TwinCAT Plastic Framework

Get ahead in plastics machine engineering

สำนักงานผู้แทนประเทศไทย

Get ahead in plastics machine engineering

Manufacturers of machines and systems for the plastics processing industry are under huge pressure to innovate. They aim to create solutions that score highly by providing precise, end-to-end digitalized, efficient, and sustainable production processes. This requires the use of advanced control technology with process-specific functions – for injection molding, blow molding, extrusion, or thermoforming, for example.

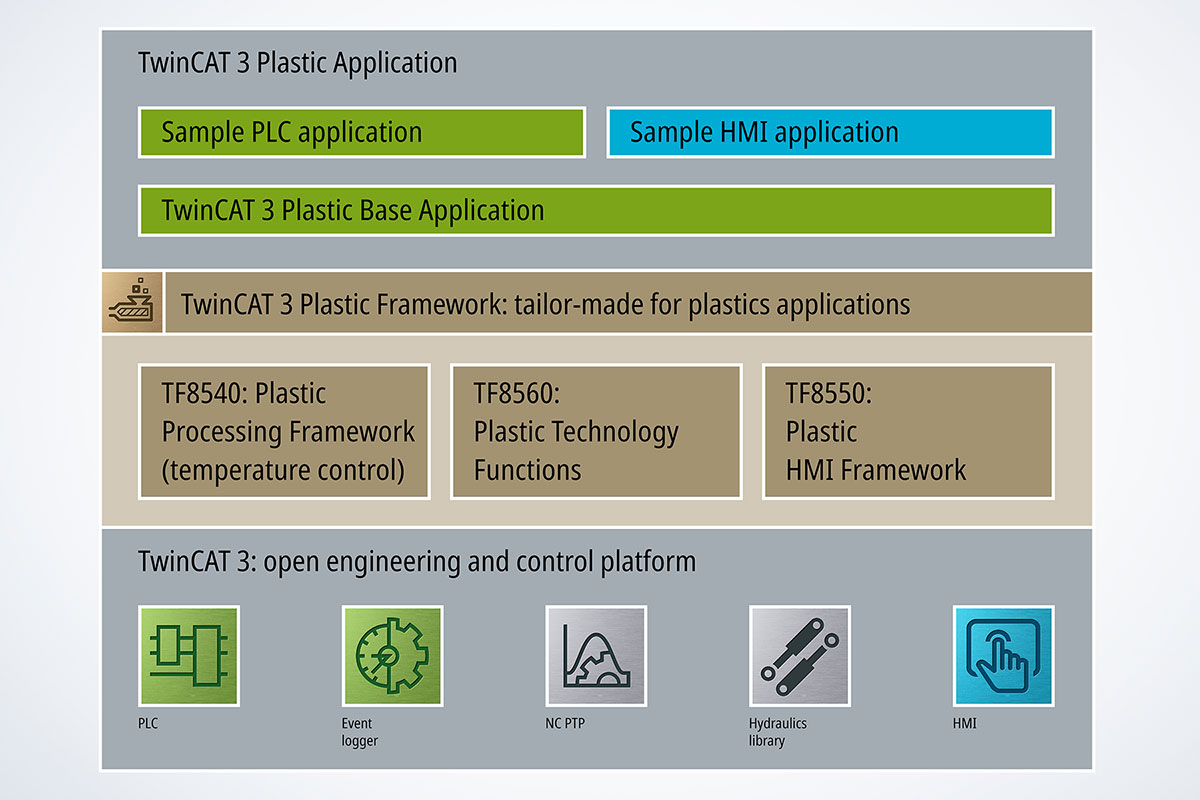

The work involved in developing control solutions of this kind and making them a reality is high. The process costs time and money, ties up experts in a time when we are already seeing a shortage of skilled workers, and reduces companies’ ability to compete as a result. That is why we offer a modular software toolbox in the form of PC-based control and our TwinCAT 3 Plastic Framework, with industry-specific solutions that minimize the work involved in development. This gives you a competitive edge right from the engineering stage – with the architectural openness typical of Beckhoff and the familiar TwinCAT 3 environment.

Do you have any questions?

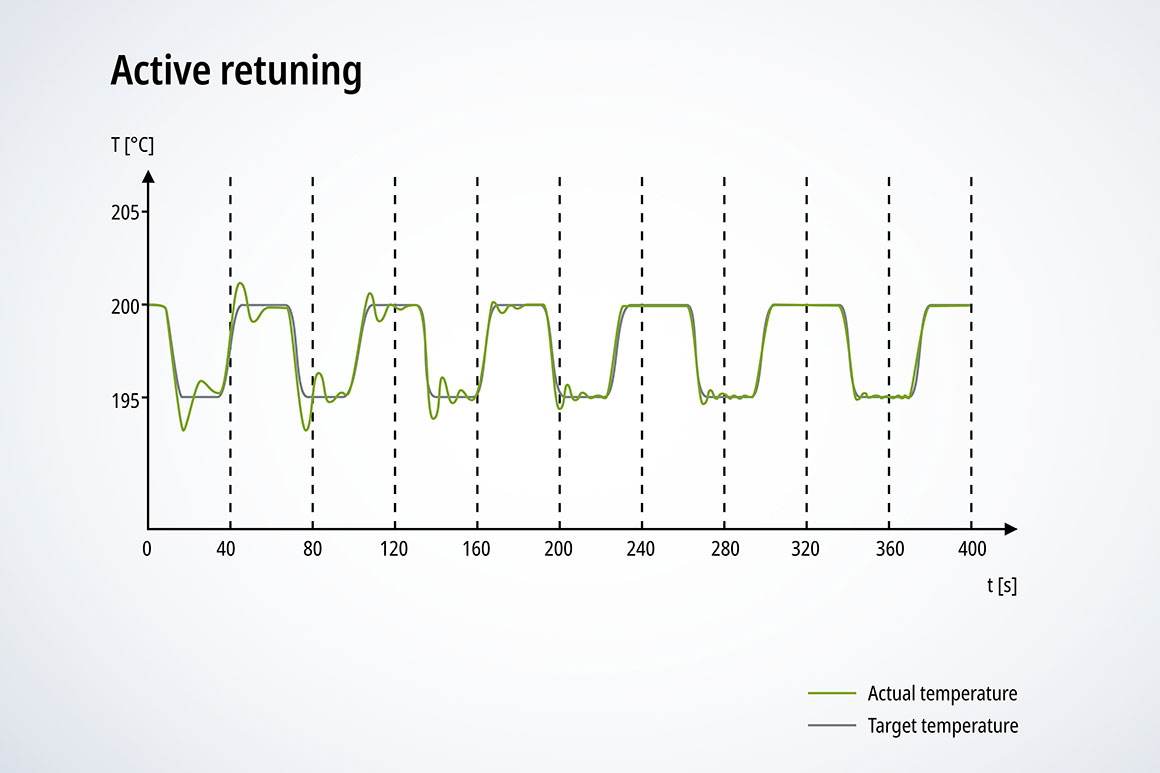

Precise temperature control in the manufacturing process is crucial for the production quality and efficiency of your plastics machines. You can achieve this with the help of the TF8540 software library from Beckhoff. It seamlessly integrates the required control functions into your TwinCAT engineering environment and contains a software-based temperature controller that is specially designed for the inertial control loops in plastics processing.

Highlights:

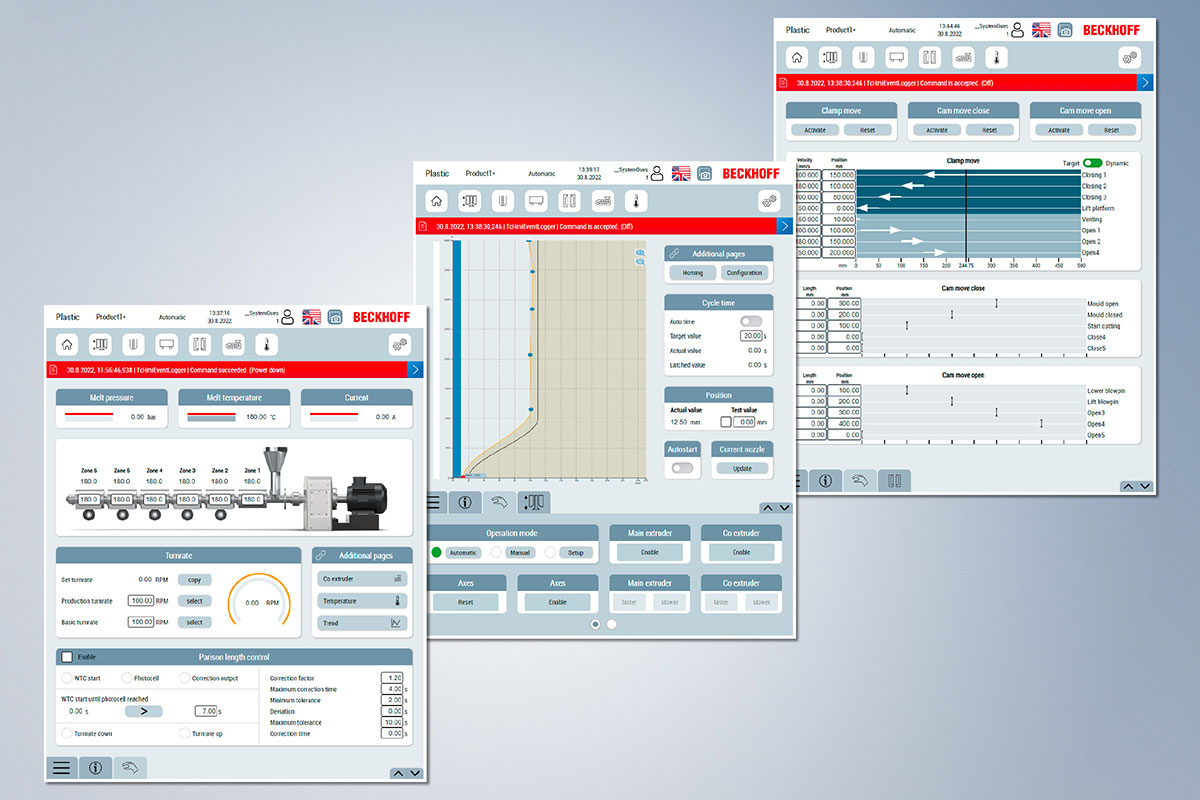

Given its intermediary role between the user and the plastics machine, the user interface must be functional, intuitive to use, and easy to customize. Everything you need for engineering can be found in the TF8550 software library, which contains a TwinCAT HMI package developed for the plastics industry with industry-typical graphical objects and a large choice of functions and controls for the processes involved in plastics processing.

Highlights:

With the TF8560 technology package, Beckhoff provides pre-developed, tried-and-tested software modules for typical motion applications in plastics machines. This significantly reduces the amount of development work you need to carry out and speeds up machine commissioning at customer premises. The motion functions are prepared for use with the Beckhoff TwinSAFE safety solution. TF8560 also supports you in commissioning motion axes and enables virtual commissioning with the help of integrated simulations.

Highlights:

The technology in the software packages and libraries presented here covers an extensive range of leading controller, function, and HMI solutions for plastics machines. What you now need to connect the technology modules to customized application solutions for your production sub-processes is a smart integration platform. This is exactly what we offer with the TwinCAT 3 Plastic Application. This connects your PLC and HMI sub-projects to specific production applications: for wall thickness control in blow molding machines or for controlling injection units in injection molding machines, for example.

Highlights:

The economical use of all resources is important in plastics processing. That is why BBM – a machine builder specializing in blow molding machines and based in Langenberg, Germany – has made the choice to use all-electric machines and innovative process control with the TwinCAT 3 Plastic Framework.

Ossberger GmbH offers a press blower for high-precision series production of large bellows for vehicle air suspensions. Beckhoff components such as AX8000 and TwinCAT 3 ensure maximum repeatability, while the close partnership between the companies drives development forward.