Universal interface enables new applications

Source: ProduktionNRW, VDMA, Germany

Author:Henning Rausch, CNC Applications Expert, Beckhoff Automation

The universal machine technology interface (umati) promises to resolve a host of familiar problems and to exploit new potential in terms of added value. Umati is a universal, OPC UA-based interface via which machine tools and systems can exchange standardized data with a higher-level controller.

The integration of diverse machines into control systems still represents a significant cost factor in the design and operation of modern production systems. Often, the main causes of this expense are the disparate range of data provided by the various control systems, as well as the lack of a universal standard with regard to structure, content and presentation of information in the industrial environment.

New applications possible

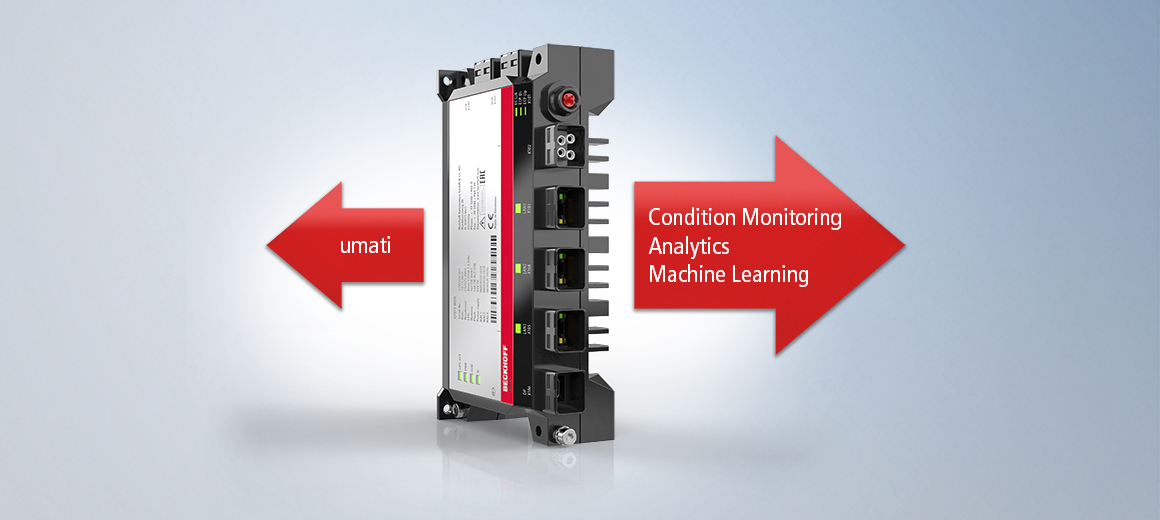

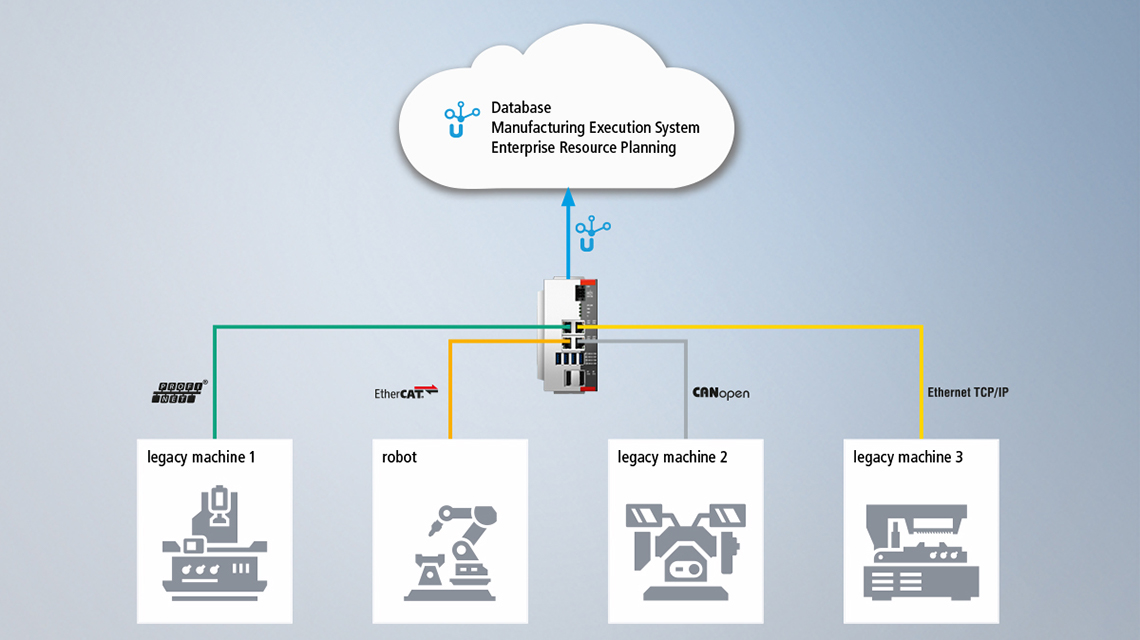

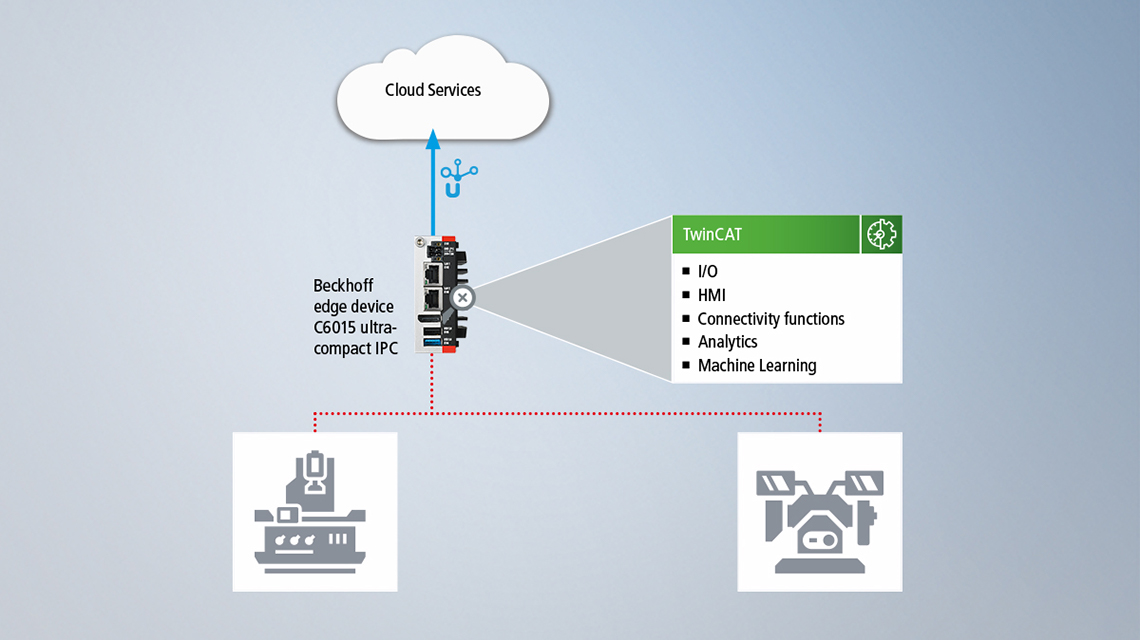

The automation specialist Beckhoff Automation sees great potential in umati as a basic orientation, not only for solving existing problems such as control system connectivity, but also for developing new applications based on PC-based control technology. Beckhoff has demonstrated a number of interesting approaches in the recent past; in the simplest case, the machine control system and OPC server run on one and the same Industrial PC. This strategy is highly efficient, as the interface between the controlled process and the OPC server is implemented solely using software. This is possible because the Industrial PCs not only have the interfaces required for integration into IT landscapes, but are also able to control the most complex workflows in hard real-time, for example, using TwinCAT automation software. This allows the companion specification for machine tools to be made available directly from TwinCAT CNC. But machine control and OPC server can also be implemented on separate devices. Whether as a result of a deliberate design decision or a retrofit, in both cases PC technology has proven to be extremely advantageous due to its openness. Industrial PCs (IPCs) can even communicate with older controllers, for example via fieldbus. The data obtained can be processed locally and made available to the outside world on an OPC server. This means existing machines can also be made umati-capable. Beckhoff has already demonstrated this scenario at the EMO 2019, where the company integrated several third-party manufacturer controllers in the VDW’s umati showcase.

For new products and retrofits alike

Industrial PCs can also be used as umati aggregation servers for several machines, for example within a manufacturing cell. The interface to the machines can be implemented either through fieldbus connectivity or umati itself. From the point of view of the individual machines, the IPC then functions as an OPC client. In practice, the above examples cannot always be clearly separated from one another. As is so often the case, the transition points are fluid. One characteristic feature, however, is that the IPC never has to be reduced to the function of purely an OPC server. The openness and scalability of this platform allow for tailor-made solutions that bring identifiable added value. For example, an aggregation server can simultaneously act as a cell control system with PLC and NC functions, and the IPC installed as part of a retrofit can provide additional condition monitoring functions. This includes the connection of the required sensors and their evaluation in real-time. The spectrum ranges from simple statistical analyses of binary signals right up to energy measurement technology and complex frequency analysis of critical components. The state variables calculated can be incorporated directly into the umati data supplied. At the same time, this information can also serve as input data for machine learning algorithms. TwinCAT executes this task on the IPC in real-time, harnessing previously unknown cause-effect relationships. This may be done to increase efficiency, or for early detection and prevention of potential machine breakdowns. Existing machines can not only be integrated into the umati world; they can be future-proofed as well. An elegant solution can be achieved if the required PC and I/O technology with protection class IP65 or higher can be mounted directly on the machine, without the need to make changes to the existing installation setup in the control cabinet. The umati concept is still young but it is already apparent that, given the broad field of possible applications, PC-based control technology will be a key factor in achieving cross-industry interoperability.