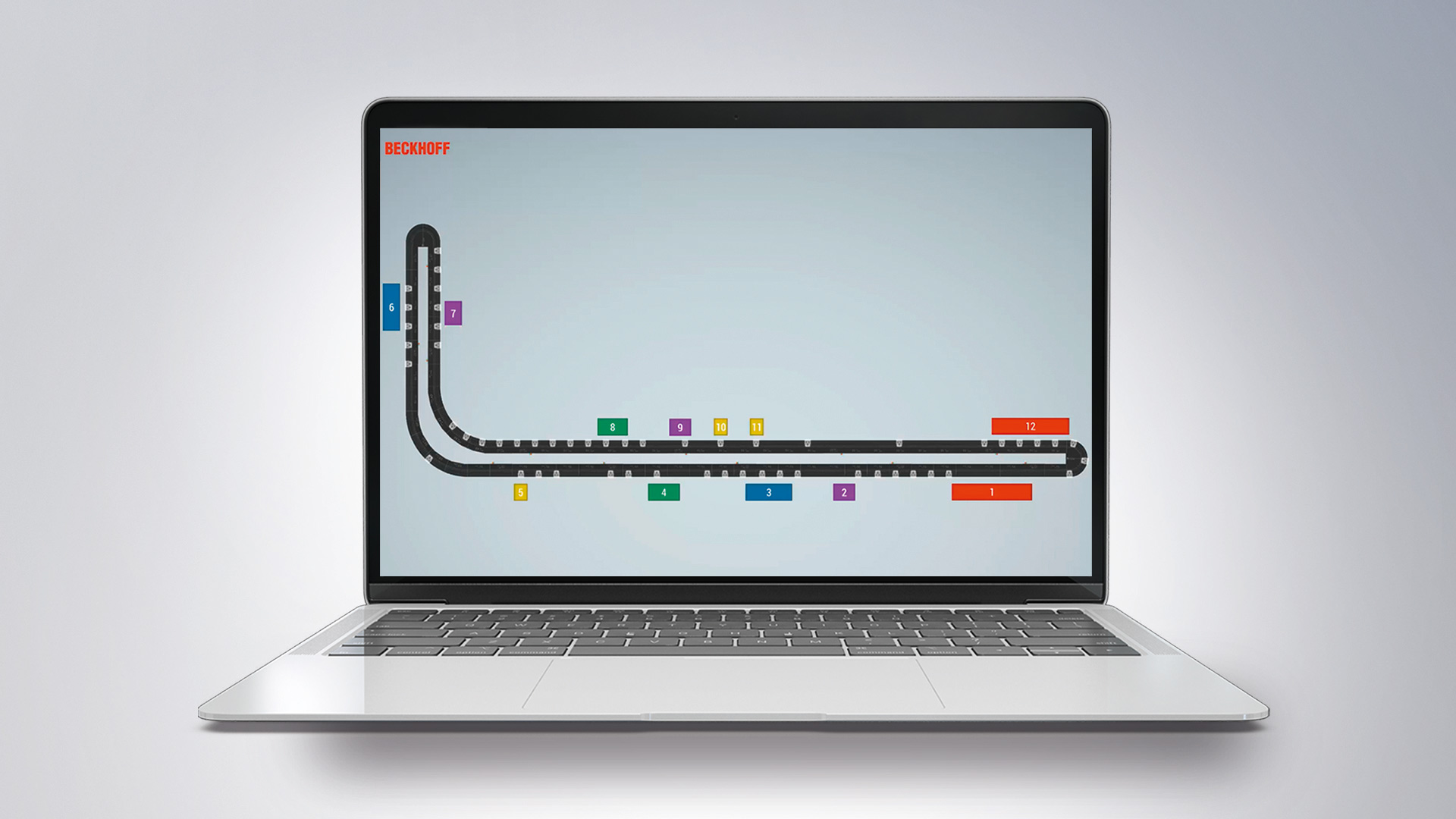

Integration of an L-shaped XTS system for optimum use of existing production spaces

As a specialist for packaging lines, Schubert Packaging Systems relies on the XTS linear transport system for a new solution for packaging vials and ampoules. An L-shaped geometry was particularly helpful here to ensure efficient use of the available hall space. In addition, XTS simulation was used at an early stage of the project so that the key parameters could be checked and optimized.

HOF Sonderanlagenbau: XTS Hygienic for the transport of pharmaceutical products

The XTS Hygienic is the central element of a new system design for the transport of pharmaceutical products at HOF Sonderanlagenbau. The stainless steel version of the intelligent XTS transport system meets all industry standards. It is designed for use in an isolator and can be cleaned with hydrogen peroxide. In addition, XTS enables particularly gentle product transport, which has reduced glass-to-glass contact.

XTS in use for high-performance packaging systems for confectionery products

Syntegon Technology in Beringen is a leading supplier of fully automated packaging systems for confectionery manufacturers around the world. The global confectionery industry is subject to many, sometimes rapidly changing trends. For manufacturers, this means producing many, different products that need to be packed in a wide variety of packages and pack sizes. "The intelligent transport system XTS gives Syntegon the flexibility to optimally solve every task with innovative ideas. In the meantime, we have been able to install around 100 packaging systems with XTS in the market," explains Kurt Gleichauf, Head of Technology & Development at Syntegon Packaging Systems AG in Beringen.

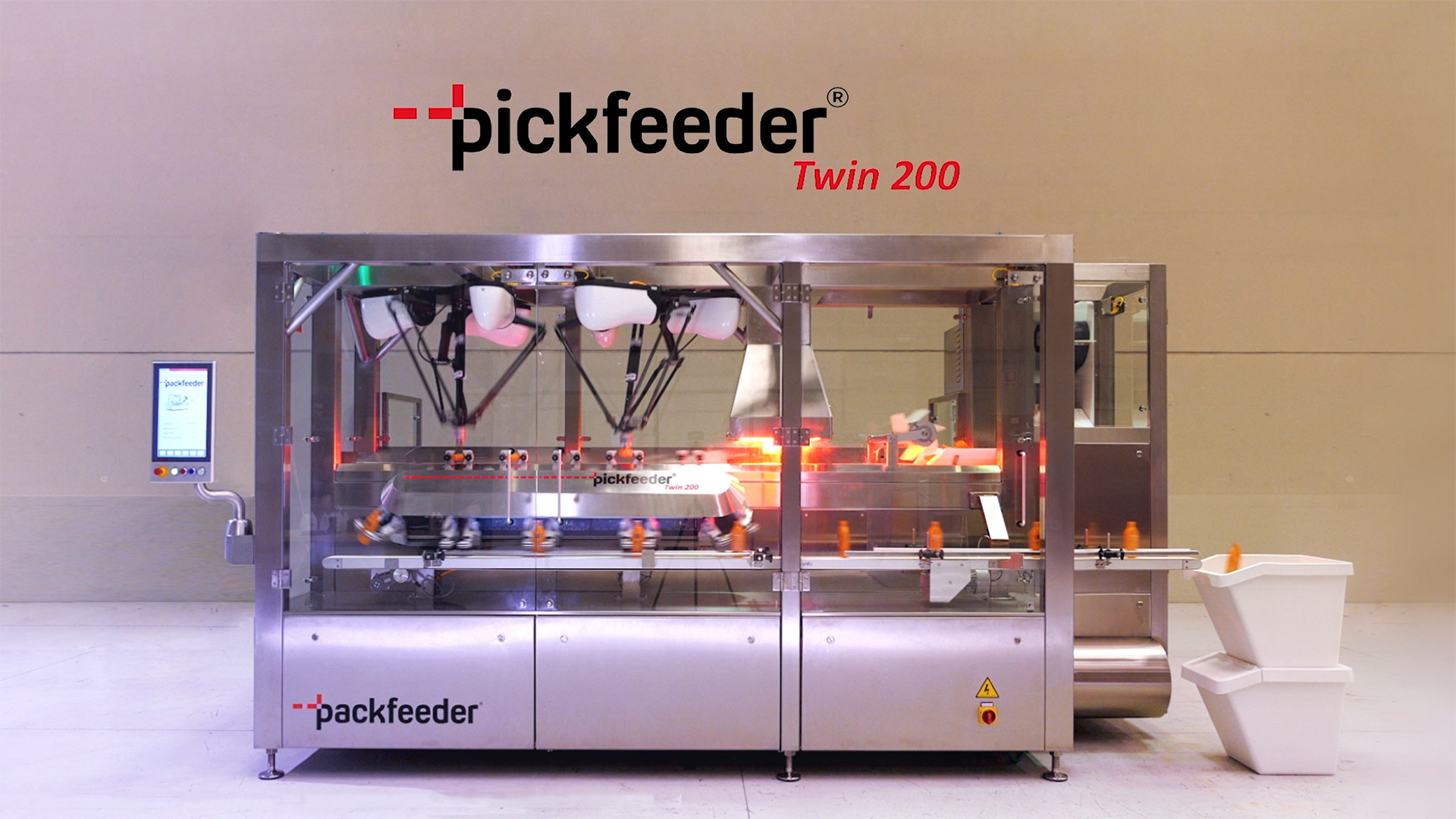

Compact design of the XTS enables highly efficient orientator for bottle

The Spanish company Packfeeder offers a complete series for automatic, robot-based bottle unscrambling with the XTS. With these systems, the particularly compact structure of the XTS enables an inclined installation position, so that bottles can be rotated from a lying to an upright position while in motion. The bottles are clamped between two movers. The changeover to other bottle formats takes place entirely in the software.

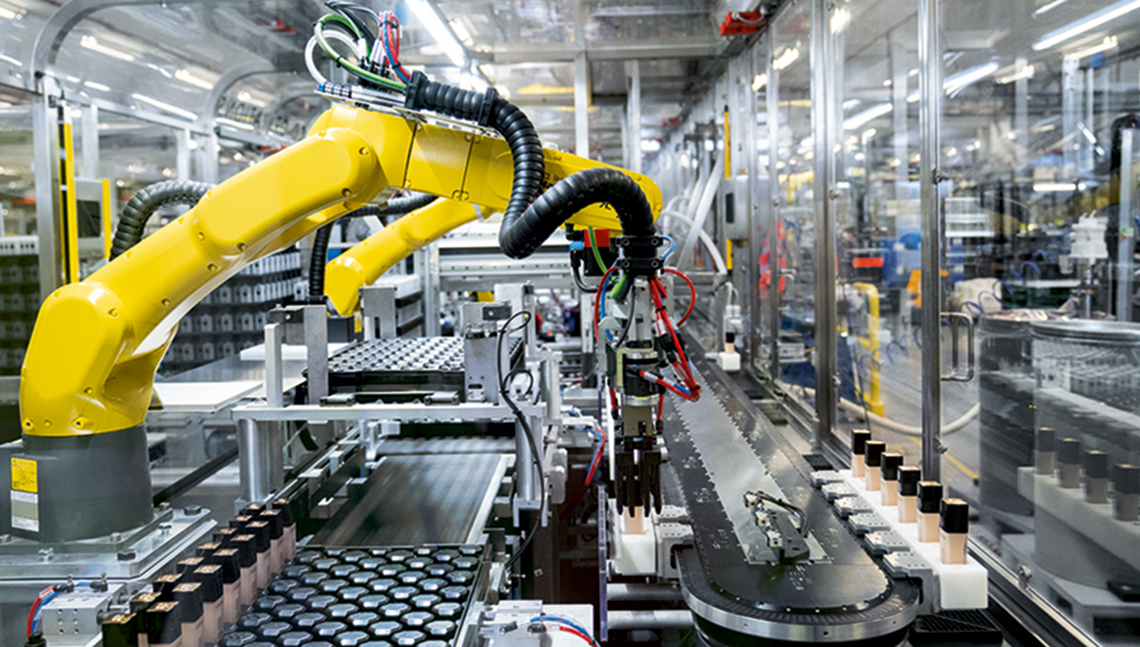

Realignment of the production: XTS as the core element of a new solution

L’Oréal is a leading cosmetics manufacturer and has set the strategic goal of making its production operations more agile. In order to achieve this, three production lines have already been equipped with the flexible XTS transport system. The XTS is the core element of the production lines and combines the functionality of five previously separate machines. The same line can now produce lot sizes ranging from a few hundred to millions of pieces as well as seven different format types with only 40 instead of 300 transport containers.

Eliminate standstills in packaging processes with XTS Track Management

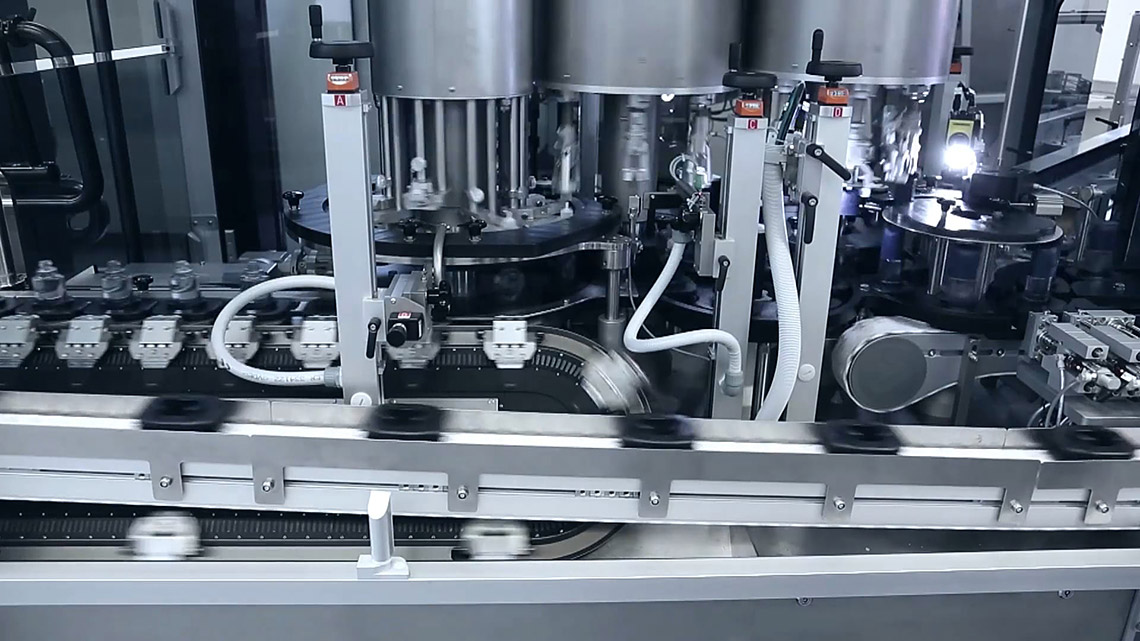

XTS makes production fault-free and completely eliminates standstills via two essential functions: firstly, all products are constantly tracked in a system with an XTS, and secondly, XTS Track Management runs through to the next stage of production without any standstills thanks to moving track sections, which are used to eject faulty parts. Track Management sections can be placed at any point in the production process, and the customer can add as many as they wish. Koch PAC’s sealing machine, as shown in this video, contains five Track Management stations.

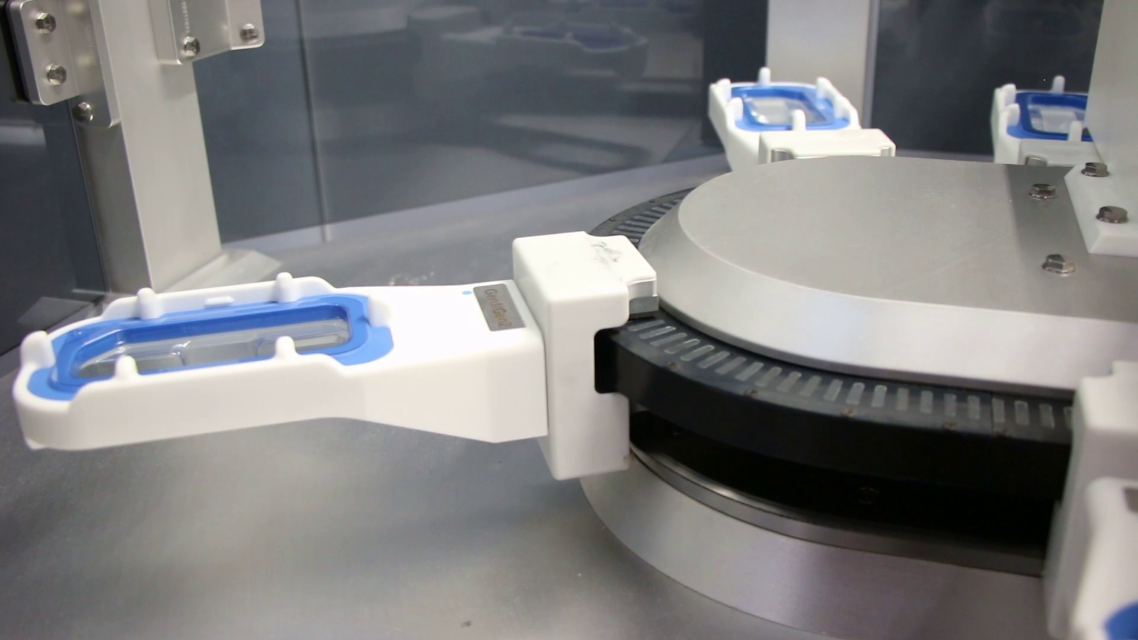

XTS enables parallel inspection processes for maximum throughput with a minimized footprint

Gefasoft has developed an exceptionally compact installation for the optical inspection of diffusors for airbags. The individual movement of the XTS movers enables individual inspection processes to be duplicated and executed in parallel. As a result, the workstations are utilized optimally and the total number of workstations is reduced. Overall, this leads to a 40 % reduction in the required footprint.

XTS enables gentle product handling with a high production rate

The machine manufacturer Groninger uses the XTS in its filling machines for the particularly gentle transport of open containers. The fully controlled product transport prevents the spillage of fluids, for example due to abrupt braking. In addition, the XTS movers are no longer subject to a common clock, which means that products can be flexibly synchronized with other processes.

More application examples

With the presentation of a new transport system in 2012, new possibilities for intelligent parts transport were created. By now, the system has found its way into numerous machine generations, not only replacing conventional conveyor belts, but also enabling an innovative design of the entire machine. Application examples are shown below.

- Multipack system with several XTS systems for different packaging units

- Linear drive system increases plant efficiency

- Quickly and easily from blister to carton packaging

- Linear transport system eliminates slow pick-and-place process

- Modular machine design and highly accurate positioning with XTS

- XTS for flexible positioning in the production of electric motors for the automotive industry

- XTS reduces changeover time from 1 hour to 1 minute

- Oval XTS line and PC-based control optimize cutting, winding and assembly of plastic hoses

- Integrating fast and flexible digital printing in the packaging process with XTS

- Efficient PSC production with XTS simplifies access to HIV tests

- XTS at the core of a labeling and grouping unit in a packaging line for toothbrushes

- Pizza case packer with XTS replaces three machines and conventional product transport technology

- Intelligent transport system as cost-effective, compact and highly flexible feeder component in cookie packaging

- Assembly solution 4.0: for more efficiency in production down to lot sizes of 1

- At the forefront of cosmetics packaging with XTS

- Flexibility boost for a pill bottle cap assembly line

- XTS doubles throughput and enhances quality

- XTS revolutionizes machine design in the packaging industry