Products

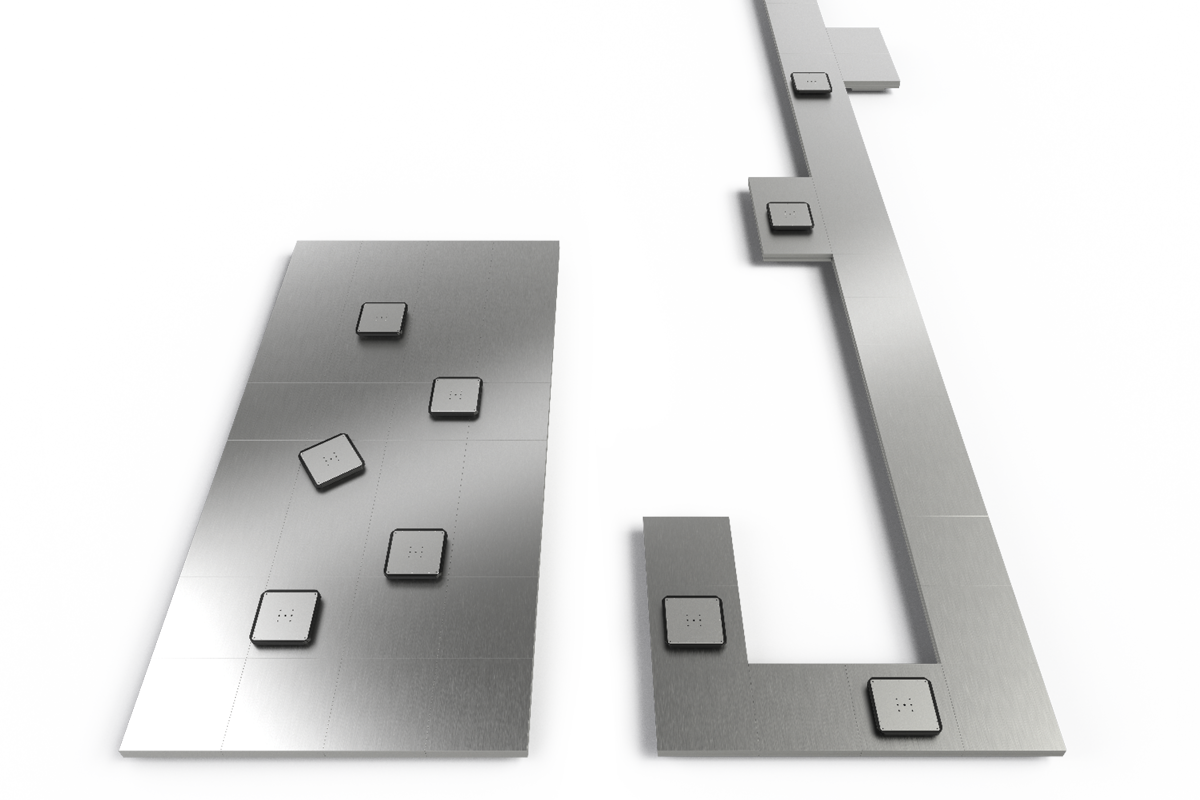

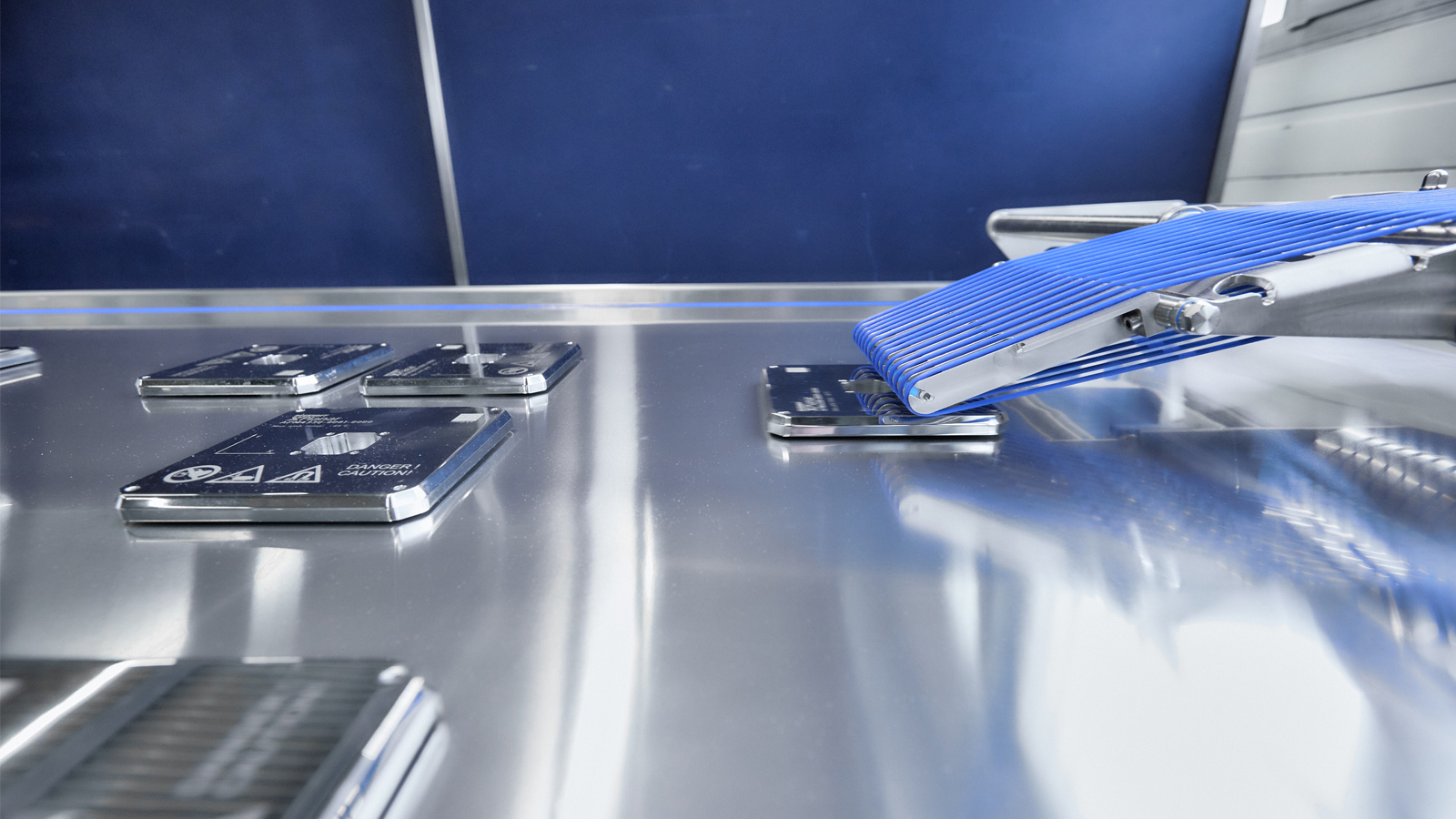

APSxxxx | XPlanar tiles

Highly compact and fully integrated drive units that allow any product to be lifted.

APMxxxx | XPlanar mover

Floating, freely movable, powerful – the ideal performer for any application.

XPlanar software

The orchestrator for modern product handling. Simple operation, maximum freedom, constant expansion.

First steps with XPlanar

The quick entry into the product handling of the future. Plug-and-play for tomorrow's machine concepts.

Floating 2D product transport with up to six degrees of freedom

The intelligent XPlanar transport system combines the advantages of conventional systems and supplements them with a unique magnetic levitation technology. With its floating 2D product transport, the planar motor system opens up a whole host of new possibilities.

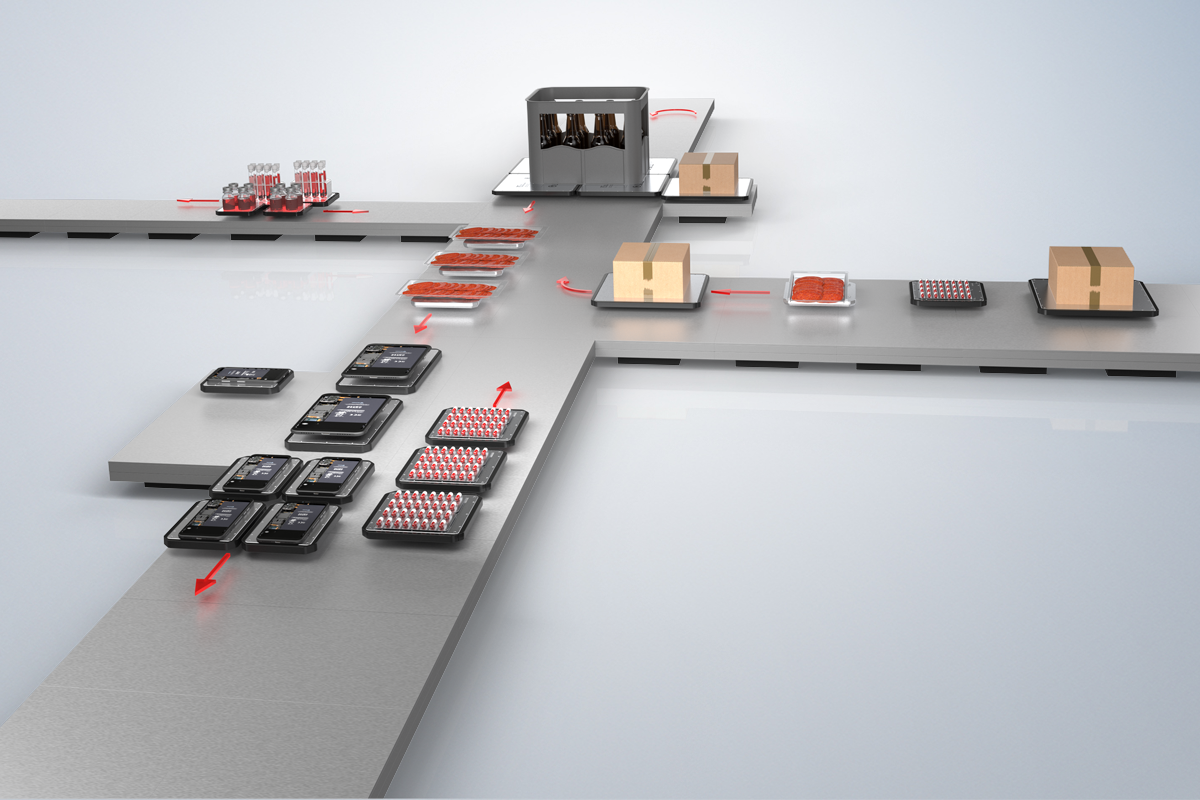

Users benefit from the individual freedom of movement afforded by driverless transport systems, with the ability to transport individual goods to any location via any route, either within a single machine or between several. In addition to this flexibility, XPlanar offers all the dynamics of a linear motor to facilitate cycle-time-optimized linking of individual production steps. XPlanar also simplifies individual production steps considerably, making the degrees of freedom and positioning accuracies familiar from robotics available for 6D product processing. For the first time ever, the transport system itself handles the positioning of a product during processing. The levitation effect replaces any and all mechanical guiding components. Cleaning and maintenance requirements are drastically reduced.

The XPlanar system

The XPlanar is a planar motor, which – like rotary motors – consists of multiple stationary, energized coils (in the tiles) and mobile permanent magnets (in the movers). In contrast to rotary motors, however, both the coils and the permanent magnets are arranged two-dimensionally on a plane. The XPlanar tiles are the electrically active part of the system, with the current in their coils causing the movers to float above them.

The movers are electrically passive and particularly hard-wearing. The unique floating effect means any pollutants or contaminants from the goods being transported are not spread throughout the system, there are no emissions, and there is no wear caused by friction. The XPlanar system is a highly recommended new drive concept for all types of product transport in the manufacturing and processing industries. Beyond its basic transportation function, it can also perform even the most demanding positioning tasks with micrometer precision.

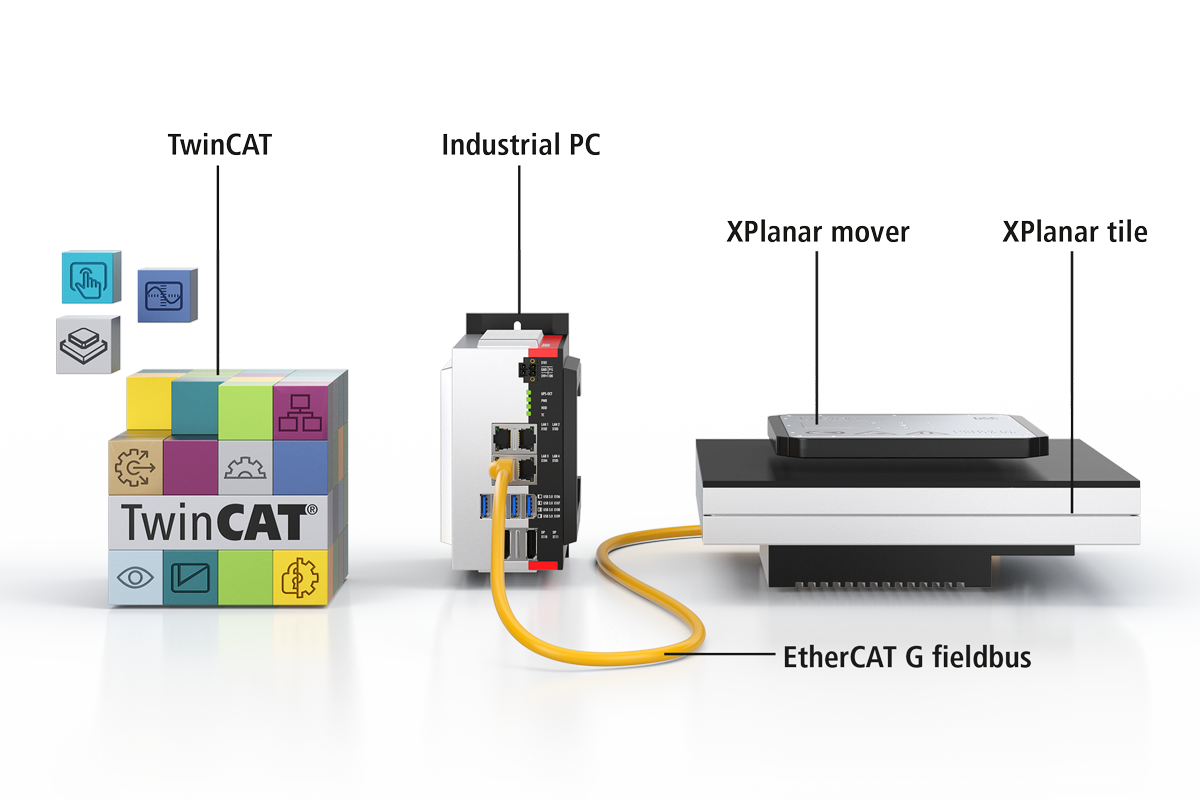

The impressive XPlanar system offers a compact system architecture, with only tiles, movers, a Beckhoff Industrial PC with TwinCAT, and cables for the power supply and EtherCAT G required for operation. The industrial PC is connected with the first XPlanar tile via EtherCAT G. From that point on, the communication continues from tile to tile via EtherCAT G. Cross-communication between individual XPlanar tiles is not necessary,

and additional infrastructure components such as external power supplies or dedicated control hardware are completely eliminated. In accordance with Beckhoff’s PC-based control philosophy, the system is accessed via a central industrial PC. This makes it easy to coordinate the XPlanar system with other plant components, run diagnostics, and optimize the machine. New system functionalities can be easily integrated into existing plants by updating the central control system software.

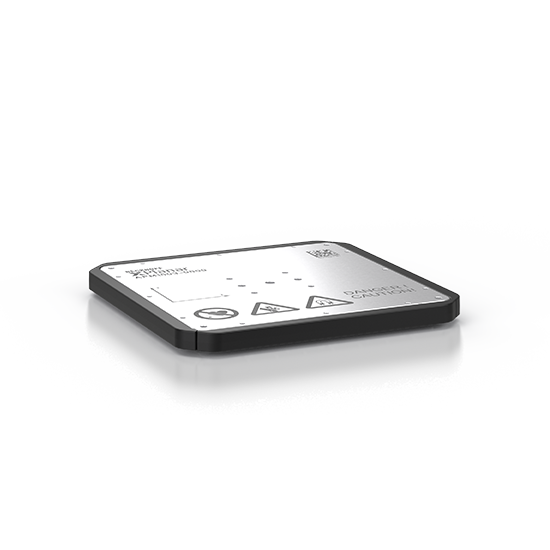

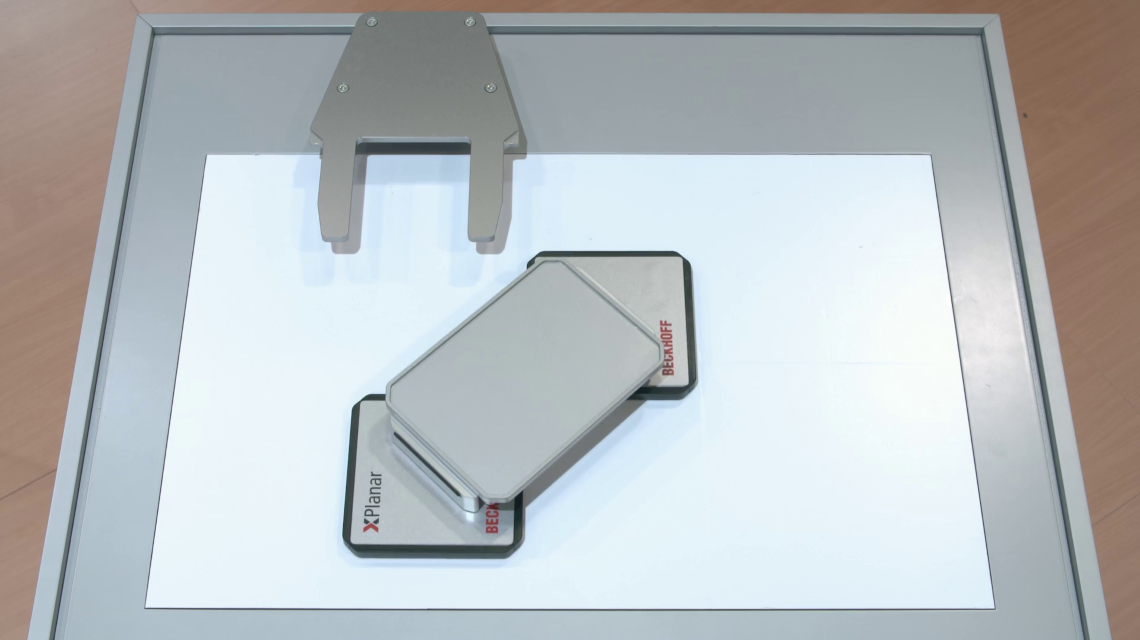

The XPlanar mover is the magnetically floating, freely movable, and wireless component of the XPlanar system. The special arrangement of the integrated permanent magnets enables the fascinating levitation effect and the free movement of loads by means of the movers. The XPlanar mover is passive and has no moving parts or connections. Its smooth surface with no sharp edges makes it easy to clean. Workpiece carriers can be fastened and aligned on the mover via threaded and preformed holes.

Various square and rectangular movers with payloads of up to 4.2 kg are available for different product sizes and weights. Three different tile sizes can be selected depending on the width of the required movers and the requirements of the respective production process – i.e., 1-way operation or 2-way operation. The right tile-mover combination guarantees the most efficient use of space, as the space required for a system can be reduced by up to half. The movers can even be mechanically linked or operated as a group to accommodate payloads above 4.2 kg. In this case, the payload capacity of the entire group is the total of the individual movers’ payload capacities.

Optional mover IDs make it possible to track products and start the system without reference travel. This way, each mover can be clearly and globally identified at any time, irrespective of its position.

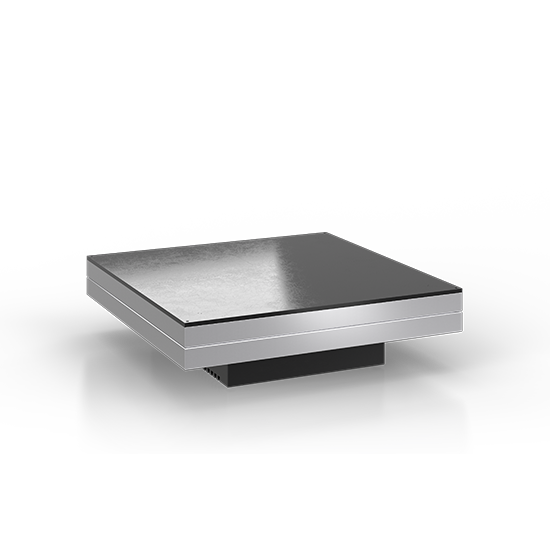

The XPlanar tile is the fully integrated drive unit of the XPlanar system, which converts the supplied energy into precisely regulated electromagnetic fields. These fields not only make the XPlanar movers float, but also guide them across the XPlanar tiles along freely selectable waypoints. All the components that are needed to generate and regulate the magnetic fields are integrated in each XPlanar tile. This includes the coil groups and their associated power electronics, as well as the position detection, power supply, and EtherCAT G communication. This level of integration makes for a compact and highly functional design that reduces the installation effort and the total system footprint.

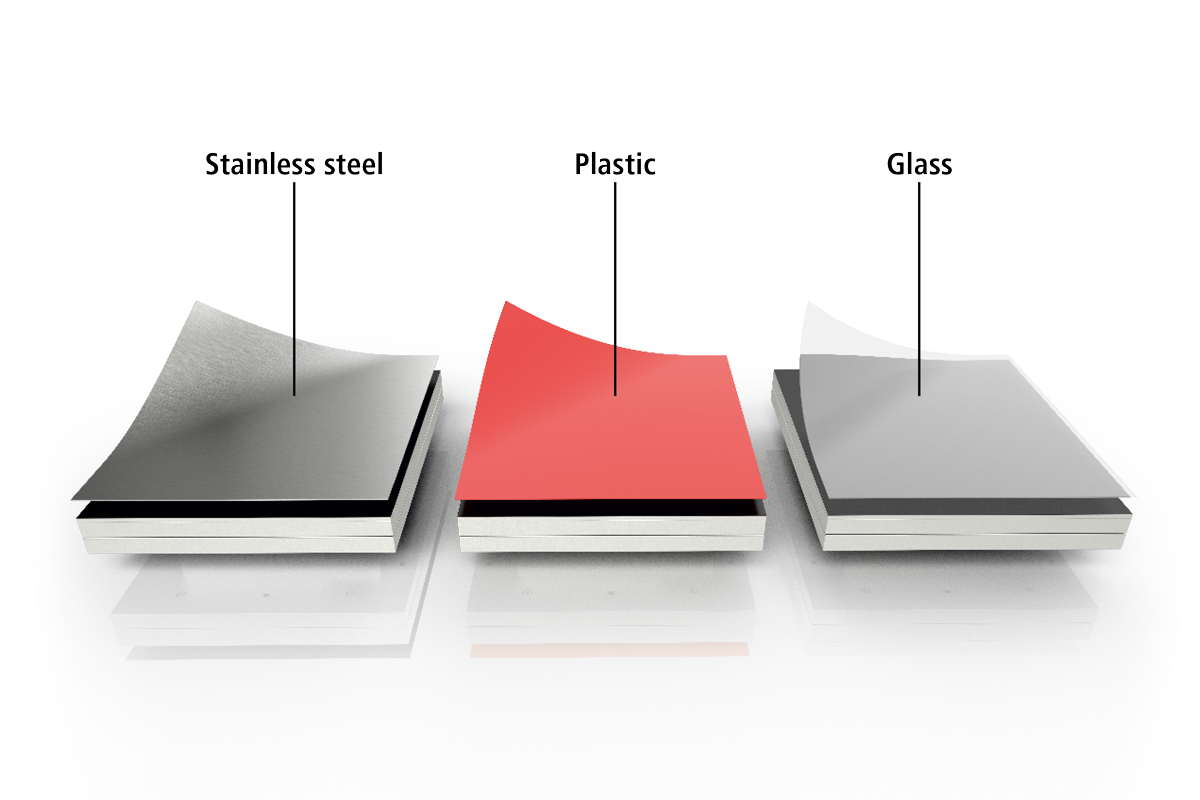

XPlanar tiles can also be adapted to various environmental requirements. Plastic films, glass panes, and even non-magnetic stainless steels can all be applied to the tile surface. This protects the tile from liquids, cleaning agents, and mechanical impact, making the XPlanar system ideal for use in demanding hygienic environments.

Tiles of different sizes are available for the space-optimized system design. The appropriate tile can be determined using the following parameters:

- operating mode (1-way vs. 2-way)

- mover type (determined based on the size and weight of the product)

For example, the 240 mm x 240 mm APS4322 tile is ideal for

- 1-way operation of products up to 4,200 g

- 2-way operation of products weighing between 400 and 1,000 g with a width of up to 120 mm

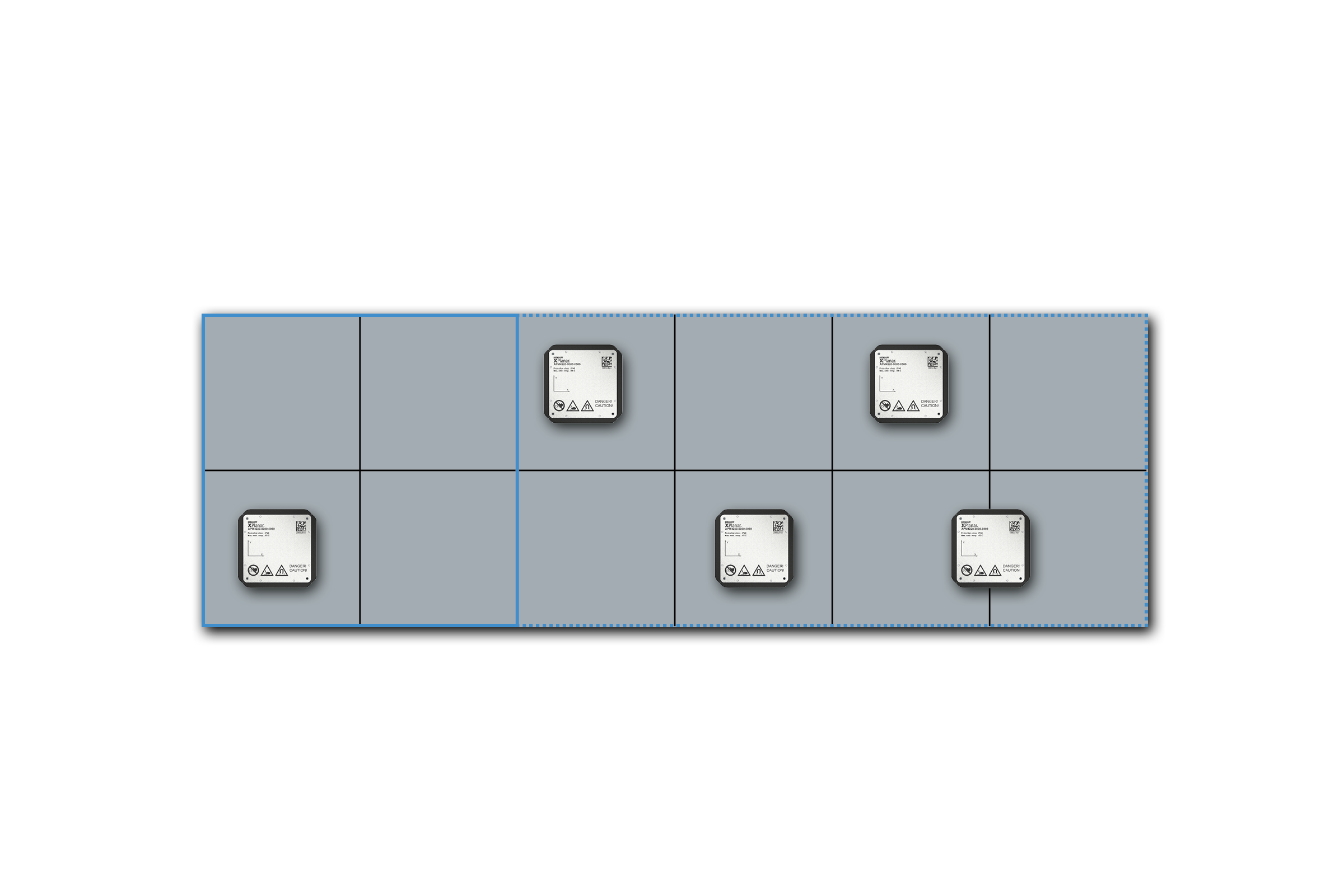

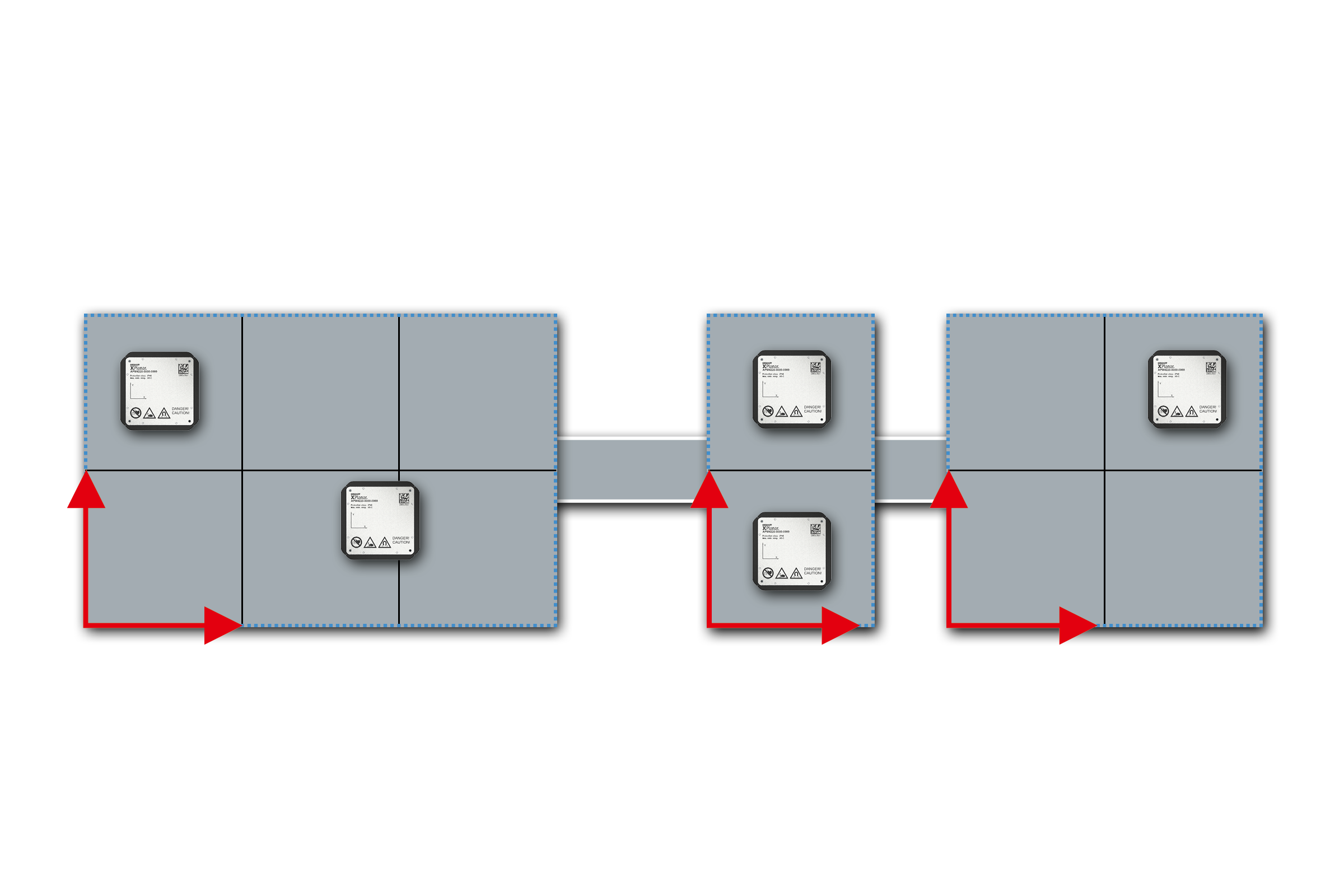

The arrangement of the XPlanar tiles is freely configurable in line with the needs of the respective application. Square, rectangular, L-shaped, and even annular systems can be achieved with ease. Depending on the size of the movers, it is even possible to build a bidirectional linear product transport path that is one or two tiles wide. Tiles are also available for 1-way operation. To adapt the XPlanar system to new requirements, individual tiles and/or movers can be added after the initial installation.

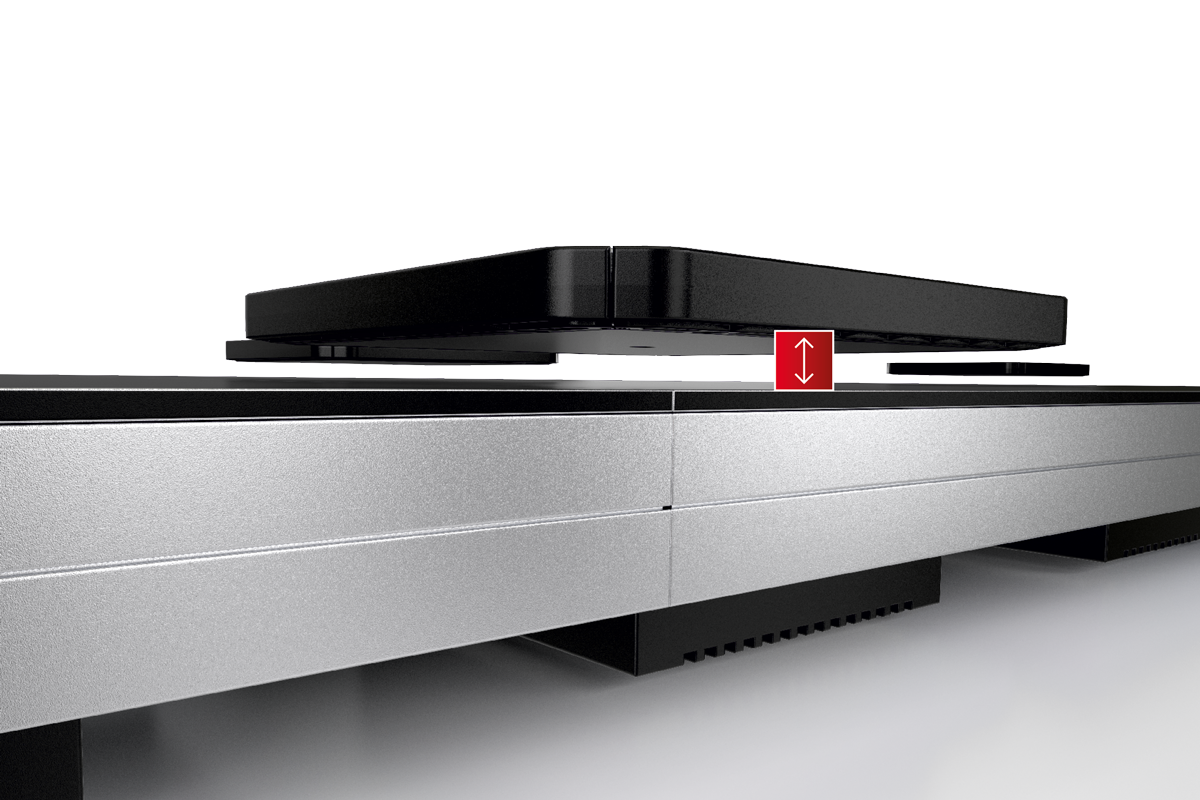

For special applications, XPlanar tiles can be moved horizontally or vertically out of the tile network with additional actuators. This ability to freely arrange and add tiles offers the highest degree of investment protection and flexibility for designing a bespoke XPlanar system. At the same time, the system’s space requirements are minimized by optimizing the ratio of tiles and movers.

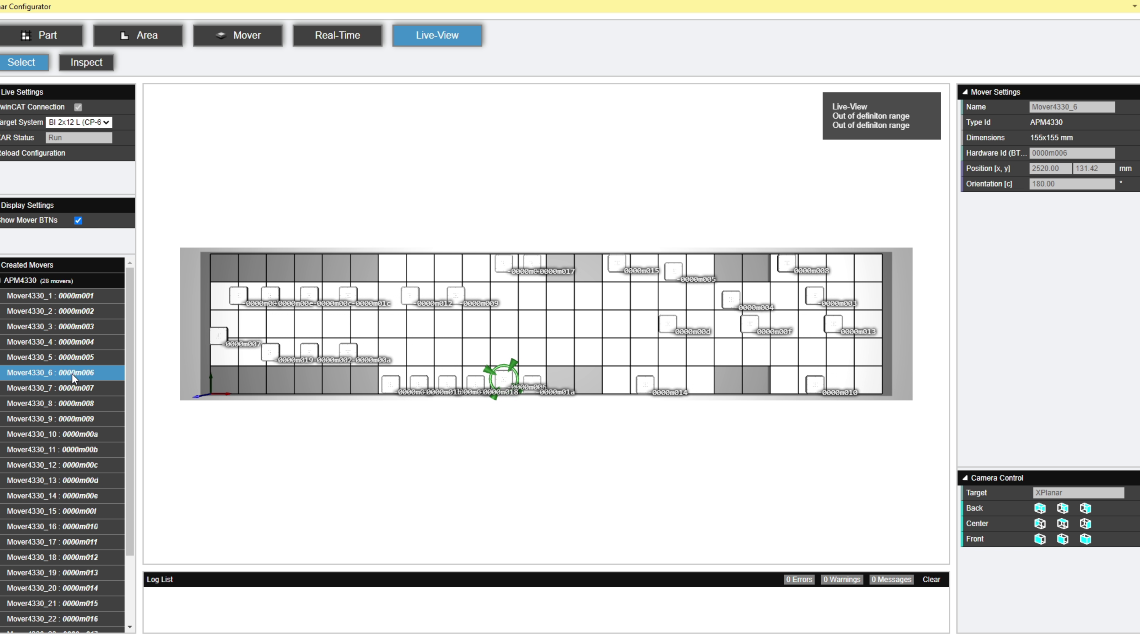

The TF5890 software, which is fully integrated into TwinCAT, controls all functionalities of the XPlanar system from a central Beckhoff Industrial PC. Its graphical system configuration, real-time system view, intelligent track planning, and precise position control all interact seamlessly with each other. The track management system handles the position setpoints of the movers, with users defining 2D tracks that the movers follow intelligently while automatically avoiding collisions. Switch functions allow the movers to switch from one track to another. Even complex, overlaid 6D movements based on CNC with GCode or CAM can be achieved, not to mention free 2D travel.

As the software is so deeply integrated into TwinCAT, all familiar possibilities of the PC-based control technology from Beckhoff are available in parallel with the XPlanar control (TwinCAT, PLC IEC 61131, motion, measurement, machine learning, vision, communication, and HMI).

XPlanar combines highly dynamic 2D product transport and precise 6D product processing in a single system. The XPlanar movers travel at up to 3 m/s and can be positioned with repeatable accuracy of ≤5 μm. And since the movers travel completely independently, each product can take its own individual path through the system. Different products can thus be manufactured side-by-side in a single machine, which is ideal for economical mass production with a lot size of one. In addition to 2D travel, commands for tilting, leaning, and lifting can also be overlaid for 6D positioning. This creates innovative possibilities for significantly streamlined processing stations. In suitable applications, XPlanar can replace XY gantries or robotics, thus reducing a machine’s mechanical complexity considerably. What’s more, the unique 360-degree rotational capability opens up further degrees of freedom for product inspection, alignment, or centrifugation.

| Positioning accuracy | ||||

|---|---|---|---|---|

| Position resolution |

1 μm (x, y, z) 0.001° (a, b, c) |

|||

|

Typical repeat accuracy (APS42xx) |

≤ ±5 µm (x, y, z) ≤ ±0.03° (a, b, c) |

|||

Comments:

- accuracies within one tile

- average tile temperature: 40°C

- average ambient temperature: 24°C

- constant mover temperature

Advantages at a glance

The unique levitation effect ensures wear-free and noiseless product movement in up to six degrees of freedom – including 360° rotation. Traveling at up to 2 m/s, products are transported on different movers simultaneously over arbitrarily designed tracks. If the load capacity of a single mover is not sufficient, several movers act in combination and position goods in the µm range.

Beyond these basic benefits, the XPlanar system is constantly being improved by a team of more than 30 Beckhoff developers. Engineers and scientists design new movers, devise additional tools for mover command, measure system characteristics, and support customers with specific applications. As a result, the possibilities and limits of the system are constantly expanding.

Highlights

The XPlanar system uses tiles of different sizes to optimize the space requirements of the overall system. Users start by selecting the right mover, whether square or rectangular, based on the size and weight of the product to be transported. The most appropriate XPlanar tile can then be selected depending on the chosen mover type.

This means that movers measuring 115 mm or 127 mm wide (APM42xx) can be optimally used for 2-way operation on an APS4322 tile (240 mm x 240 mm). Using the same tile, 1-way operation of the largest XPlanar mover (APM4550) with a width of 235 mm can be achieved in a way that optimizes space. And for movers measuring 155 mm wide, the APS4224 tile (160 mm x 320 mm) is available. The same type of mover can run on the XPlanar APS4244 tile (320 mm x 320 mm) in 2-way operation.

Depending on the application, selecting the right combination of tile and mover can enable significant space savings of up to 50%. This supports optimum utilization of the available hall space.

The XPlanar system fully unlocks another degree of freedom through 360° rotation around the Z-axis of the movers. At defined rotation positions, the orientation of the mover can be changed in 90° steps. The movement can be continued along the new orientation, and endless rotation at a speed of up to 600 revolutions per minute can be achieved.

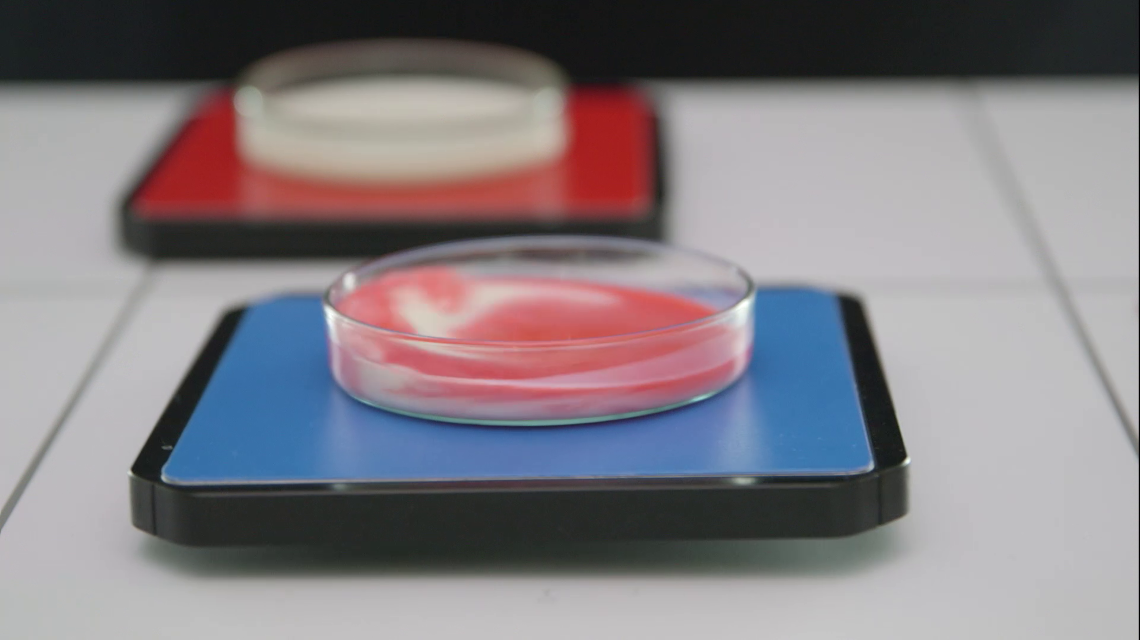

This functionality is ideal for a whole host of applications, ranging from the alignment of individual products and mixing of liquids through to the fastening of containers. No supplementary hardware is necessary. The rotation is available with the APS4xxx-0000-0000 XPlanar tiles in combination with the current version of the TF5890 XPlanar software.

Beyond the rotation positions, rotation around the Z-axis of the movers by ±10° is still possible – even during movement.

Unique identification of the XPlanar movers is made possible by the optional ID bumpers. The ID bumpers can be retrofitted at any time, with no further hardware required to identify the movers. The serial number of the respective mover is permanently stored on the ID bumper. As soon as the system starts up, the magnetic fields of all movers are detected, and the serial numbers of the movers equipped with an ID bumper are then transferred. This is how the detected mover position is linked to the communicated serial number. This gives the system all the information it needs to start operation – with appropriate application programming and without any reference travel at all. The mover ID can be read out at any position. During operation of the plant, the position of a product can be tracked at any time for quality assurance purposes. If different movers with different tools are used within a system, exciting advantages can arise during handling, as well as in the distribution of tasks.

If the 4.2 kg payload of the APM4550 is not sufficient for an application, several XPlanar movers of the same type can be coupled together via a rigid mechanical adapter. The total payload increases on a linear basis with the number of coupled movers if the appropriate distances are maintained. As a result, even transport weights above 20 kg can be moved via this floating action. In the application programming, the coupled movers appear as a single, geometrically enlarged mover. No special programming is required.

Beyond the increase in payload, the flexibility of the XPlanar system can be increased with dynamic mover coupling. The dynamic coupling of several XPlanar movers can be achieved in a number of ways, including via mobile-mounted connecting elements or clamped products. Depending on the configuration, workpieces can be rotated around their own axis during the transport movement. In addition, a quick format change can be achieved by changing the distance between two movers.

Even in the design phase of a plant, the simulation tools integrated into the TF5890 XPlanar software open up exciting possibilities. Any number of XPlanar systems can be configured and operated virtually, without the need for hardware, and users can fundamentally work out and optimize the entire machine sequence. Track networks, waiting times in individual workstations, and dynamic parameters for mover movements can all be specified for the simulation. This allows a suitable number of XPlanar movers to be determined for a specific task, advantageous tiling arrangements to be selected, and much more besides. Further components integrated into TwinCAT, such as TwinCAT HMI and TwinCAT PLC HMI, can be used to visualize the simulation results.

The application code created for the simulation can be extended in further project phases and ultimately used to operate the finished plant. There is no duplication of effort, and programming, simulation, plant design, and plant construction can all run in parallel to significantly reduce the time required for the overall project.

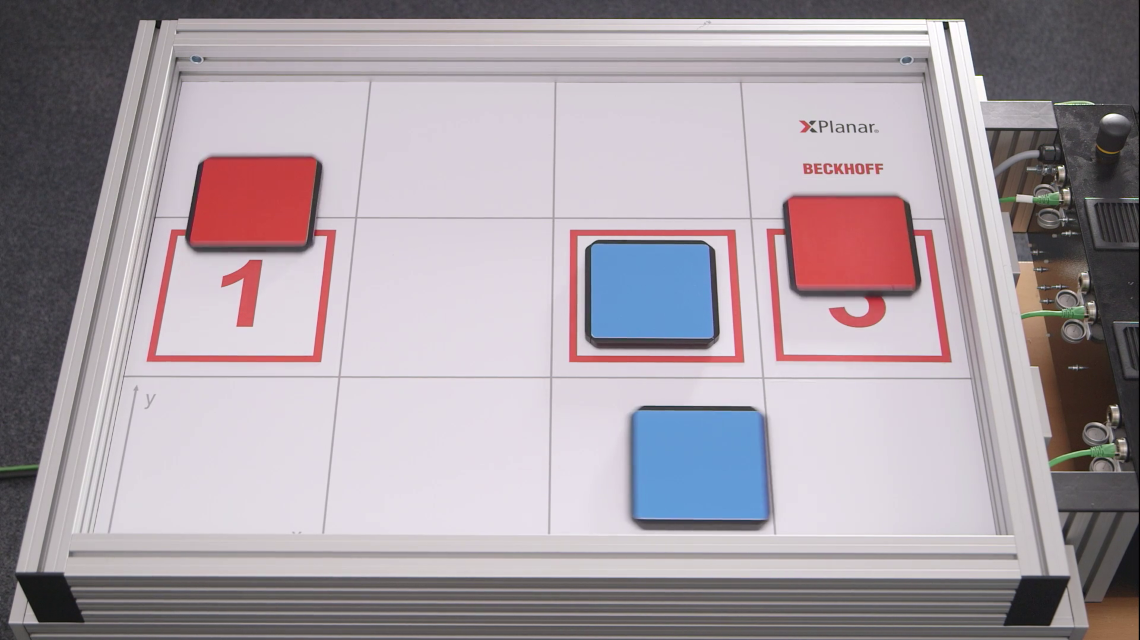

Additional flexibility in plant design is afforded by XPlanar part handling. The tile surface is first divided into individual parts. These parts consist of at least one XPlanar tile and are logically independent of each other. In this way, one part of the plant can be completely switched off electrically while the other parts of the plant are operated (Figure 1). This allows for the simple integration of manual workstations for manual rework on the product, and the exchange of individual workpiece carriers on movers.

It also allows the individual parts to be combined dynamically during the runtime of the XPlanar system. The second figure shows two permanently installed XPlanar parts on the right and left. A mobile XPlanar part is located on a linear unit between the permanently installed parts. Depending on the position of the linear unit, the mobile part is operated in isolation or in combination with the left or right XPlanar part. The parts also have logical limits that intercept unauthorized movement commands depending on the situation. The combination of XPlanar with linear units enables the linking of subsystems that are spatially separated by an airlock and much more besides.

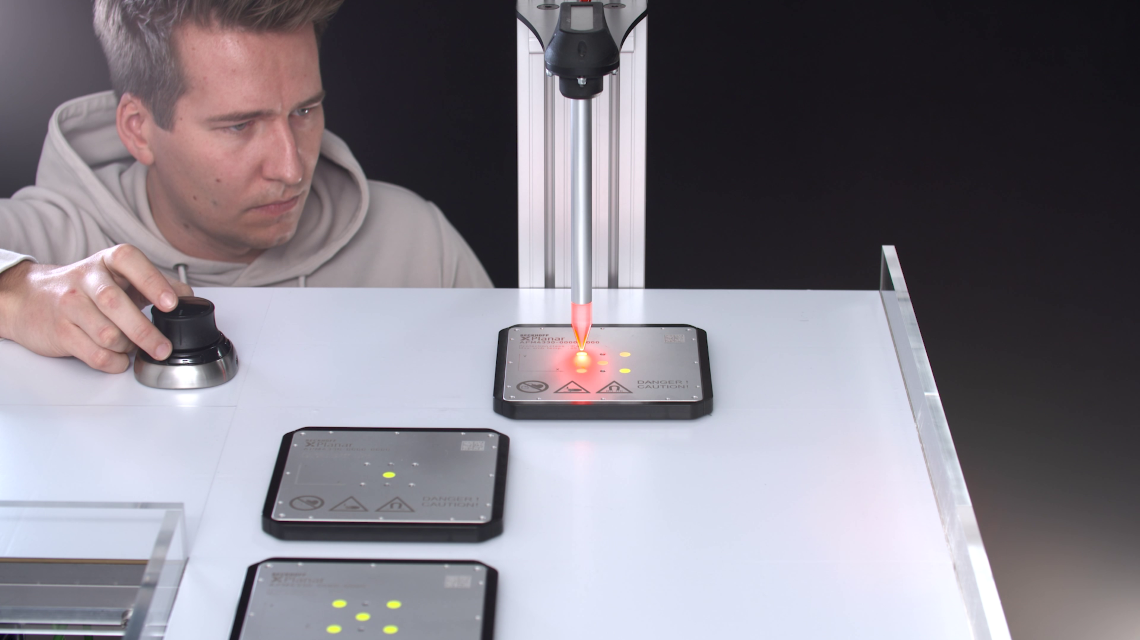

The XPlanar movers have six axes: x, y, z and the rotation axes a, b, c. The mover position for each of these six axes can be specified cyclically. Track management is the ideal solution for classic transport tasks. For complex and interpolated movements beyond basic transport, the XPlanar software features an interface for external setpoint specification. This allows the XPlanar mover to benefit from a connection to all known motion functions of the TwinCAT world and follow the setpoint specifications from TwinCAT CNC, NC, and NC Camming in all six axes. For example, the x, y, a, and b axes can be coupled by means of a cam plate to allow the mixing of fluids from within the mover movement. Additional mechanisms in the form of stirring units are replaced by software in this case, and information from control elements can be read in via TwinCAT using corresponding interpreters. Position specifications from joysticks or controllers can be assigned to the axes of an XPlanar mover. This ensures that the movers can also be controlled manually for tasks such as teaching processes and other applications.

XPlanar in practical application

Here are a few application examples that demonstrate the XPlanar system's potential. Each example shows how XPlanar technology can be used to optimize processes, increase throughput and set new standards in manufacturing flexibility across different industries and applications. From individual product guidance in assembly to precise positioning in quality control, these application examples provide inspiration and show how the XPlanar system can revolutionize your production processes.

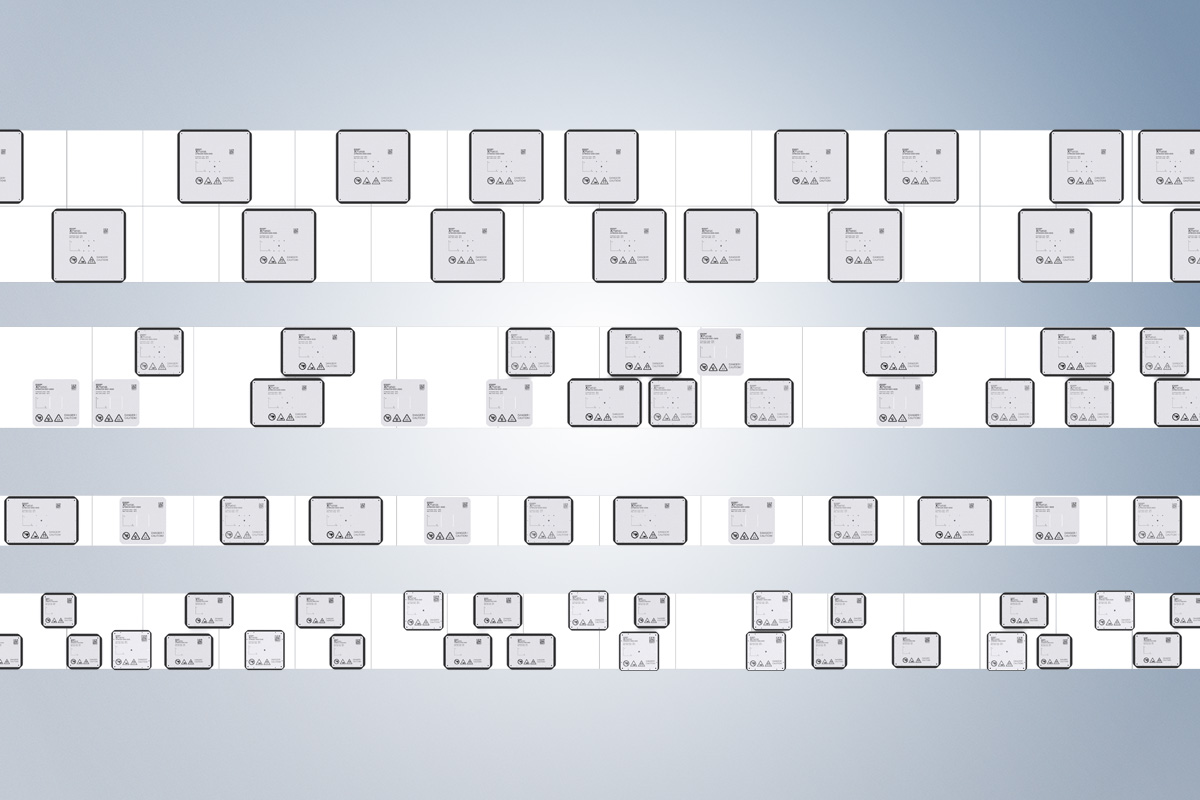

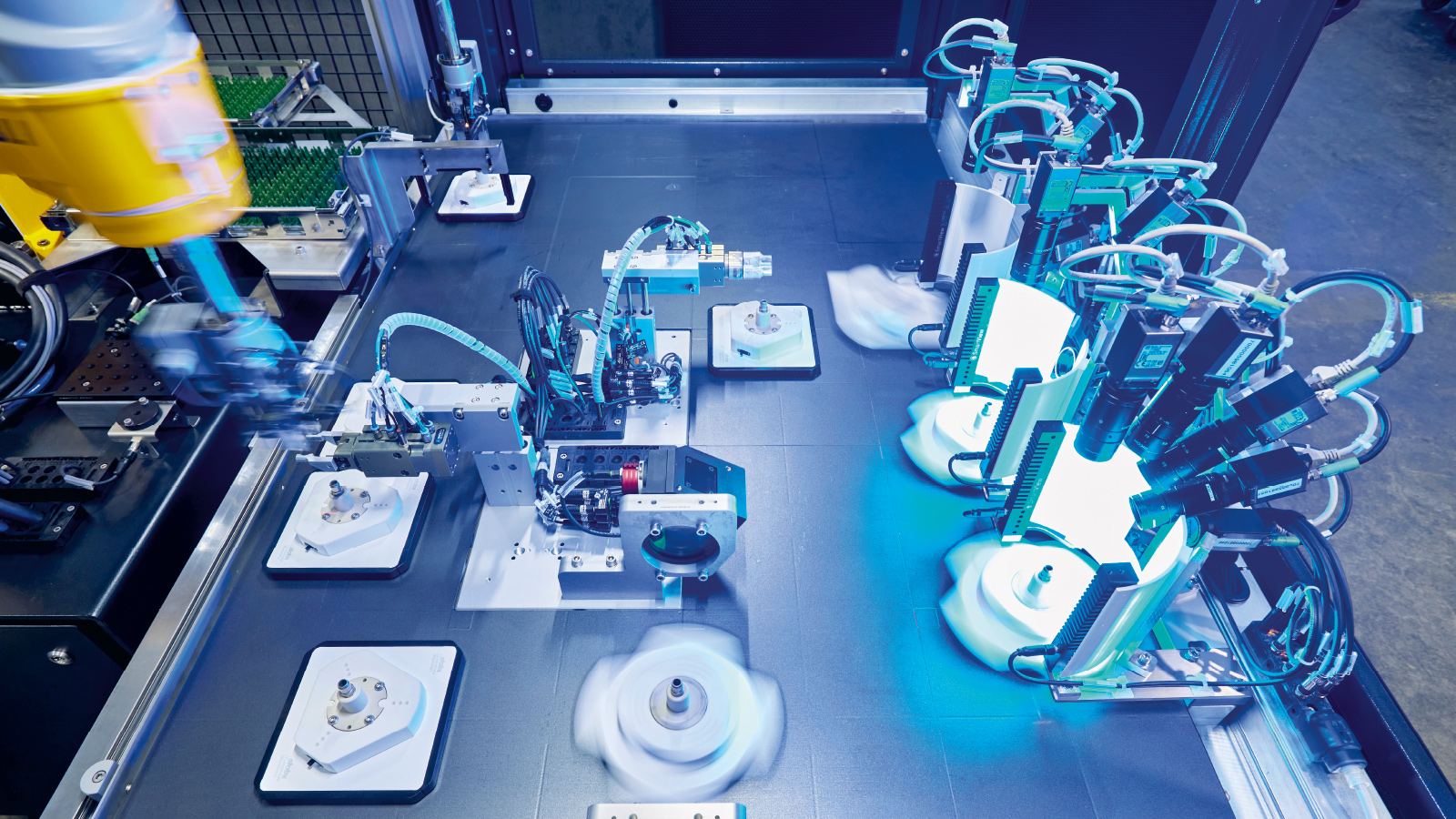

Flexible final inspection for I/O terminal production from Beckhoff

In the fall of 2021, Beckhoff began to completely rethink the way it carried out final inspections of I/O components. Its aim was to significantly increase testing capacity and throughput, even though many different types of terminals are produced. The system, which was created entirely by the company’s own equipment manufacturing department, can program, adjust, and test around 10,000 terminals per shift fully automatically. The high speed and flexibility are the result of not only the sophisticated system concept, but also the intelligent XPlanar transport system, PC-based control, and the wide range of EtherCAT Terminals.

Floating product transport cuts footprint in half and speeds up handling and cleaning

Provisur Technologies GmbH in Flawil, Switzerland, has developed an extremely compact, flexible, and hygienic handling system for sliced foods such as cheese, salami, and bacon. At the heart of the machine is the Beckhoff XPlanar planar motor system with its stainless-steel housing, which not only significantly reduces the machine footprint, but also significantly improves system performance, flexibility, and cleanability with incredibly flexible floating product transport.

Floating movers for efficient, flexible and reliable quality assurance

Achieving the shortest possible inspection times – even when working with different components – is paramount when it comes to series production. This is precisely what Memmingen-based stoba Sondermaschinen GmbH set out to achieve with its InspectorONE optical inspection system, which is based on deep learning and features the Beckhoff XPlanar planar motor system at the conveyor system core. The system allows automotive suppliers to achieve extremely short cycle times of just 3 seconds when inspecting high-pressure injection valves, for example, and so inspect around 6 million parts per year in three-shift operation.

Floating planar mover simplifies transportation of sensitive workpieces

Plasmatreat GmbH is a in Steinhagen, Germany, based manufacturer of plasma systems for high-efficiency surface treatment and environment-friendly production processes who unveiled a new plasma treatment unit at the K 2019 trade show. A key innovation with this treatment unit is that it uses XPlanar, a planar motor system from Beckhoff, to transport workpieces with precision and flexibility. XPlanar replaces prior systems used to move often sensitive workpieces and eliminates the need to install complex 6-axis robots and linear motors.

Syntegon: Product handling platform with Vision and XPlanar

Syntegon, a global supplier of process and packaging technology for the food and pharmaceutical industries, presented a product handling platform at Interpack 2023 for secondary packaging. XPlanar for product transport and Vision hardware optical quality control form the core of this platform.

Our products and technologies for your industry

The PC and EtherCAT-based control technology from Beckhoff offers open and flexible automation solutions for your industry. On our industry pages we present the advantages of PC- and EtherCAT-based control technology, tailored to your industry. We supply you with further information around the typical areas of use and properties of our products, and we provide you with an overview of our reference reports