TwinCAT | ability to see, listen and speak

Smart machine functions for TwinCAT Vision and TwinCAT Speech

More about this video

Automation

TwinCAT offers many features and various software function blocks for all automation tasks.

TwinCAT

The TwinCAT software system turns almost any PC-based system into a real-time control with multiple PLC, NC, CNC and/or robotics runtime systems.

TF4500 | TwinCAT 3 Speech

TwinCAT 3 Speech enables the multilingual input and output of queries or information implemented in an industrially compatible way. This makes interaction with TwinCAT much more efficient and convenient – in the widest variety of applications across all industries, from mechanical engineering to building automation.

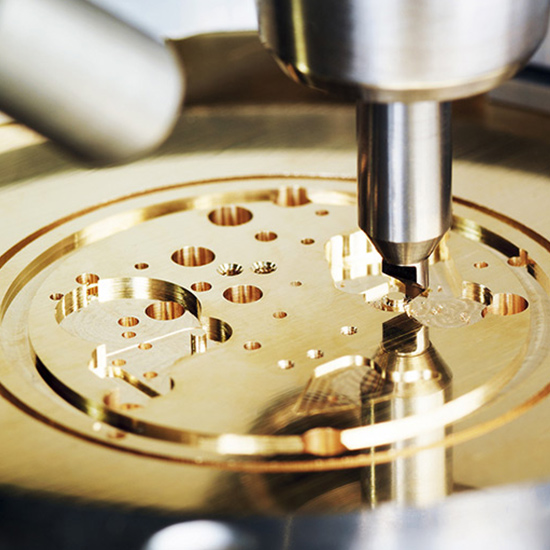

Packaging machines

PC-based control increases the productivity and flexibility of packaging machinery.

Transport und Logistik

Automation technology for sorting, conveying, and warehousing tasks in intralogistics.

Entertainment industry

The ultimate visitor experience: PC-based control for the entertainment industry.

AV and media technology

Media and control technology on a single platform with PC-based control.