Products

AMP8000 | Distributed servo drive system

Synchronous servomotor with integrated servo drive for control cabinet-free modular machine concepts.

AMI8100 | Compact integrated servo drives

Synchronous servomotor with integrated servo drive for the realization of machine concepts without a control cabinet in the low voltage range.

ASI8100 | Compact integrated stepper motor drives

Stepper motors with an integrated stepper motor output stage for low-voltage control cabinet-free machinery concepts.

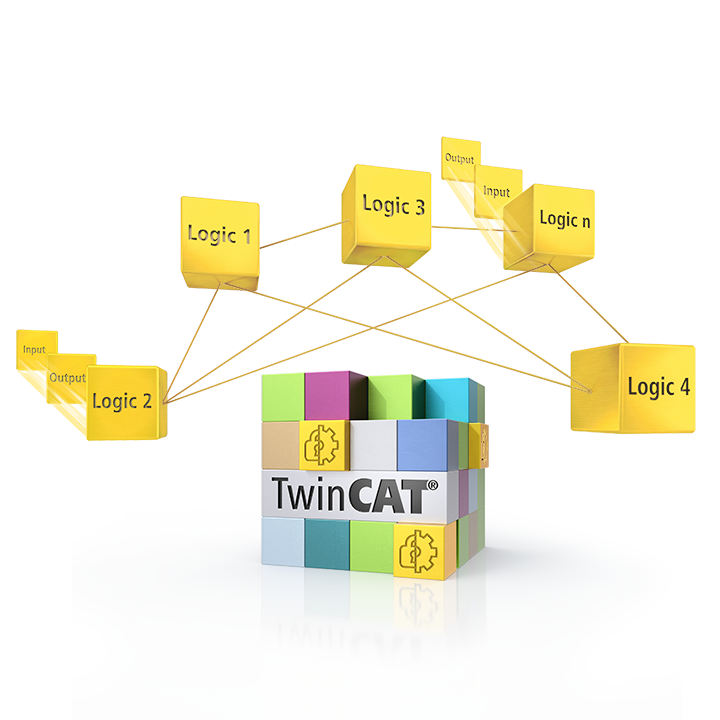

Software

The motion software products optimally support the selection and commissioning of suitable hardware components for drive solutions.

TwinSAFE safe drive technology

With the TwinSAFE safe automation technology, both basic functions and complex safety functions are available for all our drive solutions.

Distributed drive solutions for compact, flexible, and modular machine concepts

Distributed drive systems bring the drive technology out of the control cabinet and place it directly on the machine. The space required for the drive technology components in the control cabinet is eliminated, thus reducing the control cabinet size, the overall machine footprint, and cable length. In addition, the distributed product design takes modular machines' need for flexibility into account: the distributed drive systems can be easily adapted and expanded to fit the number of axes in the machine.

Compact and powerful

Beckhoff offers distributed drive solutions in the 208 V to 480 V AC voltage range, as well as for 48 V DC. The former can be achieved with the AMP8000 distributed servo drive system, in which the servo drive is integrated into the servomotor in a very compact format. The system consists of several components and can be cascaded depending on the number of axes required. For low voltage, the portfolio includes two further product families: the AMI8100 compact integrated servo drive and the ASI8100 compact integrated stepper motor drive.

The AMI8100 servomotor combines a servo drive and an EtherCAT interface in a space-saving design for all motion requirements in the power range up to 400 watts. As an EtherCAT slave, the AMI8100 can be placed directly on the machine without a control cabinet and without an upstream I/O level, which makes it possible to create compact and modular control cabinet-free machines. The monitoring is indicated by the integrated status LEDs. The distributed servo drives are optionally available with TwinSAFE STO/SS1 safety functions.

In the compact drive technology product range (up to 48 V DC), the integrated ASI8100 stepper motor drive combines a stepper motor, stepper motor output stage, and fieldbus connection in a small footprint for all motion requirements in a power range up to 250 W. As an EtherCAT slave, the ASI8100 can be placed directly on the machine, without requiring a control cabinet or an upstream I/O level, thus making the machinery compact and control cabinet-free. The monitoring is also indicated by the integrated status LEDs.

TwinSAFE for safe drive technology

TwinSAFE is a universal safety concept that integrates safe functions into the standard control platform: from the PLC to the I/Os to the drive technology. All safety functions such as an emergency stop, safety door monitoring, two-hand operation, safety mat evaluation and muting, safe position, safely limited speed, etc. can be programmed and configured on the integrated TwinCAT engineering platform. The AMP8000 distributed servo drive includes TwinSAFE as standard for implementing the drive-integrated safety functions STO/SS1 in accordance with IEC 61800-5-2 and is also optionally available with TwinSAFE Safe Motion, so that more complex and limiting safety functions can be implemented.

Supplementary and intuitive

An extensive and optimally matched range of accessories rounds off the product portfolio of the distributed servo drive systems. The system is completed with pre-assembled cables, wiring aids, and various components for energy management. The motion software products optimally support the selection and commissioning of suitable hardware components for drive solutions.