Scalable energy supply without system limits

Spanish Group Power Electronics has demonstrated its comprehensive expertise in sustainable energy supply in over 3,000 solar and energy storage projects with a total commissioned capacity of 120 GW. To control its modular systems, the company relies on open, high-performance Beckhoff control technology: powerful embedded PCs combined with TwinCAT enable flexible scaling and dynamic load changes of 330 MW within 110 ms.

Based in Llíria near Valencia, Power Electronics specializes in inverters for utility and battery storage systems and is a leading manufacturer of solar inverters for photovoltaic systems around the world. Founded in 1987, the company is represented in 36 countries and has implemented more than 3,000 solar and energy storage projects with 120 GW of installed capacity (AC), preventing the release of almost 120 million tons of CO2. In addition to the production of solar, battery, and hybrid inverters, Power Electronics also supplies its own control system for plants – with the battery controller interface (BCI) and power plant controller (PPC) as core elements.

A plant consists of many individual power blocks with solar and/or battery modules, each of which is monitored and controlled by a BCI that uses PC-based control. A power block contains an inverter for the solar modules and – if battery storage is also used – a DC/DC converter. The inverter converts the direct voltage of the solar modules into alternating voltage to supply either the grid or the batteries bidirectionally, depending on demand. The central PPC is responsible for the higher-level control and coordination of all power blocks in a plant according to the grid operator’s requirements.

Higher economic efficiency through dynamic control

With its decades of expertise, the company complies with the demanding energy supplier regulations which vary across the globe and, among other things, define how plants need to behave in order to ensure the stability of energy grids during certain events. “If a plant also meets even stricter requirements in terms of response times, it can provide what are known as support services,” says David Dobón, Applications Engineering Manager at Power Electronics, emphasizing the importance of high-performance control technology. The advantage for the operators is that they can sell the energy fed into the grid at a higher price point. “Initially, we were able to switch our systems from consuming 150 MW of power to delivering 180 MW in 130 ms, for example. Now we can do that in as little as 110 ms,” adds Agustin Cano, Team Leader Control Systems at Power Electronics. Extremely short switching times like these require a fast and sophisticated automation system, which Power Electronics implements using hardware and software from Beckhoff. It can thus control all three power block variants: solar, battery, and hybrid.

The challenge of hybrid power blocks

“The most sophisticated scenario arises when the inverter of a BCI manages both solar modules and batteries at the same time,” describes Hector Ortega, Team Leader Software at Power Electronics. These hybrid power blocks then function as small autonomous solar plants and must essentially manage themselves to maintain an energy balance.

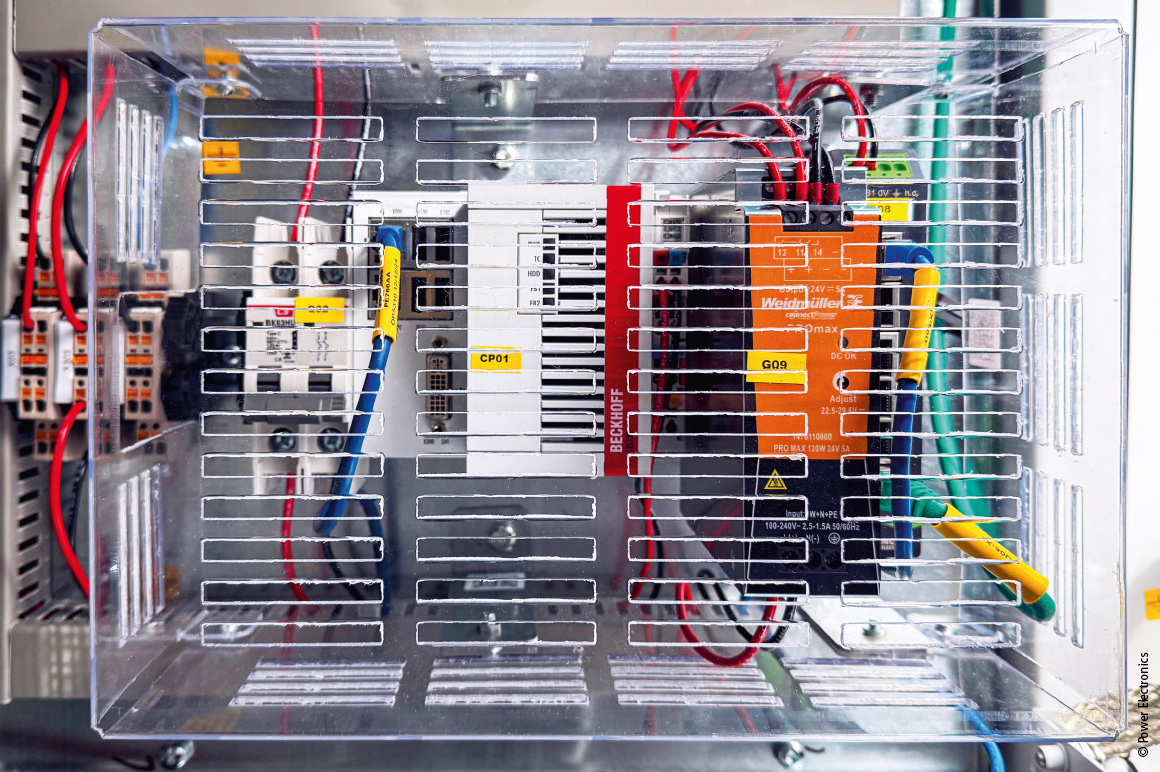

Power Electronics uses Beckhoff CX series Embedded PCs with TwinCAT 3 PLC (TC1200) to control the various battery controller interfaces. “Depending on the configuration of a power block, a CX5120 or CX5240 Embedded PC with an Intel Atom® processor is used, for example,” explains Javier Menchén, Technical Support at Beckhoff Spain. The BCIs communicate with the inverters, batteries, and other components via Modbus TCP and execute sophisticated control algorithms with very short cycle times.

TwinCAT 3 PLC HMI Web (TF1810) is also installed as a visualization system on the embedded PCs of the controls. This enables service personnel to access the parameters of the connected devices directly on site or remotely via a web interface.

Future functional enhancements and software optimizations are expected to require additional computing power. In this case, performance can easily be adjusted by switching to an CX5330 Embedded PC with two CPU cores. Miquel Coca, sales at Beckhoff Spain, comments: “Beckhoff regularly expands its portfolio of industrial PCs and embedded PCs with more powerful variants, while at the same time ensuring the long-term availability and easy scalability of its control computers.”

Battery storage as a dynamic control reserve

The PPC monitors and controls multiple BCIs and is responsible for coordinating all power blocks in a plant as a key element. Here, Power Electronics relies on a CX2033 Embedded PC with an AMD RyzenTM processor. “In one project, we have already coordinated 160 BCIs with the embedded PC and have not yet come close to its power reserve,” says David Dobón. The PPC records and processes the information from each BCI via the ADS communication protocol and provides them with the operating setpoints. “ADS is very fast, is flexible, and enables communication via the plant’s Ethernet network,” emphasizes Miquel Coca. Expansions are also planned for the PCC software, with a CX2043 Embedded PC featuring four CPU cores set to be used in future.

Openness facilitates system integration

“The use of a control PC with an open operating system enables the integration of .Net code, which is a major advantage for us,” says Hector Ortega, highlighting an important feature of PC-based Control from Beckhoff. Power Electronics was thus able to implement the DNP3 telecontrol protocol used by many energy suppliers for communication between the higher-level SCADA system and the substations. In addition, .Net is used to manage the databases and develop the visualization.

“The TwinCAT real-time task management, together with the powerful embedded PCs, is essential for ensuring the short response times of the solar plants and battery storage systems,” emphasizes Agustin Cano. What’s more, the diagnostic tools provided by TwinCAT are extremely helpful for monitoring the execution time of each task across all cores and cycles. The compatibility of the hardware and software was another criterion for choosing Beckhoff as a supplier. Cooperation between the teams at Power Electronics and Beckhoff in clarifying technical issues was quick, smooth, and efficient to boot.