Open PC-based control and drive technology in the field of additive manufacturing

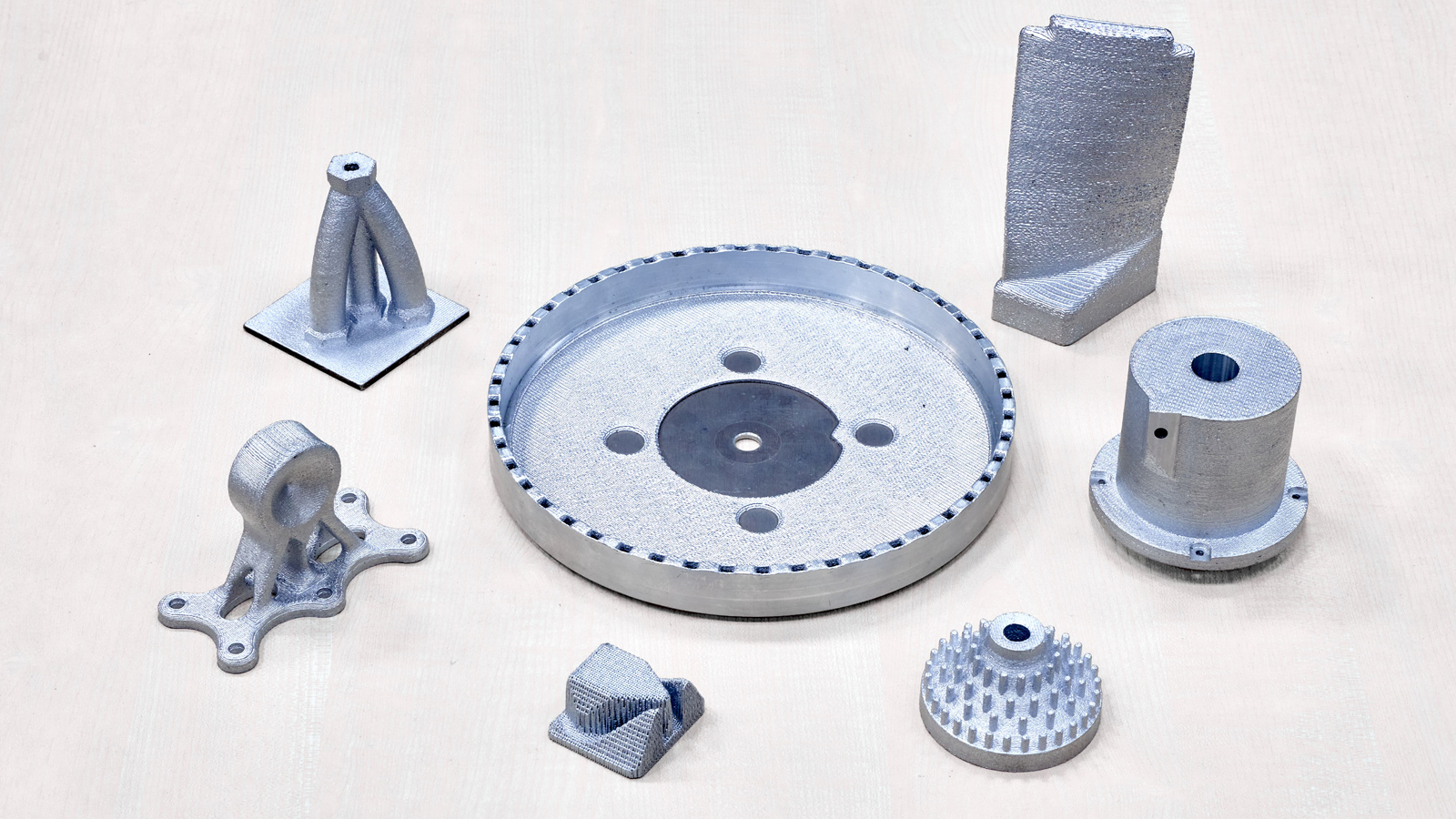

As a globally operating family business, GROB-Werke has been developing systems and machine tools for the most renowned automotive manufacturers, among others, for over 95 years. This period has been characterized not only by technical innovations, but also by the opening up of new markets. A prime example is the field of additive manufacturing, for which the first prototype machines were developed in 2019. With the new GMP300 Liquid Metal Printing machine, which is automated with PC-based control, wires made of aluminum alloys can now be used cost-effectively and efficiently in the printing process to achieve precise and fast 3D printing.

The portfolio of GROB-Werke GmbH & Co. KG, based in the German town of Mindelheim, ranges from universal machining centers to highly complex production systems and manual assembly stations to fully automated assembly lines mainly for the automotive sector. The focus on additive manufacturing equipment first came to the fore in 2018 as part of an innovation management process to assess future technology and which also included electromobility and fuel cell technology.

Economical and flexible additive manufacturing

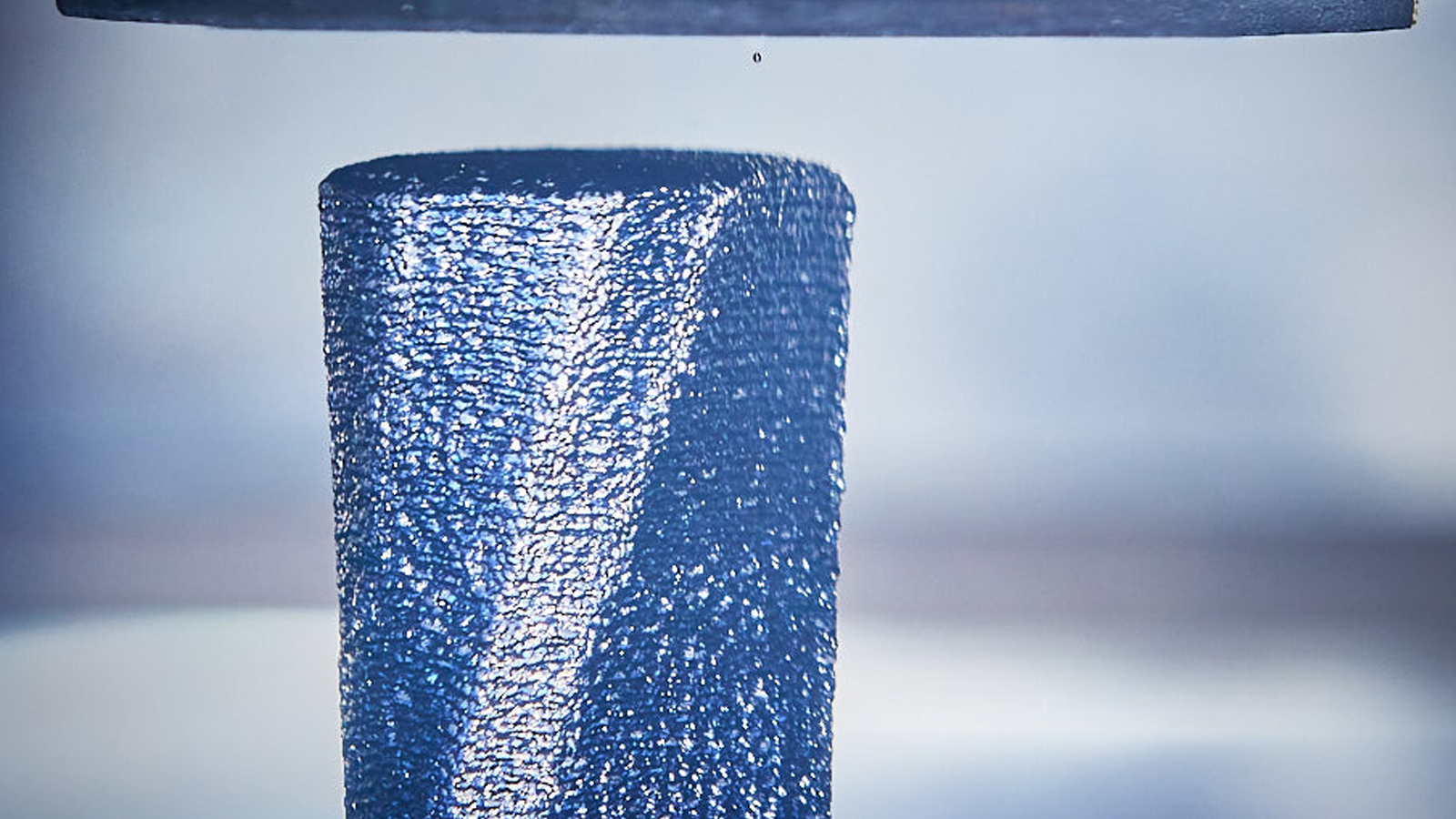

The GMP300 Liquid Metal Printing machine uses a powder-free manufacturing process to produce near-net-shape components safely and quickly. This provides customers with a reliable, efficient, and cost-effective system technology – with 3-axis kinematics and a max. axis speed of 30 m/min – while also offering maximum production flexibility. Further advantages are provided by an assembly space with an oxygen-reduced atmosphere, numerous sensors for droplet, nozzle, and component height monitoring, among others, as well as the processing of aluminum alloys supplied in wire form, and reduced hazard potential as no powder has to be handled. Dr. Johannes Glasschröder, team leader for Additive Manufacturing at GROB, explains: “We have developed a completely new technology for this which makes additive manufacturing a much more interesting prospect compared to traditional processes. For instance, the raw material in wire form is far less expensive than the usual powder material. This provides the optimum conditions for producing required components from aluminum quickly and economically in small batches.”

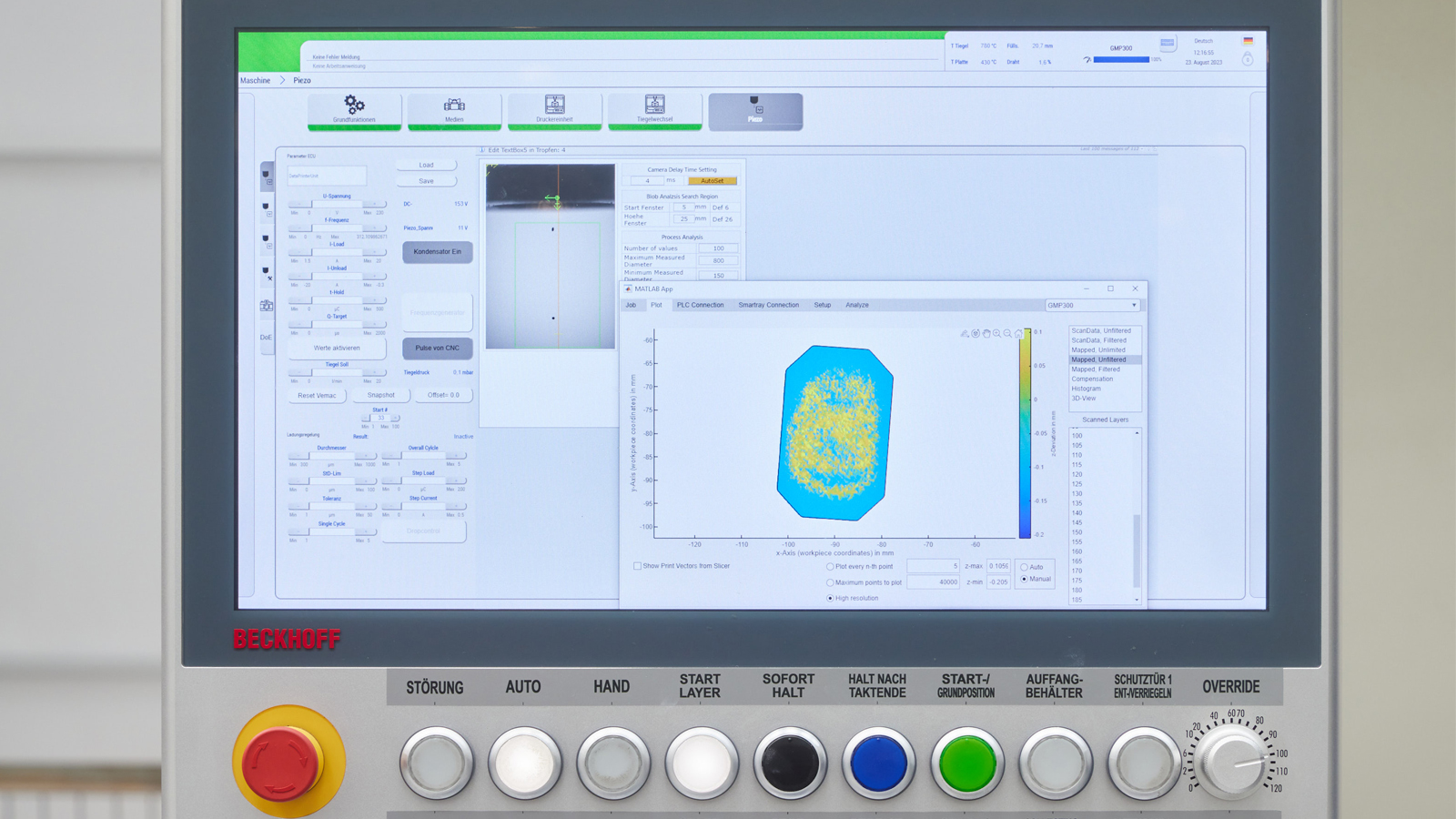

Commenting on the technical challenges accomplished, Emanuel Engelsberger from GROB’s Additive Manufacturing team adds: “The precise synchronization of the CNC with the individual aluminum droplets is crucial. For their highly accurate positioning, for example, the drop time from the print head to the component must be precisely compensated. A lot of time and expertise has gone into this development in particular to enable corners and sharp edges to be produced precisely and at maximum speed, for example. The coupling of droplet frequency and axis speed also plays an extremely important role. The same applies to the large amount of sensor data, which, as well as being recorded for analyses, also forms the basis for active parameter adjustment and process control. This is the only way to compensate for any minimal errors directly during component production.” While the conceivable range of applications is exceptionally broad – Dr. Johannes Glasschröder sees almost no limitations here – the requirements with regard to printing speed are just as varied. He explains that the print speed is usually 250 aluminum droplets per second, but that printing at up to 1,000 droplets per second has already been achieved. With the slower first value, however, the results are usually more precise and can also be achieved quickly using a larger droplet volume.

PC-based control for speed and precision

Following GROB’s previous success with PC-based control from Beckhoff in the area of electromobility, the additive manufacturing team also decided to put its trust in this technology. Emanuel Engelsberger explains: “Firstly, we benefited from existing experience and internal standards. And, secondly, the PC-based control technology was able to meet our requirements in terms of speed and precision perfectly.” This is also confirmed by Dr. Johannes Glasschröder: “On top of this, the control platform from Beckhoff is easy to use and open to the integration of our own expansions, meaning that it is also future-proof.”

The hardware core of the control solution is formed by a C6030 ultra-compact Industrial PC, which is ideally suited to this application on account of its exceptionally high single-core computing power. Dr. Johannes Glasschröder also thinks it crucial that the broad and regularly updated range of processors for Beckhoff Industrial PCs covers both future requirements and sustainability aspects. Convenient machine operation is ensured by a CP3918 multi-touch Control Panel with 18.5-inch display and customer-specific push button extension.

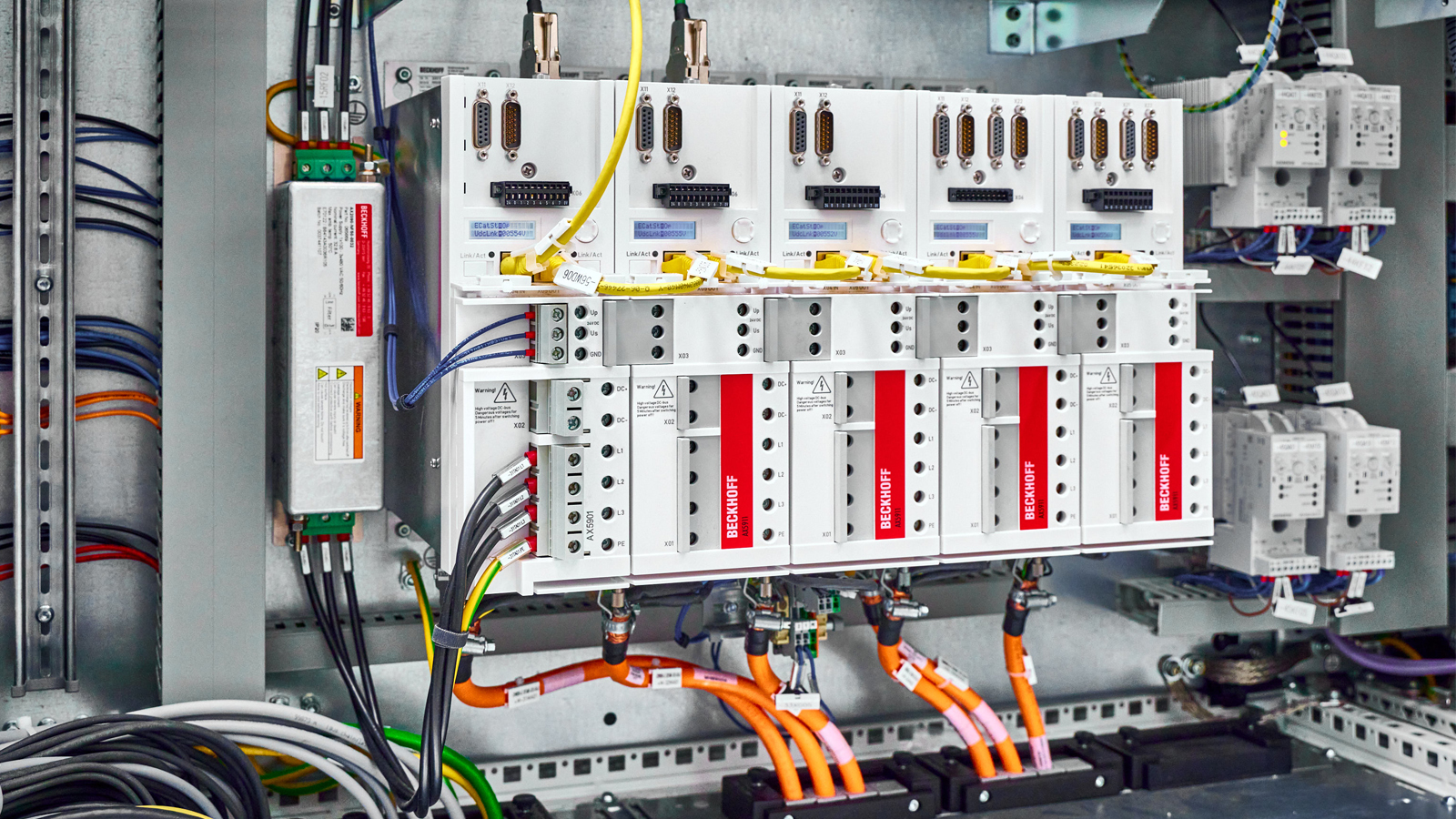

The required precise and dynamic movements of the total of seven servo axes are implemented via three 1-channel and two 2-channel AX5000 Servo Drivesas well as AM8000 servomotors. The system-integrated safety technology of PC-based control is also used here: in the servo drives via the AX5805 TwinSAFE drive option cards and in the I/O area with the EL6910 TwinSAFE Logic and several TwinSAFE Terminals. Overall, the I/O level is composed of numerous digital and analog EtherCAT Terminals and EtherCAT Box modules. Emanuel Engelsberger describes their key advantages as follows: “The decisive factors for us are speed and precision in data acquisition and processing. eXtreme Fast Control Technology (XFC) from Beckhoff, i.e., with the EL2262 oversampling terminal, is the only way we can set the corresponding trigger signal exactly according to our path planning and achieve the required synchronization with the vision system, for example. And that is precisely the core application of the GMP300.” In addition, there is the advantage of the wide range of interfaces that are available in the Beckhoff I/O portfolio, which make it very easy to integrate features such as IO-Link sensor technology (via EL6224).

Convenient and powerful software suite

According to Emanuel Engelsberger, Beckhoff TwinCAT automation software has proven its worth not least in conjunction with the numerous EtherCAT analog terminals, due in part to the wide range of control algorithms offered by the TwinCAT 3 Controller Toolbox (TF4100). For example, he says that correct temperature control is crucial when producing a homogeneous aluminum melt from the wire-shaped raw material supplied in the print head. In the engineering environment, advantages arise from the pre-simulation of machine sequences without having to spend time on changing the development environment, as well as from the extensive virtualization options.

For the application core – the path calculation – TwinCAT 3 CNC (TF5200) forms the basis, as Emanuel Engelsberger explains: “The engineering interface, software architecture, and usability of TwinCAT have already supported me during the familiarization period. Working in TcXaeShell is very straightforward and does not require a lot of effort, which ultimately makes it easier for us to implement our core expertise. So, as mentioned, in order to position the aluminum droplet in the CNC exactly, something akin to a precalculation has to take place in order to take the droplet fall time correctly into account. Therefore, we have to know exactly where the next droplet is going to be during the trajectory curve and then set the trigger accordingly.”