Flexible MOCVD system uses PC-based control to create a modular machine design

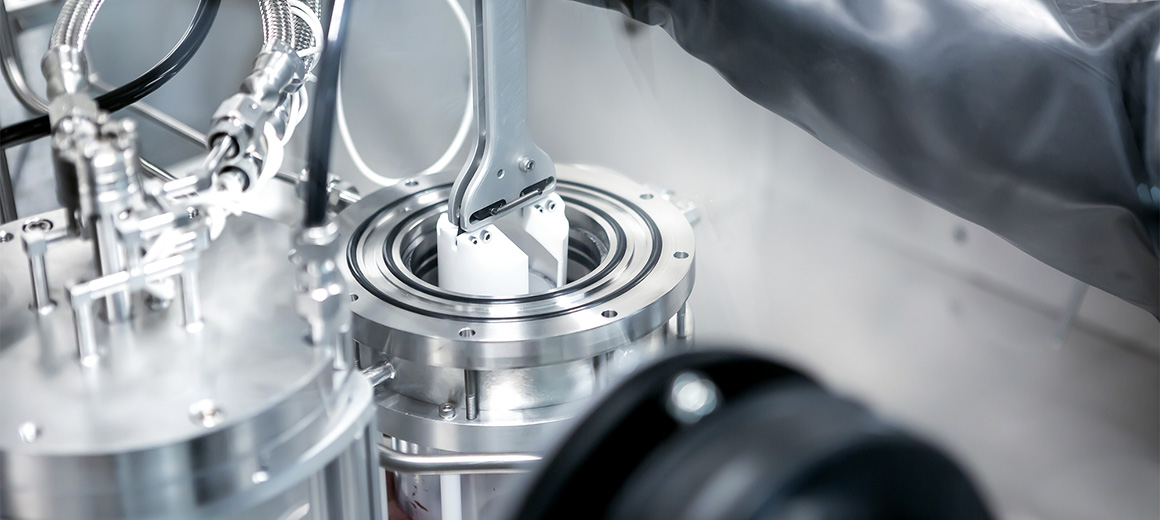

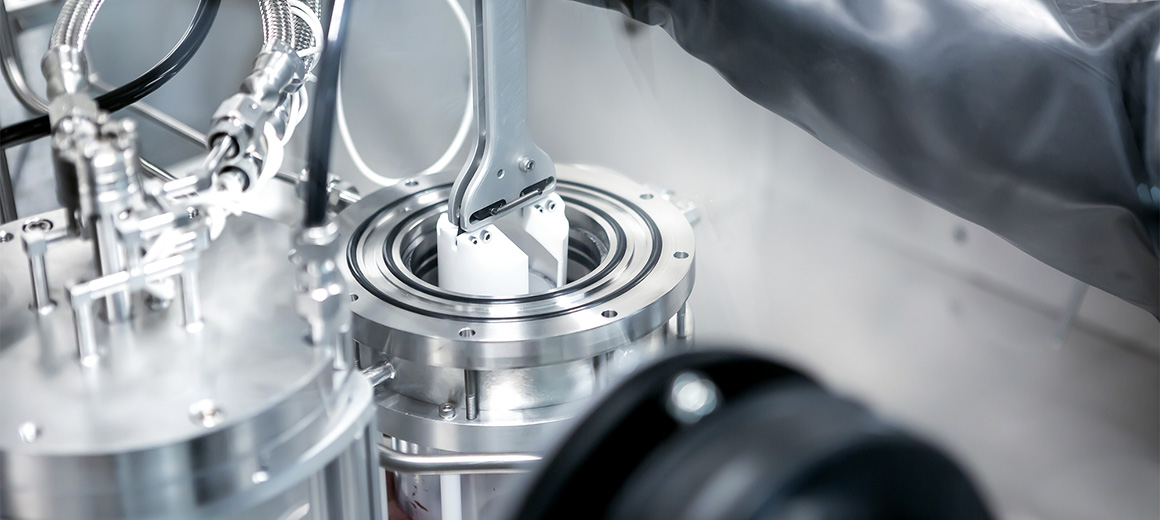

With the dual-use Agilis machine, Agnitron developed a system for the production of the semiconductor material gallium oxide through Metal Organic Chemical Vapor Deposition (MOCVD). In addition, the system provides the ability to switch to other materials if required. With PC-based control technology from Beckhoff, Agnitron not only ensures the necessary high reliability, but also the flexible scalability for diverse user requirements in research and development or small-to-medium-size production facilities.

Improving the design and production of high-voltage switches in consumer electronics, among other things, the semiconductor compound gallium oxide (Ga2O3) promises extensive and exciting benefits. However, the capabilities and use cases of this ultra-wide band gap compound must first be proven by researchers, such as Dr. Sriram Krishnamoorthy, assistant professor of electrical and computer engineering at the University of Utah.

One limitation for this kind of research is the quality of available Metal Organic Chemical Vapor Deposition (MOCVD) machines, which might not meet customization, price or reliability requirements to handle gallium oxide properly. While exploring new systems, Krishnamoorthy discovered the Agilis platform from the compound semiconductor research and development company Agnitron.

Andrei Osinsky, president and CEO of Agnitron, founded the Chanhassen, Minnesota-based company in 2008, and while many MOCVD machine builders had begun to focus primarily on large industry trends, such as LEDs, Agnitron was formed to supply new solutions to market segments with unmet needs. Since then, the company has completed its own research into beta gallium oxide applications and developed the Imperium MOVCD™ software as well as Agnitemp™ in situ metrology for their own systems. The company released the dual-use Agilis machine that can switch from growing beta gallium oxide to III-nitride materials with minor adjustments over a few days – something no other MOCVD machine currently offers. The design of the multi-purpose platform was facilitated by the modularity and flexibility of PC-based control technology.

Cost control and reliability are key

New MOCVD systems can easily surpass $1 million. Even considering the dual-use capability of Agilis, it requires a significant capital investment for Agnitron customers, who typically do not possess the kinds of budgets that giant semiconductor manufacturers do. However, requirements continue to increase for customers in both research and, especially, production to meet high quality standards and adhere to growth recipes. Ivan Yunchyk, director of controls and automation for Agnitron, explains: “We are in a cost-competitive market. It benefits us to provide versatile solutions at the lowest prices possible, but every component must be highly reliable and repeatable at the same time.”

Dr. Dmitri Volovik, senior principal engineer for Agnitron, adds: “The biggest compliment in this industry is for the customer to say a machine works exactly as it worked before. It takes these customers years of development work and millions of dollars to define processes, so they want new systems that can be programmed to maintain the semiconductor recipe exactly with no unplanned downtime.” In fact, when Agnitron encountered reliability issues with a previous vendor’s automation and control systems, the company was on the verge of losing customers until it began to explore new solutions from Beckhoff Automation, headquartered in nearby Savage, Minnesota.

Modular system is customizable for different users

With modularity in mind, the Agilis system offers two distinct control solutions: The Beckhoff CX2042 Embedded PC with a quad-core, Intel® Xeon® processor and the CX2040 Embedded PC with a quad-core, Intel® Core™ i7 processor. “We offer the CX2040 standard configuration to meet the needs of research and development customers,” Dmitri Volovik says. “However, our growing clientele in the production market required higher RAM and processing speed. Our Imperium software and SQL database must run on the same hardware, so to support more complex operations with greater data collection and the metrology requirements of Agnitemp, the CX2042 with its Xeon® processor and 1 terabyte solid state SSD drive was the optimal controller for round-the-clock production environments.”

Many refurbishment and retrofit projects also receive benefits by incorporating the more affordable CX2040. However, when existing PLCs are in acceptable working condition, the company will simply replace the legacy PCs with a Beckhoff C5102 rack-mounted Industrial PC (IPC). In either case, the backward-compatibility of Beckhoff hardware and software ensures semiconductor growth recipes are reliably maintained.

Using TwinCAT 3 automation software on the Embedded PCs allows Agnitron engineers to write the machine control logic in C# using Visual Studio. As a Windows-based device, the Embedded PC also allows them to install the Imperium control software and save data locally. By using a PC-based control system rather than a separate PC and PLC, the Agilis machine saves roughly $10,000 on control hardware.

Real-time networking capabilities while reducing space

The real-time networking capability of EtherCAT provides further benefits for the Agilis. High-density EL3318 EtherCAT Terminals connect Agilis to eight different thermocouples per terminal, which is crucial when working with beta gallium oxide and other complex semiconductor materials. These, along with other 16-channel I/O terminals, maintain a compact footprint. “Space becomes incredibly tight inside control cabinets, especially on smaller R&D systems,” Dmitri Volovik says. “The compactness of both EtherCAT I/O and the Beckhoff Embedded PCs makes a big difference.”

While EtherCAT has become the leading semiconductor industry network and is a SEMI standard today, DeviceNet was the industry’s widely accepted standard previously. In existing installations, the EL6752 DeviceNet Master/Slave Terminal creates a bridge between the EtherCAT network and DeviceNet field devices. EtherCAT also simplifies the engineering as Dmitri Volovik explains: “I can now integrate a DeviceNet network in a few hours using EtherCAT industrial Ethernet and the TwinCAT development environment. With solutions from a previous vendor, this regularly took an entire week.”

Researcher Sriram Krishnamoorthy believes the possibilities of the dual-use Agilis are game-changing for research organizations and the semiconductor industry: “No single platform available currently offers this. In fact, I have pending proposals to explore III-nitride and gallium oxide integration for very high-voltage vertical device applications, and this platform will provide an affordable option for my research and projects at many other institutions.”