PC-based control and OPC UA communication in a laser welding system for the electromobility sector

In order to serve the rapidly growing electromobility market, particularly efficient manufacturing processes are required when it comes to the production of lithium-ion battery systems. This is made possible by Manz’s BLS 500 laser welding system, which allows individual battery cells to be contacted highly precisely and thus connected to form battery modules. High efficiency is ensured by a graphical programming tool and a virtual commissioning tool from Manz, as well as through fast PC-based control technology from Beckhoff and the continuous OPC UA communication that can be achieved using it.

Manz AG, based in the German city of Reutlingen, is a globally operating hightech engineering company that focuses on production solutions for electromobility, battery production, electronics, energy, and medical technology. Its portfolio ranges from customized single machines for laboratory production or pilot and small series production to standardized modules and systems or turnkey lines for mass production. Consequently, the company has particularly high requirements regarding the flexibility and performance of the automation technology used, as can be seen in the production equipment for lithium-ion battery cells and battery systems as well as capacitors, to name but a few examples.

Application-specific customizable laser platform

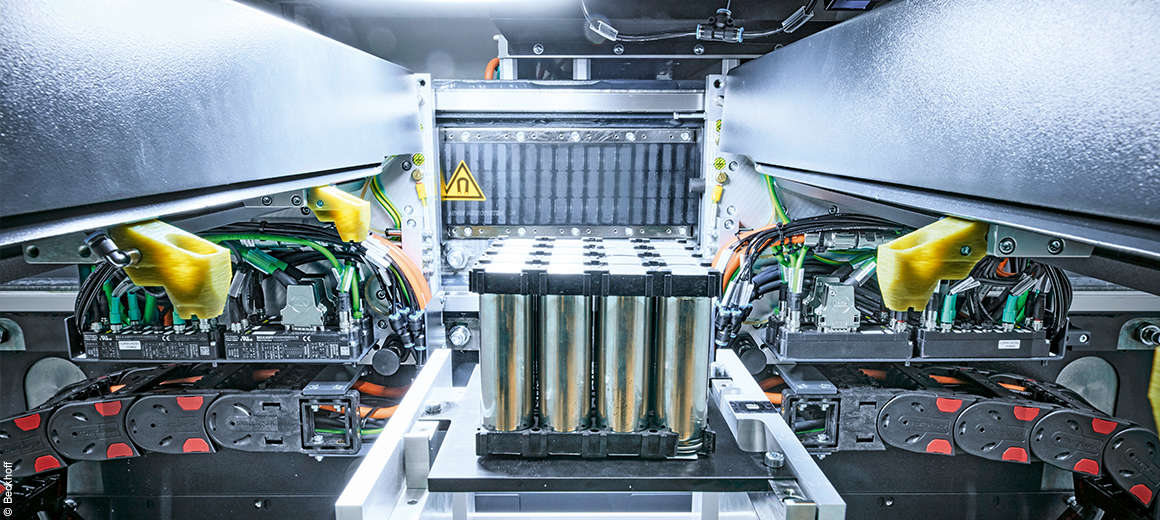

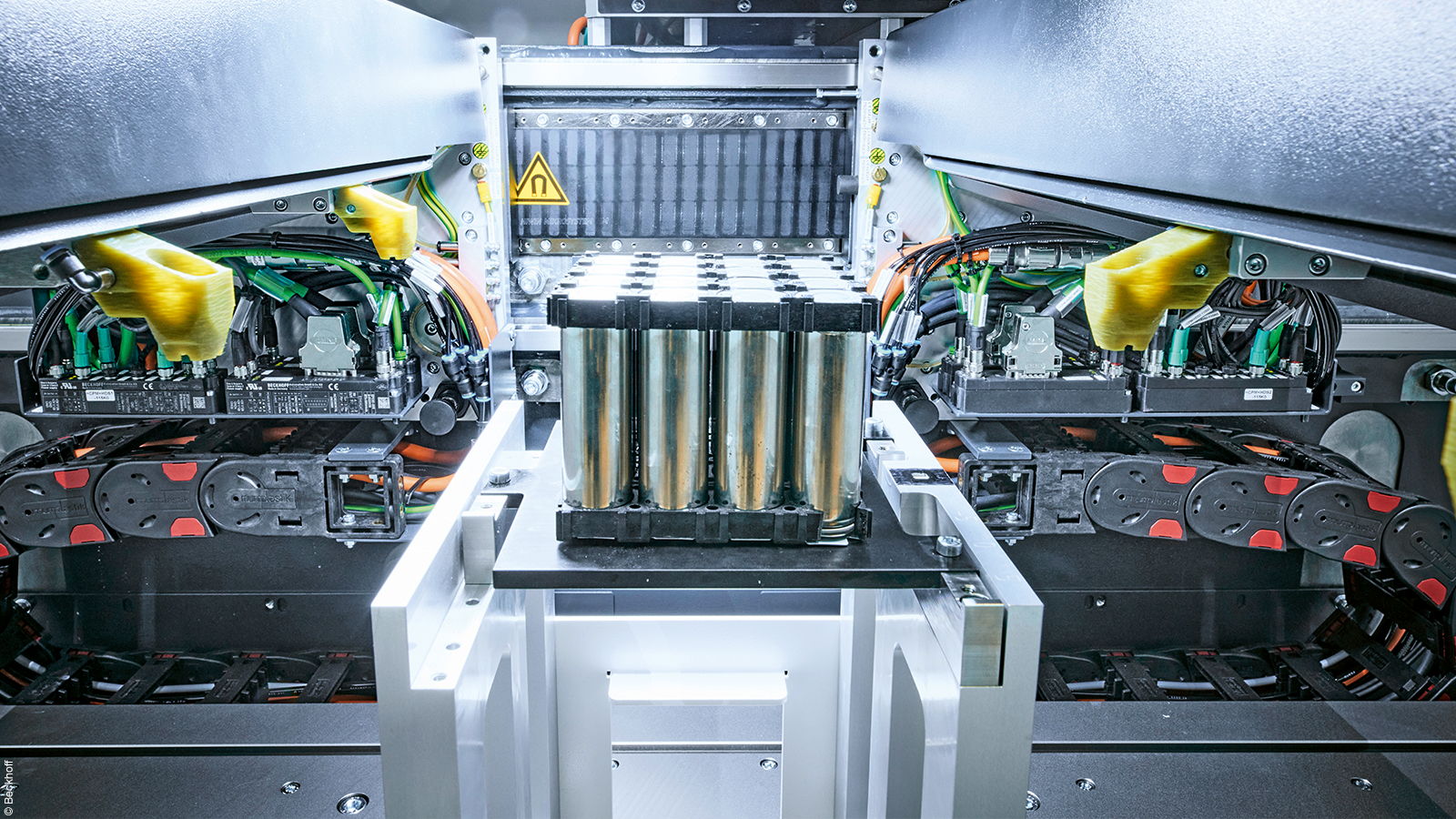

A prime example is the new Battery Laser System (BLS) 500, which is designed as a flexible platform for the various laser processes used in the manufacture of lithium-ion batteries. Starting from a standardized machine base, it can operate individually as a single system where the workpiece is loaded manually or as part of an integrated production line to achieve high-precision laser welding, as well as laser cutting and drilling, or partial material removal.

In the BLS 500 application described here, a battery module consisting of round battery cells is inserted into the machine manually in a laboratory scenario, but otherwise this is an automated process. The individual cells are then welded to the contacting elements by laser. As a graphical programming tool, the SmartLaser Assistant uses the CAD data of the underlying battery module to create the associated recipe, i.e., the optimum path calculation for all welding points as well as the appropriate laser power in each case. Stephan Lausterer, Head of Software Core Design and Product Development at Manz, describes the clear application advantage as follows: “Our programming tool makes it much easier to adapt the BLS 500 to diverse applications, i.e., to different cell types and module formats.” He adds that the result can then be conveniently examined in Manz’s virtual commissioning tool, and not only that: “Commissioning is accelerated and simplified by the fact that using the model the control program can be tested in detail and realistically in advance, i.e., before the machine has actually been mechanically assembled. In addition, high precision is achieved by using image processing to compare the CAD data of the battery pack with real-life data and to take any offset values into account during the welding process. In all these aspects, we benefit from the TwinCAT control software with its convenient and powerful OPC UA integration.”

System advantages of PC-based control

The importance of high-performance and, above all, flexible control technology has also increased significantly at Manz in recent years, and it was this that ultimately led to the partnership with Beckhoff which has been sustained for over ten years now. Stephan Lausterer explains this in more detail: “Originally, Manz developed its own control technology; however, this became increasingly difficult due to the growing relevance of electronics in mechanical engineering and the exceptionally fast innovation cycles in this field. We therefore went in search of a suitable specialist as a new control supplier. In a corresponding benchmark, PC-based control proved to be the optimal solution, in particular due to the PC-based concept and the flexible, open, and finely scalable system architecture. In addition, there was the innovative strength of Beckhoff – a factor that we regarded highly even back then.”

Tilman Plaß, automotive industry manager at Beckhoff, adds the following from an automation perspective: “The high requirements of the Manz systems can be met very well with PC-based control. These requirements include the short cycle times that can be achieved with our control technology as well as a logic that covers all processes throughout the application, an aspect which promotes speed during format changeovers in particular. The comprehensive functionality of TwinCAT up to OPC UA communication results in further advantages – and on both sides. For example, as a very early user of TwinCAT 3, Manz was able to provide us with important user feedback as part of our partnership.”

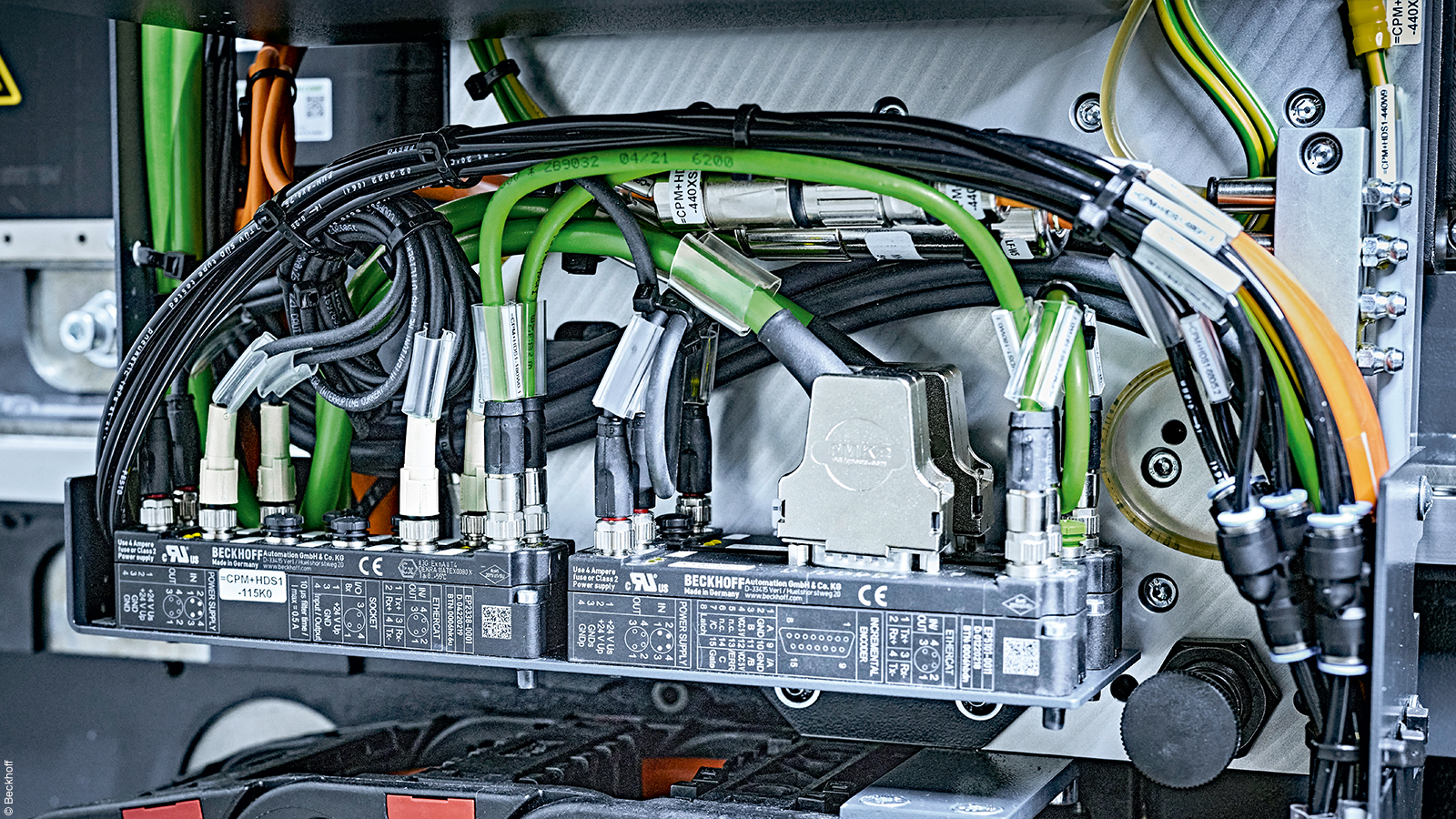

The hardware core of the BLS 500 controller is formed by a C6030 ultra-compact Industrial PC, whose main advantages Stephan Lausterer describes: “The C6030 is ideally suited to applications like this with limited installation space. In addition, the computer equipped with an Intel® CoreTM i7 CPU provides sufficient computing power for both machine control and visualization. This also holds true for future requirements, especially since Beckhoff is gradually integrating suitable new processor generations and – with the C6032 – also has a compact device variant with more interfaces in its portfolio.” Such a versatile industrial PC also makes sense for Stephan Lausterer from another perspective: “Purchasing and warehousing are significantly simplified as a result. The same applies to the entire test tool chain for hardware and software, something which is hugely important to us at Manz. Accordingly, all the software is tested on virtual machines as well as on the real hardware.”

All in all, the TwinCAT automation software meets Manz’s requirements very well, as Stephan Lausterer confirms: “Among other things, we benefit from the integration of TwinCAT in Visual Studio, as our software team also includes high-level language programmers. Added to this is the overall high level of flexibility, for example with the editors for the respective programming languages and through the variety of functions up to Safety Editor, TwinCAT Scope, and TwinCAT HMI. In our view, this level of integration is a unique selling point of TwinCAT.” He also adds that motion control can be programmed and simulated very conveniently in C++ and with the TwinCAT 3 NC PTP, NC I, and Kinematic Transformation blocks, and then run as a TcCOM module in the real-time context. In addition, the TcCOM concept makes it easier to reuse program code and provide suitable protection of intellectual property.

Higher-level communication via OPC UA

In addition to fast EtherCAT communication for the machine processes themselves, i.e., between the industrial PC and the EtherCAT terminals or drives, Manz relies on data exchange via OPC UA throughout the BLS 500. This is realized via the TwinCAT 3 function OPC UA (TF6100) for aspects including the transmission of camera images to the HMI, integration into higher-level systems, and cross-control communication. The virtual commissioning tool also exchanges data with the TwinCAT controller via OPC UA. Tilman Plaß notes the following in this regard: “The scope of OPC UA communication is very impressive. Manz recognized the advantages of standardized, secure, and vendor-independent communication early on and uses the TwinCAT OPC UA server and client at a considerable scale and with high performance.” Stephan Lausterer confirms this: “Almost all external communication runs via OPC UA, both for our Industrie 4.0 products and for customer applications. For non-OPC-UA-capable third-party components, the TwinCAT 3 function TCP/IP (TF6310) or XML Server (TF6421) is used – options which demonstrate the high level of system openness offered by PC-based control.”

In addition to manufacturer independence, IT security is an important aspect for Manz. Here, OPC UA offers the clear advantage that the corresponding security mechanisms are already integrated into the communication stacks, meaning that the necessary security capabilities are already provided from the outset. According to Stephan Lausterer, this is a topic that will become increasingly important in the future. Another benefit is that Beckhoff as an early adopter has already implemented an OPC UA client on the control side at a very early stage. Tilman Plaß also confirms this: “Beckhoff had already presented an application scenario of TwinCAT 3 in 2014 with the SOA PLC (SOA = service-oriented architecture), which combines logic functions and OPC UA services for data-consistent, secure, and standardized communication.”