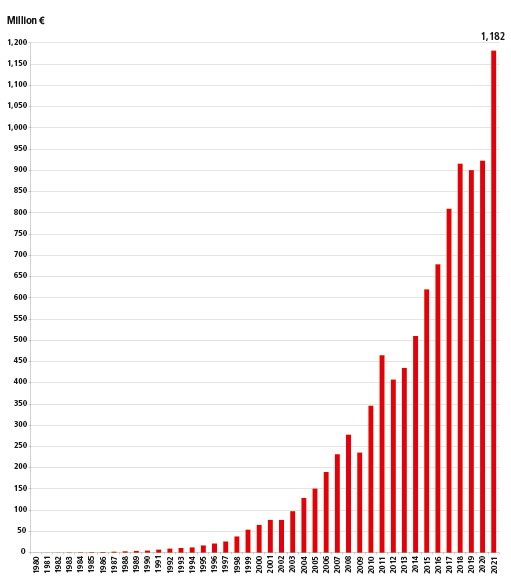

VERL, Germany, April 19, 2022 – Despite facing some real challenges along the way, fiscal year 2021 was a success for Beckhoff Automation. For the first time in its almost 42-year history, the automation technology specialist based in Verl, Germany, exceeded the one-billion-euro mark in sales. With a total worldwide result of 1.182 billion euros, the company increased its sales by around 28% in comparison to 2020.

- sales exceed 1 billion euros for the first time in 2021

- company continues on dynamic growth course

- challenges posed by component shortages and the pandemic

- MX-System revolutionizes the automation industry

“This is a great result that we are incredibly proud of,” reported Managing Owner Hans Beckhoff, whose company recorded an unprecedented level of incoming orders. “We could definitely have seen even more growth last year, but the shortage of components along with the limits on our own capacities has held us back in some areas.”

Exceptional economic developments in Germany and worldwide

For the German market, Beckhoff achieved a sales increase of around 27%, while the number of incoming orders more than doubled. The company also recorded similar trends in many other countries where it sells its products. “With one or two exceptions, we made significant gains in 2021 in almost all countries with our direct sales branches – often in the double-digit percentage range,” Hans Beckhoff said. “Our two largest subsidiaries (in China and the U.S.) also reported double-digit growth.” Similar to Germany, incoming orders abroad were mostly significantly higher than actual sales growth.

Automation technology is experiencing a global boom across all industries; however, demand is exceeding the production capacities of suppliers, which continue to fight the effects of the global pandemic. For Beckhoff, this is particularly evident in the shortage of semiconductors and other electronic components. “This bottleneck is likely to continue throughout 2022,” predicted Hans Beckhoff. “Nevertheless, we need to prepare for better raw material availability so that we can fulfill customer orders as quickly as possible. This is why we are working tirelessly to expand and optimize our entire company – from administration and development through to production.”

Corporate infrastructure expansions at the global headquarters in Verl

The rapid and dynamic growth of the technology company presents some major challenges. Production capacities have already been expanded and personnel resources increased. By the middle of this year, Beckhoff will have expanded its production capacities in Verl and the surrounding area by more than 50% compared with the beginning of 2020. “To this end, we are mobilizing the last space reserves we have and acquiring even more,” Hans Beckhoff said.

Beckhoff recently acquired a 15-hectare (37-acre) site near its existing facilities in an inter-municipal industrial park now being planned by the cities of Verl and Rietberg. “We plan to create an industrial park here that will provide space for further expansion in the future for both Beckhoff Automation and our wholly owned subsidiaries, Smyczek and Schirmer, which are also growing dynamically along with us,” he continued. “At least an additional 1,000 jobs will be created here over the next 10 years.”

Further expansion around the globe

Beckhoff is accelerating expansions across Germany – with a new sales office in Balingen and an expansion of Fertig Motors in Marktheidenfeld – and the 40 countries where it maintains subsidiaries. After delays due to the pandemic, Beckhoff Canada relocated its headquarters to a state-of-the art facility in Cambridge, Ontario, and opened a sales and support office near Vancouver. Beckhoff USA also opened new sales and support offices in Denver, Milwaukee and Orlando, as well as the Process Industry Technical Center in Houston. Globally, the company opened its first office in Lithuania, new headquarters offices in Austria and Sweden, and a production facility in Shanghai, the first one outside Germany. This facility will specifically serve the Chinese market, which represents about 22% of the company’s sales.

New Automation Technology

MX-System revolutionizes control cabinet design

As a family-owned business in East Westphalia, Beckhoff remains a pioneer of PC-based control technology and has been on the leading edge of many automation technology standards that are mainstays today. Last year, Beckhoff launched numerous developments into its existing Industrial PC (IPC), I/O, drive technology and automation software product families. With the introduction of its MX-System, the company presented the automation world with a game-changing revolution and expanded its portfolio to include a completely new product category.

“The MX-System is a modular automation toolkit. All functions that were previously housed in the control cabinet can now be easily mounted on a baseplate using appropriate modules. The robust design of the system facilitates direct mounting on the machine, so an additional protective housing is no longer necessary. The easy-to-use system represents a revolution in machine electrification and will change the face of automation forever,” explained Hans Beckhoff.

“Our MX-System is a perfect fit in terms of machine building, but the system should also offer users significant benefits when it comes to process technology, measurement technology and much more. Wherever electrical energy and intelligence are involved, the MX-System will offer real advantages,” he added. In addition to the space savings, MX-System also simplifies the design, engineering and installation of the control technologies: “For example, a control cabinet assembly that previously took 24 hours can be reduced to around one hour of simple module assembly,” reported Hans Beckhoff, who actually started his company in the early 1980s with the construction of control cabinets as its core business.

XTS transport system adds innovative No Cable Technology (NCT)

Beckhoff has expanded its eXtended Transport System (XTS) with a new technology for contactless energy and data transmission for movers. The contactless power supply and synchronous real-time data communication transforms the individual movers into mobile handling and processing stations, representing a quantum leap in terms of machine flexibility. With NCT, the modular XTS system has expanded to include a special motor module and electronics that can be mounted on the movers. The hardware required for the transmission technology is fully integrated into the motor module, which means that the existing functionalities and compact design are retained. No additional connections or supply lines are required. The control of the hardware on the mover is fully implemented in TwinCAT software. All known TwinCAT functionalities are available for simple project implementation.

ELM3002-0205 for high-voltage measurement on car batteries, generators and motors

In addition to equipping the BMW Group’s worldwide automotive production with IPCs and multi-touch control panels, Beckhoff delivers a range of control, networking and mechatronics technologies for electric vehicle (EV) production, particularly among market leaders based in the U.S. Adding to its solutions for this area, the company has launched the ELM3002-0205 EtherCAT measurement terminal, which ensures highly accurate and reliable measurements up to 1,000 V in the areas of EV production and renewable energies. The basic requirement for this is a voltage measurement in the 1,000 V range directly at the generator. The global EV market is making similar demands, for example, in the rapidly increasing large-scale production of high-quality car batteries and accumulators at sites around the world.

The 2-channel measurement terminal achieves a maximum sampling rate of 50 kSps per channel with its built-in oversampling function. This high sampling rate for high-voltage applications enables even deeper insights into the respective energy application. As a result, the ELM3002-0205 enables faster response times at the generator and, due to the high measurement accuracy, more precise frequency measurement, which leads to improved frequency stabilization in power grids. In battery testing applications, the high sampling rate supports reliable load and quality tests.

Employees

Continued workforce growth and development

In the past fiscal year, Beckhoff hired more than 500 new employees worldwide. This means that, as of March 2022, the family company now employs 5,000 employees (4,500 in the previous year): 3,850 in Germany and 1,450 abroad. Beckhoff Canada grew to more than 30 skilled employees, and Beckhoff USA now employs 200 team members.

“Having the expertise we need in-house is a major success factor for us. Beckhoff manufactures sophisticated, high-tech products that are developed by a wide array of the brightest minds working together within our company,” noted Hans Beckhoff, explaining the comparatively high total of 1,900 engineers currently numbered among his employees. “At Beckhoff, we say: ‘Engineers must save the world!’ It is our task to develop products and automate production processes in such a way that they consume fewer raw materials and less energy than in the past. Every year, efficiency and productivity must be increased to meet the worldwide desire for higher prosperity in an ecologically sustainable way.”

Beckhoff has been training young people in eight different industrial and commercial professions since the 1980s, which means that it is well-positioned to count on a valuable pool of skilled workers in the future. Since 2010, the high-tech manufacturer has also been focusing on academic training in the form of work-integrated study programs in cooperation with the Bielefeld University of Applied Sciences at its Gütersloh campus in Germany.

-

22.03.2022

Breakthrough development: Beckhoff is revolutionizing the automation industry again with its MX-System. The modular system enables control cabinet-free automation of machines and systems, saving not only space, but also a significant amount of time in the design, engineering and assembly of control systems.

Chris Bladek

Beckhoff Automation Ltd.

4 Schiedel Court, Unit 1-3

Cambridge ON N3C 0H1

Canada