PC- and EtherCAT-based control technology powers a multi-station press line for the automotive industry

The Chinese system integrator Aotto uses PC-based control from Beckhoff to enable individual presses and punches in a production line to work together in a coordinated manner. The entire product range, including AM8000 servomotors, is networked via EtherCAT. An Industrial PC acts as the motion controller and central control system. It ensures fail-safe operation, an optimized production process and maximum plant throughput.

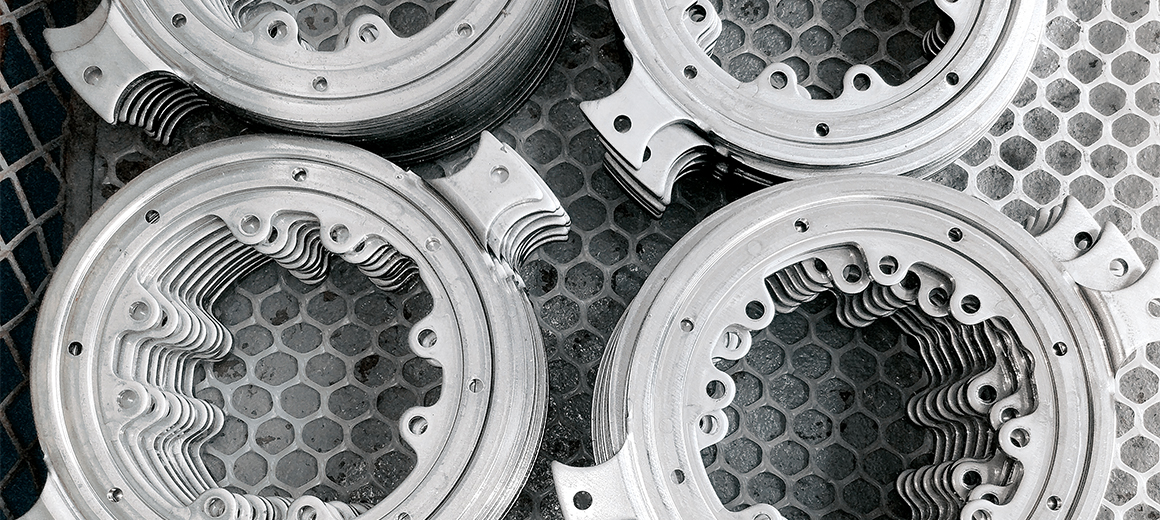

Sophisticated feeding technology is key to maximizing production throughput in a press automation system. The company Aotto Automation Co. Ltd., based in the Jinan Economic Development Zone in China, is well aware of this and therefore intended to upgrade its existing multi-station press line with new, flexible, automated punching technology. At the core of the plant is the automated feeding system of the multi-station press, which consists of a punch press, a three-coordinate feeding system, an optical component identification system and intelligent sequential control.

Optimizing process cycles, increasing efficiency

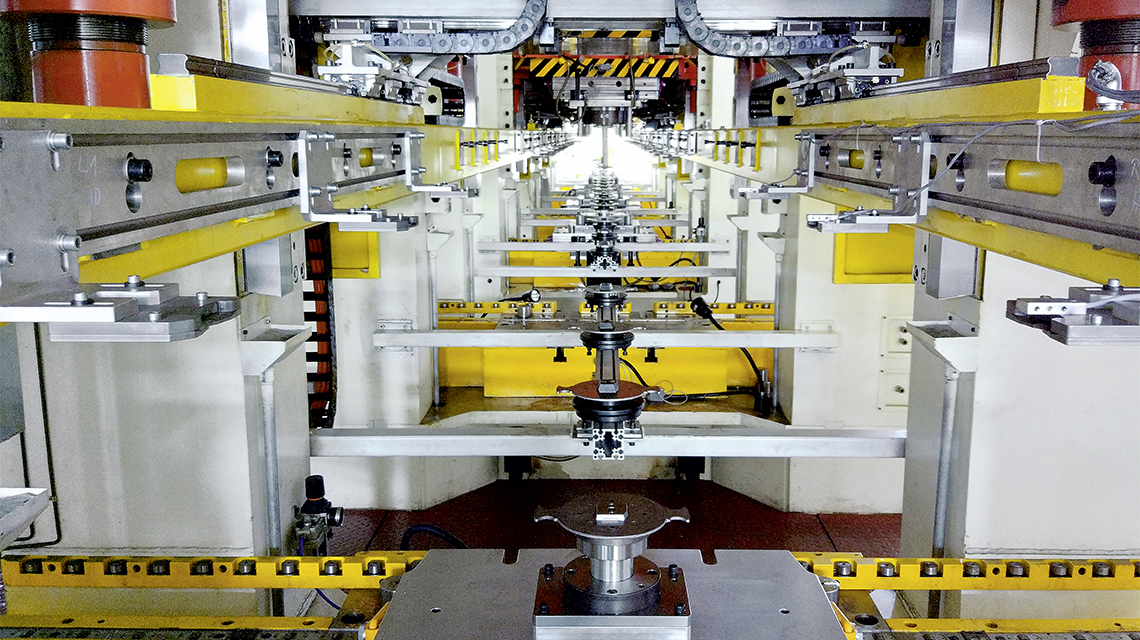

Punching takes place in several steps, at four or five stations. The automatic multi-station feeding system is adapted to the production cycle of the presses and improves the overall efficiency. Aotto relies on components from Beckhoff for its control system to optimize the complete line and its process cycles, while minimizing downtime. The feed system of the press stations relies on a C6930 control cabinet Industrial PC (IPC) as the motion controller. On the software side, PLC functionality, multi-axis NC PTP motion sequences and cam plates are implemented with TwinCAT 3. The result is a flexible and easily upgradeable motion control system with an intuitive operator interface via a built-in CP2916 multi-touch Control Panel. The impressive performance of the C6930 as a control computer for the entire production line is reflected in the wide range of tasks it handles:

- synchronized control of the AM8000 servomotors during material feed between the individual stations,

- cam plate control between feeder and press,

- monitoring of the entire production line, and

- communication with the HMI.

EtherCAT simplifies network design

Data communication within the production line takes place via EtherCAT. EtherCAT Terminals, IP67-rated EtherCAT Box modules and TwinSAFE terminals are used for this purpose. The free choice of topology and combinability of lines, branches and drop lines is particularly advantageous in this context. The required interfaces are already integrated in the corresponding EtherCAT Couplers, i.e. no additional switches are required. The central C6930 IPC communicates directly via EtherCAT with the respective local controllers at the individual press stations.

To save installation costs, the IP67-rated I/O modules of the EP series secure to a mounting rail on a station’s machine bed. The installation of the control components directly at each station also makes it easier for the operator to maintain the hardware and software. Furthermore, the control software of the entire system is integrated into a control computer, so the production management system can optimize the production efficiency.

Efficient drive technology with One Cable Technology

The automatic multi-station feeding line is the most widely used part feeding system for production lines in the automotive industry. It is based on the three-coordinate format of the X-Y-Z axes and is characterized by fast, highly efficient production cycles. Two gripper arms pick up and transport the workpieces in synchronized cycles from one station to the next. The AX5000 Servo Drives and AM8000 servomotors used for this purpose perform the clamping processes synchronously and feed the dual grippers simultaneously. Not only do both grippers move synchronously during the normal production process, but they also remain synchronized in the event of a sudden power failure until the system is restarted. This prevents the material from being deformed by asynchronous movement of the two arms. With drive technology from Beckhoff, Aotto also benefits from One Cable Technology (OCT), which combines power and feedback in a standard motor cable. This significantly reduces material and commissioning costs and reduces the risk of miswiring.