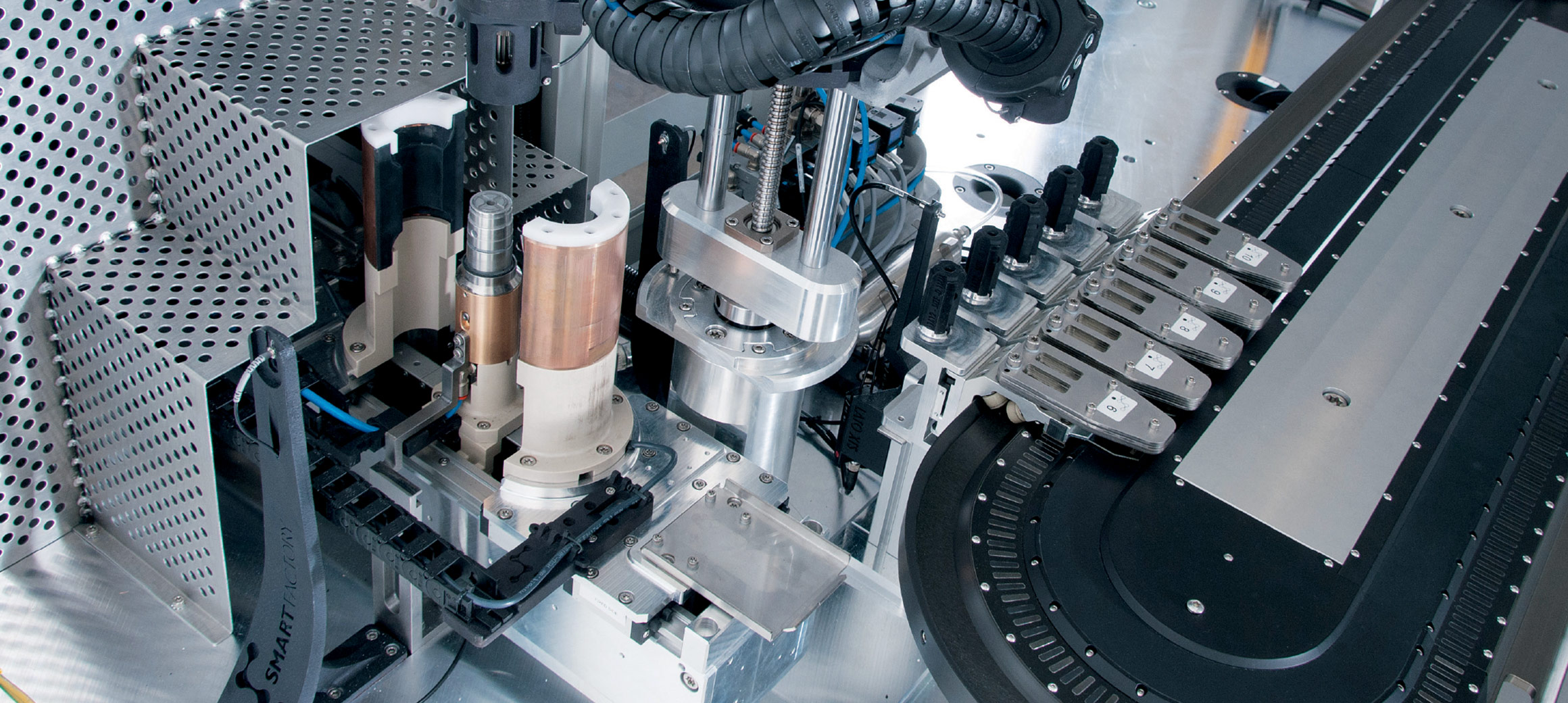

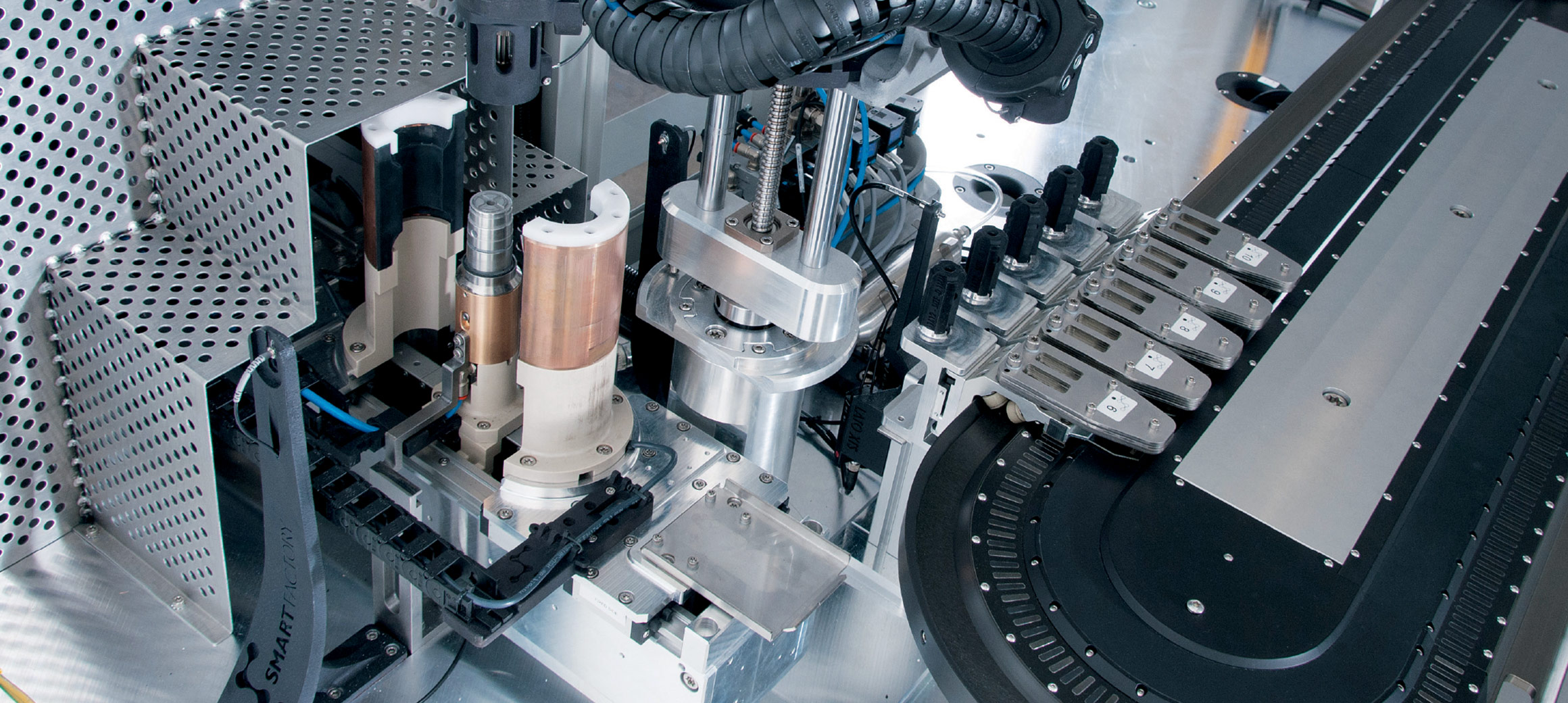

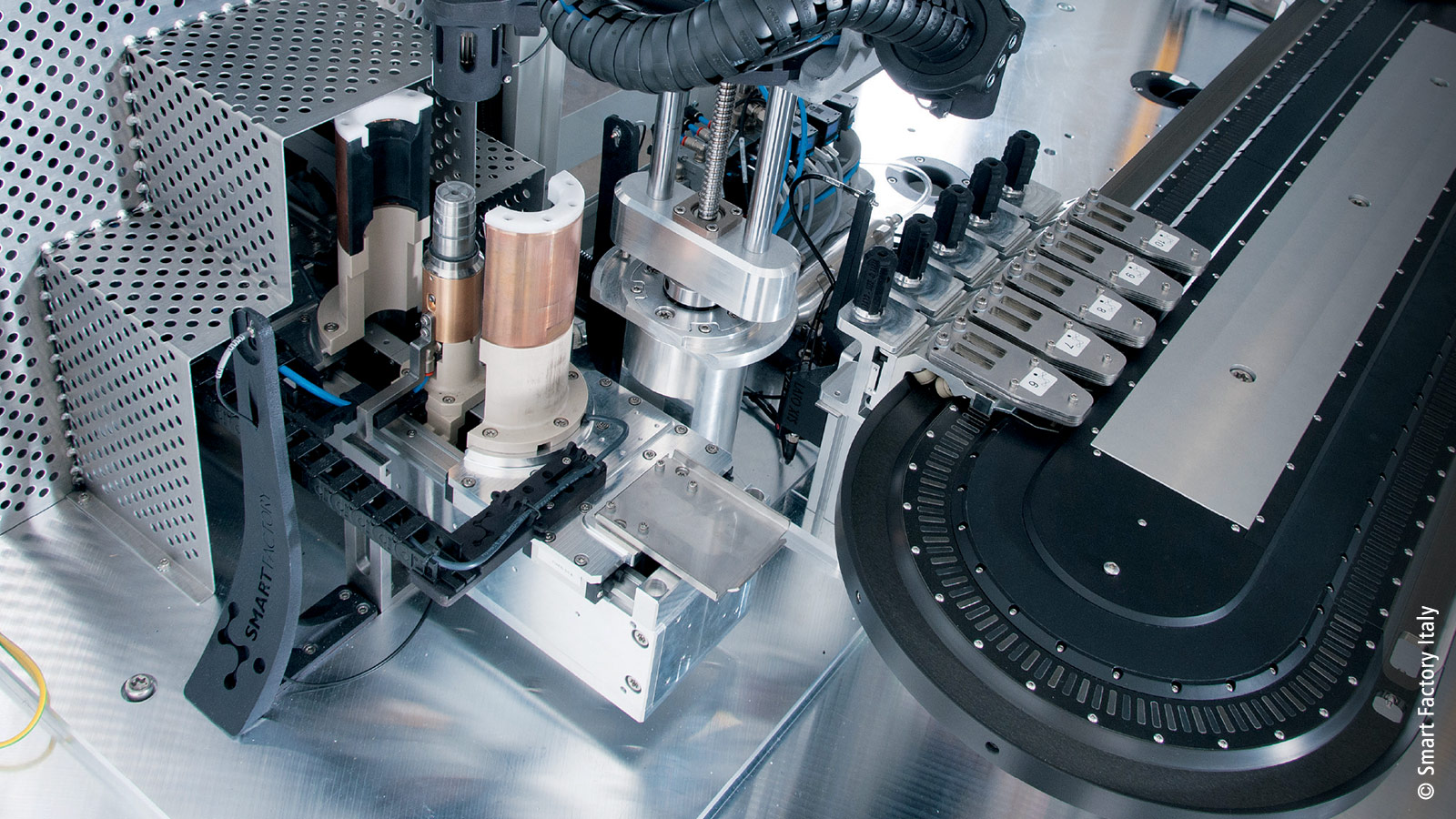

XTS transport system at the core of a smart factory concept

The “Flexim Open Automation System” combines modularity, flexibility, reconfigurability and connectivity to meet the requirements of small production lots right down to individualized production. Developed by Italian start-up company “Smart Factory”, the system consists of a basic machine module that can be extended as required with standard or customer-specific production modules and flexibly adapted to individual applications. At the core of the solution is the XTS linear transport system with the PC-based automation architecture from Beckhoff.

New, frequently changing packaging designs and the trend towards individualized marketing campaigns present companies with several challenges: smaller and smaller lots have to be produced, and increasingly frequent production changes have to be carried out quickly and efficiently. The provision of fast machines alone is not enough to achieve all this; what is also required is an automation system that offers integrated connectivity and maximum flexibility for reconfiguration.

Smart Factory, a new reality based in Northern Italy, focused on this challenge to develop a breakthrough solution with Beckhoff at its core. It is called Flexim Open Automation System, an automation solution fully reflecting Industrie 4.0 paradigms. The modular design of the system enables the flexible production of packaging solutions for different markets: the machine base can host up to 10 modules for various operations such as pressing, gluing, rolling, bolting, cutting, knurling, electromagnetic forming, ultrasonic welding, printing, quality control; any station can be connected to the basic module to perform a wide range of manufacturing processes. The system is very easy to reconfigure: the operator can connect, switch and swap modules on the machine base in just a few simple steps, thanks to a plug-and-play capability achieved by hardware and software-based configuration. In addition to the standard system modules, it is also possible to integrate customer-specific processing stations, which the company develops on demand, or to integrate a Smart Factory enabled XTS system onto a larger scale production line.

XTS as a key technology enabler for maximum flexibility in production

The XTS eXtended Transport System from Beckhoff is the centerpiece of the Flexim solution. It can be linked to a wide range different processing modules in order to implement varying assembly or machining processes. “The modular concept offers a number of advantages. The key benefit is the reduction in lead time,” explains Andrea Pozzi, who heads the research, development and design department at Smart Factory. “Another advantage is the fact that our basic machine had to be developed only once and can be adapted to different applications simply by connecting it with the various processing modules. The flexible control architecture of the PC platform is the basis for the easy configuration and reconfiguration of the system.”

The XTS transport system consists of modular linear motors with integrated power electronics and position feedback, cable-free movers and a mechanical guide rail; it therefore is a perfect match to the modular approach of the Flexim solution. “In our opinion, the XTS is a key technology enabler,” confirms Andrea Pozzi. In contrast to a classic rotary dial and index system, where all machining stations are subjected to a basic machine cycle and the complete system has to be synchronized with the cycle time of the slowest station, the XTS can be used to determine exactly how many parts per cycle are to be processed independently of each other in each station. That is, the slowest processing step will simply be carried out twice by two stations, without impeding the operation of the other stations. Since individual motion commands can be assigned to the movers, all processing steps can be controlled individually and independently of each other. “The XTS makes it very easy to set up an assembly station, for example. No mechanical operations such as positioning of reference plugs or indexing are required. Each mover reaches the programmed position with very high dynamics and accuracy,” adds Andrea Pozzi.

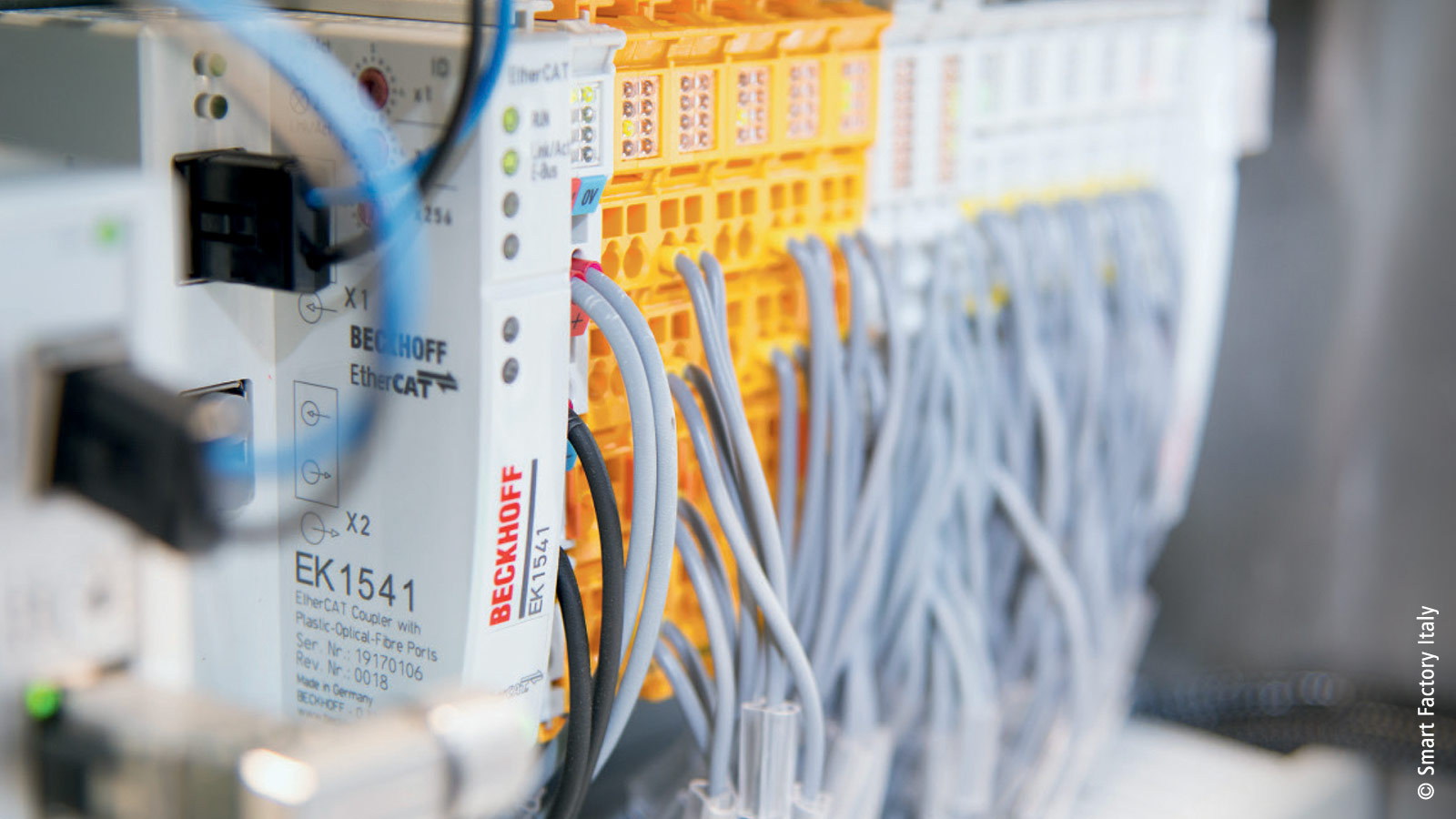

Integrated PC-based control architecture scores through openness

Beckhoff supplied the entire automation platform for the Flexim project, including the C6930-0050 Industrial PC, digital and analog I/Os, safety and measurement terminals, AX5000 Servo Drives and AM8000 series of servomotors with One Cable Technology. “Our decision to use the XTS was a fundamental one,” explains Andrea Pozzi. “The open and modular control architecture from Beckhoff offered us vital advantages at all levels in terms of hardware, software and communication.”

“For example, the use of TwinCAT 3 has enabled us to develop C# applications in a Microsoft Visual Studio® environment, which is a platform we are very familiar with,” continued Andrea Pozzi. “Moreover, EtherCAT also offers great advantages in terms of speed and flexibility.” For example, we were able to use EtherCAT to control the synchronicity during the operating cycle of a magnetic forming device. The cycle, which is characterized by a current discharge with very high intensity (about 100 kA), only lasts around one hundred microseconds. In this way, caps with potentially very complex shapes can be produced, which enhance cosmetics packaging with a high-quality appearance.

TwinCAT IoT solution increases system availability

The Flexim system meets all the typical requirements of Industrie 4.0: it offers full connectivity and is equipped with an innovative HMI solution that can be used with Beckhoff multi-touch Control Panels, but also supports all resolutions, operating systems and devices such as smartphones and tablets. The integration of an augmented reality device from Microsoft can also be used for various purposes, such as context-related search for machine documentation, employee training, troubleshooting and remote maintenance services.

Using TwinCAT IoT products, the Flexim system can exchange process data via standardized communication protocols and access special data and communication services offered by cloud service providers such as Microsoft Azure™. In this way, production-relevant information such as quantities, defects or machine downtime and process parameters including temperature, pressure, consumption etc. can all be conveniently evaluated and analyzed. In this way, detailed statistical analyses can be carried out and preventive maintenance guidelines can be defined to increase the system availability through process-related assignment of operating variables.

The modular XTS system and PC-based automation architecture from Beckhoff not only facilitate excellence in terms of dynamics and precision, they also provide the required modularity and flexibility for the Flexim Open Automation System. “By being able to use an integrated development environment, TwinCAT 3 enabled us to optimize the various design phases and achieve excellent results. Last but not least we benefited from the competent and continuously available technical support offered by Beckhoff Italy,” said Andrea Pozzi.