10 years of alpha ventus with PC-based wind turbine control

Ten years ago, Germany entered the era of offshore wind energy generation with the inauguration of the alpha ventus project. The wind farm was also the first in the world that went into operation under deep-sea conditions. Over the last 10 years, its 12 turbines linked to an offshore transformer station have fed 2.1 terawatt-hours of green electricity into the German power grid. Six of the turbines were supplied by the Spanish company Siemens Gamesa Renewable Energy (Adwen, formerly Areva). In this interview, Bernd Zickert of Adwen Technology talks about the use of PC-based technology from Beckhoff in these systems.

Which Beckhoff products have been deployed in the alpha ventus wind farm?

Bernd Zickert: The Beckhoff products are mainly used in the turbines that we installed. We defined the basic system architecture based on PC-based control back with the second prototype in 2006. Since not all EtherCAT Terminals were yet available back then or did not have sufficient operational history, we decided to deploy the BK1120 EtherCAT Bus Coupler and K-Bus terminals as I/O components and an EK1100 EtherCAT Bus Coupler with EL6731 PROFIBUS master/slave terminals in the nacelle and rotor hub. This turned out to be a great compromise that made use of EtherCAT‘s cost savings and performance as a higher-level bus system from the start. The two PROFIBUS masters in the nacelle did not require the purchase and configuration of a separate computer but were implemented smartly and cost-effectively with two EL6731 terminals.

Which industrial PC did you select back then?

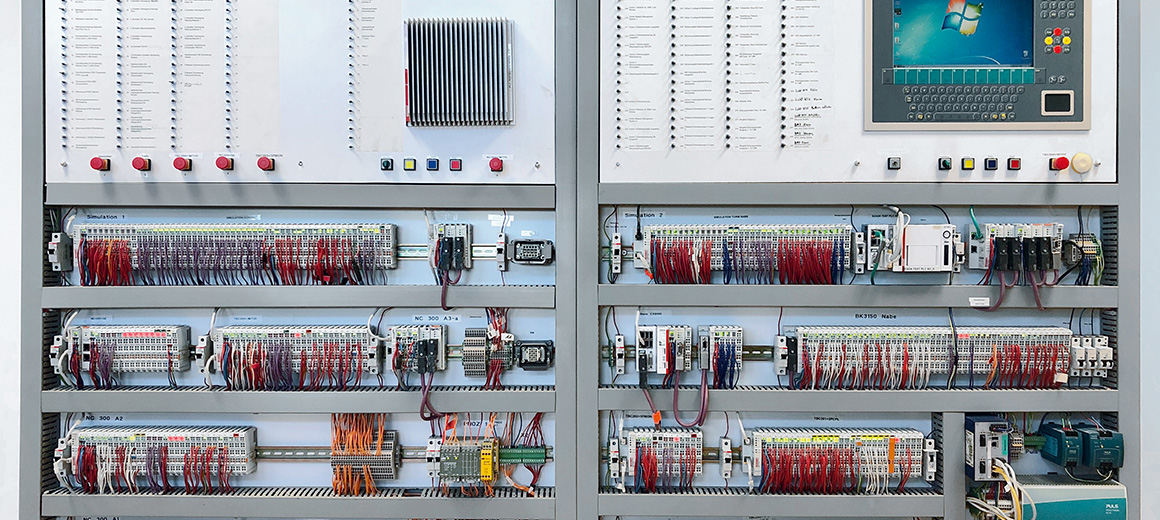

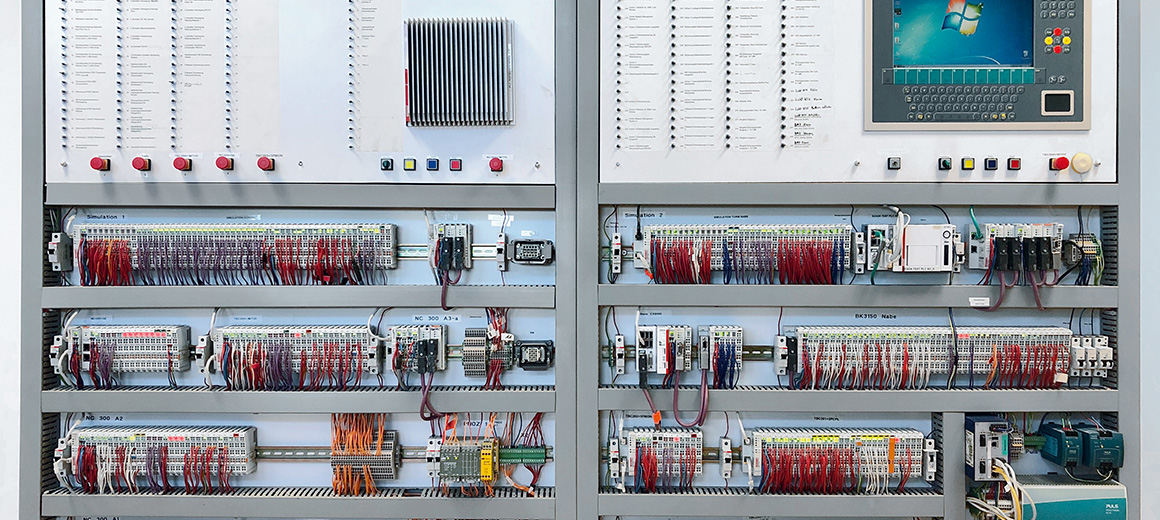

Bernd Zickert: The main computer is a built-in fanless C6515 IPC running the Windows CE operating system. It controls, among other things, the following PROFIBUS slaves: main transformer, medium-voltage switchgear and air treatment frequency converter. The slave unit is the CX9000 Embedded PC, which also runs Windows CE and communicates with the frequency converters of the rotor blade pitch adjustment via a BK3150 PROFIBUS “Compact” Bus Coupler. The operating data is exchanged between the individual turbines over real-time Ethernet and transmitted to the higher-level wind farm management system in accordance with the IEC 61400-25 standard. We also use OPC UA Server for the online visualization, Modbus TCP/IP for the data exchange with the systems that monitor the conditions of the transmissions/main bearings and blades, as well as an FTP server for uploading operating data or new PLC versions. The data traffic within each turbine runs over EtherCAT. Each has approximately 1,000 digital and 400 analog I/Os. The task cycle time we achieve is 10 ms. Since the real-time load is currently less than 30%, we have sufficient resources at our disposal for future improvements.

What has been your practical experience with Beckhoff technology?

Bernd Zickert: The consistently good experiences we had collected with PC-based control on the onshore prototypes were confirmed throughout the project. Most of the basics had already been defined with the three onshore prototypes and the M5000-116 hardware-in-the-loop (HIL) test turbine installation. Thus, alpha ventus was able to benefit from the collected findings in terms of development, function testing, commissioning and operation. The Beckhoff components are operating reliably even after 10 years; only a few of them had to be replaced. We also benefit from the modular, highly flexible I/O level and the fact the entire system can be easily maintained remotely and features great diagnostic depth and computer performance.

Are there any special advantages regarding the control software?

Bernd Zickert: The PLC programs for the wind turbines were developed in TwinCAT 2 software. Through the separation between the PLC runtime and the system manager, it was possible from the start to decouple the PLC program from the hardware. A single PLC program thus covers all M5000-116 turbine projects irrespective of their application and requirements, even with different hardware system configurations. The same PLC programs run on all M5000- 116 turbines with serial numbers 02 through 130 and on all M5000-135 turbines with serial numbers 01 through 71. This standardization has great benefits in terms of program maintenance, root cause analysis (RCA), and failure mode and effects analysis (FMEA). It allows us to make retrofits and optimizations available to every customer.

To what extent have you already implemented IoT-related concepts in your wind farm?

Bernd Zickert: Considering the general objectives of IoT, we implemented the most important steps more or less intentionally from the start. Each turbine has up to three physically separate IP networks with a total of approximately 15 computers. All the turbines are linked to an offshore transformer station with 33-kilovolt undersea cables that contain fiber optic lines for the various networks. These fiber optic lines converge in the offshore transformer station in a communication cabinet that was designed by us and built by Beckhoff. A single 110-kilovolt (kV) undersea cable with fiber optic lines runs from the transformer station to the mainland. The networks can be reached via a public IP address. Each turbine writes its operating data (e.g., metering data, high-resolution error logs, informative messages, warnings, error messages and parameter changes) to a central database autonomously. I believe that automatic data analysis tools harbor significant potential for operational and service improvements, and the automatic delivery and central storage of operating data already provides the foundation for this.

What about the cooperation and collaboration with Beckhoff?

Bernd Zickert: The cornerstone for the development of the M5000-116 for the alpha ventus wind farm had already been laid a few years earlier, and the first onshore prototype of the M5000-116 went into operation in late 2004 on behalf of the multibrid development company at the time. I/Os from Beckhoff were already part of the automation solution at the time. In order to have a uniform, open, flexible, proven, high-performing and future-proof automation solution for wind turbines starting with the second prototype, Beckhoff was selected as the control system and control cabinet supplier in late 2005. The second onshore prototype of the M5000-116 went into operation with Beckhoff CX1020/CX9000 controllers in December 2006. Beckhoff was actively involved in this project from the start, for example with the design of the automation solution for the entire turbine and the M5000-116 HIL test bed that had to be developed simultaneously, the development of the HMI framework in C#, the design and construction of the control cabinet and the on-site functional testing. It turned out to be a great benefit that Beckhoff supplied not only the control components but also the control cabinet for the low-voltage system as well as all cabinets for the testing and commissioning stages. Our cooperation with them has paid off greatly over the years for both parties.

Can you name some important intermediate steps in this cooperative relationship?

Bernd Zickert: Beckhoff developed the IEC 61400-25 server as an interface to an external wind farm management system in 2008, and as far as I know, alpha ventus was the first wind farm where it was deployed. In 2009, Beckhoff developed the OPC UA Server as an interface between the PLC and the wind turbine HMI, and in 2011 we used TwinCAT 3 for the first time for an HIL wind turbine simulation as the test environment for our wind farm management system. The 110/33-kV network modules were implemented in MATLAB®/ Simulink® with great help from Beckhoff’s support team. And in 2017 we used TwinCAT 3 to implement a hot-standby solution for the wind farm management system for which Beckhoff did most of the software development work.