Products

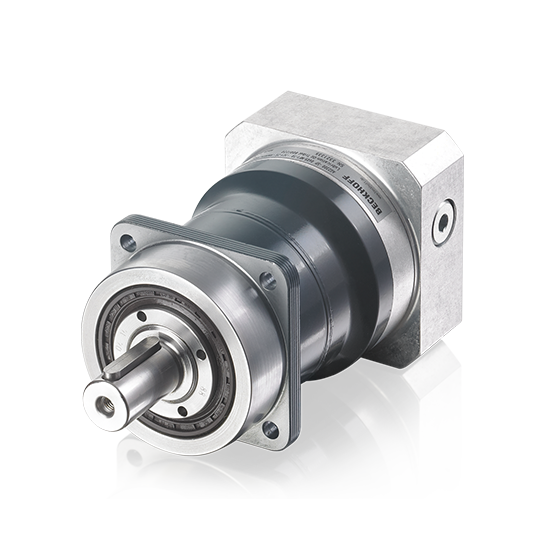

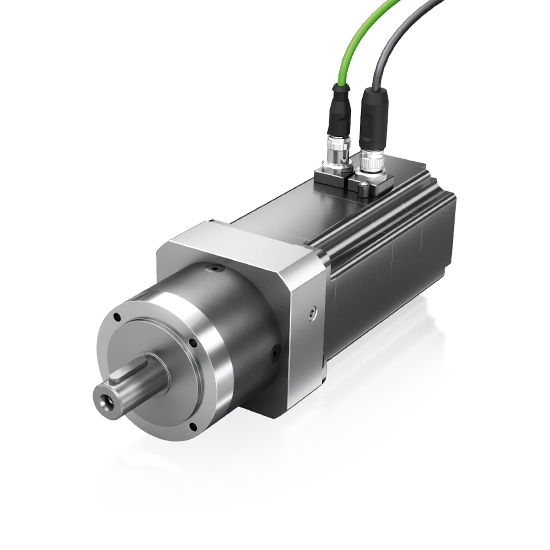

AG2300 | High-end planetary gear units with output shaft

The low-backlash high-end planetary gear units from the AG2300 series have a high power density for highly dynamic cyclic operation.

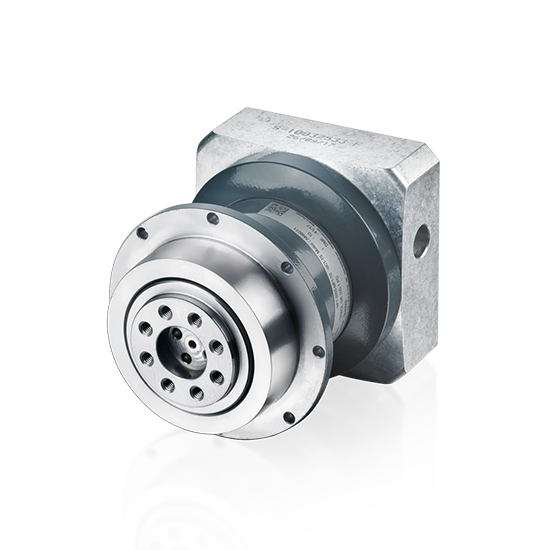

AG2400 | High-end planetary gear units with output flange

The short AG2400 high-end planetary gear units with output flange can be optimally adapted to the mechanical system.

AG3210 | Economy planetary gear units

The economy planetary gear units from the AG3210 series are extremely inexpensive to procure, efficient in operation, and maintenance-free over their entire service life.

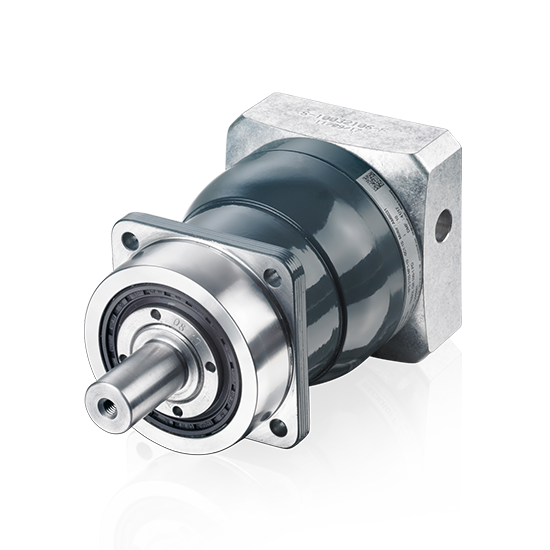

AG3300 | Economy planetary gear units

The AG3300 gear units have a high torque density and represent a cost-effective alternative to the high-end planetary gear units from the AG2300 series.

AG3400 | Economy planetary gear units with output flange

The AG3400 gear units have a high torque density and represent a cost-effective alternative to the high-end planetary gear units from the AG2400 series.

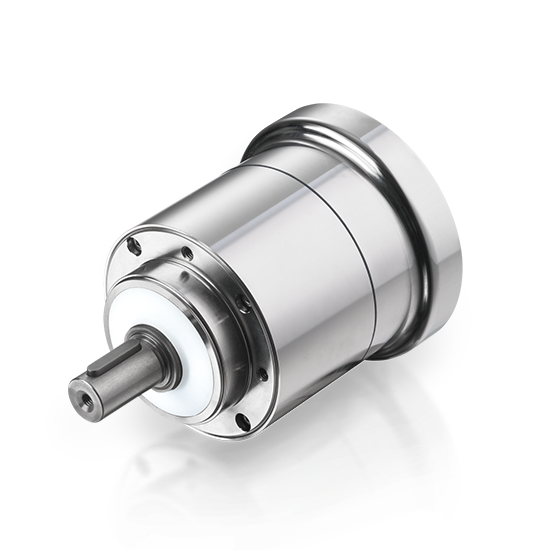

AG2800 | Planetary gear units for AM8800 stainless steel servomotors

Together with the AM8800/AM8700, the AG2800 gear units represent an innovative drivetrain for environmental conditions that are conducive to corrosion.

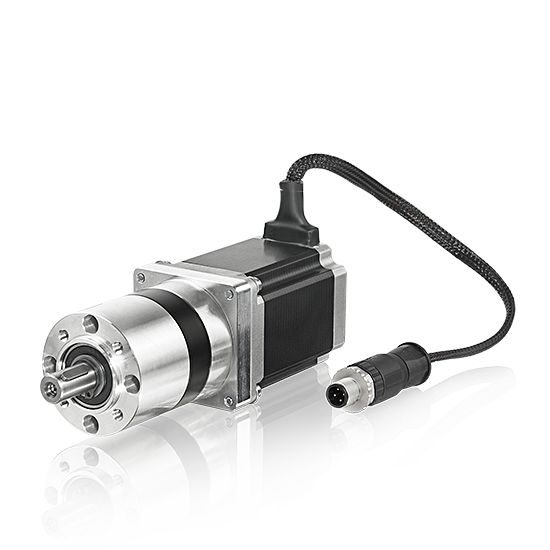

AG2250 | Planetary gear units for servo and stepper motors

The AG2250 gear units are optimally matched to the compact drive motors. They are available in both straight and right-angled designs.

AG1000 | Planetary gear units for AS1000 stepper motors

The AG1000 is the particularly cost-effective product range for use in combination with the stepper motors from the AS1000 series.

Software

The motion software products optimally support the selection and commissioning of suitable hardware components for drive solutions.

High torque and precise

Planetary gear units complement the servomotors to form a complete drive axis

Maximum precision, dynamics, and high torque density are essential demands that are placed on a reliable planetary gear unit in practice. The parameters that are important for the design of a planetary gear unit – the inertia ratios, the required torques and the motors that can thus be used – can be calculated very conveniently in TwinCAT with the TwinCAT 3 Motion Designer. In addition, the tool checks in a single work step whether the selected motor can be adapted to the gear unit. The planetary gear units are fitted to the respective motor in the factory and delivered as a complete motor/gear unit.

Precision gear units to suit every application

The Beckhoff planetary gear units are matched to the rotary servomotors and offer a wide range of choices for the most diverse applications. The AG2300 and AG2400 high-end gear unit series offer finely scaled, single-stage, and multi-stage transmission ratios between i = 3...100. The various sizes with a high-efficiency are particularly suitable for technically demanding drive solutions. The range of applications extends from the high-precision axis in machine tools and manufacturing machines through to highly dynamic packaging machines, where maximum productivity is required.

The cost-effective alternative from the economy segment

In parallel with the high-end series, the planetary gear units from the AG3210, AG3300, and AG3400 economy series represent a low-cost, but technically high-quality alternative. Primarily for applications in the price-sensitive range, Beckhoff offers two versions in each of the three economy series:

- the standard variant for applications with high positioning accuracy

- the high-torque variant for applications with high torque requirements

The planetary gear units from the economy series are suitable for the most diverse applications due to a variety of transmission ratios and output variants and open up new design freedoms for the machine manufacturer.

Planetary gear units for AM8800 stainless steel servomotors

The AG8800 low-backlash planetary gear units in a hygienic design meet the strict requirements for hygienic production and packaging machines. The main feature of the gear unit series certified by the EHEDG is the safe and efficient cleaning of the gear unit. The new concept opens up completely new freedoms for the design engineer in the design of plants with the highest requirements for hygienic and sterile production.

Planetary gear units for compact drive technology and stepper motors

The low-backlash economy planetary gear units from the AG2250 series, in straight and angled versions represent with a variety of transmission ratios an economical solution for all mechanical engineering requirements. They are optimally matched to the rotary servomtor of compact drive technology and stepper. With the AG1000 series, Beckhoff offers special planetary gear units for the stepper motors from the AS1000 series.