The sky is the limit for performance and innovative capacity

For TME, a machine builder specializing in the packaging of powdered foods, Beckhoff was the obvious choice of system supplier: Beckhoff PC-based control technology offers unlimited opportunities when it comes to the performance and innovative capacity – in terms of flexibility, scalability, and openness – of its packaging machines. This is particularly evident in the latest Cialdy Evo machine series.

Founded in Fidenza, Italy, in 1982, TME Packaging Solutions is known around the world for its packaging solutions, particularly for powdered food such as coffee in capsules and pods. “TME was one of the first companies to produce packaging lines for single-dose products and is currently focusing on technologies for sustainable packaging,” emphasizes Alice Magnani, head of HR and marketing, and member of the founding family’s second generation. TME’s export share of over 80 % reflects not only the company’s standing on an international scale, but also its reliability and ability to innovate, which is necessary in the face of tough international competition.

With the Cialdy Evo, TME has developed a compact packaging machine for coffee, barley, tea, and herbal teas in sealed paper filter pods in single-portion bags. The machine precisely dispenses and fills up to 200 pods per minute which are then sealed with the integrated sealing unit. “The special thing about this packaging machine is that the packaging process takes place around the pod that has just been formed,” explains Andrea Zuccheri, who is responsible for software engineering and automation at TME. In addition to higher productivity, the integration of the packaging and sealing process offers further advantages such as a smaller footprint of just 10 m². The compact automation components from Beckhoff also play a part.

All disciplines combined in one system

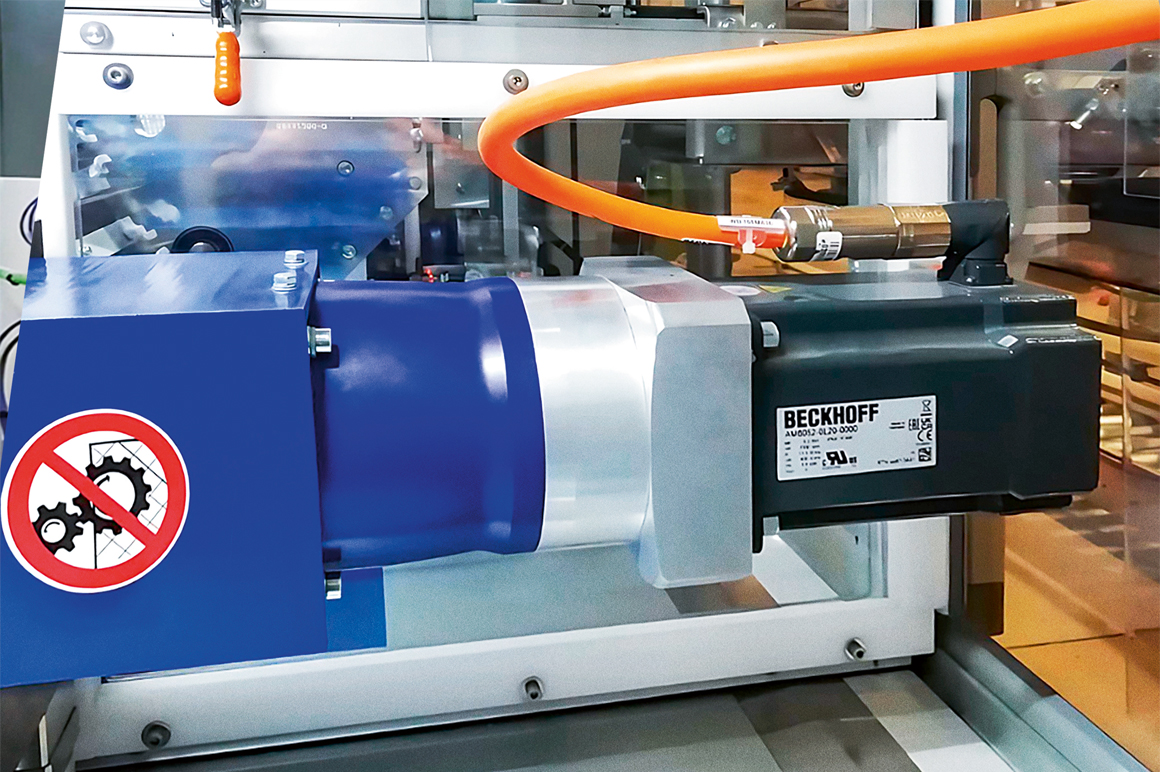

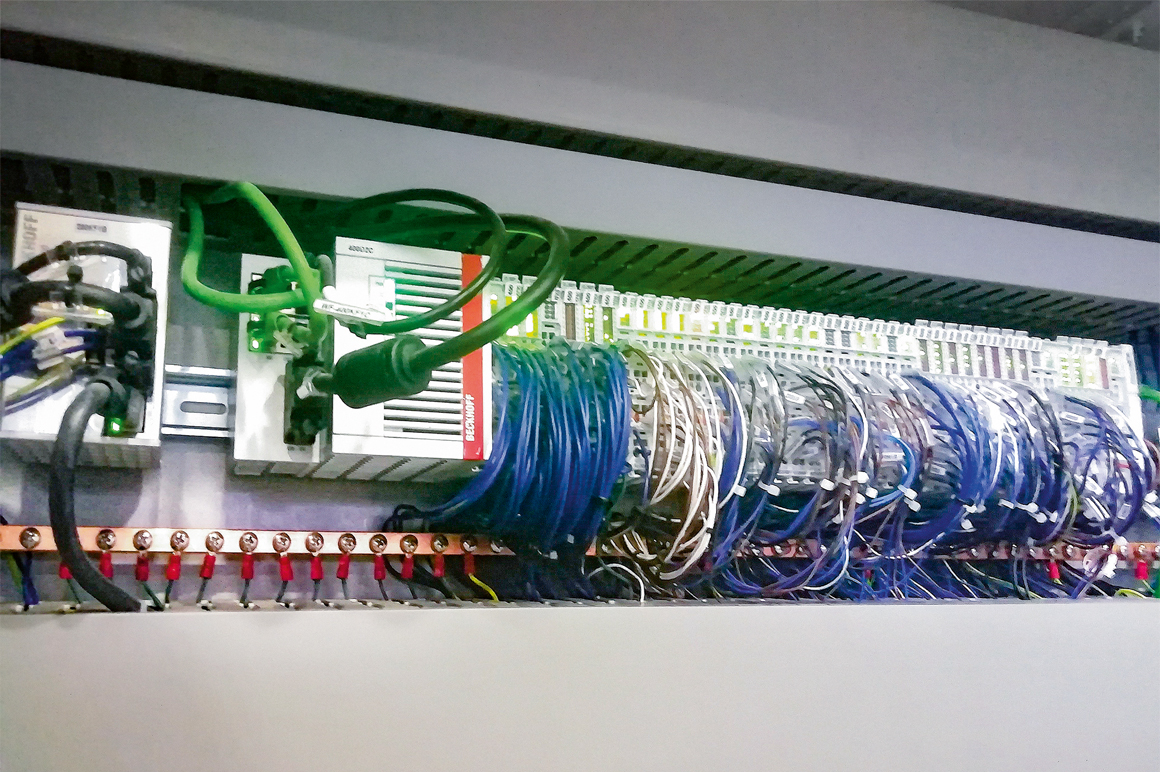

“We’re thrilled about PC-based control as an automation solution, which is why we have fully automated our machines with Beckhoff technology,” explains Andrea Zuccheri. TME has implemented the entire range of Beckhoff components, from CX series Embedded PCs and CP-Link 4 remote control panels to numerous EtherCAT Terminals, AX5000 servo drives, and AM8000 servomotors with One Cable Technology (OCT). As Andrea Zuccheri goes on to explain: “PC-based control ensures a clear control architecture, saves space in the machine, and also reduces installation, wiring, and maintenance work.” What’s more, EtherCAT ensures fast and synchronous communication with all components.

Moreover, several applications can be integrated into a single control system, including PLC and motion control, visualization and vision, as well as external applications such as the management of additional devices. For example, users can access the labeler integrated via EtherCAT in the control panel using a browser to set the parameters for labeling.

Innovation without limits

The decision in favor of PC-based control was also made due to the continuous innovations and the resulting development potential that Beckhoff offers machine builders like TME. “PC-based control offers endless possibilities in the design phase. If we have an idea, we’re certain that we’ll be able to implement it,” says Andrea Zuccheri. The system-integrated approach also makes it possible to divide scarce personnel resources between the various machine series. This has enabled TME to reduce the overall design, development, and testing times for its machines.

“You can’t build flexible and truly open machines today without using a PC-based architecture,” states Andrea Zuccheri, describing the paradigms of Industry 4.0. With PC-based control, it is possible to connect the machine to the Internet, communicate with other machines or devices on a production line and, if required, also manage devices and systems from other manufacturers. All this with a standardized, scalable solution that can be upgraded to the latest available PC technology or a more powerful CPU at any time – without having to adapt the application. This is a great advantage in the design phase, during commissioning, or when servicing.

Another argument put forward by Andrea Zuccheri is that, unlike other software platforms, the TwinCAT development environment is free of charge: “Our technicians are always able to access the complete development environment on their laptops – this means that they can carry out upgrades or software reconfigurations at our customers’ premises at any time.” In the event of acute faults, the end customer can install TwinCAT on a local computer and connect to the system within a few minutes. Using remote maintenance, the service technician can then search for and rectify the fault. “During the COVID-19 pandemic, our support team was able to carry out commissioning and maintenance tasks on systems that were thousands of kilometers away,” adds Alice Magnani.

Investing in sustainability

According to the machine builder, system supplier Beckhoff optimizes purchasing management and accelerates the implementation of innovations with its product developments. TME is currently focusing on sustainability, both in terms of reducing energy consumption and processing environmentally friendly materials. “Our upcoming machine series will be even more modular and open for integration – and will come with an app for monitoring,” concludes Andrea Zuccheri.