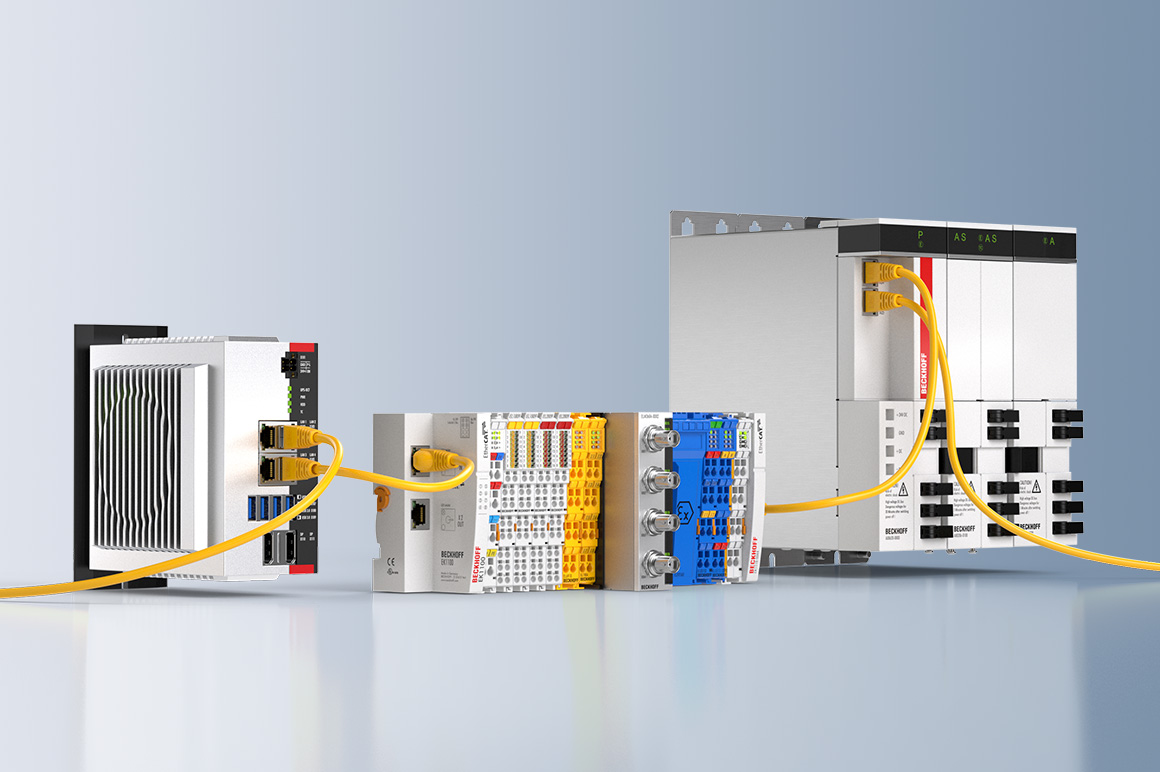

The basic building block of automation: The extensive I/O portfolio

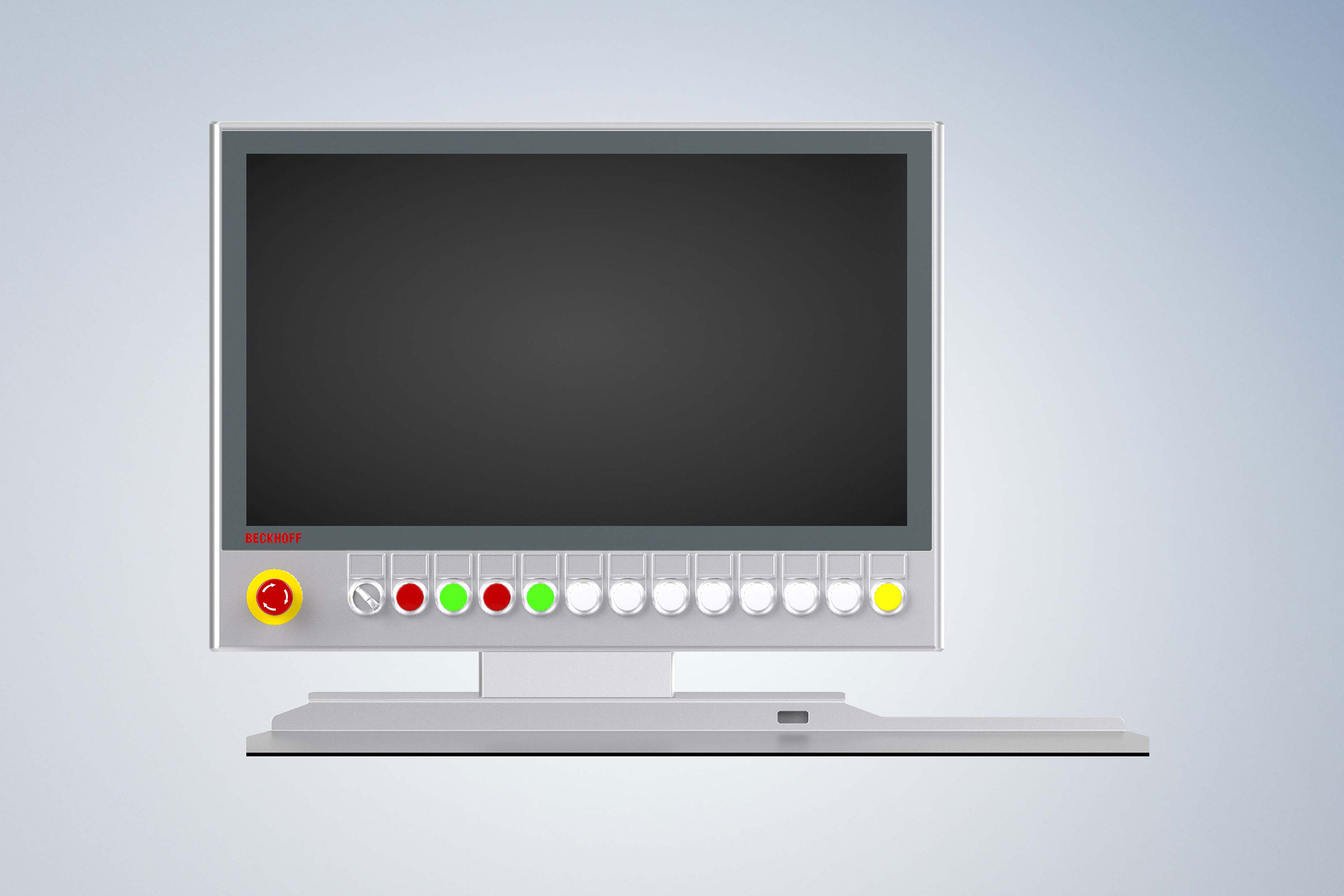

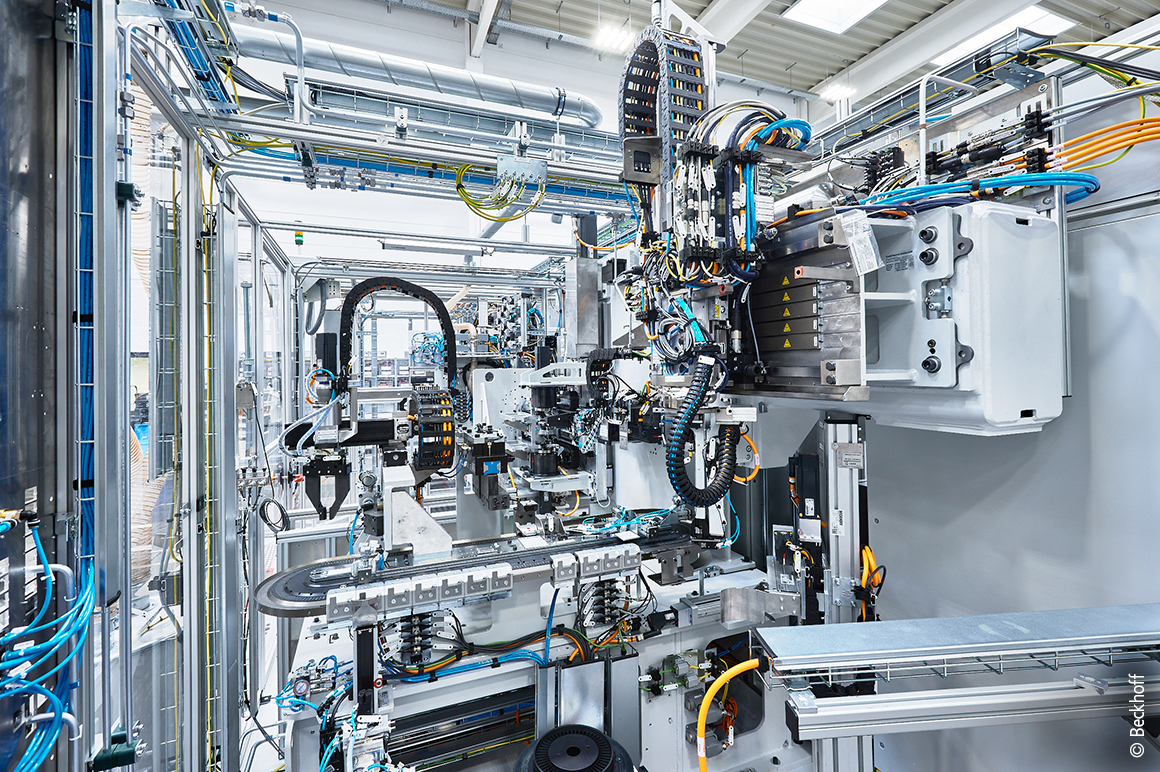

With around 1,000 I/Os for more than 100 signal types, Beckhoff’s modular automation toolkit is well equipped to cater to a whole host of requirements. An extensive range of housings, a variety of channel densities, and flexible interfaces ensure that the ideal product is available for every application scenario.

In addition to standard functions, our I/O portfolio includes products for specialist applications, such as safety technology, explosion protection, measurement technology, and the control of small drive technology motors. Communication and power measurement terminals for charging infrastructure are also available. A large number of EtherCAT-compatible sensors and actuators are available thanks to their high level of acceptance on the market. Support for common communication protocols, such as CANopen, IO-Link, PROFINET, and Modbus, offers our customers maximum freedom in terms of control design – even when it comes to retrofits or conversions of existing systems.