XFC | eXtreme Fast Control Technology

I/O response times of less than 100 µs

Sede centrale Svizzera

Beckhoff Automation AG

I/O response times of less than 100 µs

Beckhoff products with XFC technology meet the requirements of applications that demand fast control, short response times, and deterministic control in the microsecond range. The technology includes EtherCAT as fieldbus communication, high-performance industrial PCs, I/O products such as IP20 terminals and IP67 box modules, and the flexible TwinCAT automation software.

XFC technology offers significant advantages through finer time resolutions for precision-critical processes. The optimized control architecture and integration of various forms of sub-technology enable response times of well under 100 microseconds. This allows highly dynamic and time-discrete processes to be implemented with excellent precision and reliability – even with standard components.

XFC technology comprises the following forms of sub-technology from various product areas: distributed clocks, timestamp/multi-timestamp, oversampling, fast inputs and outputs in the sub-microsecond range, and microincrements. These forms of sub-technology play a key role in ensuring the high performance and accuracy of the XFC systems.

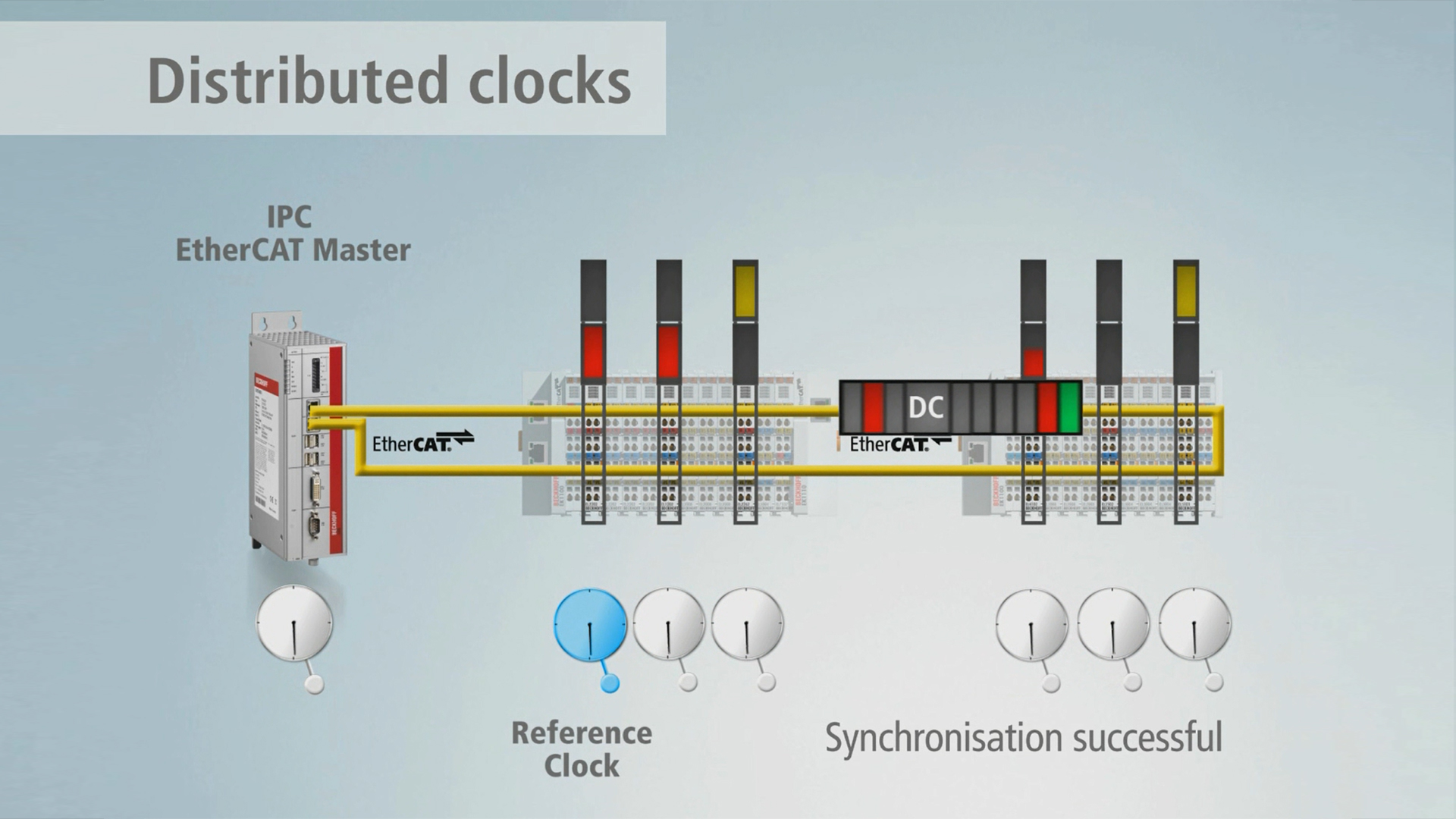

Distributed clocks create a uniform time base across all bus devices, which is essential for time-critical processes and enables precise coordination of events across different components. This decouples the control actions from the control/bus cycle and makes them freely movable on the time axis. Distributed clocks optimize the performance and reliability of industrial applications by enabling time-deterministic acquisition and output of signals. With their uniform time base, distributed clocks provide the basis for all other XFC technology.

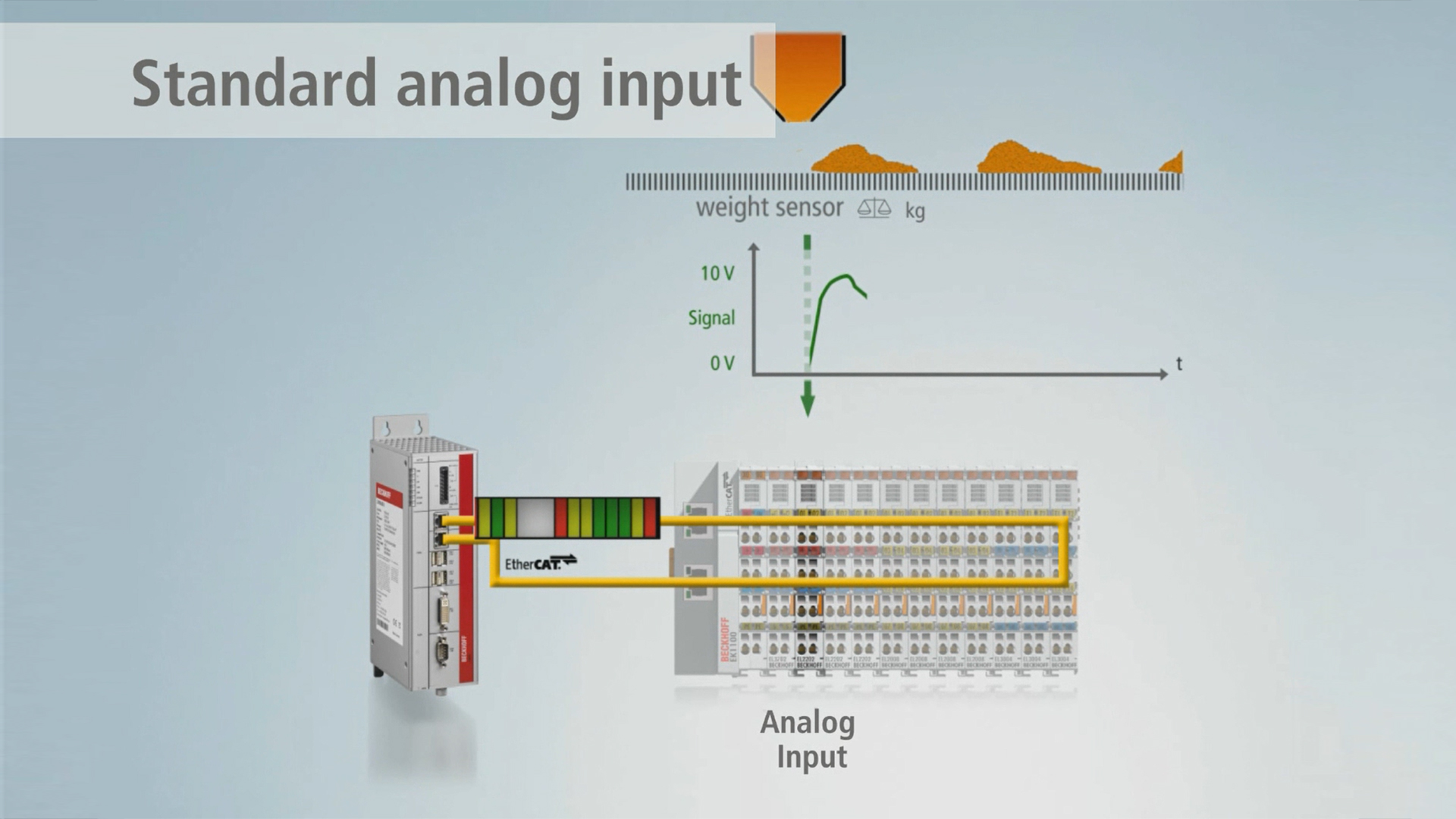

Timestamp/multi-timestamp offers the option of processing the uniform distributed clocks system time as a data type. This technology enables precise recording of timestamps for events in real time. Timestamp allows digital and analog events to be recorded and outputs to be set independently of the bus cycle. This allows multiple drive axes to be precisely synchronized with each other and with the system time, for instance. In contrast to timestamp, multi-timestamp allows several switch results to be processed per PLC cycle.

Oversampling allows higher sampling rates to be implemented on the device side without changing the PLC cycle. This involves taking multiple samples per bus cycle at time-equidistant intervals, and one package of measurement data is transmitted. The high sampling frequencies allow signals to be captured with a higher time resolution and for higher-frequency signals to be recorded compared to the standard evaluation (1 measurement per bus/control cycle). The usual way to detect such signals would be to reduce the cycle time, but this is limited by practical constraints on the control system. For oversampling outputs, higher control frequencies can be implemented compared to the cycle, so that multiple control commands can be issued per bus/control cycle.

Using I/O devices with a particularly low input and output delay of <1 µs, the bus signal can be converted directly into the physical output signal or vice versa. Together with the other XFC technologies, this enables the fastest possible signal processing within the Beckhoff standard components. In connection with the fast fieldbus communication via EtherCAT and the short control cycles of the high-performance Beckhoff Industrial PCs, extremely short response times can be achieved.

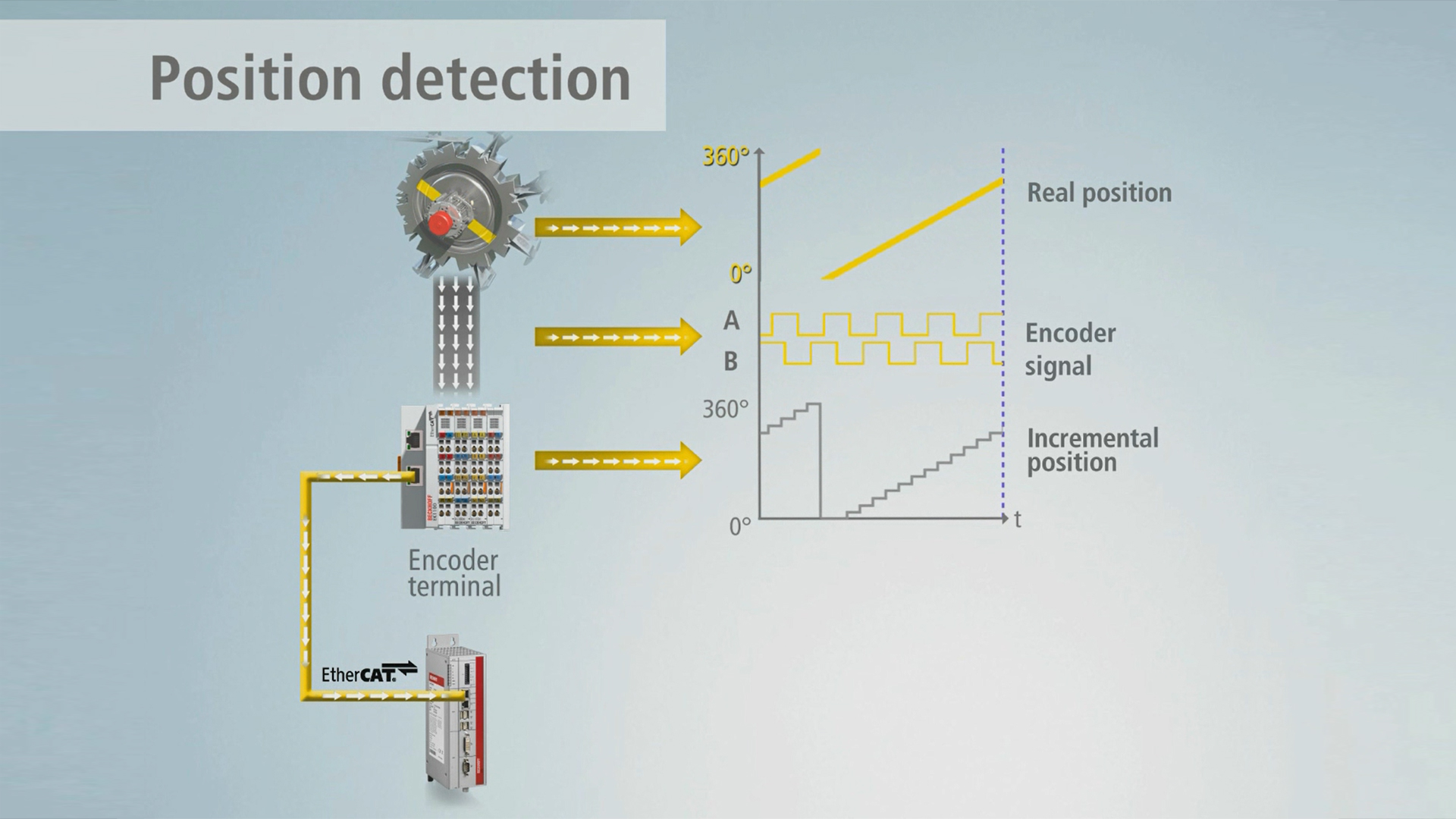

When evaluating axis positions/encoders, microincrements offer time-based interpolation of additional increments between the real counted encoder increments, which increases the spatial resolution of the encoder count value. The current speed is measured internally and the microincrements are interpolated accordingly. This brings the encoder count value closer to the real axis position.

Lasers are used for a variety of processes that require high accuracy and speed. To ensure this, lasers are controlled in many applications using XFC technology by coupling the time of laser triggering and the alignment of the laser beam via distributed clocks. A high update rate is crucial for guiding the beam quickly and precisely.

The EL2262 digital output terminal with oversampling is used for this purpose, with which the laser can be activated and deactivated at intervals of 10 µs. The laser beam is aligned via two motorized movable mirrors, which are responsible for positioning in the x and y directions. The mirrors are positioned at the same update rate via an analog oversampling current signal with the EL4712 or EL4732. This enables the laser to move synchronously from one position to the next during switch-on and off.

The precise triggering of a camera system is required for visual inspection in various production processes. The camera must be triggered at exactly the right moment in parallel with the movement of a conveyor belt, for example. The accuracy of this timing is crucial for image processing, but cannot be freely selected in conventional automation systems – the bus cycle in the ms grid determines when outputs are switched.

XFC timestamp technology is used to first determine the position of the object to be imaged on the conveyor belt with a digital input terminal with µs precision and then trigger the camera with a digital timestamp output terminal at the exact time – regardless of cycle time restrictions.

The EL2262 digital oversampling output terminal is used for the uniform and resource-saving placing of glue dots. This allows the bonding process to be carried out quickly without having to spread glue all over the material.

With oversampling, the process step speed is kept high. At the same time, glue quantities are reduced because the glue is applied selectively for the optimum bonding process. The fast switching output dispenses the glue dots depending on the current film speed and position; the switching times are calculated using the XFC library TF5065, for example.

When monitoring structures such as wind turbines, many measured values have to be recorded at different points. In the case of wind turbines, for example, several measurement technology stations are distributed over the height of the tower. If the measured values are brought into a relationship, a statement can be made about the structural integrity of the entire system.

To compare all measured values with each other, the terminals require a uniform time base for recording the measured values. Distributed clocks are used to provide this uniform time base. This means that even measured values sampled at a high frequency with oversampling can be included in the structural monitoring.

Recording force curves is very important for monitoring certain processes. If the force curve is to be displayed as a function of the position of a punching machine, temporal coordination is required between the measured values.

This coordination is provided by the common time base of distributed clocks. Furthermore, the evaluation sampling rate of the force transducer and incremental encoder must be the same. Oversampling is used to ensure that a high-resolution force-displacement curve can still be recorded during fast punching/pressing processes.

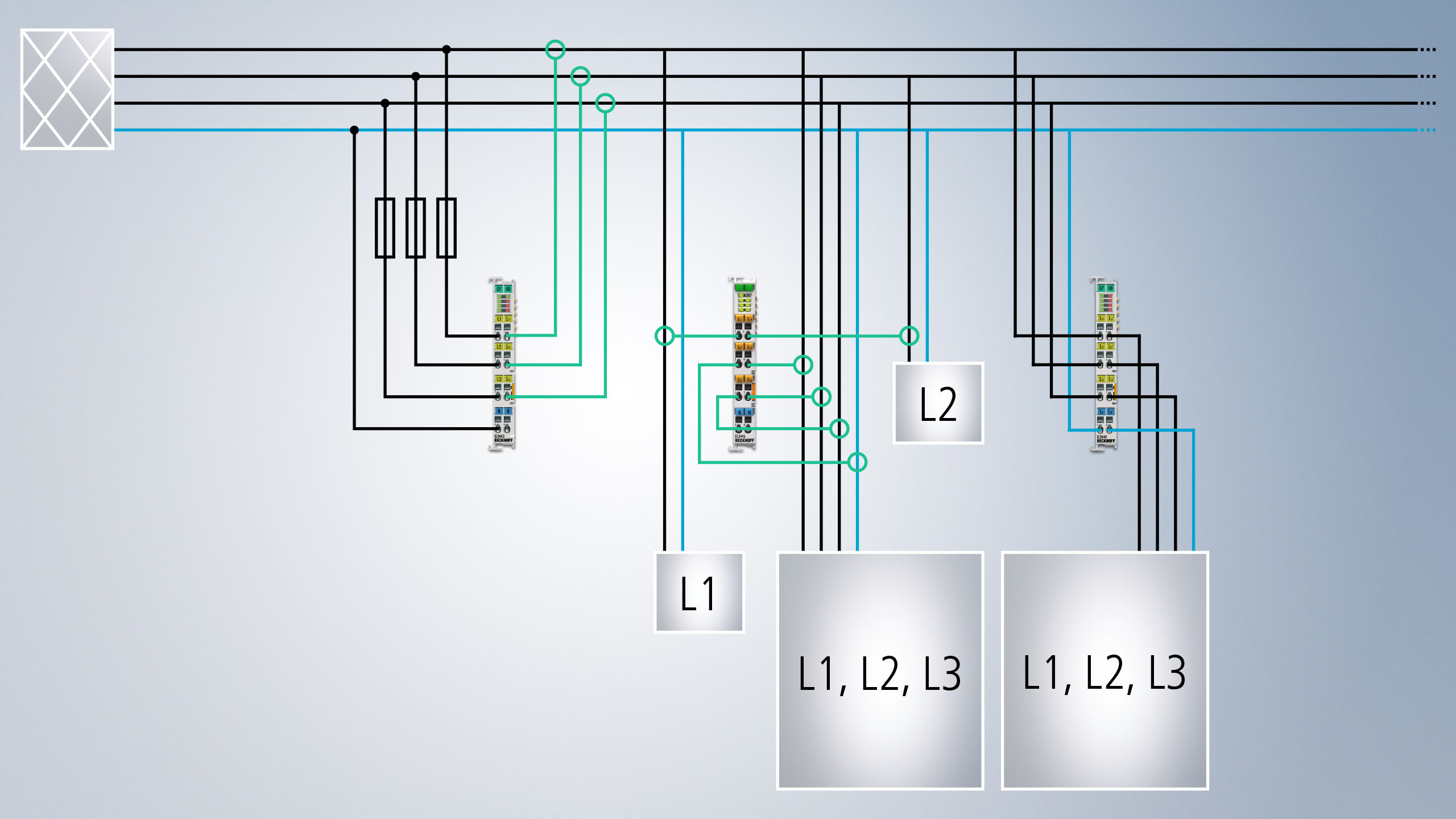

When we monitor electrical power, current and voltage often have to be measured at different locations in the distribution grid. High-precision time synchronization is needed in order to obtain reliable power data from these spatially separated current and voltage measurements. Distributed clocks in the power measurement terminals ensure this time synchronization. This means that several power measurement terminals can be flexibly distributed and still access a central voltage reference that is synchronized with high precision in the EtherCAT system, e.g. from the EL3443 EtherCAT Terminal. This allows pure current measurement terminals such as the EL3446 to provide complete power data. This significantly reduces the amount of wiring work required and saves time and money.

Electronic components and their structures are becoming smaller and smaller, making it all the more difficult to bond them. Conventional processes have long since reached the limits of what they can do in this area, but the Impulse Printing™ process developed by Dutch start-up Fonontech is bringing something new. It enables advanced packaging of semiconductors in 3D structures in the micrometer range. XFC technology components from Beckhoff and EtherCAT are key in this process.

The UK aims to build enough wind farms to power every household by 2030. The potential of wind power was demonstrated by a recent record, when on a single day in January wind farms produced 19,835 megawatts, which is enough to cover more than half of England’s electricity needs. The increased investment in renewable energy will be essential to hit the 2050 goal of Net Zero. Pulse Structural Monitoring Ltd, an Acteon company, have been tasked with monitoring selected turbine foundations in new wind farms, the solution is delivered by using Beckhoff technology and EtherCAT measurement terminals in particular throughout the design.

Texpa Maschinenbau GmbH & Co. KG in Saal an der Saale, Germany, specializes in transfer sewing lines for home textiles as well as in plaiting machines. To best adapt these machines to the customer’s requirements, the mid-sized company has made its systems as modular as possible. Texpa’s new manufacturing system for terrycloth towels signifies the importance of the openness, flexibility and compact design of PC- and EtherCAT-based control and drive technology from Beckhoff for these applications.

Fast, high-precision measurement technology provides early detection of belt damage.

In order to protect against grid fluctuations, Korean engineering firm, Power21 has developed an Energy Storage System (ESS) for frequency control. EL3773 EtherCAT Terminals with eXtreme Fast Control (XFC) technology perform high-precision frequency measurements.

Based on EtherCAT and XFC technologies, Wifag developed industrial-strength control electronics for a wide range of commercial inkjet print heads.

Today, laser cladding is often used for coating rotationally symmetrical components. Ponticon GmbH, based in Wiesbaden, Germany, is expanding its range of applications to include coating and additive manufacturing of any geometries with the pE3D system. The requirements regarding the precise control and coordination of the tripod, rotary/swivel table, and laser would have been difficult to implement without TwinCAT CNC, EtherCAT, and eXtreme Fast Control Technology (XFC) from Beckhoff.

A reliable energy supply is essential for every industrial nation. It is for that reason that CNOOC, China’s largest producer of oil and gas, places great value on monitoring its offshore platforms. The objective of a corresponding initiative implemented by Tianjin Aoling Industrial Automation Technologies Co., Ltd. (Aoling) for monitoring load-bearing structures is to make reliable predictions of load-bearing capacity on the basis of vibration analyses. To connect these technologies, the Chinese specialists rely on PC-based control and precise, system-integrated measurement technology from Beckhoff.

An enormous share of the global market for PET plastic bottles is based on preforms manufactured using machines built by the Canadian plastics industry innovator, Husky Injection Molding Systems Ltd.

Reliable steering is one of any vehicle’s most important safety-relevant elements. Correspondingly high demands are placed on system testing that accompanies the development process. Together with ZF Friedrichshafen AG, the Cologne, Germany-based Akka DNO GmbH has therefore developed a high-performance Hardware-in-the-Loop test system that acquires necessary data via high-end measurement technology directly integrated in PC-based control technology from Beckhoff.