Wind energy sector benefits from EtherCAT P and PC-based control

The next generation of wind turbines will feature rotor blades measuring 100 m long and counting, making them too big for the existing test rigs at Blaest A/S in Aalborg, Denmark, up to now. Along with the construction of a new test hall, the company completely redesigned its control and test equipment: EtherCAT P and a custom measuring amplifier box now replace hundreds of lines and increase accuracy through digitization close to the measurement points. With PC-based control, Blaest is now ready for the future.

There’s no mistaking the Blaest headquarters on the shores of the Limfjord in Aalborg, where long rows of white wind turbine blades dominate the horizon. The company grew out of the Danish National Laboratory for Sustainable Energy in 2005, which has been testing rotor blades for wind turbines since its beginnings in the 1980s. Back then, the load-bearing capacity of the blades was still measured with sandbags. Fast-forward to today and the methods have long since been sophisticated and fully digitized, with electromechanical loading systems connecting the blade to the pulling stations fixed to the hall floor. During the two- to three-month test phase, each rotor blade will be swung in different directions with great force approximately four million times.

“Our job is to perform fatigue tests on blades so that wind turbine manufacturers can get their prototypes approved,” explains Blaest Test Engineer Nicolai Vangsgaard. The blades should ultimately last between 25 and 30 years, and Blaest’s specialists prove this by putting each blade through a series of tests. “We have to prove that the blade can withstand the theoretical load for which it is designed,” says Nicolai Vangsgaard, “and do so as widely digitized and accurately as possible.” To this end, Blaest now uses PC-based control and measurement technology from Beckhoff. After all, the faster and more accurate the measurements, the more precise the data acquisition and subsequent data analysis.

Longer rotor blades require faster data acquisition

When the company decided to expand in 2018 with a new, larger test hall at its Aalborg site, the logical next step was to update the previous control system. This manages communication with the several hundred data acquisition boxes that run along the massive rotor blades and capture the measurement signals from the sensors. Traditionally, a separate cable was required for each individual measurement point, which not only generated significant costs, but also created a tangle of cables that had to be attached to the blade and connected to the control system.

“Our primary goal was to have a more flexible system with a channel count we can expand at any time as the wind turbine blades get longer and stronger,” explains the test engineer. This is because the next generation of wind turbine blades will be 100 m long as opposed to the 70 to 80 m commonly found today. This means additional sensors, more measurement channels, and therefore more data to be recorded and processed with maximum synchronicity and accuracy. What’s more, the data should be collected as close as possible to each individual measurement point to avoid the miles of cables that previously had to be constantly maintained and continuously replaced. Since Blaest uses its own, in-house software that is tailored to suit each customer, it was essential to come up with an automation system that was both open and easily adaptable.

Customized development for specific requirements

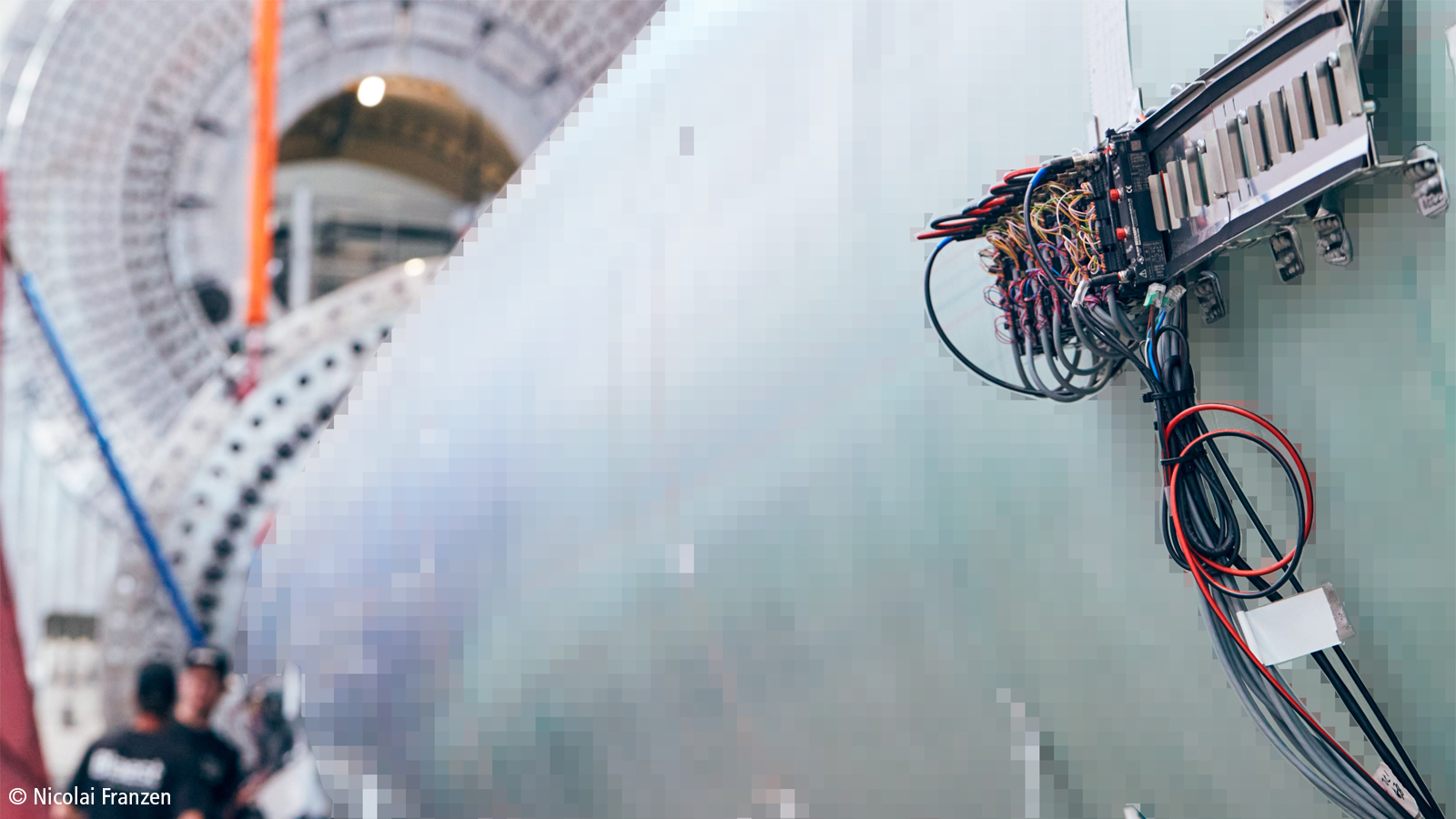

To minimize the complexity of the cabling, Beckhoff developed a decentralized, high-channel EtherCAT P Box within six months for evaluating measurement bridges that capture the signals from the strain gauge sensors on the rotor blades. Derived from the ELM3504 EtherCAT Terminal, the I/O box module supports the evaluation of full, half and quarter bridges with 24 bits and sampling rates of up to 10 ksps. As for parameters, these can all be set via EtherCAT using the CoE directory. IP20 bridge connections were implemented to suit the application scenario close to the measurement point in a protected environment. “This customer-specific development is now an integral part of our extensive EtherCAT P range in the form of the EPP3504-0023 EtherCAT P Box,” adds Jørgen Berg, Sales Engineer at Beckhoff Denmark.

The EtherCAT P Box converts the analog sensor signals into digital measured values in close proximity to the measurement point, which largely reduces the risk of cable interferences and distorted analog signals. As any test engineer will confirm, “The shorter the cable, the more accurate the measurement.” Moreover, EtherCAT P, which transmits both EtherCAT and the power supply, reduces the number of lines. “This concept was only possible because EtherCAT is able to handle large networks while also offering an extremely low real-time update time,” adds Jørgen Berg. During a wind turbine test, an average of 950 billion measured values are recorded, which corresponds to a total of 7 Terabyte of data. The measured values of the 500 load cells are streamed into a database every 4 ms.

The old measurement system required more than 10 km of cabling for each test setup. In contrast, the current system based on EtherCAT P and the EtherCAT P Box modules has a cable length of only 1 km and can easily be extended by additional load cells. Nicolai Vangsgaard puts the savings from the reduced installation effort alone at 30,000 Danish kroner per test structure (around 4,000 euros or US dollars). “Together with the price, availability and support from Beckhoff, we have gained a control system that meets the requirements we have set in terms of digitization and intelligent data acquisition while also making us more competitive – both now and in the future,” says Nicolai Vangsgaard.

“Blaest practically operates the largest EtherCAT Hot Connect system in the world,” enthuses Jørgen Berg. Each EPP box has its own address, so modules can be added or removed on the fly. According to Nicolai Vangsgaard, “The fact that everything is already preconfigured makes it easy to make changes to the configuration.” At Blaest, the control cabinets now simply consist of an IPC, a connection for EtherCAT P and a safety module. “Overall, it makes us faster and more adaptable while also lowering our costs and allowing us to take more accurate measurements. Another huge bonus is that, ultimately, the openness of the system means our test center is open to all wind turbine manufacturers, so we can adapt to pretty much anything,” emphasizes Nicolai Vangsgaard.