When it comes to large-scale battery cell production, fast and precise processes are essential. Even the smallest time or energy savings in individual process steps can add up to significantly increased output, lower costs, and reduced carbon emissions. One of the key levers for improving efficiency in battery production is product transport, and Beckhoff is setting new standards here with its intelligent XTS linear transport system and high-performance PC-based control technology.

Conventional product transport vs. XTS

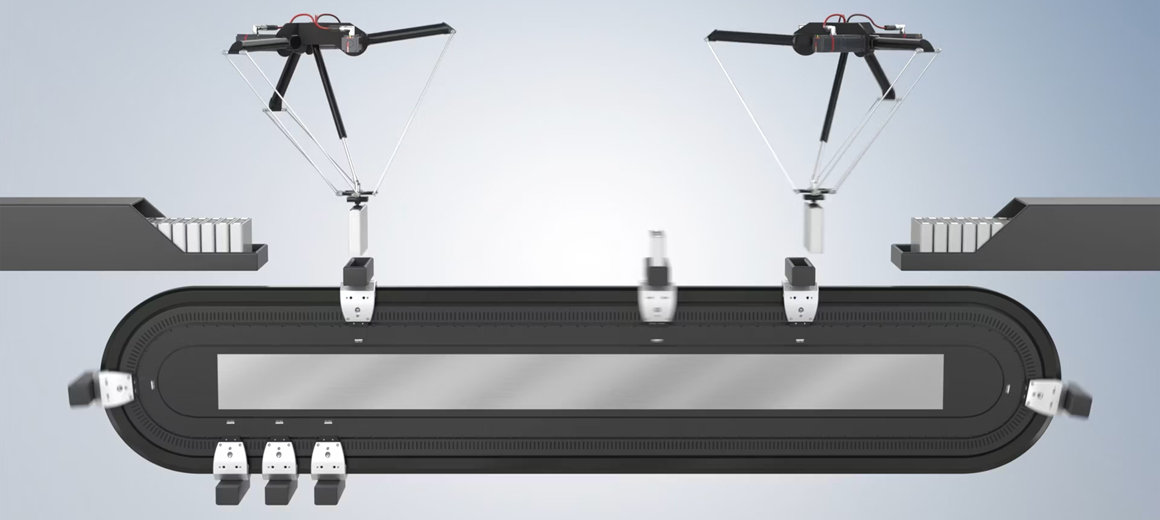

In conventional linear transport systems, the material flow is often interrupted by return paths involving empty runs. This is where Beckhoff’s XTS system takes a different approach, featuring a continuous, closed-loop track to maintain uninterrupted material flow and improve the overall efficiency of the production line. Each mover on the active XTS track is individually controlled and capable of braking, accelerating, positioning, and exerting constant force at any point – both at rest and in motion. This ensures the transported products are handled gently and securely, enables easy switching between formats, and significantly reduces buffering requirements.

Modular system for flexible product transport

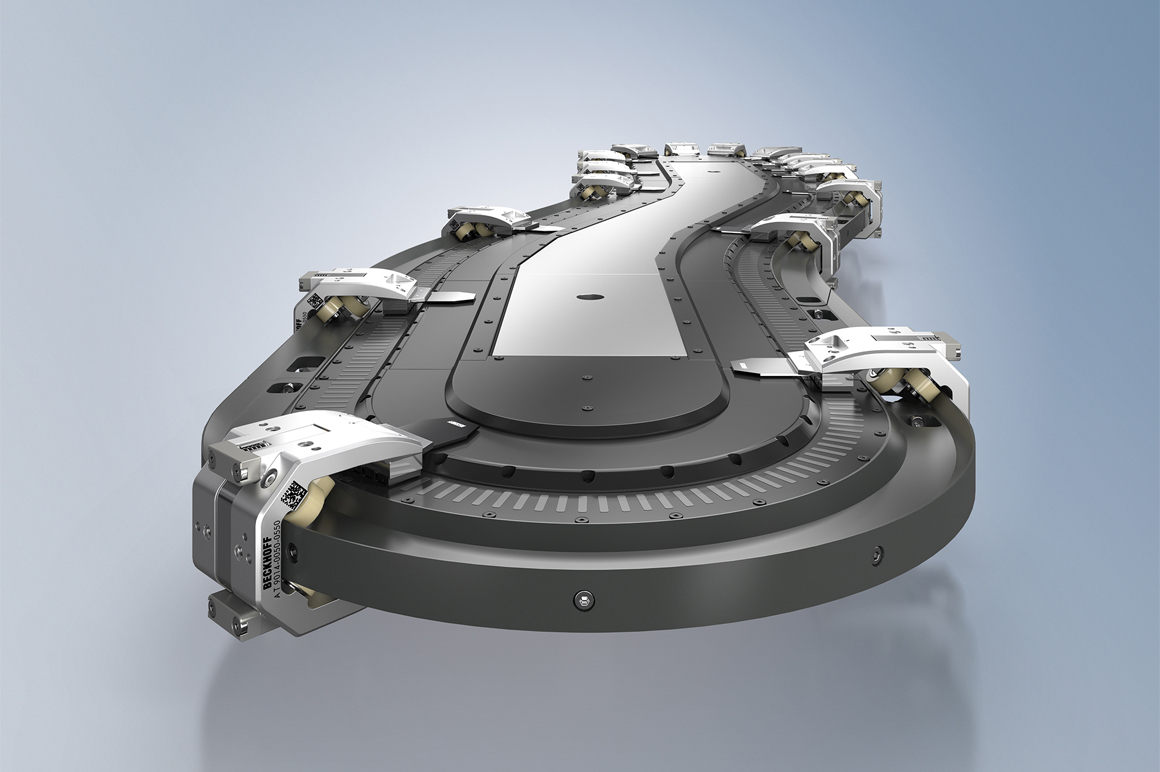

A key strength of the XTS is its modular design. The system length can be precisely scaled using different modules, allowing for customized and expandable configurations. Straight motor modules are available in various lengths, while curved modules come in a range of radii. There are also modules with an extended range of functions, such as contactless power and data transmission to the movers (NCT), as well as modules for applications that do not require maximum accuracy (EcoLine motor modules). This full compatibility across module types allows the transport path to be optimally adapted to specific battery production processes and makes the most efficient use of available space.

Optimal synchronization

With PC-based control technology from Beckhoff and the EtherCAT Industrial Ethernet communication system, movers and other processes are controlled in parallel and synchronized with high precision. This contributes to improved process quality and potential material savings. It also eliminates the need for stops during steps such as loading and unloading, helping to reduce downtime. Even movers operating on two separate systems can be linked via software, enabling greater load capacity or tighter product spacing.

High transport speeds and product throughput

With transport speeds reaching up to 4 meters per second and accelerations of up to 10 g, XTS delivers high throughput. The speed can be adjusted as required to meet the specific requirements of each production step.

Benefits throughout the entire battery production process

This kind of innovative and highly flexible product transport delivers advantages across the entire production process, as illustrated by the following example applications:

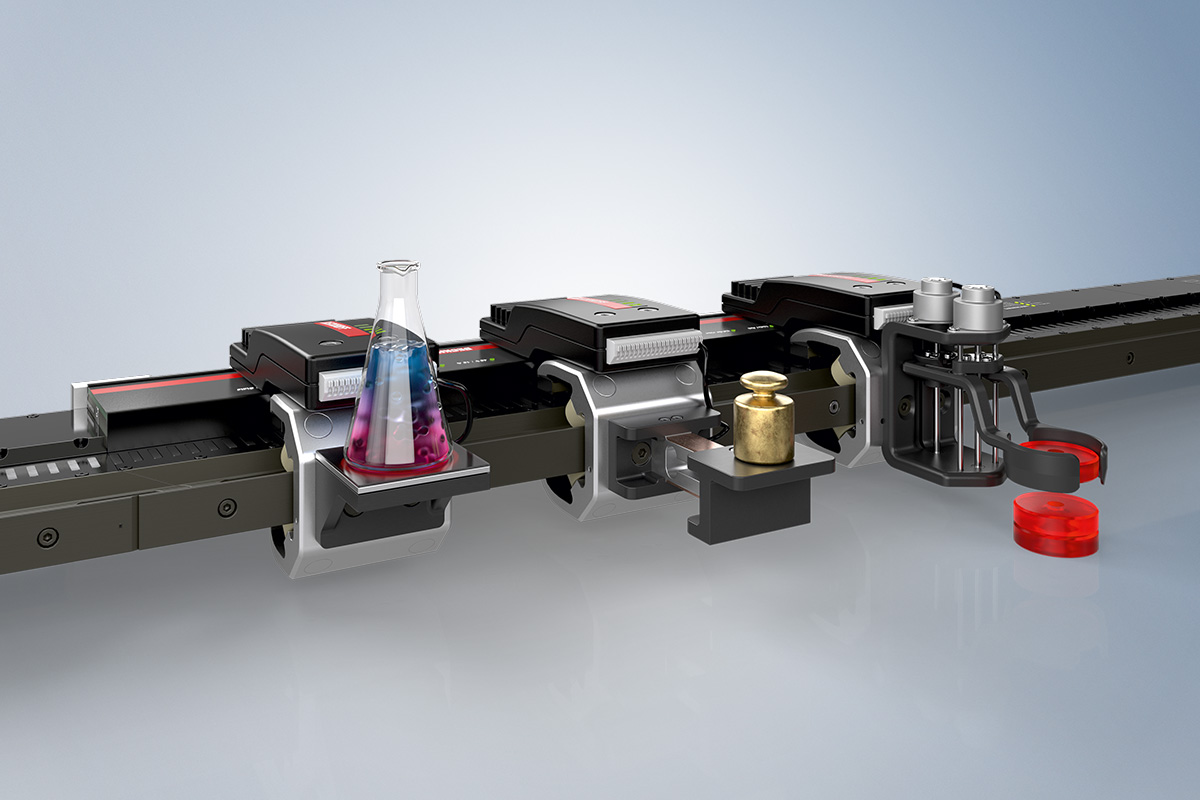

- Cell assembly: When assembling the components of battery cells, XTS provides clear benefits thanks to its flexible scalability and individualized product handling. Secure and gentle clamping of cell components, along with the option to switch easily between different product formats, ensures high precision and efficiency throughout this process.

- Optical inspection: During battery cell inspection, mover or cell positions can be synchronized using a camera system. It is also possible to use several cameras at the same time to inspect different sides of the cells. This reduces cycle time, lowers the number of required stations, and enhances quality by improving accuracy and ensuring clear image referencing.

- Cleaning: Whether plasma-based or chemical, battery cell cleaning can be carried out efficiently by rotating the product mechanically or electrically on the mover. An actuator can be powered and controlled using contactless energy and data transmission (NCT) for this rotation. Both options ensure that the cells are thoroughly cleaned and prepared for the next production steps.

- Adhesive application: The application of liquid adhesive or tape can be carried out on the fly while the cell is in motion. This avoids process stops, accelerates the bonding process, and delivers fast, uniform, and precise adhesive coverage.

- Joining: XTS enables the simultaneous joining of several battery cells. This ensures high precision and speed in the joining process and helps to increase the efficiency of the entire production line. The number of cells to be joined can also be flexibly adjusted via software.

- Rejects: XTS supports the efficient early discharge of battery cells that fail testing. The system uses end-to-end traceability and precise mover control to assign good cells and rejects to different downstream processes. This ensures fast and precise sorting of the cells, improves the quality of the end product and prevents unnecessary processing of rejects – ultimately reducing disposal costs.

Conclusion

The intelligent XTS linear transport system from Beckhoff offers a revolutionary solution for product transport in battery production. Its modularity, flexible installation positions, and optimal synchronization open up new dimensions in how production processes are designed. The result is greater efficiency, higher quality, and faster throughput – providing a future-ready foundation for battery cell production.