Integrated and open control platform maximizes project development efficiency

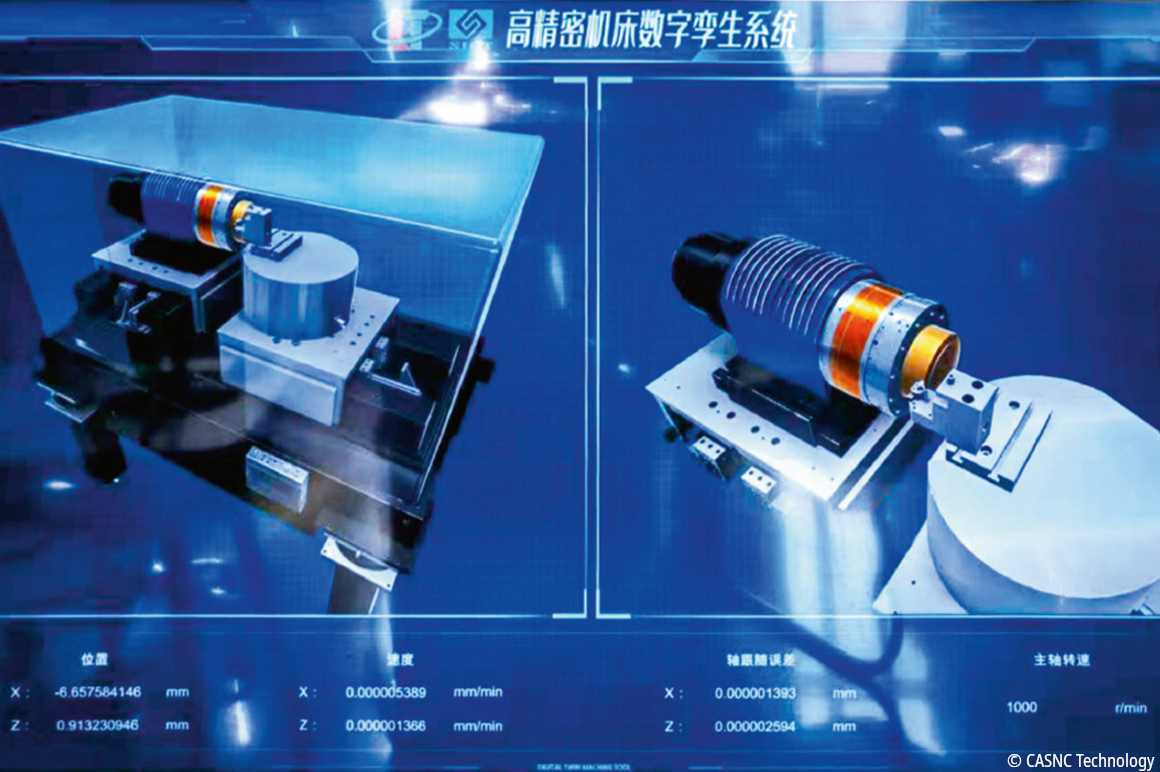

Shenyang CASNC Technology’s CNC solutions rely on the integration of sensors, data acquisition systems, and network communication technologies to monitor and analyze machine tool operating statuses, process sequences, and machine conditions in real time. By seamlessly integrating advanced information technology, the company is driving digitalization in this area. TwinCAT 3 automation software from Beckhoff serves as the cornerstone for the successful implementation of digitalization and virtualization strategies.

Machine tools are central pieces of equipment in the manufacturing sector, with a wide range of applications, such as in aerospace and automotive manufacturing, as well as in the energy sector. From the perspective of Shenyang CASNC Technology Co., Ltd. (CASNC Technology), the performance of machine tools is directly related to a country’s industrial competitiveness, which is why they are regarded as “pillars of the nation” in China. The Chinese high-tech company specializes in the development and manufacture of CNC systems, servo drives, robot controllers, automation equipment, digitalized manufacturing as well as mechanical and electrical products. The results are advanced machine tools such as 5-axis machining centers.

Digitalization and virtualization in TwinCAT

The Beckhoff TwinCAT software is used as an important cornerstone. Firstly, it enables the use of standard programming languages in accordance with IEC 61131-3, which is consistent with customers’ established debugging practices. What’s more, TwinCAT 3 also benefits the digitalization and virtualization of systems. MATLAB® and MapleSim offer user-friendly graphic design environments with which even sophisticated systems can be modeled using simple and intuitive operations, making them a universal option in areas such as model simulation. For the current project, these simulations can be executed seamlessly within TwinCAT using TwinCAT 3 Target for FMI in the XAE development environment and on the corresponding XAR models exported from MapleSim. Position commands interpolated by TwinCAT 3 NC I are fed into the model, while the model outputs the collected voltage and current data. TwinCAT 3 ADS is used to dynamically display the actual position of the machine tool movement in the interface. This not only facilitates hardware-in-the-loop (HIL) simulation, but also enables digital twins to be generated without the need for physical objects. This allows aspects such as the rationality of path planning and the efficiency of milling machine processing to be evaluated at an early stage.

From CASNC Technology’s perspective, the digitalization and virtualization of machine tools is primarily based on an open software platform. In this context, TwinCAT offers inherent advantages due to its integration in Visual Studio, the robust compilation environment, and its own real-time operating kernel. In the project development and design phase, the ECAD tools can be integrated via TwinCAT 3 XCAD Interface in order to import the data directly into the TwinCAT PLC with ease. This reduces errors between hardware and software and increases programming efficiency. TwinCAT 3 PLC Static Analysis can be used to analyze the source code to minimize ambiguities and optimize its usability. TwinCAT 3 PLC Profiler enables the runtime behavior of PLC projects to be analyzed in order to identify time-intensive calls and program segments for subsequent code optimizations. In addition, TwinCAT 3 Realtime Monitor ensures precise diagnostics and optimization of the temporal behavior of the controller. The tool analyzes the execution sequence and priority of the code during the operation of multi-core or multitasking programs. TwinCAT 3 Scope View can also be used to collect data with precise timestamps to form XY, YT, or even XYZ diagrams in TwinCAT 3 Vision, which, among other things, enriches debugging methods and enables event-driven recordings.

With TwinCAT 3 EtherCAT Simulation, virtual debugging is achieved without the need for real hardware. This not only supports basic PDOs, but also offers corresponding functions for CoE, SoE, AoE, and even distributed clocks. Errors can also be simulated in order to test the corresponding mechanisms and codes. TwinCAT 3 Interface for Inventor® provides an interactive connection between TwinCAT and 3D CAD systems for simple 3D simulation of models. TwinCAT 3 Target for Simulink®, for MATLAB®, for Embedded Coder®, and for MATLAB® and Simulink® enable model-in-the-loop (MIL), HIL, and software-in-the-loop (SIL) simulations.

In this cooperation project, CASNC Technology used TwinCAT 3 Target for FMI to export the machine tool axis models generated by the MapSim software to TwinCAT 3 for execution in real time. The models record the initial positions from the Beckhoff interpolation algorithm, which converts the position signals internally into current and voltage signals. By simulating the inertia and other factors of the actual hardware load, the algorithm recalculates the actual speed and position that the axis can achieve. This position is then sent to another host software for simulation and display of the actual motor position. Fast communication is facilitated by ADS and the correspondingly low latency in the millisecond range. According to CASNC Technology, this approach allows MIL and HIL simulations to be realized in an optimum manner and used as an implementation basis for digital twins via third-party tools. In addition, vibration sensors are included in new projects in order to carry out predictive maintenance and life cycle management using the sensor data and algorithms developed in-house.

Powerful and EtherCAT-based hardware

CASNC Technology not only relies on the integration and openness of PC-based control for the digitalization and virtualization of its machine tools: The powerful, flexible Beckhoff hardware, which benefits from the IT environment, is also used to implement new technologies and functions in machine tool applications. The diverse, sophisticated path planning in this area places high demands on the computing power of the controllers. In addition, further performance is required for digital simulation, virtual operations, and extensive data acquisition as a basis for data analysis, predictive maintenance, and life cycle tracking of machine tools.

For the control core, CASNC Technology has opted for the C6030 ultra-compact Industrial PC, which is equipped with an Intel® Core™ i5 processor. TwinCAT allows its high multi-core computing power to be fully utilized. Based on CASNC Technology’s experience, this leads to faster processing times for the controller and shorter control cycles for the servo axes, which has further increased control accuracy. In combination with the EtherCAT XFC terminals from Beckhoff, precise control can be achieved through multi-timestamps independent of the task cycle.

The EtherCAT master interface of the C6030 provides a simple connection to the dynamic and cost-effective EtherCAT servo drives. EtherCAT also offers topology freedom: Linear networks can be set up with EtherCAT Couplers such as EK1100 and EK1110 and star topologies using EtherCAT junctions such as EK1122. In connection with the EL3351 analog EtherCAT input terminal, a flexible static and dynamic weighing function and strain measurement can be implemented. With the EL3632 analog input terminal, IEPE vibration sensors can be connected directly, and a current source of 2 to 8 mA can be integrated without the need for an additional converter. The data obtained can be evaluated in TwinCAT 3 with the vibration analysis library for frequency range, time range, envelope diagrams, etc. or – owing to the system openness – also via customer-specific algorithms or standard analysis libraries from third-party providers. Analog temperature measurement terminals such as EL3204 and EL3314 can directly access information on resistance and thermoelectric voltages and convert this into precise temperature information using integrated characteristic curves, which also supports the predictive maintenance of machine tools, according to CASNC Technology.

Further advantages for CASNC Technology are the extensive range of EtherCAT hardware and the powerful, simple, and flexible EtherCAT fault diagnosis and localization. Added to this is the openness of the PC- and Windows-based Beckhoff control technology, which enables seamless interaction with higher-level planning systems. By using sockets, web servers, FTP, SMTP, etc. to integrate numerous IT concepts into the automation technology, the systems are also freely expandable and easy to develop further.

Dynamic and precise servo drive technology

Machine tools place high demands on the accuracy and speed of axis movements in particular. The position, speed, and current control loops of the AX5000 servo drive from Beckhoff can achieve a cycle time of 62.5 ms. According to CASNC Technology, this is sufficient to meet the requirements of the control algorithms. Regardless of whether it is a 1-channel or 2-channel version of the drive, each channel is equipped with up to two feedback signals. By selecting the AX5805 TwinSAFE drive option card, various safe stopping methods can be implemented, such as SLS, SSR, and STO. For application scenarios with higher synchronization requirements for stops, this can be implemented in connection with the gantry function of the AX5000.

Both internal and external brakes are supported for vertical axes; corresponding parameter settings for counterbalance systems are provided. A PID parameter autotuning function can also be used. TwinCAT 3 Bode Plot is suitable for analyzing the overall system and can be used to identify resonance points and apply suitable filters by means of slight, controllable oscillations. This approach enables the stability of the system to be improved, the rigidity to be increased, subsequent faults to be reduced, and the service life to be extended.

The AX8000 multi-axis servo system, which mainly consists of a power supply module and several axis modules – or alternatively a combined power supply and axis module – is also suitable for controlling the Beckhoff AM8000 servomotors. There is also a capacitor module to support the DC link and the AX8820 universal regenerative unit for feeding regenerative energy back into the supply grid. AX8000 not only makes it easier to save energy, but also increases the efficiency of servo axis movements, decreases overall power consumption, lowers the cost of braking resistors, reduces the temperature rise in the control cabinet, and minimizes its magnitude.

The trend toward control cabinet-free automation can also be implemented with PC-based control from Beckhoff: firstly, with the MX-System as a pluggable system solution to completely replace control cabinets and, secondly, with the AMP8000 distributed servo drive system consisting of distributed servo drives as well as supply, distribution, and coupling modules. The latter can replace the servo drive technology in the control cabinet, saving a significant amount of space.