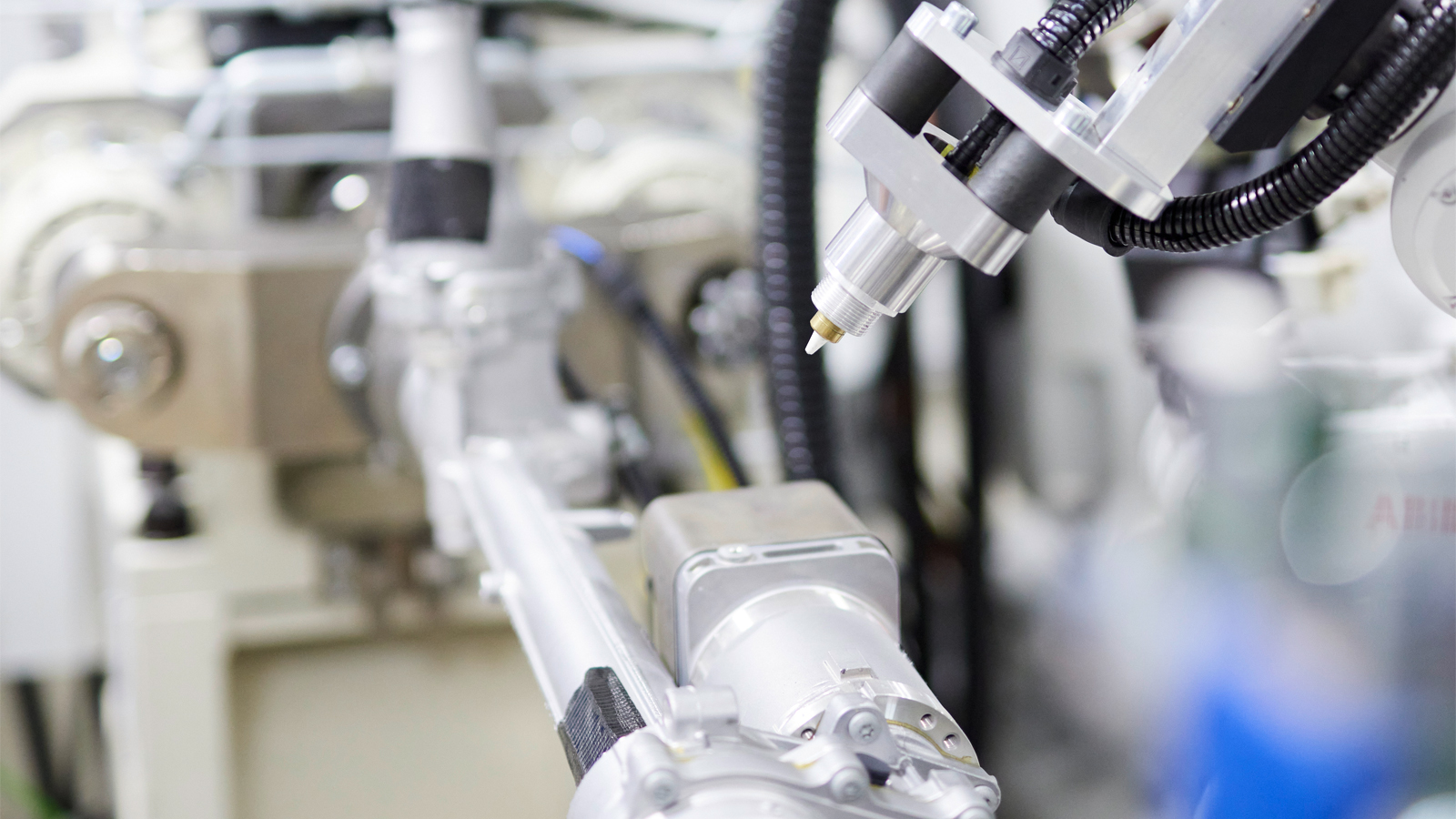

Precision measurement terminals in the final inspection of steering systems

Nobody wants to hear cracking, scratching, knocking, or whirring while driving. But how can subjective noise perception be quantified and measured objectively? thyssenkrupp Presta tests this by measuring structure-borne noise during end-of-line testing. Joachim Sutterlüty, Karsten Mauersberger, Michael Sauerwein, and Julius Ellmann have replaced the previous external electronics with high-end ELM measurement terminals in conjunction with TwinCAT Scope. This saves a lot of engineering work and time, in addition to a great deal of space and money.

Just a few moments are crucial in the life of a steering system – when thyssenkrupp Presta puts it through its paces in an end-of-line test rig, as it does with every steering system. In addition to various functional tests, the noise generated plays an essential role. “Acoustic testing is about ensuring that drivers do not perceive any annoying noises while driving,” explains Joachim Sutterlüty, head of automation at thyssenkrupp Presta. Translating these noise perceptions into measurable values is the job of the experts at the thyssenkrupp Presta acoustic center of excellence. Together with customers, they analyze and define noise behavior right from the development stage on prototypes and pilot series, and measure subjective acoustic properties in objective terms. This noise profile and its permissible limits later form the basis for measuring structure-borne noise in production.

If the noise spectrum of a steering system lies outside this profile, it is returned from the test rig to a rework station, where the measured structure-borne sound spectrum is used to decide whether to rework or disassemble the component. As Joachim Sutterlüty says: “With our sensors, together with the measurement terminals and PC-based control from Beckhoff, we can evaluate the noise so precisely that the worker can narrow down the cause of the noise accurately based on the displayed spectrum.”

Structure-borne sound – a complex matter

A large number of tests on prototypes are needed before a noise profile of this type can be developed. Accordingly, thyssenkrupp Presta has a large number of test rigs in operation in the prototype shop, where the acoustics of a steering system are designed. These must then be adhered to in the fully automated assembly plant. “As development is incredibly dynamic with frequently changing variants, we need a very high level of flexibility,” says Joachim Sutterlüty. That’s why Presta designs and automates all test rigs completely in-house, purchasing only the mechanical setup and electrical components. For the latter, the automotive supplier has relied on Beckhoff components for more than 20 years. It now also uses the high-end measurement technology ELM3604 EtherCAT Terminals and the TwinCAT Scope for measurement data acquisition.

High-end measurement terminals replace stand-alone system

The previous concept was based on an external system for acoustic testing, which necessitated complex interfaces and signal splitters for the actual test rig control system. As electrical engineer Michael Sauerwein says: “This equipment alone required a separate control cabinet and repeatedly caused problems during commissioning, from complex EMC shielding to double calibration and wiring errors.” Additional considerations were the project planning, configuration, and programming of the separate system. With PC-based control, EtherCAT, and the high-end measurement terminals, he was able to completely eliminate these interfaces, gaining significant flexibility and time with a massive reduction in complexity and costs. “Roughly speaking, we save about 5 % of the investment costs per test module,” says Joachim Sutterlüty.

In 2020, the new concept was intensively tested and examined in an initial testing plant in Eschen. The Beckhoff technology was then integrated into the test field and the sensor signals were tapped in parallel with a previous system to verify the results. Would the high-end measurement technology from Beckhoff come close to the external system? Acoustics expert Julius Ellmann comments: “We wanted to see if we could replace the old system with something that would live up to the same measurement quality.” After all, some sensor signals have to be recorded synchronously at a high resolution with 24 bits and up to 20 ksamples/s. All of the requirements for metrological complexity were met, and at much better value for money. This is because the ELM360x EtherCAT measurement terminals are directly integrated into EtherCAT. They are also very flexible in terms of the number of channels and – with TwinCAT Scope – are very quickly configured for data collection. “As part of the changeover to ELM measurement technology, we were able to increase the number of measurement channels due to the advantageous price. Together with optimized measurement sensor technology, we were also able to enhance the measurement quality,” explains Julius Ellmann.

Resolving the software interface bottleneck

The success of the changeover was due in no small part to the flexibility and openness of PC-based control. This was confirmed when TwinCAT was integrated into the external evaluation software – something that was required because Joachim Sutterlüty was not willing or able to dispense with the existing evaluation software from the previous manufacturer, as various departments use functions of the software. “But the TwinCAT Scope API from Beckhoff is a powerful interface for reading out the data,” says Maurus Kaelin from Sales at Beckhoff Switzerland. However, the interface of the evaluation software turned out to be a bottleneck. “We had to optimize the software interface so that the data packets could be received and analyzed quickly enough,” recalls Karsten Mauersberger, who develops the software for the test rigs.

Pascal Dresselhaus, Product Manager TwinCAT, was on hand with his Scope development team to work with thyssenkrupp Presta and the evaluation software provider and achieve the best possible performance for the application. “Joachim Sutterlüty and his team set out their requirement for a powerful, state-of-the-art interface for data acquisition,” recalls Pascal Dresselhaus. Many TwinCAT users are familiar with TwinCAT Scope only from its integration in Microsoft Visual Studio for measurement data analysis and machine commissioning. However, in addition to the front end in the TwinCAT engineering environment, there is also an extensive programming interface (API) for TwinCAT Scope (TE1300). Especially in the .NET environment, this can be used to integrate the charts of a Scope View as a Control in your own visualization, for example. This finalizes all of the charting, including the back end with the Scope Server. Many Scope properties can be used on a highly customizable basis, so in some cases it may not even be possible to spot a TwinCAT Scope from Beckhoff performing its role.

In this specific case, however, the API was not used in the conventional manner for the visual display, but instead for relaying the recorded measurement data from the ELM3604 terminals. Using sample code with sophisticated data buffers, smooth integration with the third-party software could be ensured. “In terms of functionality, it was possible to implement the application directly based on the current state of the Scope API. Our support essentially consisted of writing a kind of best practice for using high-resolution data,” says the TwinCAT Scope and Analytics product manager.

The openness of the software solution was an important criterion for thyssenkrupp Presta. This was highly advantageous when it came to integrating the evaluation software and the many export formats. At the same time, thyssenkrupp Presta also retains the ability to use the analysis options available in TwinCAT. “All options are available, particularly those involving TwinCAT Analytics,” emphasizes Pascal Dresselhaus: “We have great engineering products for data analysis with over 100 algorithms. From the cycle times of the test rigs to frequency analyses of noise development, as soon as the data is available in the Scope format svdx, TwinCAT Analytics can be used to find many needles in the data haystack,” says the product manager, highlighting the additional possibilities for thyssenkrupp.

Global roll-out under way

What began around two years ago with an initial concept is now proving itself in practice: in addition to the test rig at the company headquarters in Eschen, the first systems are already in regular operation at the production plant in Hungary. “Further systems are currently on their way to China and Mexico or are already being set up there,” says the automation expert. Due to the results in the areas of both measurement accuracy and test speed, as well as the much simpler implementation and commissioning processes, the concept based on the high-end measurement technology EtherCAT Terminals will form the basis for all further acoustic measurement modules. In the future, all new acoustic test systems in the production area will be equipped with it. That is because the advantages of PC-based control are compelling, as Joachim Sutterlüty explains: “We can completely replace external measurement technology hardware.”