XTS in quality assurance for complex and safety-relevant automotive components

The safety and quality requirements for components are growing continuously, particularly in the automotive industry. To meet these requirements, it is essential to implement clear, objective, traceable, and efficient quality inspection processes for these components. As a solution, Automation W+R has developed an integration platform that, as they say, takes production processes and product quality to the next level using high-speed 3D inspection. The core element in this is the XTS linear transport system from Beckhoff, which connects the three basic modules for supply, inspection, and sorting.

Based in Munich, Automation W+R GmbH is a leading system integrator for turnkey inline testing systems with a focus on the automotive industry and battery production. The company is also active in rail transportation, the steel industry, fuel cell production, and the aerospace sector. A special feature of the systems for weld seam inspection and surface testing is the combination of robotics, inspection, and measurement technology. Managing Director Paul Gruber explains the strict requirements in the automotive industry: “Safety through automated quality inspection is of the utmost relevance in this industry. After all, the safety of everyone involved – from the manufacturing company to the user of the vehicle – is based on the quality of the individual components, and therefore their quality inspection.” COO Markus Schmid adds: “In addition to high quality requirements and unequivocal traceability, the large quantities and tight production spaces pose particular challenges.”

Advantages through integrated and PC-based quality assurance

End-of-line control requires batches to be delivered just-in-time. This means that 100% of the components produced must undergo an outgoing goods inspection before they can be further processed or installed. The components are not only inspected visually, but also in a wide variety of ways, including precise mechanical classification. Michael Zinßer, Head of Engineering at Automation W+R, explains: “The relevant machine is already designed as a very compact unit from the concept phase on to avoid unnecessary parts handling, while integrating all necessary test functions. The aim is to ensure that all stations are utilized optimally and the system throughput is maximized.”

The test systems from Automation W+R are ideal for applications with high requirements in terms of throughput and process times and, according to Dennis Hildebrandt, Head of System Development at Automation W+R, require appropriately powerful control technology: “Communication with the test heads, triggering in real time, and communication with the test software on the industrial PCs are basic requirements for our solutions. And this is exactly what the PC-based control technology from Beckhoff makes possible. In addition, the modularity, scalability, and openness of the system mean that new modules and additional functions can be added with little effort and without any new hardware – and with optimal support through decades of excellent collaboration with Beckhoff.”

PC-based control from Beckhoff – the C6032 ultra-compact Industrial PC, TwinCAT, EtherCAT I/Os, XTS, and rotary drive technology – takes over the higher-level control of the system and the individual functions in real time. Powerful automation software is crucial when it comes to minimizing setup times and keeping required production spaces small, not least due to the large component variance and the corresponding requirements for generic component handling. As Dennis Hildebrandt explains: “Anything that can be controlled by software to adapt to different component avoids time-consuming hardware changes, enabling quick changeovers to be completed at the push of a button.”

The system operation and visualization – via a CP3921 multi-touch Control Panel – have a consistent focus on the production processes and system utilization. At a subordinate level, maintenance requires additional functions and a view of individual modules. Manual functions, monitoring, and testing of individual steps are therefore also mapped in the control architecture and efficiently integrated via the modular software-based PLC. The object-oriented programming in TwinCAT enables the necessary scalability for a solution that requires no complex interfaces and permits expansion throughout the entire system life cycle without great effort. The following TwinCAT Functions are used:

- TwinCAT 3 XTS Extension for controlling and monitoring the XTS system and with many configuration options,

- TwinCAT 3 NC PTP as motion control for axis movements with simple operation and numerous configuration options,

- TwinCAT 3 OPC UA as a service-oriented communication architecture and interface for visualization and the customer network,

- TwinCAT 3 TCP/IP and TwinCAT 3 Database Server for further data exchange.

The central handling element is the XTS linear transport system, which, like the entire system, is controlled by a powerful C6032 ultra-compact Industrial PC. This is enabled by high-performance data communication via EtherCAT, which also offers the advantage of hot connect functionality for exchanging network devices during ongoing operation. According to Dennis Hildebrandt, PC-based control from Beckhoff also benefits Automation W+R due to the system-integrated safety functionality with TwinSAFE, which offers central programming in TwinCAT, reduced wiring requirements, and a wide range of ready-to-use function blocks. He adds that the broad Beckhoff I/O system of EtherCAT Terminals offering flexible expansion options – such as the EL1809 16-channel digital input terminal and the EL2522 2-channel incremental encoder simulation terminal – is just as versatile. He considers the main advantages to be the compact design, high level of flexibility, and easy expansion capabilities. In his view, the same applies to the EtherCAT Box modules from the EP series, which can be mounted in a decentralized solution and can be used with plug-and-play functionality with little installation effort. Finally, Dennis Hildebrandt says that the rotary drive technology from Beckhoff, i.e., the AX8000 servo drives and AM8000 servomotors, can also be installed efficiently due to the One Cable Technology (OCT).

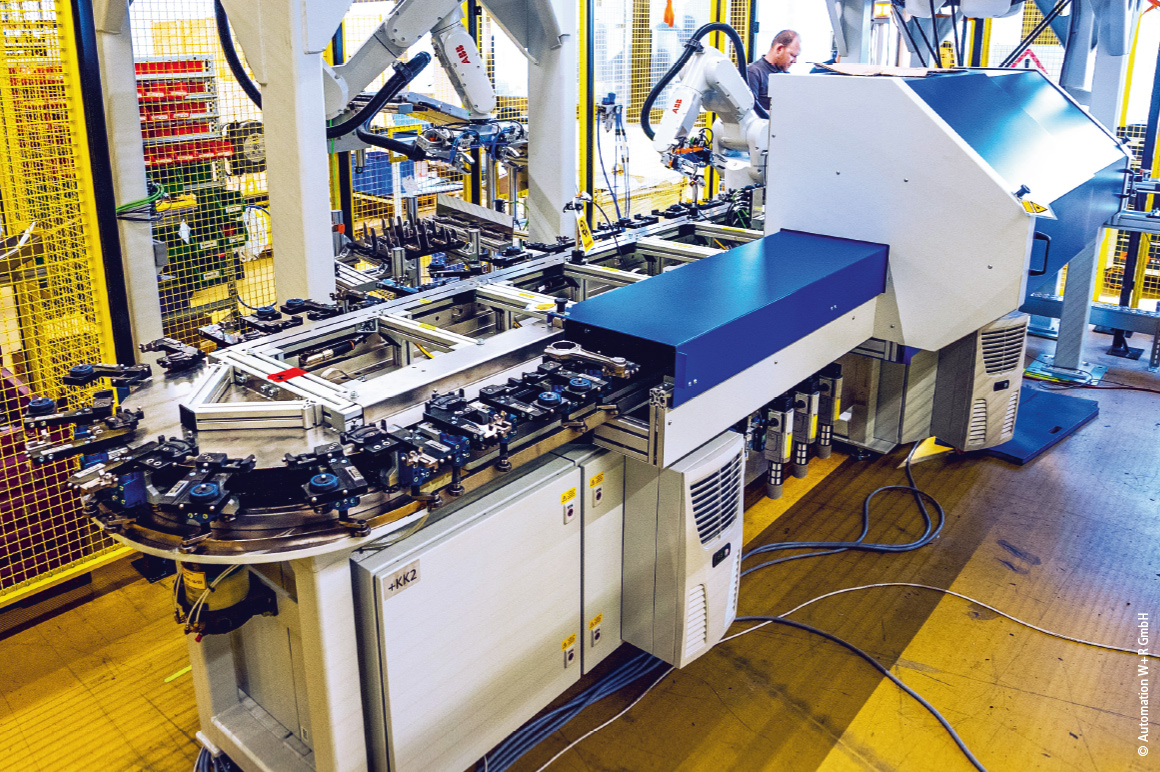

Specific implementation examples with XTS as core element

A prime example of the implementation of Automation W+R’s integration platform is a 4-in-1 complete solution for drop-forged parts. The multi-inspection system checks four bevel gears in parallel for impact marks on the top and bottom, as well as for plug connections, dimensions, and hardness. A high-speed cycle time of 1.5 s is achieved with maximum accuracy and with XTS over a minimum test distance. The modular concept covers a wide range of applications due to specific test scenarios for different component series, which can be changed quickly and easily. As a genuine end-of-line inspection, the system monitors the entire production process with a large number of test steps, all while guaranteeing 100% traceability through visualization of defects, documentation of all test steps, and production data acquisition.

The components to be inspected are picked up by a robot from fed-in baskets and placed four at a time on a workpiece carrier mounted on the XTS mover on the 9.5 m-long XTS line (with a total of 36 movers). They are then cycled into the first station for visual inspection. This is where the impact mark test is conducted on the underside of the component. The workpiece carrier is rotated vertically in this process to enable a 360° image capture of the bottom of the component. To check the top, the workpieces are turned horizontally 180° in the turning station. This is followed by two mechanical tests: The internal gearing is checked using a gauge. For this purpose, the components are moved by the movers to the corresponding workstation and lifted using an AM8000 servomotor to prevent process forces acting on the XTS. For installation distance classification, the workpiece carriers are transported to the next station, then lifted again, and moved against a stop with a measuring sensor for height measurement. Before the components leave the XTS line and are transferred to the outfeed line, all good parts are laser-marked. The final test is the hardness test on the run-out section, where the component is cycled under a coil and lifted out.

In the area of forging technology, Automation W+R implemented another integration platform for testing connecting rods. In addition to a compact footprint, this platform is characterized by the option to make finely scalable adjustments in terms of geometry, number of XTS movers, range of functions, and process speeds. According to Dennis Hildebrandt, this is made possible by XTS and flexible motion profiles, which allow simple or complex sequences to be implemented so that the entire production process can be optimized. The connecting rods are fully inspected and classified on all surfaces with a minimum cycle time of less than 3 s.