Measuring forces at the detection limit with PC-based control

Calibrating multidimensional force sensors is considered the supreme discipline of measurement and testing technology. GTM Testing and Metrology GmbH in Bickenbach, Hesse, is taking multi-component calibration to the next level with a new approach. It is not just the measuring range, design and size of the measuring equipment that are unique, but the automation concept as well: PC-based control, EtherCAT and servo drive technology control and regulate the force application via a hexapod, while precision measurement terminals from the ELM series record all forces and torques in real time and with maximum accuracy.

When it comes to multi-component calibration, no one can match the metrology specialists at GTM, one of the leading suppliers of strain gauge-based precision transducers and measuring equipment, precision electronics, and calibration services for forces and torques: Back in 2005, the company was the world’s first DIN EN ISO/IEC 17025-accredited laboratory for multi-component measurement technology. Since then, the company – based in Bickenbach near Frankfurt – has been calibrating not only force and torque transducers, but also multi-component transducers. There are two possibilities here: The magnitude of the force is determined very precisely for each individual component; the other variables such as force application points, force direction and lever arms, on the other hand, are merely estimated as precisely as possible. These measurements take place on uniaxial measuring equipment. “Another option is to measure the force vector in its entirety,” says Daniel Schwind, managing director and technical director at GTM, pointing out a second approach much discussed in metrology. The advantage here is that the only source of measurement uncertainty is the measurement setup. GTM is convinced that this complete vector measurement will become established in the long term at government institutes such as the Physikalisch-Technische Bundesanstalt (PTB) and as an industry standard. Consequently, the decision to invest in a new, fully automatic system to work alongside its manual multi-component reference standard measuring equipment – which has been in operation since 2005 – was a logical development step for GTM.

With its measuring equipment, GTM has cut a technological path into metrologically difficult terrain. This is because all existing multi-component calibration methods have weak points somewhere or other, be it the achievable measurement uncertainty or the calibration effort. “The multi-component reference standard measuring equipment, as we have implemented it, was terra incognita,” says Daniel Schwind. As a result, basic research was necessary in some areas. This work on the comparative measurement and verification was carried out in advance of and, to some extent, in parallel with the development of the measuring equipment. “The discussions with the assessor about our procedure and the traceability of our measuring equipment during accreditation were very fruitful,” recalls Torsten Hahn, deputy head of the calibration laboratory. Deliberations about the measuring equipment began as early as mid-2016, when inquiries for multi-component calibration increased to such an extent that it was no longer possible to fulfill all orders on the existing measuring equipment and with the existing calibration procedure. This is because the manual calibration process used to date is very time-consuming: the calibration object must be precisely installed in the measuring equipment and repositioned several times for the measurements. The entire calibration process thus involves a lot of setup time. “Previously, such a calibration took around two days,” says Marcel Richter, director of product management & marketing at GTM. On the new measuring equipment, the time required is reduced considerably – the only steps involved are clamping the test specimen, configuring the measuring equipment for the calibration object, and configuring the automatic calibration process in the operating software. “Due to the integration of all components, calibration can be carried out fully automatically overnight,” says Torsten Hahn, pointing out a huge advantage over the previous process.

Accuracy improved from 0.5% to 0.1%

The measuring equipment, which was developed completely in-house, reduces the measurement uncertainty of the calibration by a factor of five compared to the previous accreditation and makes GTM a pioneer in the field of multi-component measurement technology and calibration. At the same time, the calibration range has been extended significantly – with realistic and application-oriented installation conditions for the calibration object. “In order to achieve the necessary flexibility, we have designed a very large test chamber of 4.5 m3 for the customer’s setup,” says Martin Eller, measurement systems team leader and the responsible design engineer.

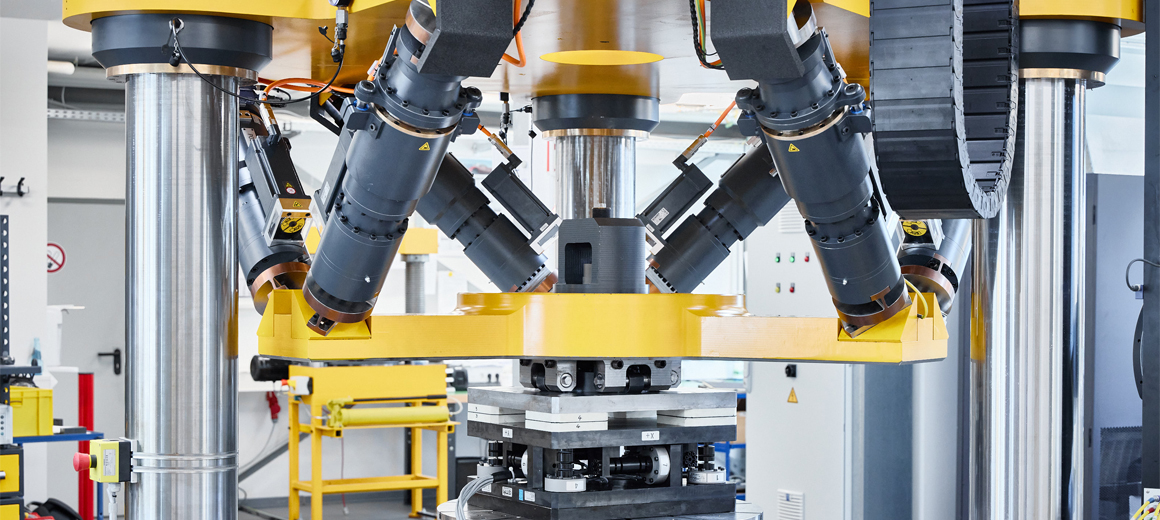

GTM is also breaking new ground in terms of measurement uncertainty. “We are at the top of the calibration hierarchy with a proven measurement uncertainty of 0.1%,” says Daniel Schwind, “for forces from 4 to 500 kN axial and 2 to 200 kN transverse.” The measuring equipment can apply and precisely measure torques between 2 and 50 kNm. “The only other way to achieve these large measuring ranges with such a low measurement uncertainty is with uniaxial measuring equipment,” adds Martin Eller. In order to achieve this key data, a huge amount of effort was put into the design right from the start. The core element is made up of three different basic measuring platforms to ensure maximum flexibility with regard to the size of the calibration objects, equipped with high-precision K series force transducers specially adapted to the new measuring equipment. Furthermore, it quickly became apparent during the design and construction phase that there were no suitable mechanical components – such as a hexapod including control system – on the market. “This unit was initially planned as purchased parts but in the end we had to develop it ourselves. With PC-based control and the drive technology from Beckhoff, we found a suitable, high-performance platform that integrates well – including the precision measurement electronics,” emphasizes Martin Urbanski, who is responsible for the software development of the measuring equipment.

The measuring equipment is servo-electrically adapted to the calibration object via three spindles. During the calibration process, six screw drives driven by the AX8000 multi-axis servo system and AM8042 servomotors generate the required forces and torques – with maximum precision. “With a measurement uncertainty of 0.1%, we are playing in a different league and enabling users to take new approaches in order to improve their applications,” says Marcel Richter, pointing out the motivation for GTM. With much more precise calibration, guesses become more accurate measurements, more reliable knowledge – providing the basis for GTM customers to further optimize their processes and manufacturing tolerances. “More precise multi-component transducers enable the aerospace industry to measure more details in their aerodynamic tests in the wind tunnel, for example, and to evaluate the effect of modifications to the aircraft,” says Christian Lindemann, product manager for precision measurement technology at Beckhoff, highlighting the potential. Even small improvements to the models can significantly increase the efficiency of an aircraft in subsequent operation. The same applies to rotor blades of wind turbines, ship propulsion systems or rolling resistance measurements on car tires. Another advantage of the design is that GTM can reproduce gravity very precisely in any direction via the hexapod’s six axes and thus calibrate the customer-specific application virtually under real-life installation conditions. “This is an innovative and trend-setting solution for customer-specific multi-component measurement technology that is not available anywhere else,” Daniel Schwind emphasizes.

Calibration depends on the entire measurement chain

The calibration sequence – loading, unloading, load changes, measuring ranges as well as repetitions – is configured by measurement technicians via GTM’s proprietary WebForceManager operating software. This controls the measuring equipment fully automatically on the basis of the calibration sequence used, which consists of sequential commands. These commands are transferred to TwinCAT and processed further. Furthermore, program sections that had to fulfill a real-time requirement, such as the realization of the hexapod kinematics and the simultaneous acquisition of all measuring signals, are also implemented in TwinCAT.

When it comes to control hardware, GTM relies on embedded PCs and high-end ELM3504 measurement terminals. All measurement terminals are designed with 6-wire technology. The measurement technology is supplemented by the EKM1101 EtherCAT Coupler and the ELM9410 power supply terminals, both infrastructure components that ensure a high-quality supply to the measurement terminals. Christian Lindemann comments: “We are pleased that GTM took a very close look at our industrial measurement terminals and selected them for this demanding calibration system.” The ELM3504 high-end measurement terminals faced tough competition from established measurement technology suppliers and GTM’s own measurement electronics and had to prove their suitability for the task at hand, including as a measurement chain in combination with the high-precision K series force transducers used. “We put the Beckhoff Terminals through their paces together with our high-precision force sensors and found that the terminals work much more precisely under our ambient conditions in the calibration laboratory than specified in the data sheet,” says Daniel Schwind. GTM had initially considered making its own measurement electronics EtherCAT-capable. “However, once we had the ELM measurement terminals on the table, we were able to save ourselves the effort,” says Daniel Schwind. “We are always conservative with our specifications and only promise something if our components can still deliver it under more difficult practical conditions,” adds Beckhoff product manager Christian Lindemann.

A total of six 4-channel ELM high-end measurement terminals are used in the measuring equipment for recording the force and torque input via the hexapod and for measuring the calibration object. Further EtherCAT Terminals from the EL series are also used. “Their standard resolution is perfectly sufficient for this,” emphasizes Holger Schneider, who is responsible for the electronic components in the measuring equipment. They are used, among other things, to monitor the actuators for compliance with the maximum forces via strain gauges. The six hexapod cylinders are driven by servo drives and the AX8000 multi-axis servo system. The power transmission – also an in-house development by GTM – involves a gearbox and a screw drive. As a result, the relatively small servomotors generate high forces and torques – “and with the highest precision,” adds Martin Eller. The compact multi-axis system from Beckhoff in conjunction with PC-based control and simultaneous data transmission of the measured values in real time via EtherCAT helps here. “This has simplified our task of controlling all drives on the basis of the measured values,” emphasizes Martin Urbanski.

The selected control architecture also has a positive effect elsewhere – in the control cabinet. Since GTM obtains almost all of the components from Beckhoff, from the measuring amplifiers and other I/O components to the industrial PCs and drive technology, the electronics are much more compact overall. Holger Schneider explains: “With our initial plans for a control concept based on separate servo and measurement technology from different suppliers, we would have needed three control cabinets.” Not to mention the integration and engineering effort required for the different systems.