PC-based control and safe drive technology for profile bending

Moser-Baer AG in Switzerland is streamlining the production process for its world-famous railroad clocks with a new type of profile bending machine: With four bending rollers instead of the usual three, the Mobamatic MPB23 profile bending machine, with the mechanical platform developed and built by Moser-Baer, can bend a wide variety of profiles without straight end pieces. The automation specialist Pneutronic AG implemented the complete drive and control technology. PC-based control and the AX8000 multi-axis servo system with TwinSAFE ensure a compact design, precision, and safe operation without safety guards and laser scanners.

© Beckhoff

Moser-Baer AG, founded in 1938 with its headquarters and production facilities in Sumiswald, has been manufacturing clock and timing systems under the MOBATIME brand for over 80 years. Everyone has come across this famous product: the round clocks that hang on countless train platforms, in station concourses, airports, universities, schools, and public buildings.

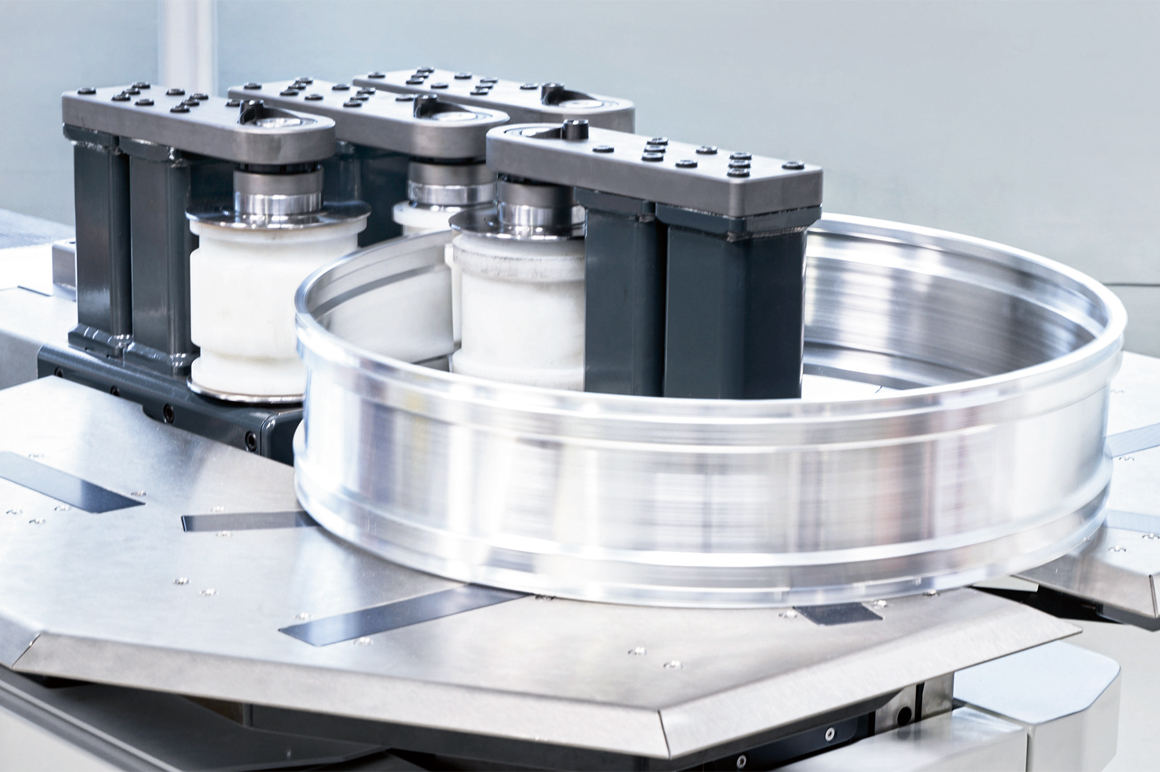

The clock cases are based on aluminum or sheet steel profiles that are bent into a ring. Depending on the type of clock, the profiles are made of aluminum up to 3 mm thick or thin angled steel profiles up to 200 mm high. To date, the cases have been manufactured by skilled workers on manually adjusted bending machines. This requires a great deal of experience, as many factors influence the precision of the finished component during the plastic forming of sheet metal, starting with changing resistance moments and different material behavior due to ageing or batch-related factors.

“We have developed the bending machine for our standard portfolio of station clocks with a diameter ranging between 40 and 120 cm – but we also want to be able to bend special constructions with a diameter of several meters,” explains Thomas Steffen, head of mechanical development and equipment manufacturing at Moser-Baer. Such large cases are assembled from several profiles. Roundness and adhering to the radius are therefore essential quality criteria for the profile bending process.

Fourth bending roller replaces process step

Moser-Baer’s primary motivation for the development was to be able to completely bend the profiles without straight end pieces. “This is impossible in kinematic terms with conventional three-roll bending,” explains Marcel Gloor, CTO at Pneutronic AG. The solution: a fourth, independently adjustable roller. This is the only way to achieve the required reversal of the bending direction and bend the profiles completely with the defined radius – without creating a straight section at the end of the profile. This part previously had to be sawn off in a further work step. Thomas Steffen explains: “Curved profiles are always difficult to clamp and saw. This also produces chips and sharp burrs.” By avoiding the straight end pieces, 15–20% material savings can be achieved on the case for each clock produced. This represents both a significant gain in economic efficiency and a contribution to sustainable, resource-saving production – something that Moser-Baer always strives for. In addition, 50% of time savings can be achieved in case ring production by eliminating the separation process after bending.

Safe drive technology reduces the footprint

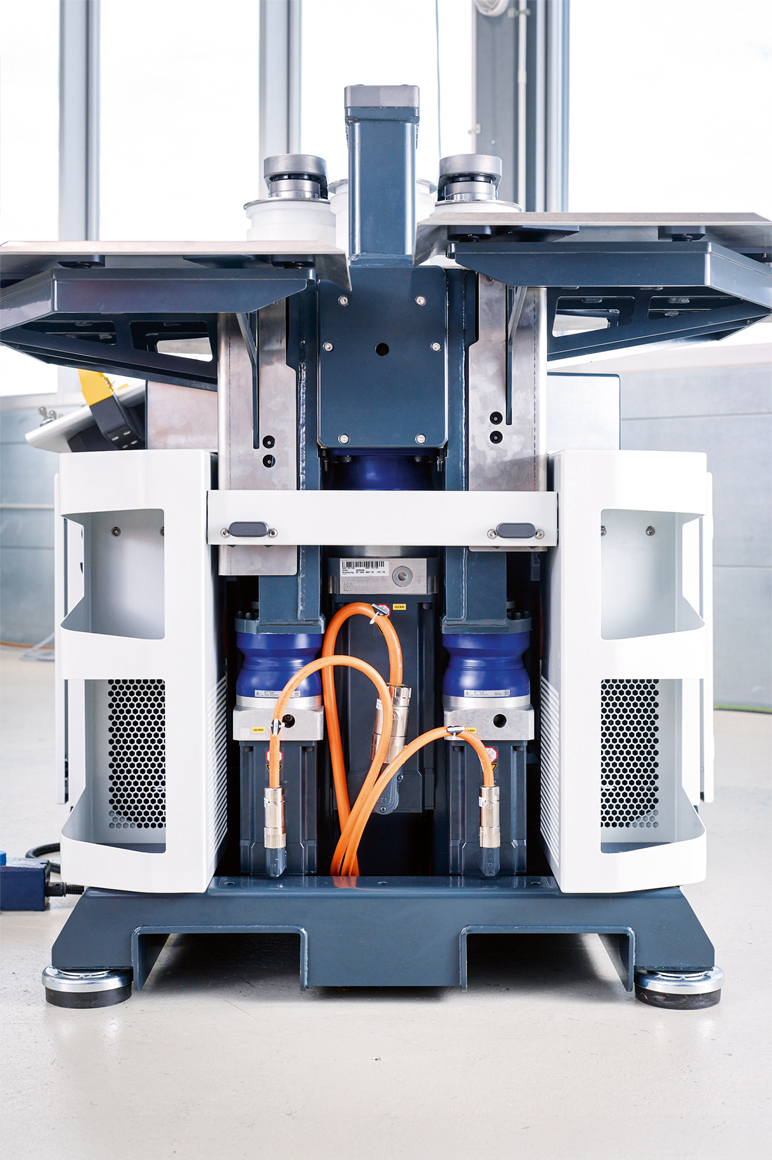

“Bending processes always involve the risk of trapping and crushing fingers or hands,” emphasizes Remo Kissling, managing director of Pneutronic AG, with regard to the safety requirements to be met by the bending machine. Nevertheless, the bending machine was designed without an enclosure, light grid, or laser scanner. This was made possible by a sophisticated safety concept based on the AX8000 multi-axis servo system with TwinSAFE and the AM8000 servomotors from Beckhoff. “We use almost all safe drive functions, such as safety limited speed (SLS) in connection with an enabling switch for set-up mode,” says Marcel Gloor. Once again, operators need to use both hands to insert and clamp the profile. To prevent injuries, the clamping stroke, which is only a few millimeters, can only be triggered from a safe distance using a foot switch. The foot switch is positioned close to the machine so that the profile can be inserted accurately.

The automatic bending process is started using two-hand buttons, which must be permanently actuated. If the operator releases one of the buttons, e.g., to check something or because another person steps up to the machine, the process stops immediately. The axes are brought to a safe operating stop (SOS). However, the control remains active and continues the bending process as soon as both buttons are pressed again. “Without the wide range of functions such as SLS, SLI, SOS, STO, and the safe drive technology from Beckhoff, this machine could not have been designed without a safety fence or laser scanner,” confirms Remo Kissling.

Nine axes in a confined space

A total of nine axes have to be controlled during the process: In addition to the four independent drives for the bending rollers and the three linear infeed and clamping axes, the height adjustment of the two work tables is also controlled. There is also an axis for the hand wheel which is used to set up the processes as well as the virtual X-axis for the feed of the synchronized and linearly transformed bending roller drives. The virtual X-axis represents the straight metal profile, which is used to control all real movements of the bending rollers. “The TwinCAT 3 Motion Designer gave us the flexibility to design the ideal drive system”, explains Marcel Gloor.

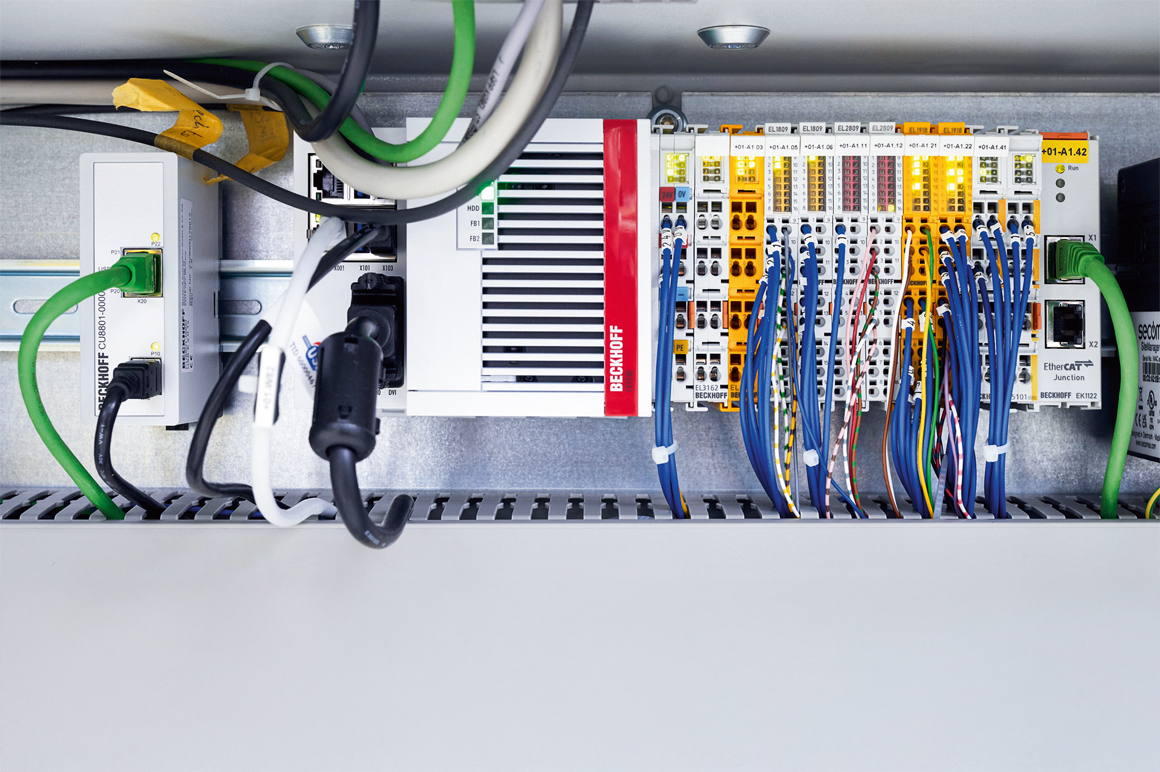

The machine design is extremely compact – in particular thanks to the small dimensions of the AX8000 multi-axis servo system, the space-saving One Cable Technology (OCT) for connecting the AM8000 servomotors, and the flexible installation options offered by EtherCAT. Eric Schaller, sales at Beckhoff Switzerland: “Pneutronic was able to install the compact drive amplifiers in a second control cabinet and connect them to the CX5240 Embedded PC in the control cabinet via EtherCAT.” Marcel Gloor adds: “Without using One Cable Technology as the connection technology for the servomotors, we would have needed additional cables for the safe encoders and would not have been able to design the roller adjusters under the work table in such a compact way.”

Teach-in programming

The experts at Moser-Baer teach the movement sequences for a profile using the hand wheel. The employees move all axes to the position in question and save the position values of each axis at the touch of a button. These motion profiles are then stored in the TwinCAT HMI recipe management system and can be called up at any time via the customer-specific CP3918 Control Panel and modified as required. During automatic bending, TwinCAT 3 NC PTP takes over sequence control and moves all axes synchronously from teach point to teach point.

The machine is currently being used to bend rings for clock cases, but the control technology and mechanics were deliberately designed to enable the production of all parts in the same way as on a conventional 3-roller bending machine. If required, it can also be used to produce design elements with curves, free-form arches, and straight intermediate pieces. “There are no limits in terms of control thanks to TwinCAT 3 and the powerful CX5240 Embedded PC,” enthuses Marcel Gloor.

Pneutronic has been realizing a wide range of projects with PC-based control from Beckhoff since 2010. Remo Kissling cites the excellent hardware and software performance, the broad product portfolio, and the scalability of the automation system as reasons for this. The use of TwinCAT as the engineering software and its modular design help to create tailor-made solutions. “My colleagues and I wouldn’t want to go back to a time where we didn’t integrate GitHub for source code management,” says Marcel Gloor, highlighting one feature in particular. What’s more, Beckhoff is always at hand to provide support with its expertise. “Manufacturers like Pneutronic that automate innovative machine concepts will, at times, require a little support. We get this from Beckhoff whenever necessary,” says Remo Kissling.

As a Beckhoff Solution Provider that automates many different machines, Pneutronic consistently relies on standardization in terms of the technologies, software, and methods used. That explains why it works exclusively with TwinCAT 3 – in particular the TwinCAT 3 Motion Designer – and Beckhoff components. “We always try to solve the basic tasks in the same way and gain efficiency through standardization in all project phases – from project planning to programming and wiring,” says Remo Kissling. In terms of I/Os, for example, Pneutronic has specified twelve EtherCAT I/O Terminals from the wide range that are used to automate projects as standard. “For special functions, Pneutronic can still use the entire range of EtherCAT Terminals at any time,” emphasizes Eric Schaller.