MX-System: Plug-in system for control cabinet-free automation

With the MX-System as a modular automation toolkit, Beckhoff has packaged its comprehensive product portfolio in a robust new housing system for direct machine mounting. The resulting solution can completely replace traditional automation systems installed in control cabinets, reduce machine footprint and cut energy consumption from fans and other cooling devices. In doing so, Beckhoff – in its role as a technology leader – is once again initiating a revolution in automation technology and setting new standards in cabinet-free machine design.

While the first Programmable Logic Controllers only took over the link between the input and output signals of machines and systems, today’s PC-based control technology can take on all the automated functions found in modern manufacturing processes. I/Os, drive technology, safety technology, data inputs, connections to higher-level systems, and even image processing tasks – everything is handled by the central controller. This increase in different tasks explains why control cabinets often have not become more compact, despite the fact that electronics are constantly getting smaller and more powerful – even with safety functions integrated inside them. Often, the opposite can even be observed – additional automated machine functionalities have continuously increased the number of function-specific components in control cabinets.

A conventional control cabinet can usually be divided into different functional areas:

- energy supply, fuse protection, and distribution

- generation and fuse protection of auxiliary voltages

- sequence control with the inputs and outputs

- motor control

- connection level for the field devices

If we compare the control cabinet technology of past decades, it becomes clear that the basic structure, including the areas mentioned, has remained almost unchanged – regardless of the number and size of components. Today, manual processes are still used to place components and establish the electrical connection within and between the individual areas of the control cabinet. In order to dispense with the large amount of wiring effort involved, Beckhoff has recognized that the reduction of effort is only possible in the long term on the basis of uniform interfaces of all devices or functional units. The goal is not only to make the planning and production of control cabinets more efficient through digitization and automation, but also to completely substitute control cabinets in their current form. With this in mind, a modular toolkit – the MX-System – has been developed in which pluggable modules with standardized electrical and mechanical interfaces are interconnected via a base unit.

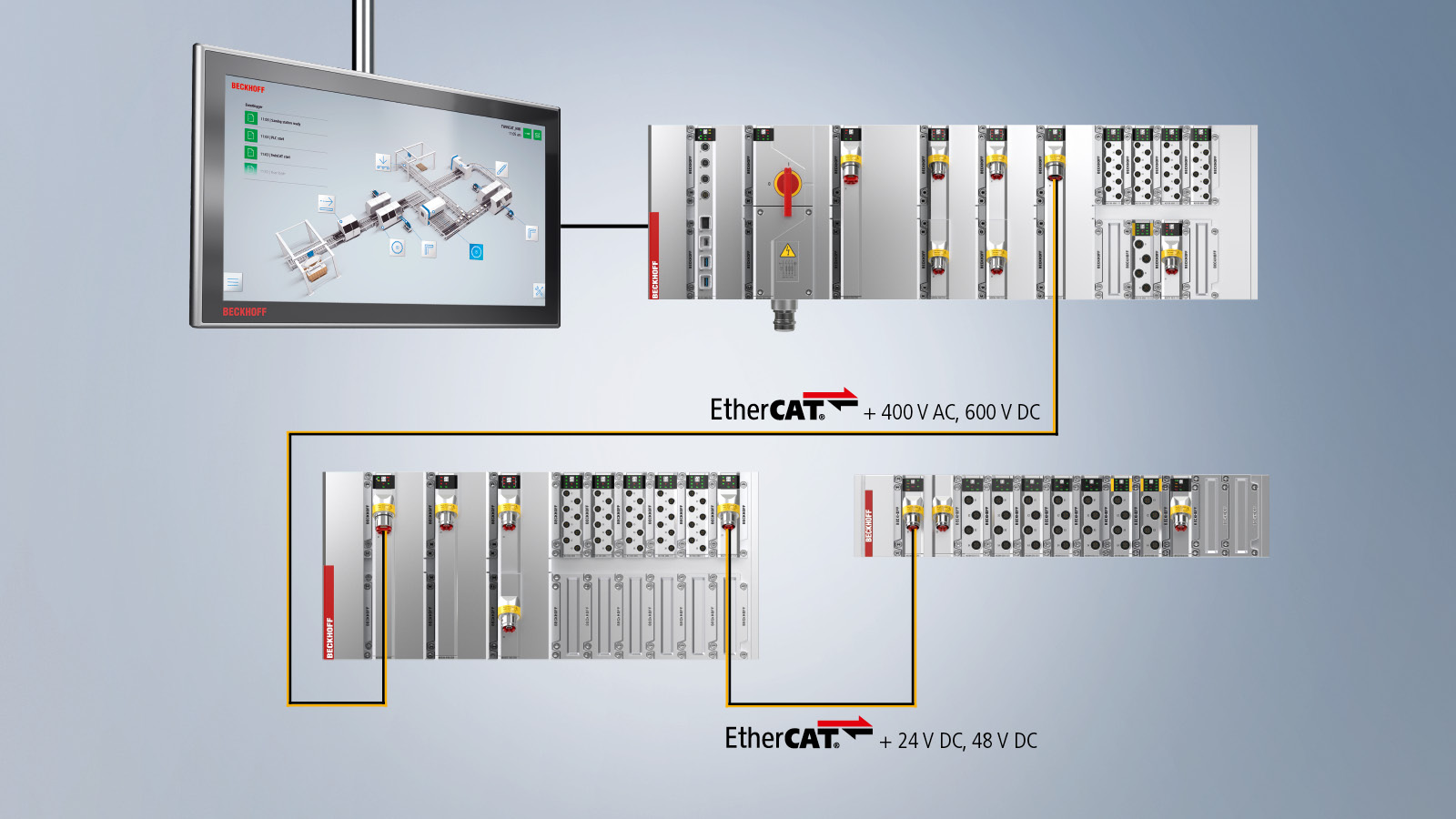

EtherCAT as the system-wide standard interface

EtherCAT forms the technological foundation for the standard interfaces of the MX-System. Due to its special functional principle – data processing on the fly – this globally established communication standard is ideally suited to this task. EtherCAT is able to connect a large number of I/O modules, drives, and other components to a controller in almost any topology and sequence. Functional safety is also integrated. The highly accurate synchronization of all components in the system is made possible by the distributed clocks of the EtherCAT technology, with which deviations of less than 100 ns are achieved. The extensive diagnostic features of EtherCAT ensure stable system communication, as any faults can be detected, localized, and eliminated at an early stage.

As EtherCAT covers the entire range of data transmission requirements, one bus system is sufficient for internal system communication as well as for external expansions, which can also be connected via EtherCAT P. This is the One Cable Automation extension of EtherCAT technology and involves the transmission of data and power on one line. Within the MX-System, only the power has to be transmitted in addition to EtherCAT, meaning that it is possible to reduce the number of internal interfaces to just two. The first interface includes the extra-low safety voltages 24 and 48 V DC as well as the EtherCAT protocol. This mix of voltages and signals is brought together on a single data connector. As a second interface, the mains voltage up to a maximum of 530 V AC (3-phase, plus neutral conductor and PE) as well as the drive system’s DC link bus with a voltage of up to 848 V DC are output on another connector.

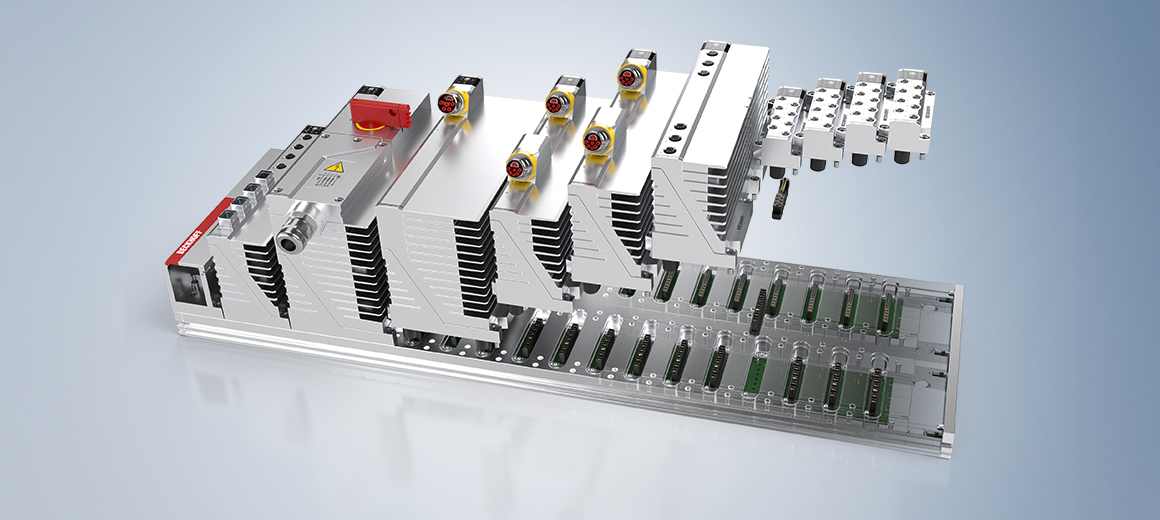

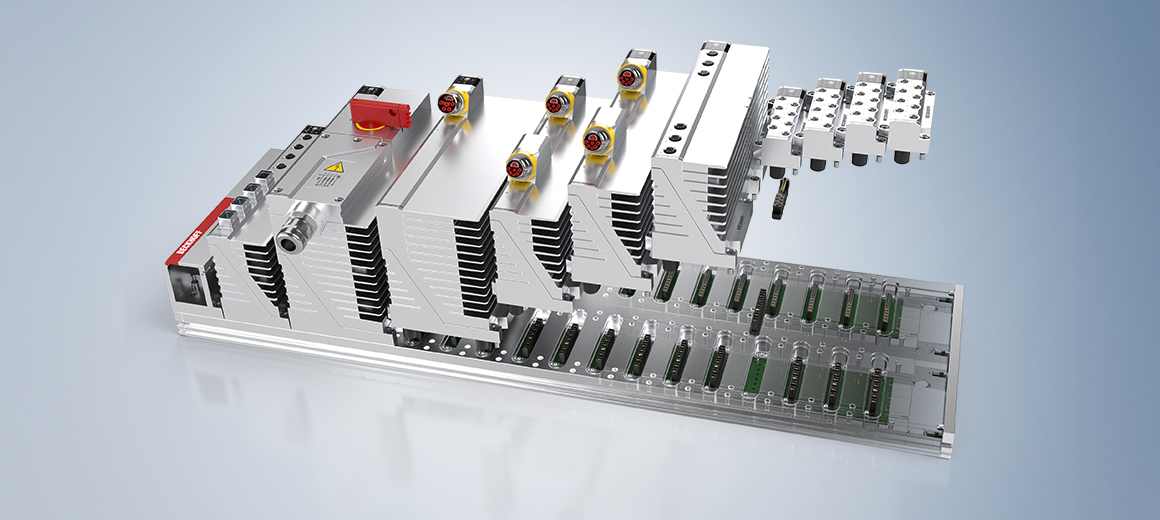

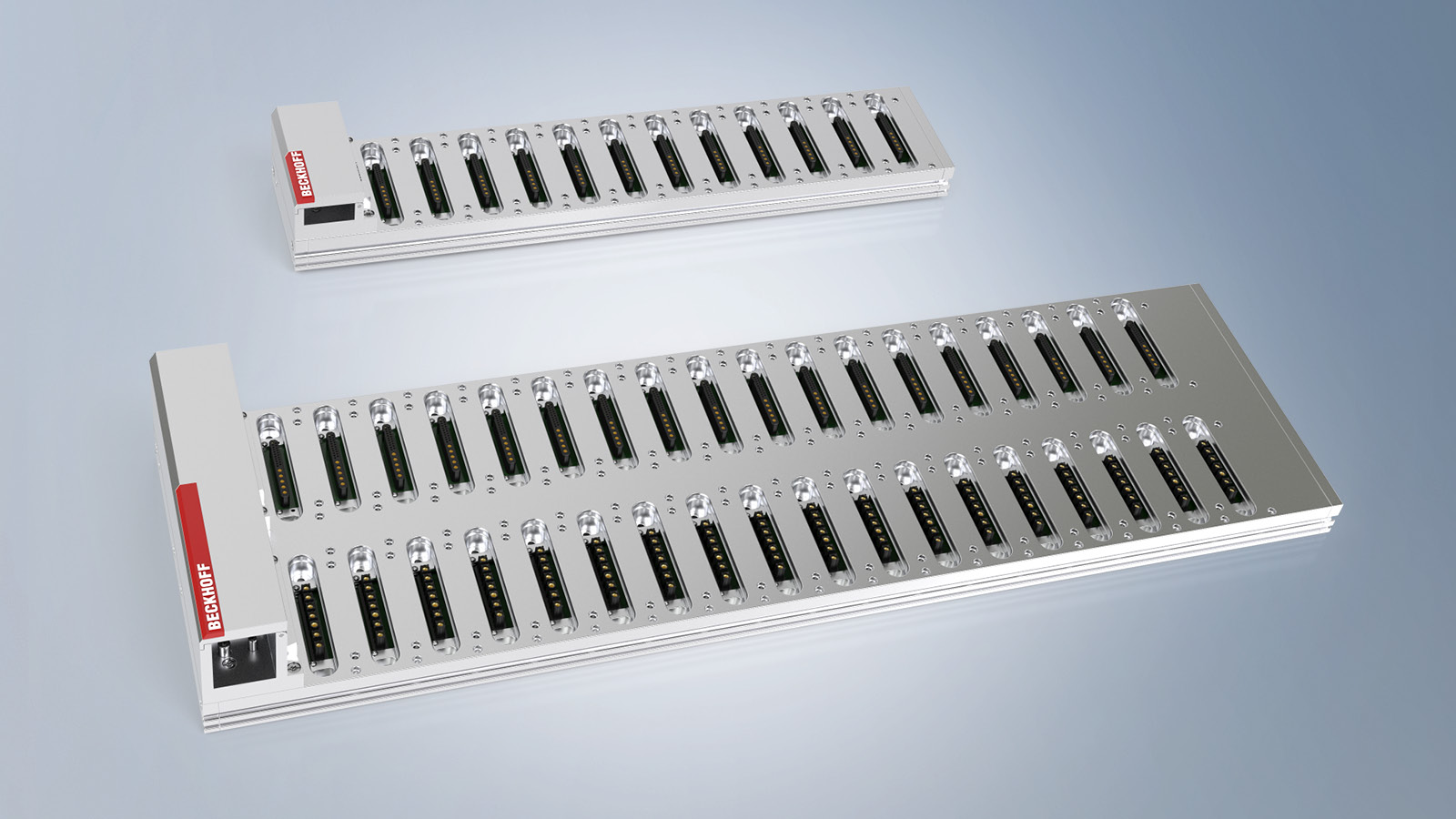

Durable baseplate concept as control cabinet replacement

The connectors of the MX-System, together with the PCB backplane, are well protected in a robust aluminum extrusion profile onto which the function modules are plugged and screwed in place. This unit, which consists of the housing and electronics, is called the baseplate and, in addition to the mechanical enclosure, also includes backplanes, on the one hand for control voltages and communication, and on the other hand for supply voltages. The combination of baseplate and function modules meets the requirements of protection rating IP67 and is passively cooled within a temperature range of 0 to +50 °C. This eliminates the need for additional protective housings and allows the unit to be mounted directly on the machine or system. A central, manually installed control cabinet is therefore no longer necessary. To create a complete MX-System assembly, only a single tool is needed to screw the modules to the baseplate.

The baseplate’s current carrying capacity of 63 A for power and 30 A for the extra-low voltages for machine safety is able to cover most requirements in automation. The length of the baseplate is initially limited to 1 m and 24 connection points for system modules. The integrated housekeeping system records environmental parameters such as temperature and humidity as well as vibrations and shocks within the baseplate.

The baseplate is available in different versions. A compact control for direct mains connection can be set up even with the 1-row baseplate with data connectors for the function modules measuring 110 mm in height. The 24 V power supplies and IPCs required for this are included in the function module portfolio. The 2-row baseplates include both data connectors and underlying power connectors. Further baseplate variants will offer, among other things, a hybrid mix of connectors within the rows as well as an expansion stage with three rows, something that is required for more powerful drive modules.

Modules for all control functions

The MX-System baseplate replaces the wiring between the components of a control cabinet and in this form is a real innovation in automation technology. The function modules take over the essential properties of the components typically installed in a conventional control cabinet. However, they are not a 1:1 replacement, as several control cabinet functions are always combined into one function module. Each module comes with various features already integrated. These include fuses for outgoing lines and the connection level, which is provided via M8 and M12 signal connectors or connectors from Beckhoff’s ECP/ENP series if higher power levels are involved. In addition, many power modules provide integrated inputs for the sensors associated with an actuator. These and many other solutions have been developed in close collaboration with leading customers from various industries.

The hot-swappable function modules cover all functions required on a machine and are divided into the IPC, Bus Coupler, I/O, motion, relay, and system product areas. They are based on the proven range of PC- and EtherCAT-based control and drive technology from Beckhoff. This portfolio has been expanded to include functions for direct switching of 1- or 3-phase AC actuators such as asynchronous motors or electric heaters. The motion product area has been expanded to include frequency converters. Also new for Beckhoff are the system modules that provide the required infrastructure for the control functions. Examples include switching power supplies for 24 and 48 V DC, UPS modules, and Ethernet switches.

In addition, modules with a hybrid design have been developed. These include power feeds that provide, among other things, the mains connection point, main switch, mains filter, energy measurement technology, residual current measurement and 24 V DC power supply as a functional package in one housing. Another example are EtherCAT P outputs with the fuses for line protection for both the protective extra-low voltages and the low voltages.

In the event that a function needs to be mapped by a device installed in a traditional control cabinet, the baseplate extension function module is available. This extends the baseplate beyond the right side and provides a protected installation space for IP20 devices. Here, both the voltages of the data connector and power connector as well as an EtherCAT connection are provided. Just like all other function modules, the system modules are characterized by the fact that they are EtherCAT devices. This enables high adjustability, actual value evaluation and detailed diagnostics directly from the machine control.

Advantages for machine builders

The inherently modular MX-System significantly reduces the planning effort and the required number of components for the machine builder in the design phase. According to initial experience, the scope of the circuit diagram and the work involved are only 20% in some cases. This will also be reflected in a corresponding reduction in overall costs.

Machines and systems can also be designed to be much more space-saving and application-specific. Machine builders can mount the compact MX-System directly on the machine, which eliminates the need for a separate control cabinet with its own cable routes. This reduces the overall installation effort, especially in conjunction with pre-assembled cables. In addition, the pluggable installation can be handled by a mechanic rather than specialized electricians only. Machine modularity, which is now an absolutely essential prerequisite, is also consistently and optimally supported by the MX-System as it can be distributed across the machine in modules.

Certification is another important aspect from a machine building perspective. The MX-System is a control cabinet replacement that complies with the relevant control cabinet standards and, unlike conventional cabinets, is already IEC, UL and CSA-compliant, making it a globally standardized solution. The machine builder can therefore manufacture from stock without any problems and does not have to consider which target country the machine is intended for before delivery, i.e. during assembly.

Advantages for control cabinet construction

The control cabinet and panel builder industry is set to benefit enormously from the simple plug-in solution that eliminates complex individual wiring. For example, a control cabinet assembly process that previously took 24 hours can now be reduced to approximately one hour of system installation. In addition, the significant risk of wiring errors, especially in the case of sophisticated control cabinets, is avoided. The error-prone individual production processes that the control cabinet builder previously had to carry out manually have now been transferred to the prefabricated functional modules.

There are also advantages for control cabinet construction from a logistical point of view. Analyses have shown that, in some cases, 90 % of previous parts list items required for classic control cabinets are no longer needed. Furthermore, many machine builders will be able to simplify their logistics processes, since this easy-to-install technology often eliminates the need for external control cabinet construction.

Advantages for the machine end user

One major diagnostic advantage compared to the classic control cabinet is that the MX-System only uses networked components. This means that the status of each individual fuse, power supply or main switch module, for example, can be queried at any time – as would normally be the case for a device in an EtherCAT network. As part of the new Beckhoff Device Diagnostics, the familiar extensive diagnostic options of EtherCAT are supplemented by a serial number that is unique for each module. This is placed as a data matrix code on the front of the module and can be scanned using a smartphone app. The smartphone connects to the controller by wireless technology and displays the respective diagnostic data, such as the module status or error memory. In this way, the smartphone becomes a “universal digital voltmeter and scope”, which goes above and beyond simply replacing traditional measuring devices. Maintenance and service technicians benefit from precise information about the state of a function or assembly without having to measure up the hardware. This has an overall positive effect on plant operation.

The corresponding advantages for machine and system operators result primarily from the fact that maintenance and service are significantly easier due to simple module exchange and the new Beckhoff Device Diagnostics. By encapsulating the individual automation functions in a single module, simple diagnostics for electrical faults can be performed at the module level. This means that the maintenance engineer only has to determine the state of the module – using status LEDs, a smartphone or Beckhoff Device Diagnostics. In turn, it makes it easy to determine whether the module, the cable to the field device or the device itself needs to be replaced.

Simplified maintenance and servicing offer many advantages for the operator of the machines and systems, e.g. repairs take significantly less time, as the maintenance engineer can identify the fault location (e.g. cable or module) with the aid of the device diagnosis. The pluggability of the modules makes it easier to replace them if necessary. The hot-swap functionality even enables this during operation. The encapsulation of individual functions in a function module brings the additional advantage of only a few spare parts that need to be stocked. The complete EtherCAT networking of the system ensures that the requirements of modern predictive maintenance management are fully met. All in all, it can be seen that the individual advantages resulting from the use of the MX-System reflect the requirements of both machine builders and machine operators. This paves the way for a future without control cabinets.